1 Introduction

Elucidation of the mechanisms of turbulent thermal convection in very-low-Prandtl-number fluids is crucial for our understanding of the universe and the advancement of cooling technology. Turbulent thermal convection takes place, for example, on the surfaces of stars, where the Prandtl number (![]() $Pr$) varies from

$Pr$) varies from ![]() $10^{-8}$ to

$10^{-8}$ to ![]() $10^{-4}$ (Spiegel Reference Spiegel1962; Hanasoge, Gizon & Sreenivasan Reference Hanasoge, Gizon and Sreenivasan2016). Furthermore, turbulent thermal convection in liquid metals (

$10^{-4}$ (Spiegel Reference Spiegel1962; Hanasoge, Gizon & Sreenivasan Reference Hanasoge, Gizon and Sreenivasan2016). Furthermore, turbulent thermal convection in liquid metals (![]() $Pr\ll 1$) is relevant in engineering applications, especially in cooling systems of tokamaks and fast breeder reactors (Zhilin et al. Reference Zhilin, Sviridov, Razuvanov, Ivochkin, Listratov, Sviridov and Belyaev2009; Belyaev et al. Reference Belyaev, Genin, Listratov, Melnikov, Sviridov, Sviridov, Ivochkin, Razuvanov and Shpansky2013). Liquid sodium is of particular interest because of its very low Prandtl number (

$Pr\ll 1$) is relevant in engineering applications, especially in cooling systems of tokamaks and fast breeder reactors (Zhilin et al. Reference Zhilin, Sviridov, Razuvanov, Ivochkin, Listratov, Sviridov and Belyaev2009; Belyaev et al. Reference Belyaev, Genin, Listratov, Melnikov, Sviridov, Sviridov, Ivochkin, Razuvanov and Shpansky2013). Liquid sodium is of particular interest because of its very low Prandtl number (![]() $Pr\approx 0.009$) and it is widely used as cooling agent in fast neutron reactors (Heinzel et al. Reference Heinzel, Hering, Konys, Marocco, Litfin, Mueller, Pacio, Schroer, Stieglitz and Stoppel2017).

$Pr\approx 0.009$) and it is widely used as cooling agent in fast neutron reactors (Heinzel et al. Reference Heinzel, Hering, Konys, Marocco, Litfin, Mueller, Pacio, Schroer, Stieglitz and Stoppel2017).

One classical model of thermal convection is Rayleigh–Bénard convection (RBC), where the fluid is confined between a heated lower plate and a cooled upper plate, and the main driving force is buoyancy. The temperature inhomogeneity varies the fluid density, which in presence of gravity leads to the convective fluid motion. For reviews on RBC we refer to Bodenschatz, Pesch & Ahlers (Reference Bodenschatz, Pesch and Ahlers2000), Ahlers, Grossmann & Lohse (Reference Ahlers, Grossmann and Lohse2009), Lohse & Xia (Reference Lohse and Xia2010) and Chillà & Schumacher (Reference Chillà and Schumacher2012).

Thermal convection inevitably arises in the case of a horizontal temperature gradient. This is known as vertical convection (VC), convection in cavities or side-heated convection. In vertical convection, the heated and cooled plates are located parallel to the gravity vector and shear plays the key role, see Ng et al. (Reference Ng, Ooi, Lohse and Chung2015, Reference Ng, Ooi, Lohse and Chung2017) and Shishkina (Reference Shishkina2016).

The concept of inclined convection (IC) is a generalisation of RBC and VC, i.e. the fluid layer between the parallel plates is tilted with respect to the direction of gravity, and both buoyancy and shear act on the flow. This type of convection was studied previously by Daniels, Wiener & Bodenschatz (Reference Daniels, Wiener and Bodenschatz2003), Chillà et al. (Reference Chillà, Rastello, Chaumat and Castaing2004), Sun, Xi & Xia (Reference Sun, Xi and Xia2005), Ahlers, Brown & Nikolaenko (Reference Ahlers, Brown and Nikolaenko2006b), Riedinger et al. (Reference Riedinger, Tisserand, Seychelles, Castaing and Chillá2013), Weiss & Ahlers (Reference Weiss and Ahlers2013) and Langebach & Haberstroh (Reference Langebach, Haberstroh and Weisend2014), and more recently by Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015), Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015), Vasil’ev et al. (Reference Vasil’ev, Kolesnichenko, Mamykin, Frick, Khalilov, Rogozhkin and Pakholkov2015), Kolesnichenko et al. (Reference Kolesnichenko, Mamykin, Pavlinov, Pakholkov, Rogozhkin, Frick, Khalilov and Shepelev2015), Shishkina & Horn (Reference Shishkina and Horn2016), Teimurazov & Frick (Reference Teimurazov and Frick2017), Mandrykin & Teimurazov (Reference Mandrykin and Teimurazov2019), Khalilov et al. (Reference Khalilov, Kolesnichenko, Pavlinov, Mamykin, Shestakov and Frick2018) and Zwirner & Shishkina (Reference Zwirner and Shishkina2018).

In thermal convection, the global flow structures and heat and momentum transport are determined mainly by the following system parameters: the Rayleigh number ![]() $Ra$, the Prandtl number

$Ra$, the Prandtl number ![]() $Pr$ and the aspect ratio of the container

$Pr$ and the aspect ratio of the container ![]() $\unicode[STIX]{x1D6E4}$. These are defined as

$\unicode[STIX]{x1D6E4}$. These are defined as

respectively. Here, ![]() $\unicode[STIX]{x1D6FC}$ denotes the isobaric thermal expansion coefficient,

$\unicode[STIX]{x1D6FC}$ denotes the isobaric thermal expansion coefficient, ![]() $\unicode[STIX]{x1D708}$ the kinematic viscosity,

$\unicode[STIX]{x1D708}$ the kinematic viscosity, ![]() $\unicode[STIX]{x1D705}$ the thermal diffusivity of the fluid,

$\unicode[STIX]{x1D705}$ the thermal diffusivity of the fluid, ![]() $g$ the acceleration due to gravity,

$g$ the acceleration due to gravity, ![]() $\unicode[STIX]{x1D6E5}\equiv T_{+}-T_{-}$ the difference between the temperatures at the heated plate (

$\unicode[STIX]{x1D6E5}\equiv T_{+}-T_{-}$ the difference between the temperatures at the heated plate (![]() $T_{+}$) and at the cooled plate (

$T_{+}$) and at the cooled plate (![]() $T_{-}$),

$T_{-}$), ![]() $L$ the distance between the plates and

$L$ the distance between the plates and ![]() $D$ the diameter of the plates.

$D$ the diameter of the plates.

The main response characteristics of a natural convective system are the mean total heat flux across the heated/cooled plates, ![]() $q$, normalised by the conductive part of the total heat flux,

$q$, normalised by the conductive part of the total heat flux, ![]() $\hat{q}$, i.e. the Nusselt number

$\hat{q}$, i.e. the Nusselt number ![]() $Nu$, and the Reynolds number

$Nu$, and the Reynolds number ![]() $Re$:

$Re$:

Here, ![]() $U$ is the reference velocity, which is usually determined by either the maximum of the time-averaged velocity along the plates or by

$U$ is the reference velocity, which is usually determined by either the maximum of the time-averaged velocity along the plates or by ![]() $\langle \boldsymbol{u}\boldsymbol{\cdot }\boldsymbol{u}\rangle ^{1/2}$, i.e. it is based on the mean kinetic energy;

$\langle \boldsymbol{u}\boldsymbol{\cdot }\boldsymbol{u}\rangle ^{1/2}$, i.e. it is based on the mean kinetic energy; ![]() $\boldsymbol{u}$ is the velocity vector field and

$\boldsymbol{u}$ is the velocity vector field and ![]() $\langle \cdot \rangle$ denotes the average in time and over the whole convection cell. Note that, even for a fixed set-up in natural thermal convection with no additional shear imposed on the system, the scaling relations of the mean heat and momentum transport, represented by

$\langle \cdot \rangle$ denotes the average in time and over the whole convection cell. Note that, even for a fixed set-up in natural thermal convection with no additional shear imposed on the system, the scaling relations of the mean heat and momentum transport, represented by ![]() $Nu$ and

$Nu$ and ![]() $Re$, with the input parameters

$Re$, with the input parameters ![]() $Ra$ and

$Ra$ and ![]() $Pr$, are not universal and are influenced by non-Oberbeck–Boussinesq (NOB) effects, see Kraichnan (Reference Kraichnan1962), Grossmann & Lohse (Reference Grossmann and Lohse2000), Ahlers et al. (Reference Ahlers, Brown, Araujo, Funfschilling, Grossmann and Lohse2006a, Reference Ahlers, Grossmann and Lohse2009), Lohse & Xia (Reference Lohse and Xia2010), Shishkina, Grossmann & Lohse (Reference Shishkina, Grossmann and Lohse2016a), Shishkina, Weiss & Bodenschatz (Reference Shishkina, Weiss and Bodenschatz2016b) and Weiss et al. (Reference Weiss, He, Ahlers, Bodenschatz and Shishkina2018).

$Pr$, are not universal and are influenced by non-Oberbeck–Boussinesq (NOB) effects, see Kraichnan (Reference Kraichnan1962), Grossmann & Lohse (Reference Grossmann and Lohse2000), Ahlers et al. (Reference Ahlers, Brown, Araujo, Funfschilling, Grossmann and Lohse2006a, Reference Ahlers, Grossmann and Lohse2009), Lohse & Xia (Reference Lohse and Xia2010), Shishkina, Grossmann & Lohse (Reference Shishkina, Grossmann and Lohse2016a), Shishkina, Weiss & Bodenschatz (Reference Shishkina, Weiss and Bodenschatz2016b) and Weiss et al. (Reference Weiss, He, Ahlers, Bodenschatz and Shishkina2018).

Here, one should note that, apart from ![]() $Pr$ and

$Pr$ and ![]() $Ra$, the geometrical confinement of the convection cell also determines the strength of the heat transport (Huang et al. Reference Huang, Kaczorowski, Ni and Xia2013; Chong et al. Reference Chong, Huang, Kaczorowski and Xia2015; Chong & Xia Reference Chong and Xia2016). Thus, in experiments by Huang et al. (Reference Huang, Kaczorowski, Ni and Xia2013) for

$Ra$, the geometrical confinement of the convection cell also determines the strength of the heat transport (Huang et al. Reference Huang, Kaczorowski, Ni and Xia2013; Chong et al. Reference Chong, Huang, Kaczorowski and Xia2015; Chong & Xia Reference Chong and Xia2016). Thus, in experiments by Huang et al. (Reference Huang, Kaczorowski, Ni and Xia2013) for ![]() $Pr=4.38$, an increase of

$Pr=4.38$, an increase of ![]() $Nu$ due to the cell confinement was obtained, while in the direct numerical simulations (DNS) by Wagner & Shishkina (Reference Wagner and Shishkina2013) for

$Nu$ due to the cell confinement was obtained, while in the direct numerical simulations (DNS) by Wagner & Shishkina (Reference Wagner and Shishkina2013) for ![]() $Pr=0.786$, the heat and mass transport gradually reduced with increasing confinement. This virtual contradiction was recently resolved in Chong et al. (Reference Chong, Wagner, Kaczorowski, Shishkina and Xia2018). It was found that

$Pr=0.786$, the heat and mass transport gradually reduced with increasing confinement. This virtual contradiction was recently resolved in Chong et al. (Reference Chong, Wagner, Kaczorowski, Shishkina and Xia2018). It was found that ![]() $Pr$ determines whether the optimal

$Pr$ determines whether the optimal ![]() $\unicode[STIX]{x1D6E4}$, at which the maximal heat transport takes place, exists or not. For

$\unicode[STIX]{x1D6E4}$, at which the maximal heat transport takes place, exists or not. For ![]() $Pr>0.5$ (

$Pr>0.5$ (![]() $Ra=10^{8}$) an enhancement of

$Ra=10^{8}$) an enhancement of ![]() $Nu$ was observed, where the optimal

$Nu$ was observed, where the optimal ![]() $\unicode[STIX]{x1D6E4}$ decreases with increasing

$\unicode[STIX]{x1D6E4}$ decreases with increasing ![]() $Pr$, but for

$Pr$, but for ![]() $Pr\leqslant 0.5$ a gradual reduction of the heat transport with increasing confinement was obtained. For all

$Pr\leqslant 0.5$ a gradual reduction of the heat transport with increasing confinement was obtained. For all ![]() $Pr$, the confinement induced friction causes a reduction of

$Pr$, the confinement induced friction causes a reduction of ![]() $Re$.

