Article contents

Additively manufactured copper matrix composites: Heterogeneous microstructures and combined strengthening effects

Published online by Cambridge University Press: 27 April 2020

Abstract

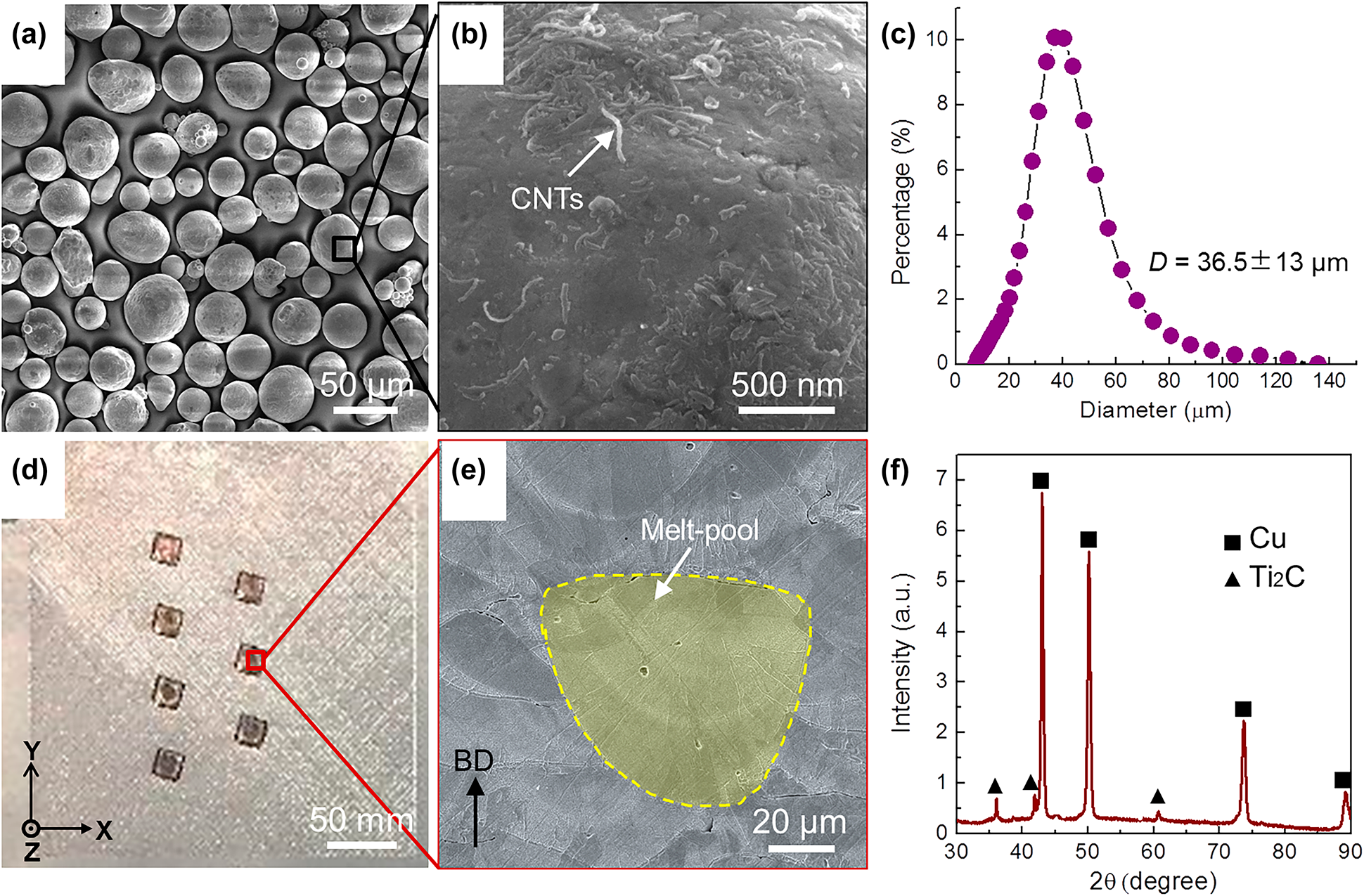

We here design and fabricate a new kind of copper matrix composites, where titanium carbide nanoparticles are in situ incorporated into and embedded within the copper matrix, by virtue of laser powder-bed-fusion (L-PBF) process. We made a multiscale examination on the microstructures of the additively manufactured samples, unraveling that there are many unusual microstructural features, including grain refinement, the existence of high-density dislocations, and supersaturation of titanium solute atoms in the as-printed metal matrix composites. These unique microstructural features are mainly interpreted by the intense thermal history and the rapid solidification nature of the L-PBF process. The resultant composites then integrate the most important four strengthening mechanisms in metals: grain boundary strengthening, dislocation strengthening, solid solution strengthening, and second-phase strengthening, rendering this new kind of copper matrix composites a remarkably high yield strength (~490 MPa) and large uniform elongation (~12%), surpassing many high-performance copper matrix composites and copper alloys.

- Type

- Article

- Information

- Journal of Materials Research , Volume 35 , Issue 15: Focus Issue: Additive Manufacturing of Metals: Complex Microstructures and Architecture Design , 14 August 2020 , pp. 1913 - 1921

- Copyright

- Copyright © Materials Research Society 2020

References

- 4

- Cited by