Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Lash, M. H.

Fedorchak, M. V.

McCarthy, J. J.

and

Little, S. R.

2015.

Scaling up self-assembly: bottom-up approaches to macroscopic particle organization.

Soft Matter,

Vol. 11,

Issue. 28,

p.

5597.

Chen, Yanyu

and

Wang, Lifeng

2015.

Bio-inspired heterogeneous composites for broadband vibration mitigation.

Scientific Reports,

Vol. 5,

Issue. 1,

Liu, Jialin

Huang, Zaiwang

Pan, Zhiliang

Wei, Qiuming

Li, Xiaodong

and

Qi, Yue

2017.

Atomistic Origin of Deformation Twinning in Biomineral Aragonite.

Physical Review Letters,

Vol. 118,

Issue. 10,

Zhang, Yunya

and

Li, Xiaodong

2017.

Bioinspired, Graphene/Al2O3 Doubly Reinforced Aluminum Composites with High Strength and Toughness.

Nano Letters,

Vol. 17,

Issue. 11,

p.

6907.

Cruz-Chú, Eduardo R.

Xiao, Shijun

Patil, Sandeep P.

Gkagkas, Konstantinos

and

Gräter, Frauke

2017.

Organic Filling Mitigates Flaw-Sensitivity of Nanoscale Aragonite.

ACS Biomaterials Science & Engineering,

Vol. 3,

Issue. 3,

p.

260.

Lemloh, Marie-Louise

Verch, Andreas

and

Weiss, Ingrid M.

2017.

Aqueous ball milling of nacre constituents facilitates directional self-assembly of aragonite nanoparticles of the gastropod

Haliotis glabra

.

Journal of The Royal Society Interface,

Vol. 14,

Issue. 136,

p.

20170450.

Song, Jingru

Fan, Cuncai

Ma, Hansong

Liang, Lihong

and

Wei, Yueguang

2018.

Crack deflection occurs by constrained microcracking in nacre.

Acta Mechanica Sinica,

Vol. 34,

Issue. 1,

p.

143.

Ji, H. M.

Liang, S. M.

Li, X. W.

and

Chen, D. L.

2018.

A self-assembled smart architecture against drilling predation in a Pinctada maxima shell: protective mechanisms.

Journal of Materials Science,

Vol. 53,

Issue. 5,

p.

3417.

Zhong, Fan

Thomann, Ralf

Thomann, Yi

Burk, Laura

and

Mülhaupt, Rolf

2019.

Melt-Processable Nacre-Mimetic Hydrocarbon Composites via Polymer 1D Nanostructure Formation.

Macromolecules,

Vol. 52,

Issue. 23,

p.

9272.

Zhang, Yunya

Heim, Frederick M.

Bartlett, Jamison L.

Song, Ningning

Isheim, Dieter

and

Li, Xiaodong

2019.

Bioinspired, graphene-enabled Ni composites with high strength and toughness.

Science Advances,

Vol. 5,

Issue. 5,

Wang, M

Yang, S C

and

Lu, G L

2019.

Fictional mechanism of materials with soft & hard phases.

IOP Conference Series: Materials Science and Engineering,

Vol. 504,

Issue. ,

p.

012058.

Huang, Jiacheng

Daryadel, Soheil

and

Minary-Jolandan, Majid

2019.

Low-Cost Manufacturing of Metal–Ceramic Composites through Electrodeposition of Metal into Ceramic Scaffold.

ACS Applied Materials & Interfaces,

Vol. 11,

Issue. 4,

p.

4364.

Li, Haoze

Shen, Jianghua

Wei, Qiuming

and

Li, Xiaodong

2019.

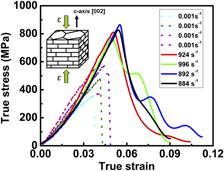

Dynamic self-strengthening of a bio-nanostructured armor — conch shell.

Materials Science and Engineering: C,

Vol. 103,

Issue. ,

p.

109820.

Wu, Kaijin

Zheng, Zhijun

Zhang, Shuaishuai

He, Linghui

Yao, Hongbin

Gong, Xinglong

and

Ni, Yong

2019.

Interfacial strength-controlled energy dissipation mechanism and optimization in impact-resistant nacreous structure.

Materials & Design,

Vol. 163,

Issue. ,

p.

107532.

Li, Haoze

and

Li, Xiaodong

2019.

The Art of Curved Reinforcing in Biological Armors — Seashells.

Journal of Bionic Engineering,

Vol. 16,

Issue. 4,

p.

711.

Alghamdi, Saleh

Du, Fen

Yang, Jie

Pinder, George

and

Tan, Ting

2020.

Tensile and shear behavior of microscale growth layers between nacre in red abalone.

Journal of the Mechanics and Physics of Solids,

Vol. 138,

Issue. ,

p.

103928.

Ji, H.M.

Liang, S.M.

Li, X.W.

and

Chen, D.L.

2020.

Kinking and cracking behavior in nacre under stepwise compressive loading.

Materials Science and Engineering: C,

Vol. 108,

Issue. ,

p.

110364.

Zhang, Binjie

Han, Qigang

Zhang, Junqiu

Han, Zhiwu

Niu, Shichao

and

Ren, Luquan

2020.

Advanced bio-inspired structural materials: Local properties determine overall performance.

Materials Today,

Vol. 41,

Issue. ,

p.

177.

Troncoso, Omar P

Torres, Fernando G

Arroyo, Junior

Gonzales, Karen N

Fernández-García, Marta

and

López, Daniel

2020.

Mechanical properties of calcite- and aragonite-based structures by nanoindentation tests.

Bioinspired, Biomimetic and Nanobiomaterials,

Vol. 9,

Issue. 2,

p.

112.

Iwase, Kenji

and

Mori, Kazuhiro

2020.

Crystal Structure, Microhardness, and Toughness of Biomineral CaCO3.

Crystal Growth & Design,

Vol. 20,

Issue. 3,

p.

2091.