Article contents

Effects of alumina hollow microspheres on the properties of water-borne polyurethane films

Published online by Cambridge University Press: 06 August 2018

Abstract

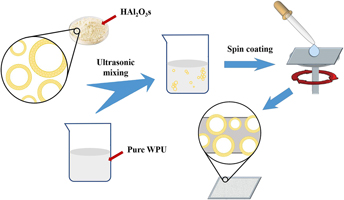

Water-based polyurethane/alumina hollow microsphere (WPU-hAl2O3) composite films were prepared via a facile spin coating method. The pristine WPU, as the matrix of the composite films, was tailor-made by hAl2O3 with the diameter of 2–5 μm to improve the mechanical and physical properties of the films. The hardness, surface morphology, infrared emissivity, wettability, and light transmittance of the WPU-hAl2O3 films with different hAl2O3 contents were investigated. The results indicate that the Vickers hardness, coefficient of friction, infrared emissivity at the wavelength of 2–22 μm, and wetting angle of the WPU-hAl2O3 films (30 wt%) increased by 53.6%, 51.7%, 21.1%, and 19.0%, respectively, compared with the pristine WPU films. Meanwhile, with the rising of hAl2O3 content, the light transmittance decreased by 75.3% at the wavelength of 400–800 nm. This work not only designs a kind of lightweight multifunctional composite film but also provides an effective route for extending further applications of hAl2O3 in the field of composite films.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 5

- Cited by