$Re$.

In the general case of inclined thermal convection, the cell inclination angle ![]() $\unicode[STIX]{x1D6FD}$ (

$\unicode[STIX]{x1D6FD}$ (![]() $\unicode[STIX]{x1D6FD}=0^{\circ }$ in RBC and

$\unicode[STIX]{x1D6FD}=0^{\circ }$ in RBC and ![]() $\unicode[STIX]{x1D6FD}=90^{\circ }$ in VC) is an influential input parameter of the convective system, apart from

$\unicode[STIX]{x1D6FD}=90^{\circ }$ in VC) is an influential input parameter of the convective system, apart from ![]() $Ra$,

$Ra$, ![]() $Pr$ and the geometry of the container. Experimental studies of inclined thermal liquid-sodium convection in cylinders of different aspect ratios, showed that the convective heat transfer between the heated and cooled surfaces of the container is most efficient neither in a standing position of the cylinder (

$Pr$ and the geometry of the container. Experimental studies of inclined thermal liquid-sodium convection in cylinders of different aspect ratios, showed that the convective heat transfer between the heated and cooled surfaces of the container is most efficient neither in a standing position of the cylinder (![]() $\unicode[STIX]{x1D6FD}=0^{\circ }$), nor in a lying position (

$\unicode[STIX]{x1D6FD}=0^{\circ }$), nor in a lying position (![]() $\unicode[STIX]{x1D6FD}=90^{\circ }$), but at an inclined position for a certain intermediate value of

$\unicode[STIX]{x1D6FD}=90^{\circ }$), but at an inclined position for a certain intermediate value of ![]() $\unicode[STIX]{x1D6FD}$,

$\unicode[STIX]{x1D6FD}$, ![]() $0^{\circ }<\unicode[STIX]{x1D6FD}<90^{\circ }$, see Vasil’ev et al. (Reference Vasil’ev, Kolesnichenko, Mamykin, Frick, Khalilov, Rogozhkin and Pakholkov2015) for

$0^{\circ }<\unicode[STIX]{x1D6FD}<90^{\circ }$, see Vasil’ev et al. (Reference Vasil’ev, Kolesnichenko, Mamykin, Frick, Khalilov, Rogozhkin and Pakholkov2015) for ![]() $L=20D$, Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) for

$L=20D$, Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) for ![]() $L=5D$ and Khalilov et al. (Reference Khalilov, Kolesnichenko, Pavlinov, Mamykin, Shestakov and Frick2018) for

$L=5D$ and Khalilov et al. (Reference Khalilov, Kolesnichenko, Pavlinov, Mamykin, Shestakov and Frick2018) for ![]() $L=D$. Moreover, these experiments showed that, for

$L=D$. Moreover, these experiments showed that, for ![]() $Pr\ll 1$ and

$Pr\ll 1$ and ![]() $Ra\gtrsim 10^{9}$, any tilt

$Ra\gtrsim 10^{9}$, any tilt ![]() $\unicode[STIX]{x1D6FD}$,

$\unicode[STIX]{x1D6FD}$, ![]() $0^{\circ }<\unicode[STIX]{x1D6FD}\leqslant 90^{\circ }$, of the cell leads to a larger mean heat flux (

$0^{\circ }<\unicode[STIX]{x1D6FD}\leqslant 90^{\circ }$, of the cell leads to a larger mean heat flux (![]() $Nu$) than in RBC, at similar values of

$Nu$) than in RBC, at similar values of ![]() $Ra$ and

$Ra$ and ![]() $Pr$. Note that the effect of the cell tilting on the convective heat transport in low-

$Pr$. Note that the effect of the cell tilting on the convective heat transport in low-![]() $Pr$ fluids is very different from that in the case of large

$Pr$ fluids is very different from that in the case of large ![]() $Pr$ (Shishkina & Horn Reference Shishkina and Horn2016). For example, for

$Pr$ (Shishkina & Horn Reference Shishkina and Horn2016). For example, for ![]() $Pr\approx 6.7$ and

$Pr\approx 6.7$ and ![]() $Ra\approx 4.4\times 10^{9}$, a monotonic reduction of

$Ra\approx 4.4\times 10^{9}$, a monotonic reduction of ![]() $Nu$ with increasing

$Nu$ with increasing ![]() $\unicode[STIX]{x1D6FD}$ in the interval

$\unicode[STIX]{x1D6FD}$ in the interval ![]() $\unicode[STIX]{x1D6FD}\in [0^{\circ },90^{\circ }]$ takes place, as it was obtained in measurements by Guo et al. (Reference Guo, Zhou, Cen, Qu, Lu, Sun and Shang2015).

$\unicode[STIX]{x1D6FD}\in [0^{\circ },90^{\circ }]$ takes place, as it was obtained in measurements by Guo et al. (Reference Guo, Zhou, Cen, Qu, Lu, Sun and Shang2015).

One should mention that there are only a few experimental and numerical studies of IC in a broad range of ![]() $\unicode[STIX]{x1D6FD}$, whereas most of the investigations of the cell-tilt effects on the mean heat transport were conducted in a narrow region of

$\unicode[STIX]{x1D6FD}$, whereas most of the investigations of the cell-tilt effects on the mean heat transport were conducted in a narrow region of ![]() $\unicode[STIX]{x1D6FD}$ close to

$\unicode[STIX]{x1D6FD}$ close to ![]() $0^{\circ }$ and mainly for large-

$0^{\circ }$ and mainly for large-![]() $Pr$ fluids. These studies showed generally a small effect of

$Pr$ fluids. These studies showed generally a small effect of ![]() $\unicode[STIX]{x1D6FD}$ on

$\unicode[STIX]{x1D6FD}$ on ![]() $Nu$, reflected in a tiny reduction of

$Nu$, reflected in a tiny reduction of ![]() $Nu$ with increasing

$Nu$ with increasing ![]() $\unicode[STIX]{x1D6FD}$ close to

$\unicode[STIX]{x1D6FD}$ close to ![]() $\unicode[STIX]{x1D6FD}=0^{\circ }$, see Ciliberto, Cioni & Laroche (Reference Ciliberto, Cioni and Laroche1996), Cioni, Ciliberto & Sommeria (Reference Cioni, Ciliberto and Sommeria1997), Chillà et al. (Reference Chillà, Rastello, Chaumat and Castaing2004), Sun et al. (Reference Sun, Xi and Xia2005), Ahlers et al. (Reference Ahlers, Brown and Nikolaenko2006b), Roche et al. (Reference Roche, Gauthier, Kaiser and Salort2010) and Wei & Xia (Reference Wei and Xia2013). A tiny local increase of

$\unicode[STIX]{x1D6FD}=0^{\circ }$, see Ciliberto, Cioni & Laroche (Reference Ciliberto, Cioni and Laroche1996), Cioni, Ciliberto & Sommeria (Reference Cioni, Ciliberto and Sommeria1997), Chillà et al. (Reference Chillà, Rastello, Chaumat and Castaing2004), Sun et al. (Reference Sun, Xi and Xia2005), Ahlers et al. (Reference Ahlers, Brown and Nikolaenko2006b), Roche et al. (Reference Roche, Gauthier, Kaiser and Salort2010) and Wei & Xia (Reference Wei and Xia2013). A tiny local increase of ![]() $Nu$ with a small inclination of the RBC cell filled with a fluid of

$Nu$ with a small inclination of the RBC cell filled with a fluid of ![]() $Pr>1$ is possible only when a two-roll form of the global large-scale circulation (LSC) is present in RBC, which usually almost immediately transforms into a single-roll form of the LSC with any inclination (Weiss & Ahlers Reference Weiss and Ahlers2013). The single-roll LSC is known to be more efficient in the heat transport than its double-roll form, as was proved in the measurements (Xi & Xia Reference Xi and Xia2008; Weiss & Ahlers Reference Weiss and Ahlers2013) and DNS (Zwirner & Shishkina Reference Zwirner and Shishkina2018).

$Pr>1$ is possible only when a two-roll form of the global large-scale circulation (LSC) is present in RBC, which usually almost immediately transforms into a single-roll form of the LSC with any inclination (Weiss & Ahlers Reference Weiss and Ahlers2013). The single-roll LSC is known to be more efficient in the heat transport than its double-roll form, as was proved in the measurements (Xi & Xia Reference Xi and Xia2008; Weiss & Ahlers Reference Weiss and Ahlers2013) and DNS (Zwirner & Shishkina Reference Zwirner and Shishkina2018).

The IC in a broad range of the inclination angle ![]() $\unicode[STIX]{x1D6FD}$ (from

$\unicode[STIX]{x1D6FD}$ (from ![]() $0^{\circ }$ to

$0^{\circ }$ to ![]() $90^{\circ }$) in liquid sodium has been studied so far by Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015), Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015), Vasil’ev et al. (Reference Vasil’ev, Kolesnichenko, Mamykin, Frick, Khalilov, Rogozhkin and Pakholkov2015), Kolesnichenko et al. (Reference Kolesnichenko, Mamykin, Pavlinov, Pakholkov, Rogozhkin, Frick, Khalilov and Shepelev2015) and Khalilov et al. (Reference Khalilov, Kolesnichenko, Pavlinov, Mamykin, Shestakov and Frick2018). These sodium experiments were conducted in relatively long cylinders, in which the scaling exponents are essentially increased due to the geometrical confinement. For RBC in a cylinder with

$90^{\circ }$) in liquid sodium has been studied so far by Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015), Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015), Vasil’ev et al. (Reference Vasil’ev, Kolesnichenko, Mamykin, Frick, Khalilov, Rogozhkin and Pakholkov2015), Kolesnichenko et al. (Reference Kolesnichenko, Mamykin, Pavlinov, Pakholkov, Rogozhkin, Frick, Khalilov and Shepelev2015) and Khalilov et al. (Reference Khalilov, Kolesnichenko, Pavlinov, Mamykin, Shestakov and Frick2018). These sodium experiments were conducted in relatively long cylinders, in which the scaling exponents are essentially increased due to the geometrical confinement. For RBC in a cylinder with ![]() $L=5D$, Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015) reported

$L=5D$, Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015) reported ![]() $Nu\sim Ra^{0.4}$ and for RBC in a very long cylinder with

$Nu\sim Ra^{0.4}$ and for RBC in a very long cylinder with ![]() $L=20D$, Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) obtained

$L=20D$, Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) obtained ![]() $Nu\sim Ra^{0.77}$. In both studies, also IC in liquid sodium for

$Nu\sim Ra^{0.77}$. In both studies, also IC in liquid sodium for ![]() $\unicode[STIX]{x1D6FD}=45^{\circ }$ was investigated, and the following scaling laws were obtained for this inclination angle:

$\unicode[STIX]{x1D6FD}=45^{\circ }$ was investigated, and the following scaling laws were obtained for this inclination angle: ![]() $Nu\sim Ra^{0.54}$ for

$Nu\sim Ra^{0.54}$ for ![]() $L=5D$ and

$L=5D$ and ![]() $Nu\sim Ra^{0.7}$ for

$Nu\sim Ra^{0.7}$ for ![]() $L=20D$. Note that in both IC measurements, much higher mean heat fluxes were obtained, compared to those in VC or RBC configurations.

$L=20D$. Note that in both IC measurements, much higher mean heat fluxes were obtained, compared to those in VC or RBC configurations.

Thus, all available experimental and numerical results on IC show that the ![]() $Nu(\unicode[STIX]{x1D6FD})/Nu(0)$ dependence is a complex function of

$Nu(\unicode[STIX]{x1D6FD})/Nu(0)$ dependence is a complex function of ![]() $Ra$,

$Ra$, ![]() $Pr$ and

$Pr$ and ![]() $\unicode[STIX]{x1D6E4}$, which cannot be represented as a simple combination of their power functions.

$\unicode[STIX]{x1D6E4}$, which cannot be represented as a simple combination of their power functions.

An analogy can be seen between the IC flows and convective flows, which occur from the imposed temperature differences at both the horizontal and vertical surfaces of a cubical container. With a different balance between the imposed horizontal and vertical temperature gradients, where the resulting effective temperature gradient has non-vanishing horizontal and vertical components, one can mimic the IC flows at different inclination angles. Experimental studies on these type of convective flows were conducted by Zimin, Frik & Shaidurov (Reference Zimin, Frik and Shaidurov1982).

Although there is no scaling theory for general IC, for the limiting configurations of IC (![]() $\unicode[STIX]{x1D6FD}=0^{\circ }$ and

$\unicode[STIX]{x1D6FD}=0^{\circ }$ and ![]() $\unicode[STIX]{x1D6FD}=90^{\circ }$) and sufficiently wide heated/cooled plates, there are theoretical studies of the scaling relations of

$\unicode[STIX]{x1D6FD}=90^{\circ }$) and sufficiently wide heated/cooled plates, there are theoretical studies of the scaling relations of ![]() $Nu$ and

$Nu$ and ![]() $Re$ with

$Re$ with ![]() $Pr$ and

$Pr$ and ![]() $Ra$. For RBC (

$Ra$. For RBC (![]() $\unicode[STIX]{x1D6FD}=0$), Grossmann & Lohse (Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001, Reference Grossmann and Lohse2011) (hereafter GL) developed a scaling theory which is based on a decomposition into boundary-layer (BL) and bulk contributions of the time- and volume-averaged kinetic (

$\unicode[STIX]{x1D6FD}=0$), Grossmann & Lohse (Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001, Reference Grossmann and Lohse2011) (hereafter GL) developed a scaling theory which is based on a decomposition into boundary-layer (BL) and bulk contributions of the time- and volume-averaged kinetic (![]() $\unicode[STIX]{x1D716}_{u}$) and thermal (

$\unicode[STIX]{x1D716}_{u}$) and thermal (![]() $\unicode[STIX]{x1D716}_{\unicode[STIX]{x1D703}}$) dissipation rates, for which analytical relations with

$\unicode[STIX]{x1D716}_{\unicode[STIX]{x1D703}}$) dissipation rates, for which analytical relations with ![]() $Nu$,

$Nu$, ![]() $Ra$ and

$Ra$ and ![]() $Pr$ exist. Equating

$Pr$ exist. Equating ![]() $\unicode[STIX]{x1D716}_{u}$ and

$\unicode[STIX]{x1D716}_{u}$ and ![]() $\unicode[STIX]{x1D716}_{\unicode[STIX]{x1D703}}$ to their estimated either bulk or BL contributions and employing in the BL dominated regimes the Prandtl–Blasius BL theory (Prandtl Reference Prandtl1905; Blasius Reference Blasius1908; Landau & Lifshitz Reference Landau and Lifshitz1987; Schlichting & Gersten Reference Schlichting and Gersten2000), theoretically possible limiting scaling regimes were derived. The theory allows us to predict

$\unicode[STIX]{x1D716}_{\unicode[STIX]{x1D703}}$ to their estimated either bulk or BL contributions and employing in the BL dominated regimes the Prandtl–Blasius BL theory (Prandtl Reference Prandtl1905; Blasius Reference Blasius1908; Landau & Lifshitz Reference Landau and Lifshitz1987; Schlichting & Gersten Reference Schlichting and Gersten2000), theoretically possible limiting scaling regimes were derived. The theory allows us to predict ![]() $Nu$ and

$Nu$ and ![]() $Re$ in RBC if the pre-factors fitted with the latest experimental and numerical data are used, see Stevens et al. (Reference Stevens, van der Poel, Grossmann and Lohse2013) and Shishkina et al. (Reference Shishkina, Emran, Grossmann and Lohse2017).

$Re$ in RBC if the pre-factors fitted with the latest experimental and numerical data are used, see Stevens et al. (Reference Stevens, van der Poel, Grossmann and Lohse2013) and Shishkina et al. (Reference Shishkina, Emran, Grossmann and Lohse2017).

In the other limiting case of IC, which is VC (![]() $\unicode[STIX]{x1D6FD}=90^{\circ }$), the mean kinetic dissipation rate

$\unicode[STIX]{x1D6FD}=90^{\circ }$), the mean kinetic dissipation rate ![]() $\unicode[STIX]{x1D716}_{u}$ cannot be derived analytically from

$\unicode[STIX]{x1D716}_{u}$ cannot be derived analytically from ![]() $Ra$,

$Ra$, ![]() $Pr$ and

$Pr$ and ![]() $Nu$, and this impedes an extension of the GL theory to VC. However, for the case of laminar free convection between two differentially heated plates (i.e. VC), it is possible to derive the dependences of

$Nu$, and this impedes an extension of the GL theory to VC. However, for the case of laminar free convection between two differentially heated plates (i.e. VC), it is possible to derive the dependences of ![]() $Re$ and

$Re$ and ![]() $Nu$ on

$Nu$ on ![]() $Ra$ and

$Ra$ and ![]() $Pr$ from the BL equations, under the assumption that a similarity solution exists (Shishkina Reference Shishkina2016). Although this problem is solved for the laminar case, to our knowledge, there is no theoretical model to predict

$Pr$ from the BL equations, under the assumption that a similarity solution exists (Shishkina Reference Shishkina2016). Although this problem is solved for the laminar case, to our knowledge, there is no theoretical model to predict ![]() $Nu$ and

$Nu$ and ![]() $Re$ in turbulent VC. It is expected, however, that in the asymptotic regime of high

$Re$ in turbulent VC. It is expected, however, that in the asymptotic regime of high ![]() $Ra$, the scaling exponent in the

$Ra$, the scaling exponent in the ![]() $Nu$ versus

$Nu$ versus ![]() $Ra$ and

$Ra$ and ![]() $Re$ versus

$Re$ versus ![]() $Ra$ scalings is

$Ra$ scalings is ![]() $1/2$, as in RBC (Ng et al. Reference Ng, Ooi, Lohse and Chung2018).

$1/2$, as in RBC (Ng et al. Reference Ng, Ooi, Lohse and Chung2018).

Generally, the dependences of ![]() $Nu$ and

$Nu$ and ![]() $Re$ on

$Re$ on ![]() $Ra$ and

$Ra$ and ![]() $Pr$ in VC have been less investigated than those in RBC. For similar cell geometry and ranges of

$Pr$ in VC have been less investigated than those in RBC. For similar cell geometry and ranges of ![]() $Ra$ and

$Ra$ and ![]() $Pr$, not only the heat transport in VC differs quantitatively from that in RBC (Bailon-Cuba et al. Reference Bailon-Cuba, Shishkina, Wagner and Schumacher2012; Wagner & Shishkina Reference Wagner and Shishkina2013, Reference Wagner and Shishkina2015; Ng et al. Reference Ng, Ooi, Lohse and Chung2015), but the VC and RBC flows can even be in different states. For example, for

$Pr$, not only the heat transport in VC differs quantitatively from that in RBC (Bailon-Cuba et al. Reference Bailon-Cuba, Shishkina, Wagner and Schumacher2012; Wagner & Shishkina Reference Wagner and Shishkina2013, Reference Wagner and Shishkina2015; Ng et al. Reference Ng, Ooi, Lohse and Chung2015), but the VC and RBC flows can even be in different states. For example, for ![]() $Pr=1$,

$Pr=1$, ![]() $Ra=10^{8}$ and a cylindrical container of

$Ra=10^{8}$ and a cylindrical container of ![]() $\unicode[STIX]{x1D6E4}=1$, the VC flow is steady, while the RBC flow is already turbulent (Shishkina & Horn Reference Shishkina and Horn2016). Previous experimental and numerical studies of free thermal convection under an imposed horizontal temperature gradient (i.e. VC) reported the scaling exponent

$\unicode[STIX]{x1D6E4}=1$, the VC flow is steady, while the RBC flow is already turbulent (Shishkina & Horn Reference Shishkina and Horn2016). Previous experimental and numerical studies of free thermal convection under an imposed horizontal temperature gradient (i.e. VC) reported the scaling exponent ![]() $\unicode[STIX]{x1D6FE}$ in the power law

$\unicode[STIX]{x1D6FE}$ in the power law ![]() $Nu\sim Ra^{\unicode[STIX]{x1D6FE}}$, varying from

$Nu\sim Ra^{\unicode[STIX]{x1D6FE}}$, varying from ![]() $1/4$ to

$1/4$ to ![]() $1/3$. In laminar VC, it is approximately

$1/3$. In laminar VC, it is approximately ![]() $1/4$ (Schmidt & Beckmann Reference Schmidt and Beckmann1930; Lorenz Reference Lorenz1934; Saunders Reference Saunders1939; Churchill & Chu Reference Churchill and Chu1975), being slightly larger for very small

$1/4$ (Schmidt & Beckmann Reference Schmidt and Beckmann1930; Lorenz Reference Lorenz1934; Saunders Reference Saunders1939; Churchill & Chu Reference Churchill and Chu1975), being slightly larger for very small ![]() $Ra$, where the geometrical cell confinement influences the heat transport (Versteegh & Nieuwstadt Reference Versteegh and Nieuwstadt1999; Yu, Li & Ecke Reference Yu, Li and Ecke2007; Kis & Herwig Reference Kis and Herwig2012; Ng et al. Reference Ng, Ooi, Lohse and Chung2015). The scaling exponent

$Ra$, where the geometrical cell confinement influences the heat transport (Versteegh & Nieuwstadt Reference Versteegh and Nieuwstadt1999; Yu, Li & Ecke Reference Yu, Li and Ecke2007; Kis & Herwig Reference Kis and Herwig2012; Ng et al. Reference Ng, Ooi, Lohse and Chung2015). The scaling exponent ![]() $\unicode[STIX]{x1D6FE}$ is also larger for very high

$\unicode[STIX]{x1D6FE}$ is also larger for very high ![]() $Ra$, where, with growing

$Ra$, where, with growing ![]() $Ra$, the VC flows become first transitional (Ng et al. Reference Ng, Ooi, Lohse and Chung2017) and later on fully turbulent (Fujii et al. Reference Fujii, Takeuchi, Fujii, Suzaki and Uehar1970; George & Capp Reference George and Capp1979). Note that all the mentioned experiments and simulations of VC were conducted for fluids of

$Ra$, the VC flows become first transitional (Ng et al. Reference Ng, Ooi, Lohse and Chung2017) and later on fully turbulent (Fujii et al. Reference Fujii, Takeuchi, Fujii, Suzaki and Uehar1970; George & Capp Reference George and Capp1979). Note that all the mentioned experiments and simulations of VC were conducted for fluids of ![]() $Pr$ about or larger than 1.

$Pr$ about or larger than 1.

For the case of small ![]() $Pr$, in the experiments by Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015) and Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) on turbulent VC in liquid sodium (

$Pr$, in the experiments by Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015) and Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) on turbulent VC in liquid sodium (![]() $Pr\approx 0.01$) in elongated cylinders, significantly larger scaling exponents were observed, due to the geometrical confinement. Thus, for a cylinder with

$Pr\approx 0.01$) in elongated cylinders, significantly larger scaling exponents were observed, due to the geometrical confinement. Thus, for a cylinder with ![]() $L=5D$ and the Rayleigh numbers, based on the cylinder diameter, up to

$L=5D$ and the Rayleigh numbers, based on the cylinder diameter, up to ![]() $10^{7}$, Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015) obtained

$10^{7}$, Frick et al. (Reference Frick, Khalilov, Kolesnichenko, Mamykin, Pakholkov, Pavlinov and Rogozhkin2015) obtained ![]() $Nu\sim Ra^{0.43}$ and

$Nu\sim Ra^{0.43}$ and ![]() $Re\sim Gr^{0.44}$, where

$Re\sim Gr^{0.44}$, where ![]() $Gr$ is the Grashof number,

$Gr$ is the Grashof number, ![]() $Gr\equiv Ra/Pr$. For an extremely strong geometrical confinement, namely, for a cylindrical convection cell with

$Gr\equiv Ra/Pr$. For an extremely strong geometrical confinement, namely, for a cylindrical convection cell with ![]() $L=20D$, and a similar Rayleigh number range, Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) found

$L=20D$, and a similar Rayleigh number range, Mamykin et al. (Reference Mamykin, Frick, Khalilov, Kolesnichenko, Pakholkov, Rogozhkin and Vasiliev2015) found ![]() $Nu\sim Ra^{0.95}$ and

$Nu\sim Ra^{0.95}$ and ![]() $Re\sim Gr^{0.63}$.

$Re\sim Gr^{0.63}$.

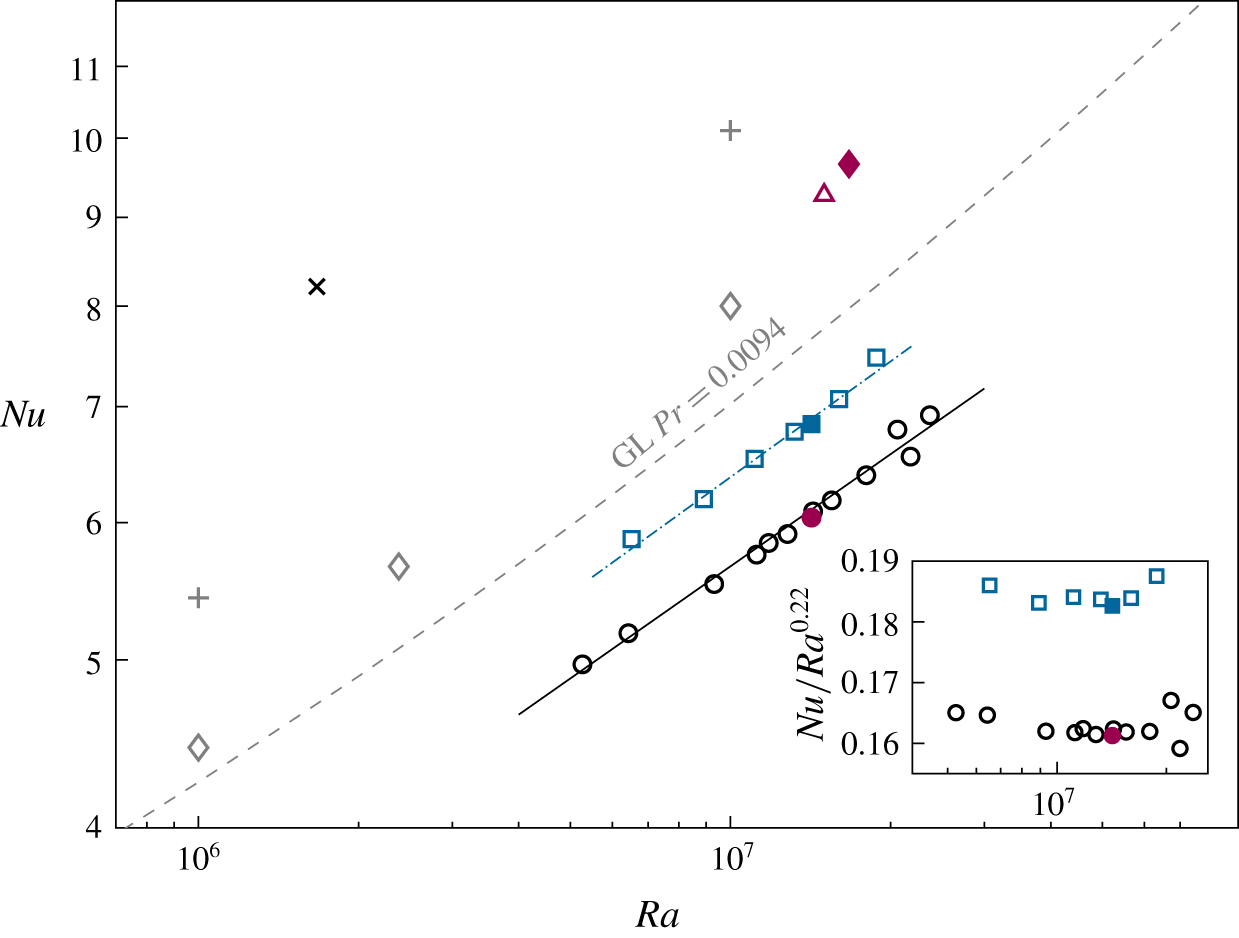

There exist a few measurements of the scaling relations of ![]() $Nu$ versus

$Nu$ versus ![]() $Ra$ in liquid–metal Rayleigh–Bénard convection (without any cell inclination). For mercury (

$Ra$ in liquid–metal Rayleigh–Bénard convection (without any cell inclination). For mercury (![]() $Pr\approx 0.024$), it was reported

$Pr\approx 0.024$), it was reported ![]() $Nu\sim Ra^{0.27}$ for

$Nu\sim Ra^{0.27}$ for ![]() $2\times 10^{6}<Ra<8\times 10^{7}$ by Takeshita et al. (Reference Takeshita, Segawa, Glazier and Sano1996),

$2\times 10^{6}<Ra<8\times 10^{7}$ by Takeshita et al. (Reference Takeshita, Segawa, Glazier and Sano1996), ![]() $Nu\sim Ra^{0.26}$ for

$Nu\sim Ra^{0.26}$ for ![]() $7\times 10^{6}<Ra<4.5\times 10^{8}$ and

$7\times 10^{6}<Ra<4.5\times 10^{8}$ and ![]() $Nu\sim Ra^{0.20}$ for

$Nu\sim Ra^{0.20}$ for ![]() $4.5\times 10^{8}<Ra<2.1\times 10^{9}$ by Cioni et al. (Reference Cioni, Ciliberto and Sommeria1997) and

$4.5\times 10^{8}<Ra<2.1\times 10^{9}$ by Cioni et al. (Reference Cioni, Ciliberto and Sommeria1997) and ![]() $Nu\sim Ra^{0.29}$ for

$Nu\sim Ra^{0.29}$ for ![]() $2\times 10^{5}<Ra<7\times 10^{10}$ by Glazier et al. (Reference Glazier, Segawa, Naert and Sano1999). For liquid gallium (

$2\times 10^{5}<Ra<7\times 10^{10}$ by Glazier et al. (Reference Glazier, Segawa, Naert and Sano1999). For liquid gallium (![]() $Pr\approx 0.025$), King & Aurnou (Reference King and Aurnou2013) measured

$Pr\approx 0.025$), King & Aurnou (Reference King and Aurnou2013) measured ![]() $Nu\sim Ra^{0.25}$ for

$Nu\sim Ra^{0.25}$ for ![]() $2\times 10^{6}<Ra<10^{8}$, and for GaInSn (

$2\times 10^{6}<Ra<10^{8}$, and for GaInSn (![]() $Pr=0.029$), Zürner et al. (Reference Zürner, Schindler, Vogt, Eckert and Schumacher2019) measured

$Pr=0.029$), Zürner et al. (Reference Zürner, Schindler, Vogt, Eckert and Schumacher2019) measured ![]() $Nu\sim Ra^{0.27}$ for

$Nu\sim Ra^{0.27}$ for ![]() $4\times 10^{6}<Ra<6\times 10^{7}$. For liquid sodium (

$4\times 10^{6}<Ra<6\times 10^{7}$. For liquid sodium (![]() $Pr=0.006$), Horanyi, Krebs & Müller (Reference Horanyi, Krebs and Müller1999) measured

$Pr=0.006$), Horanyi, Krebs & Müller (Reference Horanyi, Krebs and Müller1999) measured ![]() $Nu\sim Ra^{0.25}$ for

$Nu\sim Ra^{0.25}$ for ![]() $2\times 10^{4}<Ra<5\times 10^{6}$.

$2\times 10^{4}<Ra<5\times 10^{6}$.

Conducting accurate DNS of natural thermal convection at high ![]() $Ra$ and very low

$Ra$ and very low ![]() $Pr$ is very challenging, since it requires very fine meshes in space and short steps in time due to the necessity to resolve the Kolmogorov microscales in the bulk of the flows as well in the viscous BLs (Shishkina et al. Reference Shishkina, Stevens, Grossmann and Lohse2010). When

$Pr$ is very challenging, since it requires very fine meshes in space and short steps in time due to the necessity to resolve the Kolmogorov microscales in the bulk of the flows as well in the viscous BLs (Shishkina et al. Reference Shishkina, Stevens, Grossmann and Lohse2010). When ![]() $Pr\ll 1$, the thermal diffusion, represented by

$Pr\ll 1$, the thermal diffusion, represented by ![]() $\unicode[STIX]{x1D705}$, is much larger than the momentum diffusion, represented by

$\unicode[STIX]{x1D705}$, is much larger than the momentum diffusion, represented by ![]() $\unicode[STIX]{x1D708}$, and therefore, the viscous BLs become extremely thin at large

$\unicode[STIX]{x1D708}$, and therefore, the viscous BLs become extremely thin at large ![]() $Ra$. Thus, there exist only a few DNS of thermal convection for a combination of large

$Ra$. Thus, there exist only a few DNS of thermal convection for a combination of large ![]() $Ra$ and very low Prandtl numbers,

$Ra$ and very low Prandtl numbers, ![]() $Pr\leqslant 0.025$, which, moreover, have been conducted exclusively for the Rayleigh–Bénard configuration (Scheel & Schumacher Reference Scheel and Schumacher2016, Reference Scheel and Schumacher2017; Schumacher et al. Reference Schumacher, Bandaru, Pandey and Scheel2016; Horn & Schmid Reference Horn and Schmid2017; Vogt et al. Reference Vogt, Horn, Grannan and Aurnou2018).

$Pr\leqslant 0.025$, which, moreover, have been conducted exclusively for the Rayleigh–Bénard configuration (Scheel & Schumacher Reference Scheel and Schumacher2016, Reference Scheel and Schumacher2017; Schumacher et al. Reference Schumacher, Bandaru, Pandey and Scheel2016; Horn & Schmid Reference Horn and Schmid2017; Vogt et al. Reference Vogt, Horn, Grannan and Aurnou2018).

DNS of turbulent flows at extremely large ![]() $Gr$ and extremely small Prandtl numbers, for example convective flow of magnesium that develops in a titanium reduction reactor (characterised by

$Gr$ and extremely small Prandtl numbers, for example convective flow of magnesium that develops in a titanium reduction reactor (characterised by ![]() $Gr$ of the order of

$Gr$ of the order of ![]() $10^{12}$), is currently unrealisable. Therefore, further development of reduced mathematical models is still required. Computational codes for large-eddy simulations (LES) of turbulent thermal convection in liquid metals, verified against the corresponding experiments and DNS, can be useful in solving this kind of problem (Teimurazov, Frick & Stefani Reference Teimurazov, Frick and Stefani2017).

$10^{12}$), is currently unrealisable. Therefore, further development of reduced mathematical models is still required. Computational codes for large-eddy simulations (LES) of turbulent thermal convection in liquid metals, verified against the corresponding experiments and DNS, can be useful in solving this kind of problem (Teimurazov, Frick & Stefani Reference Teimurazov, Frick and Stefani2017).

Although knowledge on thermal convection in liquid metals is required for the development of safe and efficient liquid metal heat exchangers, the experimental database of the corresponding measurements remains quite restricted due to the known difficulties in conducting thermal measurements in liquid metals. Apart from general problems, occurring from the high temperature and aggressivity of liquid sodium, natural convective flows are known to be relatively slow and are very sensitive to the imposed disturbances. While probe measurements in the core part of pipe and channel flows are possible (Heinzel et al. Reference Heinzel, Hering, Konys, Marocco, Litfin, Mueller, Pacio, Schroer, Stieglitz and Stoppel2017; Onea et al. Reference Onea, Hering, Lux and Stieglitz2017a,Reference Onea, Perez-Martin, Jaeger, Hering and Stieglitzb), since the flow is influenced only downstream, they will unavoidably induce too strong disturbances in the case of natural thermal convection.

Thus, IC measurements in liquid sodium at large ![]() $Ra$ and the corresponding precise numerical simulations are in great demand and, therefore, we devote our present work to this topic. Combining experiments, DNS and LES, we aim to paint a complementary picture of turbulent thermal liquid-sodium convection. Using these three viewpoints on liquid-sodium convection helps us to overcome their individual difficulties and simultaneously verify their observations.

$Ra$ and the corresponding precise numerical simulations are in great demand and, therefore, we devote our present work to this topic. Combining experiments, DNS and LES, we aim to paint a complementary picture of turbulent thermal liquid-sodium convection. Using these three viewpoints on liquid-sodium convection helps us to overcome their individual difficulties and simultaneously verify their observations.

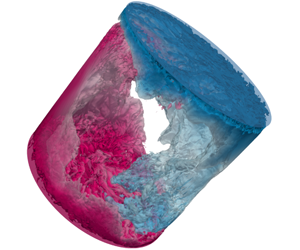

The outline of this work is as follows: in § 2 we introduce the experiment, DNS, LES and methods of data analysis. Section 3 presents the obtained results on how the global flow structures (mainly LSC) and their evolution in time affect the heat and momentum transport in case of liquid-sodium convection. An analogy of the global flow structures and global heat transport in flows with similar values of ![]() $Ra\,Pr$ is also discussed there. The final section summarises our results.

$Ra\,Pr$ is also discussed there. The final section summarises our results.

2 Methods

2.1 Experiment

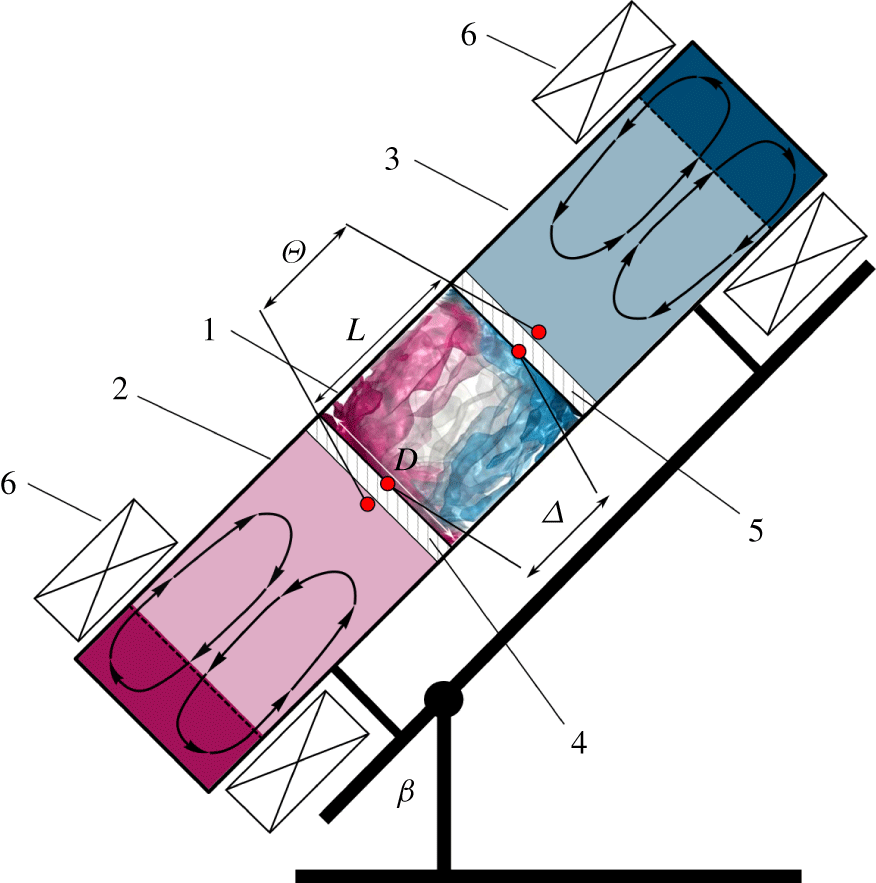

All experimental data presented in this paper are obtained at the experimental facility described in detail in Khalilov et al. (Reference Khalilov, Kolesnichenko, Pavlinov, Mamykin, Shestakov and Frick2018). The convection cell is made of a stainless steel pipe with a 3.5 mm thick wall. The inner length of the convection cell is ![]() $L=216~\text{mm}$ and the inner diameter

$L=216~\text{mm}$ and the inner diameter ![]() $D=212~\text{mm}$. Both end faces of the convection cell are separated from the heat exchanger chambers by 1 mm thick copper discs, see a sketch in figure 1. The convection cell is filled with liquid sodium. The heat exchanger chambers are filled also with liquid sodium and the temperature there is kept constant. The thin end-face copper plates are intensively washed with liquid sodium from the chamber sides, ensuring homogeneous temperature distributions at their surfaces (Kolesnichenko et al. Reference Kolesnichenko, Khalilov, Teimurazov and Frick2017). The entire set-up is placed on a swing frame, so that the convection cell can be tilted from a vertical position to a horizontal one. Inclination of the convection cell is then characterised by the angle

$D=212~\text{mm}$. Both end faces of the convection cell are separated from the heat exchanger chambers by 1 mm thick copper discs, see a sketch in figure 1. The convection cell is filled with liquid sodium. The heat exchanger chambers are filled also with liquid sodium and the temperature there is kept constant. The thin end-face copper plates are intensively washed with liquid sodium from the chamber sides, ensuring homogeneous temperature distributions at their surfaces (Kolesnichenko et al. Reference Kolesnichenko, Khalilov, Teimurazov and Frick2017). The entire set-up is placed on a swing frame, so that the convection cell can be tilted from a vertical position to a horizontal one. Inclination of the convection cell is then characterised by the angle ![]() $\unicode[STIX]{x1D6FD}$ between the vertical and the cylinder axis, see figure 1.

$\unicode[STIX]{x1D6FD}$ between the vertical and the cylinder axis, see figure 1.

Figure 1. Sketch of the experimental facility, which consists of: (1) a cylindrical convection cell, (2) a hot heat exchanger chamber, (3) a cold heat exchanger chamber, (4) a heated copper plate, (5) a cooled copper plate and (6) inductor coils. The convection cell (1) and heat exchangers (2, 3) are filled with liquid sodium. ![]() $D$ is the diameter and

$D$ is the diameter and ![]() $L$ the length of the cylindrical convection cell (1),

$L$ the length of the cylindrical convection cell (1), ![]() $\unicode[STIX]{x1D6FD}$ is the cell inclination angle,

$\unicode[STIX]{x1D6FD}$ is the cell inclination angle, ![]() $\unicode[STIX]{x1D6E9}$ the temperature drop between the hot and cold heat exchanger chambers,

$\unicode[STIX]{x1D6E9}$ the temperature drop between the hot and cold heat exchanger chambers, ![]() $\unicode[STIX]{x1D6E5}$ the resulting temperature drop between the inner surfaces of the heated and cooled plates of the convection cell (1).

$\unicode[STIX]{x1D6E5}$ the resulting temperature drop between the inner surfaces of the heated and cooled plates of the convection cell (1).

Table 1. The thermal conductivity ![]() $\unicode[STIX]{x1D706}$ and the thermal diffusivity

$\unicode[STIX]{x1D706}$ and the thermal diffusivity ![]() $\unicode[STIX]{x1D705}$ of stainless steel, liquid sodium (Na) and copper (Cu) at the mean temperature of the experiment of approximately 410 K.

$\unicode[STIX]{x1D705}$ of stainless steel, liquid sodium (Na) and copper (Cu) at the mean temperature of the experiment of approximately 410 K.

Obviously, the boundary conditions in a real liquid–metal experiment and the idealised boundary conditions that are considered in numerical simulations, are different. For example, in the simulations, the cylindrical sidewall is assumed to be adiabatic, while in the real experiment it is made from 3.5 mm thick stainless steel and is additionally covered by a 30 mm thick layer of mineral wool. In table 1, the thermal characteristics of stainless steel, liquid sodium and copper are presented. One can see that the thermal diffusivity of the stainless steel, although being smaller compared to that of liquid sodium, is not negligible. Copper, which is known to be the best material for the heat exchangers in the experiments with moderate or high ![]() $Pr$ fluids, has the thermal diffusivity of the same order as the thermal diffusivity of sodium. Therefore, massive copper plates would not provide a uniform temperature at the surfaces of the plates (Kolesnichenko et al. Reference Kolesnichenko, Mamykin, Pavlinov, Pakholkov, Rogozhkin, Frick, Khalilov and Shepelev2015). To avoid this undesirable inhomogeneity, in our experiment, instead of thick copper plates, we use rather thin ones, which are intensively washed from the outside by liquid sodium of prescribed temperature (see figure 1). The latter process takes place in two heat exchanger chambers, a hot one and a cold one, which are equipped with induction coils. A sodium flow in each heat exchanger chamber is provided by a travelling magnetic field. The induction coils are attached near the outer end faces of the corresponding heat exchanger, thus ensuring that the electromagnetic influence of the inductors on the liquid metal in the convection cell is negligible (Kolesnichenko et al. Reference Kolesnichenko, Khalilov, Teimurazov and Frick2017). Typical velocities of the sodium flows in the heat exchangers are approximately

$Pr$ fluids, has the thermal diffusivity of the same order as the thermal diffusivity of sodium. Therefore, massive copper plates would not provide a uniform temperature at the surfaces of the plates (Kolesnichenko et al. Reference Kolesnichenko, Mamykin, Pavlinov, Pakholkov, Rogozhkin, Frick, Khalilov and Shepelev2015). To avoid this undesirable inhomogeneity, in our experiment, instead of thick copper plates, we use rather thin ones, which are intensively washed from the outside by liquid sodium of prescribed temperature (see figure 1). The latter process takes place in two heat exchanger chambers, a hot one and a cold one, which are equipped with induction coils. A sodium flow in each heat exchanger chamber is provided by a travelling magnetic field. The induction coils are attached near the outer end faces of the corresponding heat exchanger, thus ensuring that the electromagnetic influence of the inductors on the liquid metal in the convection cell is negligible (Kolesnichenko et al. Reference Kolesnichenko, Khalilov, Teimurazov and Frick2017). Typical velocities of the sodium flows in the heat exchangers are approximately ![]() $1~\text{m}~\text{s}^{-1}$, being an order of magnitude higher than the convective velocity inside the convection cell.

$1~\text{m}~\text{s}^{-1}$, being an order of magnitude higher than the convective velocity inside the convection cell.

In all conducted experiments, the mean temperature of liquid sodium inside the convection cell is approximately ![]() $T_{m}=139.8\,^{\circ }\text{C}$, for which the Prandtl number equals

$T_{m}=139.8\,^{\circ }\text{C}$, for which the Prandtl number equals ![]() $Pr\approx 0.0093$. Each experiment is performed for a prescribed and known applied temperature difference

$Pr\approx 0.0093$. Each experiment is performed for a prescribed and known applied temperature difference ![]() $\unicode[STIX]{x1D6E9}=T_{hot}-T_{cold}$, where

$\unicode[STIX]{x1D6E9}=T_{hot}-T_{cold}$, where ![]() $T_{hot}$ and

$T_{hot}$ and ![]() $T_{cold}$ are the time-averaged temperatures of sodium in, respectively, the hot and cold heat exchanger chambers, which are measured close to the copper plates (see figure 1).

$T_{cold}$ are the time-averaged temperatures of sodium in, respectively, the hot and cold heat exchanger chambers, which are measured close to the copper plates (see figure 1).

In any hot liquid–metal experiment, there exist unavoidable heat losses due to the high temperature of the set-up. To estimate the corresponding power losses ![]() $Q_{loss}$, one needs to measure additionally the power, which is required to maintain the same mean temperature

$Q_{loss}$, one needs to measure additionally the power, which is required to maintain the same mean temperature ![]() $T_{m}$ of liquid sodium inside the convection cell, but under the condition of equal temperatures in both heat exchanger chambers, that is, for

$T_{m}$ of liquid sodium inside the convection cell, but under the condition of equal temperatures in both heat exchanger chambers, that is, for ![]() $\unicode[STIX]{x1D6E9}=0$. From

$\unicode[STIX]{x1D6E9}=0$. From ![]() $Q_{loss}$ and the total power consumption

$Q_{loss}$ and the total power consumption ![]() $Q$ in the convective experiment at

$Q$ in the convective experiment at ![]() $\unicode[STIX]{x1D6E9}\neq 0$, one calculates the effective power

$\unicode[STIX]{x1D6E9}\neq 0$, one calculates the effective power ![]() $Q_{eff}=Q-Q_{loss}$ in any particular experiment.

$Q_{eff}=Q-Q_{loss}$ in any particular experiment.

Although the thermal resistance of the two thin copper plates themselves is negligible, the sodium–copper interfaces provide additional effective thermal resistance of the plates mainly due to inevitable oxide films. The temperature drop ![]() $\unicode[STIX]{x1D6E5}_{pl}$ through both copper plates covered by the oxide films could be calculated then from

$\unicode[STIX]{x1D6E5}_{pl}$ through both copper plates covered by the oxide films could be calculated then from ![]() $\unicode[STIX]{x1D6E5}_{pl}=Q_{eff}R_{pl}$, as soon as the effective thermal resistance of the plates,

$\unicode[STIX]{x1D6E5}_{pl}=Q_{eff}R_{pl}$, as soon as the effective thermal resistance of the plates, ![]() $R_{pl}$, is known. Note that for a fixed mean temperature

$R_{pl}$, is known. Note that for a fixed mean temperature ![]() $T_{m}$, the value of

$T_{m}$, the value of ![]() $R_{pl}$ depends on

$R_{pl}$ depends on ![]() $\unicode[STIX]{x1D6E9}$, since the effective thermal conductivities of the two plates are different due to their different temperatures.

$\unicode[STIX]{x1D6E9}$, since the effective thermal conductivities of the two plates are different due to their different temperatures.

The values of ![]() $R_{pl}(\unicode[STIX]{x1D6E9})$ for different

$R_{pl}(\unicode[STIX]{x1D6E9})$ for different ![]() $\unicode[STIX]{x1D6E9}$ are calculated in a series of auxiliary measurements for the case of

$\unicode[STIX]{x1D6E9}$ are calculated in a series of auxiliary measurements for the case of ![]() $\unicode[STIX]{x1D6FD}=0$ and stable temperature stratification, where the heat is applied from above, to suppress convection. In this purely conductive case, the effective thermal resistance of the plates,

$\unicode[STIX]{x1D6FD}=0$ and stable temperature stratification, where the heat is applied from above, to suppress convection. In this purely conductive case, the effective thermal resistance of the plates, ![]() $R_{pl}$, can be calculated from

$R_{pl}$, can be calculated from ![]() $\unicode[STIX]{x1D6E9}$ and the measured effective power

$\unicode[STIX]{x1D6E9}$ and the measured effective power ![]() $\bar{Q}_{eff}$ from the relation

$\bar{Q}_{eff}$ from the relation ![]() $\unicode[STIX]{x1D6E9}=\bar{Q}_{eff}(R_{Na}+R_{pl})$, where the thermal resistance of the liquid sodium equals

$\unicode[STIX]{x1D6E9}=\bar{Q}_{eff}(R_{Na}+R_{pl})$, where the thermal resistance of the liquid sodium equals ![]() $R_{Na}=L/(\unicode[STIX]{x1D706}_{Na}S)$ with

$R_{Na}=L/(\unicode[STIX]{x1D706}_{Na}S)$ with ![]() $\unicode[STIX]{x1D706}_{Na}$ being the liquid-sodium thermal conductivity and

$\unicode[STIX]{x1D706}_{Na}$ being the liquid-sodium thermal conductivity and ![]() $S=\unicode[STIX]{x03C0}R^{2}$ with the cylinder radius

$S=\unicode[STIX]{x03C0}R^{2}$ with the cylinder radius ![]() $R$.

$R$.

Using the above measured effective thermal resistances of the plates, ![]() $R_{pl}(\unicode[STIX]{x1D6E9})$, in any convection experiment for a given

$R_{pl}(\unicode[STIX]{x1D6E9})$, in any convection experiment for a given ![]() $Ra$ and

$Ra$ and ![]() $\unicode[STIX]{x1D6FD}$ and the mean temperature

$\unicode[STIX]{x1D6FD}$ and the mean temperature ![]() $T_{m}$, the previously unknown temperature drop

$T_{m}$, the previously unknown temperature drop ![]() $\unicode[STIX]{x1D6E5}$ inside the convection cell can be calculated from

$\unicode[STIX]{x1D6E5}$ inside the convection cell can be calculated from ![]() $\unicode[STIX]{x1D6E9}$,

$\unicode[STIX]{x1D6E9}$, ![]() $R_{pl}(\unicode[STIX]{x1D6E9})$ and measured

$R_{pl}(\unicode[STIX]{x1D6E9})$ and measured ![]() $Q_{eff}$ as follows:

$Q_{eff}$ as follows:

Note that in all our measurements in liquid sodium, for all considered inclination angles of the convection cell, the obtained mean temperature and the temperature drop within the cell equal, respectively, ![]() $T_{m}\approx 139.8^{\circ }$ and

$T_{m}\approx 139.8^{\circ }$ and ![]() $\unicode[STIX]{x1D6E5}\approx 25.3~\text{K}$.

$\unicode[STIX]{x1D6E5}\approx 25.3~\text{K}$.

The Nusselt number is then calculated as

For a comparison of the experimental results with the DNS and LES results, where the temperatures at the plates inside the convection cell are known a priori, the experimental temperature at the hot plate, ![]() $T_{+}$, and that at the cooled plate,

$T_{+}$, and that at the cooled plate, ![]() $T_{-}$, are calculated as follows:

$T_{-}$, are calculated as follows:

The Rayleigh number in the experiment is evaluated as

which slightly differs from the value defined in (1.1), since ![]() $D$ is slightly smaller than

$D$ is slightly smaller than ![]() $L$. Thus, for

$L$. Thus, for ![]() $\unicode[STIX]{x1D6FC}=2.56\times 10^{-4}~\text{K}^{-1}$,

$\unicode[STIX]{x1D6FC}=2.56\times 10^{-4}~\text{K}^{-1}$, ![]() $g=9.81~\text{m}~\text{s}^{-2}$,

$g=9.81~\text{m}~\text{s}^{-2}$, ![]() $\unicode[STIX]{x1D6E5}=25.3~\text{K}$,

$\unicode[STIX]{x1D6E5}=25.3~\text{K}$, ![]() $\unicode[STIX]{x1D708}=6.174\times 10^{-7}~\text{m}^{2}~\text{s}^{-1}$ and

$\unicode[STIX]{x1D708}=6.174\times 10^{-7}~\text{m}^{2}~\text{s}^{-1}$ and ![]() $\unicode[STIX]{x1D705}=6.651\times 10^{-5}~\text{m}^{2}~\text{s}^{-1}$, the Rayleigh number equals

$\unicode[STIX]{x1D705}=6.651\times 10^{-5}~\text{m}^{2}~\text{s}^{-1}$, the Rayleigh number equals ![]() $Ra=(1.42\pm 0.03)\times 10^{7}$.

$Ra=(1.42\pm 0.03)\times 10^{7}$.

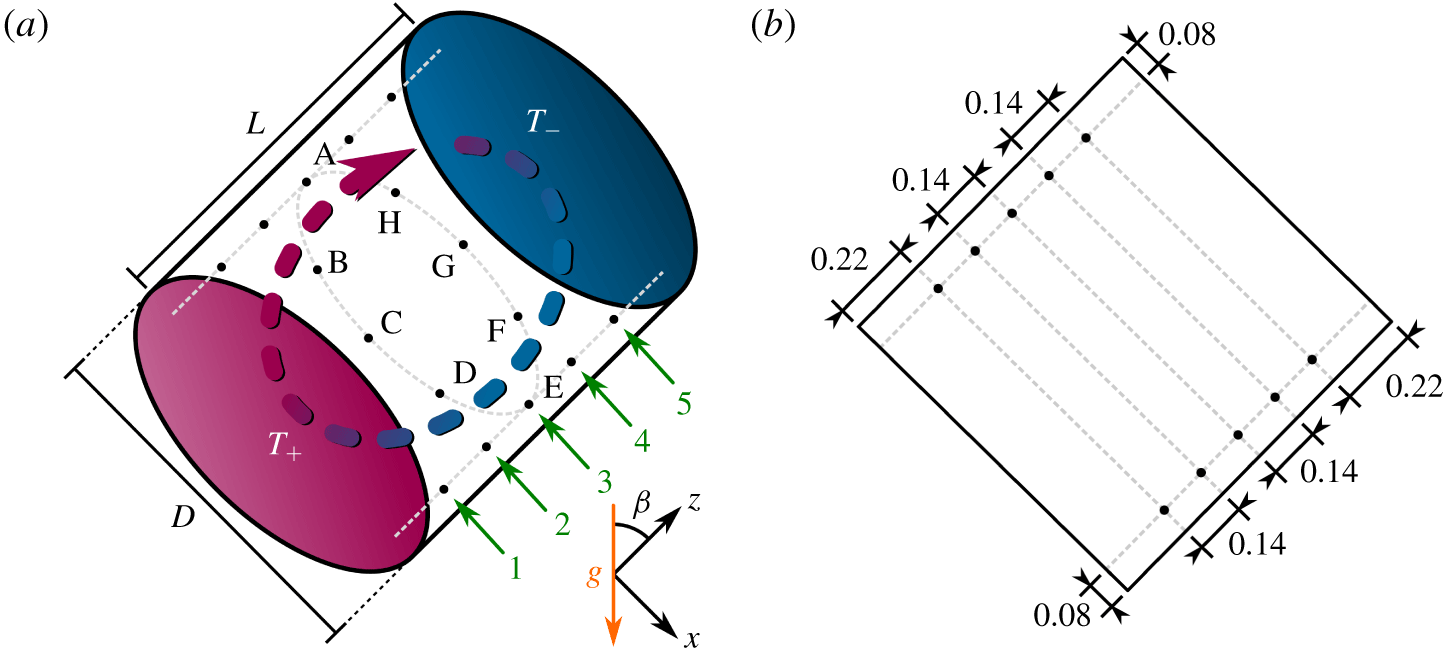

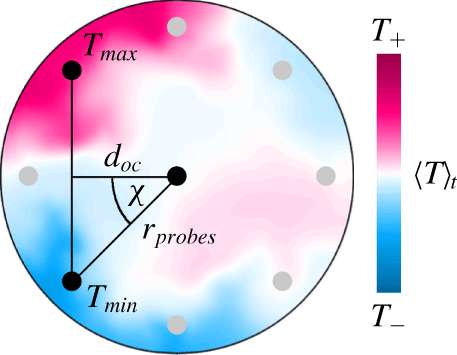

For a deep analysis of the convective liquid-sodium flows, the convection cell is equipped with 28 thermocouples, each with an isolated junction of 1 mm. The thermocouples are located on 8 lines aligned parallel to the cylinder axis (see figure 2). The azimuthal locations of these lines are distributed with an equal azimuthal step of ![]() $45^{\circ }$ and are marked in figure 2 by capital letters A to H (counterclockwise, if looking from the cold end face). The line A has the upper position if

$45^{\circ }$ and are marked in figure 2 by capital letters A to H (counterclockwise, if looking from the cold end face). The line A has the upper position if ![]() $\unicode[STIX]{x1D6FD}>0^{\circ }$. On each of the eight lines (A to H), 3 or 5 thermocouples are placed. Thus, all thermocouples are located in five cross-sections of the convection cell, which are parallel to the end faces. The thermocouples are installed inside the convection cell at the same distance of 17 mm from the inner cylinder sidewall and thus are located on five circles, which are marked in figure 2 with numbers

$\unicode[STIX]{x1D6FD}>0^{\circ }$. On each of the eight lines (A to H), 3 or 5 thermocouples are placed. Thus, all thermocouples are located in five cross-sections of the convection cell, which are parallel to the end faces. The thermocouples are installed inside the convection cell at the same distance of 17 mm from the inner cylinder sidewall and thus are located on five circles, which are marked in figure 2 with numbers ![]() $1,\ldots ,5$. The circles 1, 3 and 5 include eight thermocouples, and the circles 2 and 4 only two thermocouples (A and E).

$1,\ldots ,5$. The circles 1, 3 and 5 include eight thermocouples, and the circles 2 and 4 only two thermocouples (A and E).

Figure 2. (a) Sketch of an inclined convection cell. ![]() $D$ is the diameter and

$D$ is the diameter and ![]() $L$ the height of the cylindrical sample,

$L$ the height of the cylindrical sample, ![]() $\unicode[STIX]{x1D6FD}$ is the inclination angle,

$\unicode[STIX]{x1D6FD}$ is the inclination angle, ![]() $T_{+}$ (

$T_{+}$ (![]() $T_{-}$) the temperature of the heated (cooled) surfaces. Positioning and naming of the 40 probes inside the cylinder, as considered in the DNS (all combinations of the azimuthal locations A, B, C, D, E, F, G, H and circles

$T_{-}$) the temperature of the heated (cooled) surfaces. Positioning and naming of the 40 probes inside the cylinder, as considered in the DNS (all combinations of the azimuthal locations A, B, C, D, E, F, G, H and circles ![]() $1,\ldots ,5$) and 28 probes in the experiments (all combinations of the eight locations

$1,\ldots ,5$) and 28 probes in the experiments (all combinations of the eight locations ![]() $\text{A},\ldots ,\text{H}$ for the circles 1, 3 and 5 plus four additional probes: A2, A4, E2, E4). Note that the azimuthal locations are shown only for the circle 3, not to overload the sketch. For any inclination angle

$\text{A},\ldots ,\text{H}$ for the circles 1, 3 and 5 plus four additional probes: A2, A4, E2, E4). Note that the azimuthal locations are shown only for the circle 3, not to overload the sketch. For any inclination angle ![]() $\unicode[STIX]{x1D6FD}>0^{\circ }$, the upper azimuthal location is A. (b) Sketch of a central vertical cross-section of the set-up from figure (a), with shown distances (normalised with

$\unicode[STIX]{x1D6FD}>0^{\circ }$, the upper azimuthal location is A. (b) Sketch of a central vertical cross-section of the set-up from figure (a), with shown distances (normalised with ![]() $L=D$) between the neighbouring probes and between the probes and the sidewall of the cylindrical convection cell.

$L=D$) between the neighbouring probes and between the probes and the sidewall of the cylindrical convection cell.

In this paper, besides the measurements by Khalilov et al. (Reference Khalilov, Kolesnichenko, Pavlinov, Mamykin, Shestakov and Frick2018), where a single Rayleigh number ![]() $Ra=(1.42\pm 0.03)\times 10^{7}$ was considered, we present and analyse also new experimental data, which are obtained for a certain range of the Rayleigh number, based on different imposed temperature gradients.

$Ra=(1.42\pm 0.03)\times 10^{7}$ was considered, we present and analyse also new experimental data, which are obtained for a certain range of the Rayleigh number, based on different imposed temperature gradients.

2.2 Direct numerical simulations

The problem of inclined thermal convection within the Oberbeck–Boussinesq (OB) approximation, which is studied in the DNS, is defined by the following Navier–Stokes, temperature and continuity equations in cylindrical coordinates ![]() $(r,\unicode[STIX]{x1D719},z)$:

$(r,\unicode[STIX]{x1D719},z)$:

where ![]() $D_{t}$ denotes the substantial derivative,

$D_{t}$ denotes the substantial derivative, ![]() $\boldsymbol{u}=(u_{r},u_{\unicode[STIX]{x1D719}},u_{z})$ the velocity vector field, with the component

$\boldsymbol{u}=(u_{r},u_{\unicode[STIX]{x1D719}},u_{z})$ the velocity vector field, with the component ![]() $u_{z}$ in the direction

$u_{z}$ in the direction ![]() $z$, which is orthogonal to the plates,

$z$, which is orthogonal to the plates, ![]() $p$ is the reduced kinetic pressure,

$p$ is the reduced kinetic pressure, ![]() $T$ the temperature,

$T$ the temperature, ![]() $T_{0}=(T_{+}+T_{-})/2$ and

$T_{0}=(T_{+}+T_{-})/2$ and ![]() $\hat{\boldsymbol{e}}$ is the unit vector,

$\hat{\boldsymbol{e}}$ is the unit vector, ![]() $\hat{\boldsymbol{e}}=(-\text{sin}(\unicode[STIX]{x1D6FD})\cos (\unicode[STIX]{x1D719}),\sin (\unicode[STIX]{x1D6FD})\sin (\unicode[STIX]{x1D719}),\cos (\unicode[STIX]{x1D6FD}))$. Within the considered OB approximation, it is assumed that the fluid properties are independent of the temperature and pressure, apart from the buoyancy term in the Navier–Stokes equation, where the density is taken linearly dependent on the temperature.

$\hat{\boldsymbol{e}}=(-\text{sin}(\unicode[STIX]{x1D6FD})\cos (\unicode[STIX]{x1D719}),\sin (\unicode[STIX]{x1D6FD})\sin (\unicode[STIX]{x1D719}),\cos (\unicode[STIX]{x1D6FD}))$. Within the considered OB approximation, it is assumed that the fluid properties are independent of the temperature and pressure, apart from the buoyancy term in the Navier–Stokes equation, where the density is taken linearly dependent on the temperature.

These equations are non-dimensionalised by using the cylinder radius ![]() $R$, the free-fall velocity

$R$, the free-fall velocity ![]() $U_{f}$, the free-fall time

$U_{f}$, the free-fall time ![]() $t_{f}$,

$t_{f}$,

and the temperature drop between the heated plate and the cooled plate, ![]() $\unicode[STIX]{x1D6E5}$, as units of length, velocity, time and temperature, respectively.

$\unicode[STIX]{x1D6E5}$, as units of length, velocity, time and temperature, respectively.

To close the system (2.5)–(2.7), the following boundary conditions are considered: no slip for the velocity at all boundaries, ![]() $\boldsymbol{u}=0$, constant temperatures (

$\boldsymbol{u}=0$, constant temperatures (![]() $T_{-}$ or

$T_{-}$ or ![]() $T_{+}$) at the face ends of the cylinder and adiabatic boundary condition at the sidewall,

$T_{+}$) at the face ends of the cylinder and adiabatic boundary condition at the sidewall, ![]() $\unicode[STIX]{x2202}T/\unicode[STIX]{x2202}r=0$.

$\unicode[STIX]{x2202}T/\unicode[STIX]{x2202}r=0$.

The resulting dimensionless equations are solved numerically with the finite-volume computational code goldfish, which uses high-order interpolation schemes in space and a direct solver for the pressure (Kooij et al. Reference Kooij, Botchev, Frederix, Geurts, Horn, Lohse, van der Poel, Shishkina, Stevens and Verzicco2018). No turbulence model is applied in the simulations. The utilised staggered computational grids of approximately ![]() $1.5\times 10^{8}$ nodes, which are clustered near all rigid walls, are sufficiently fine to resolve the Kolmogorov microscales (see table 2). Statistical averaging is usually carried out for several hundred free-fall time units, which is sufficient not only for integral quantities like the Nusselt number and Reynolds number to converge, but also for the flow fields. The exceptions are the most expensive DNS for liquid sodium. Statistical averaging in our liquid-sodium DNS is, however, the longest known for such low Prandtl numbers and the integral quantities and also the velocity and temperature profiles are converged to a reasonable degree.

$1.5\times 10^{8}$ nodes, which are clustered near all rigid walls, are sufficiently fine to resolve the Kolmogorov microscales (see table 2). Statistical averaging is usually carried out for several hundred free-fall time units, which is sufficient not only for integral quantities like the Nusselt number and Reynolds number to converge, but also for the flow fields. The exceptions are the most expensive DNS for liquid sodium. Statistical averaging in our liquid-sodium DNS is, however, the longest known for such low Prandtl numbers and the integral quantities and also the velocity and temperature profiles are converged to a reasonable degree.

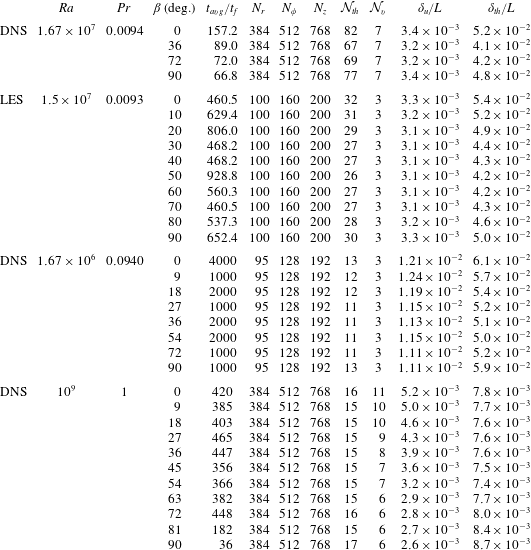

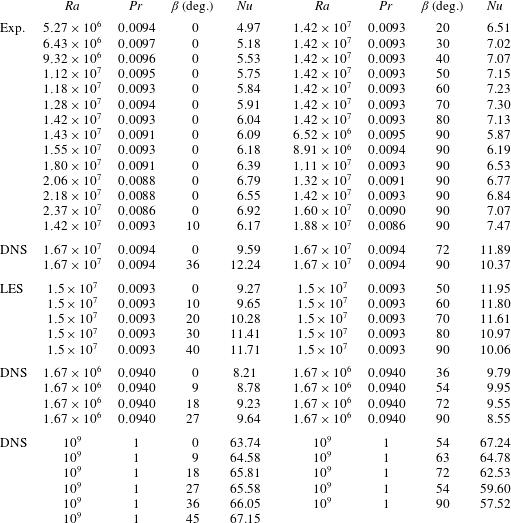

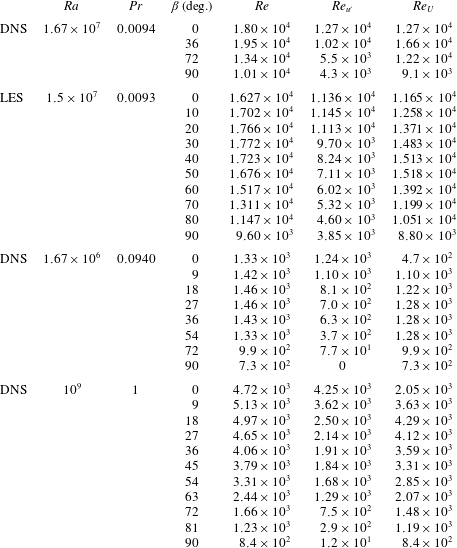

Table 2. Details on the conducted DNS and LES, including the time of statistical averaging, ![]() $t_{avg}$, normalised with the free-fall time

$t_{avg}$, normalised with the free-fall time ![]() $t_{f}$; number of nodes

$t_{f}$; number of nodes ![]() $N_{r}$,

$N_{r}$, ![]() $N_{\unicode[STIX]{x1D719}}$,

$N_{\unicode[STIX]{x1D719}}$, ![]() $N_{z}$ in the directions

$N_{z}$ in the directions ![]() $r$,

$r$, ![]() $\unicode[STIX]{x1D719}$ and

$\unicode[STIX]{x1D719}$ and ![]() $z$, respectively; the number of the nodes within the thermal boundary layer,

$z$, respectively; the number of the nodes within the thermal boundary layer, ![]() ${\mathcal{N}}_{th}$, and within the viscous boundary layer,

${\mathcal{N}}_{th}$, and within the viscous boundary layer, ![]() ${\mathcal{N}}_{v}$, and the relative thickness of the viscous boundary layer

${\mathcal{N}}_{v}$, and the relative thickness of the viscous boundary layer ![]() $\unicode[STIX]{x1D6FF}_{u}/L$ (2.17) and the thermal boundary layer

$\unicode[STIX]{x1D6FF}_{u}/L$ (2.17) and the thermal boundary layer ![]() $\unicode[STIX]{x1D6FF}_{th}/L$ (2.16).

$\unicode[STIX]{x1D6FF}_{th}/L$ (2.16).

Since simulations on such fine meshes are extremely expensive, only four inclination angles are considered for the main case of ![]() $Pr=0.0094$ and

$Pr=0.0094$ and ![]() $Ra=1.67\times 10^{7}$, which are

$Ra=1.67\times 10^{7}$, which are ![]() $\unicode[STIX]{x1D6FD}=0^{\circ }$,

$\unicode[STIX]{x1D6FD}=0^{\circ }$, ![]() $\unicode[STIX]{x1D6FD}=36^{\circ }$,

$\unicode[STIX]{x1D6FD}=36^{\circ }$, ![]() $\unicode[STIX]{x1D6FD}=72^{\circ }$ and

$\unicode[STIX]{x1D6FD}=72^{\circ }$ and ![]() $\unicode[STIX]{x1D6FD}=90^{\circ }$. To study similarities of the flows with respect to the global heat transport and global flow structures for an almost constant Grashof number,

$\unicode[STIX]{x1D6FD}=90^{\circ }$. To study similarities of the flows with respect to the global heat transport and global flow structures for an almost constant Grashof number, ![]() $Gr\equiv Ra/Pr$, and for a fixed value of

$Gr\equiv Ra/Pr$, and for a fixed value of ![]() $Ra\,Pr$, some additional DNS of IC were conducted for the combinations of

$Ra\,Pr$, some additional DNS of IC were conducted for the combinations of ![]() $Pr=0.094$ with

$Pr=0.094$ with ![]() $Ra=1.67\times 10^{6}$ and

$Ra=1.67\times 10^{6}$ and ![]() $Pr=1$ with

$Pr=1$ with ![]() $Ra=10^{9}$. Note that the Grashof number of the auxiliary DNS (

$Ra=10^{9}$. Note that the Grashof number of the auxiliary DNS (![]() $Gr=10^{9}$) is slightly different from that of the liquid-sodium DNS (

$Gr=10^{9}$) is slightly different from that of the liquid-sodium DNS (![]() $Gr=1.78\times 10^{9}$). In the former additional DNS, eight different inclination angles are considered, while in the latter additional DNS, 11 different values of

$Gr=1.78\times 10^{9}$). In the former additional DNS, eight different inclination angles are considered, while in the latter additional DNS, 11 different values of ![]() $\unicode[STIX]{x1D6FD}$ are examined (see table 2). The computational grids, used in the auxiliary DNS for similar

$\unicode[STIX]{x1D6FD}$ are examined (see table 2). The computational grids, used in the auxiliary DNS for similar ![]() $Ra\,Pr$, contain only three nodes within each viscous boundary layer, however, a convergence study, using twice as many nodes in each direction, for three different inclination angles demonstrated a deviation in

$Ra\,Pr$, contain only three nodes within each viscous boundary layer, however, a convergence study, using twice as many nodes in each direction, for three different inclination angles demonstrated a deviation in ![]() $Nu$ and

$Nu$ and ![]() $Ra$ within 1 %.

$Ra$ within 1 %.

2.3 Large-eddy simulations

At any fixed time slice, LES generally require more computational effort per computational node, than the DNS. However, since the LES are relieved from the requirement to resolve the spatial Kolmogorov microscales, one can use significantly coarser meshes in the LES compared to those in the DNS, as soon as the LES are verified against the measurements from the physical point of view and against the DNS from the numerical point of view. Thus, the verified LES open the possibility of obtaining reliable data faster, compared to the DNS, using modest computational resources.

In our study, the OB equations (2.5)–(2.7) of thermogravitational convection with the LES approach for small-scale turbulence modelling are solved numerically using the open-source package OpenFOAM 4.1 (Weller et al. Reference Weller, Tabor, Jasak and Fureby1998) for ![]() $Pr=0.0093$ and

$Pr=0.0093$ and ![]() $Ra=1.5\times 10^{7}$ and 10 different inclination angles, equidistantly distributed between

$Ra=1.5\times 10^{7}$ and 10 different inclination angles, equidistantly distributed between ![]() $\unicode[STIX]{x1D6FD}=0^{\circ }$ and

$\unicode[STIX]{x1D6FD}=0^{\circ }$ and ![]() $\unicode[STIX]{x1D6FD}=90^{\circ }$.

$\unicode[STIX]{x1D6FD}=90^{\circ }$.

The package is configured as follows. The used LES model is that by Smagorinsky–Lilly (Deardorff Reference Deardorff1970) with the Smagorinsky constant ![]() $C_{s}=0.17$, which is compatible with the value of the Kolmogorov spectrum constant for the inertial subrange. The turbulent Prandtl number in the core part of the domain equals

$C_{s}=0.17$, which is compatible with the value of the Kolmogorov spectrum constant for the inertial subrange. The turbulent Prandtl number in the core part of the domain equals ![]() $Pr_{t}=0.9$ and smoothly vanishes close to the rigid walls. According to different models for liquid metals, the

$Pr_{t}=0.9$ and smoothly vanishes close to the rigid walls. According to different models for liquid metals, the ![]() $Pr_{t}$ value can be higher than this one (Chen et al. Reference Chen, Huai, Cai, Li and Meng2013). To estimate the effect of the

$Pr_{t}$ value can be higher than this one (Chen et al. Reference Chen, Huai, Cai, Li and Meng2013). To estimate the effect of the ![]() $Pr_{t}$ value on the simulation results we carried out additional LES with

$Pr_{t}$ value on the simulation results we carried out additional LES with ![]() $Pr_{t}$ values up to 4.12 and showed that the specific choice of

$Pr_{t}$ values up to 4.12 and showed that the specific choice of ![]() $Pr_{t}$ does not significantly affect the results. The utilised finite-volume solver is buoyantBoussinesqPimpleFoam with the pressure implicit with splitting of operators (PISO) algorithm by Issa (Reference Issa1986). Time integration is realised with the implicit Euler scheme; the diffusive and convective terms are also treated linearly (more precisely, using the filteredLinear scheme). The resulting systems of linear equations are solved with the preconditioned conjugate gradient method with the diagonal-based incomplete Cholesky preconditioner for the pressure and preconditioned biconjugate gradient method with the diagonal-based incomplete lower–upper (LU) preconditioner for other flow components (Fletcher Reference Fletcher1976; Ferziger & Perić Reference Ferziger and Perić2002).

$Pr_{t}$ does not significantly affect the results. The utilised finite-volume solver is buoyantBoussinesqPimpleFoam with the pressure implicit with splitting of operators (PISO) algorithm by Issa (Reference Issa1986). Time integration is realised with the implicit Euler scheme; the diffusive and convective terms are also treated linearly (more precisely, using the filteredLinear scheme). The resulting systems of linear equations are solved with the preconditioned conjugate gradient method with the diagonal-based incomplete Cholesky preconditioner for the pressure and preconditioned biconjugate gradient method with the diagonal-based incomplete lower–upper (LU) preconditioner for other flow components (Fletcher Reference Fletcher1976; Ferziger & Perić Reference Ferziger and Perić2002).

All simulations are carried out on a collocated non-equidistant computational grid consisting of 2.9 million nodes (see table 2). The grid has a higher density of nodes near the boundaries, in order to resolve the boundary layers. Further details on the numerical method, construction of the computational grid and model verification can be found in Mandrykin & Teimurazov (Reference Mandrykin and Teimurazov2019).

2.4 Methods of data analysis

2.4.1 Nusselt number and Reynolds number

The main response characteristics of the convective system are the global heat and momentum transport represented by the dimensionless Nusselt number ![]() $Nu$ and Reynolds number

$Nu$ and Reynolds number ![]() $Re$, respectively. Within the OB approximation, the Nusselt number equals

$Re$, respectively. Within the OB approximation, the Nusselt number equals

where ![]() $\unicode[STIX]{x1D6FA}_{z}$ is a component of the heat-flux vector along the cylinder axis:

$\unicode[STIX]{x1D6FA}_{z}$ is a component of the heat-flux vector along the cylinder axis:

and ![]() $\langle \cdot \rangle _{z}$ denotes the average in time and over a cross-section at any distance

$\langle \cdot \rangle _{z}$ denotes the average in time and over a cross-section at any distance ![]() $z$ from the heated plate.

$z$ from the heated plate.

The Reynolds number can be defined in different ways and one of the common definitions is based on the total kinetic energy of the system

Here, ![]() $\langle \cdot \rangle$ denotes the averaging in time and over the entire volume. We consider also the large-scale Reynolds number

$\langle \cdot \rangle$ denotes the averaging in time and over the entire volume. We consider also the large-scale Reynolds number

where ![]() $\langle \cdot \rangle _{t}$ denotes the averaging in time and

$\langle \cdot \rangle _{t}$ denotes the averaging in time and ![]() $\langle \cdot \rangle _{V}$ the averaging over the whole convection cell. Following Teimurazov & Frick (Reference Teimurazov and Frick2017), we also evaluate the Reynolds number based on the volume-averaged velocity fluctuations, or small-scale Reynolds number, as

$\langle \cdot \rangle _{V}$ the averaging over the whole convection cell. Following Teimurazov & Frick (Reference Teimurazov and Frick2017), we also evaluate the Reynolds number based on the volume-averaged velocity fluctuations, or small-scale Reynolds number, as

Finally, one can calculate the Reynolds number based on the ‘wind of turbulence’ as follows:

where the velocity of the wind, which is parallel to the heated or cooled plates, can be estimated by

where ![]() $u_{\unicode[STIX]{x1D719}}$ and

$u_{\unicode[STIX]{x1D719}}$ and ![]() $u_{r}$ are the azimuthal and radial components of the velocity, respectively.

$u_{r}$ are the azimuthal and radial components of the velocity, respectively.

In the experiments, the Reynolds number is evaluated based on the average of the estimated axial velocities between the probes along the positions A and E. The velocities are estimated as written below in § 2.4.4.

2.4.2 Boundary-layer thicknesses

Close to the heated and cooled plates, thermal and viscous boundary layers develop. The thickness of the thermal boundary layer is calculated as

This is the standard way to define the thickness of the thermal boundary layer under the assumption of pure conductive heat transport within this layer, cf. Ahlers et al. (Reference Ahlers, Grossmann and Lohse2009).

Using the slope method (cf. Zhou & Xia Reference Zhou and Xia2010), from the ![]() $U_{w}(z)$ profile along the cylinder axis, see (2.15), the viscous boundary-layer thickness

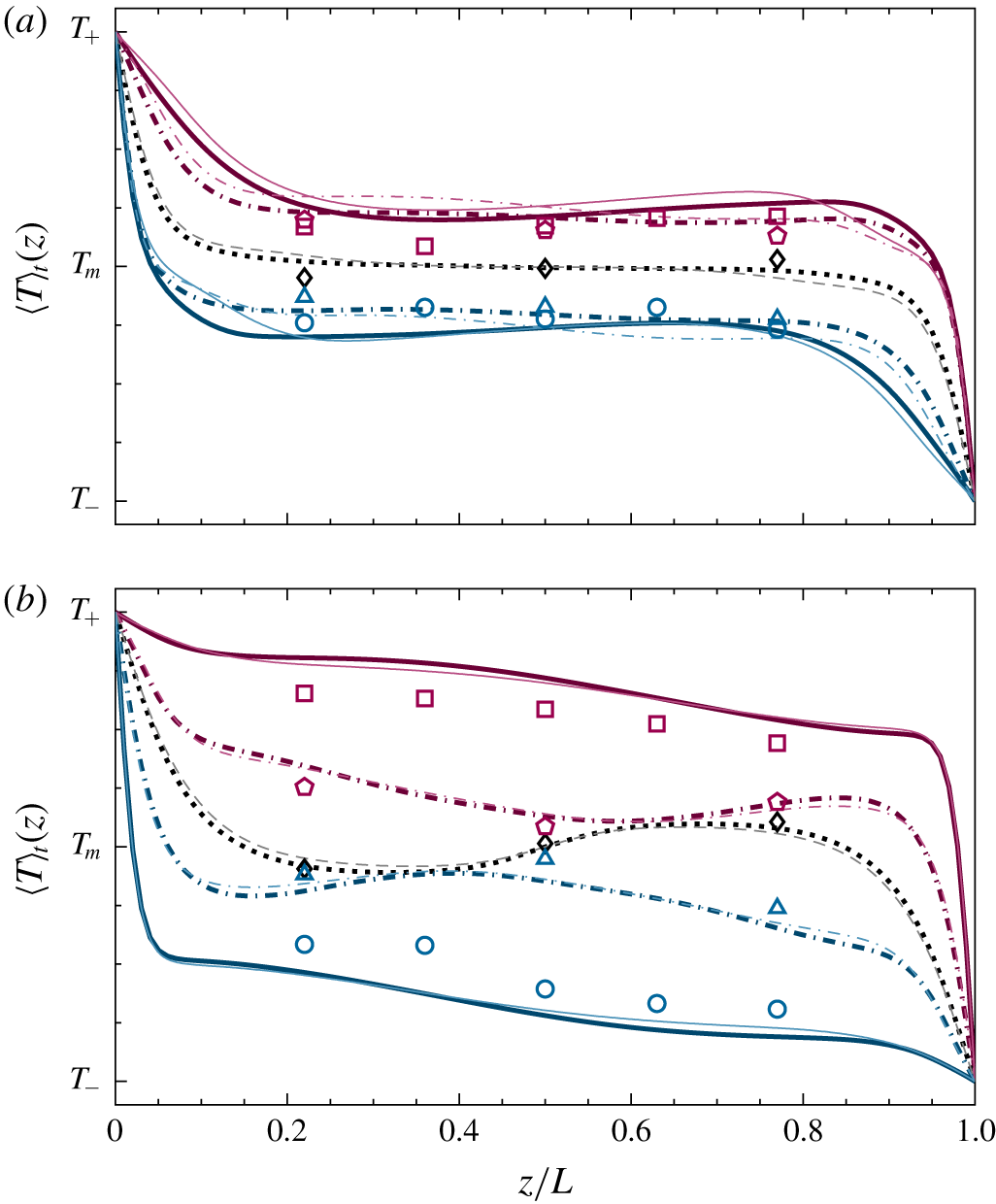

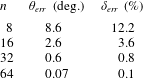

$U_{w}(z)$ profile along the cylinder axis, see (2.15), the viscous boundary-layer thickness ![]() $\unicode[STIX]{x1D6FF}_{u}$ is defined as follows: