Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Amini, Abbas

Cheng, Chun

Kan, Qianhua

Naebe, Minoo

and

Song, Haisheng

2013.

Phase Transformation Evolution in NiTi Shape Memory Alloy under Cyclic Nanoindentation Loadings at Dissimilar Rates.

Scientific Reports,

Vol. 3,

Issue. 1,

Pan, Guanjun

Cao, Zhenhua

Shi, Jun

Wei, Mingzhen

Xu, Lijun

and

Meng, Xiangkang

2014.

Different mechanical response of TiNi film induced by the shape of indenter during nanoindentation.

Sensors and Actuators A: Physical,

Vol. 217,

Issue. ,

p.

75.

Wu, W.-P.

Wei, Y.

and

Liu, P.

2015.

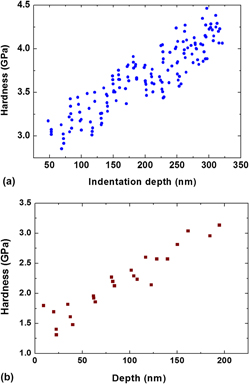

Indentation depth-dependence of the hardness of NiTi shape memory alloy and Al single crystal: phase transition versus plasticity.

Materials Research Innovations,

Vol. 19,

Issue. sup5,

p.

S5-37.

Sun, Y.

Zhao, G.

and

Yang, F.

2015.

Effect of electric current on nanoindentation of superelastic NiTi alloy.

Experimental Mechanics,

Vol. 55,

Issue. 8,

p.

1503.

Priyadarshini, B. Geetha

Aich, S.

and

Chakraborty, M.

2016.

Nano-crystalline Ni Ti alloy thin films fabricated using magnetron co-sputtering from elemental targets: Effect of substrate conditions.

Thin Solid Films,

Vol. 616,

Issue. ,

p.

733.

Dhala, Satyabrata

Mishra, Sushil

Tewari, Asim

and

Alankar, Alankar

2019.

Analyses of orientation dependent nanoindentation response of pseudoelastic NiTi alloy using a crystal plasticity model.

Mechanics of Materials,

Vol. 135,

Issue. ,

p.

1.

Goryczka, Tomasz

Zubko, Maciej

Lelątko, Józef

Salwa, Piotr

Wierzchoń, Tadeusz

Wojewoda-Budka, Joanna

and

Janusz-Skuza, Marta

2019.

Structure and Mechanical Properties of Multi-Functional Layer Deposited on Surface of Ni–Ti Shape Memory Alloy.

MATERIALS TRANSACTIONS,

Vol. 60,

Issue. 5,

p.

693.

Esmaeili, Yasaman

Bidram, Elham

Zarrabi, Ali

Amini, Abbas

and

Cheng, Chun

2020.

Graphene oxide and its derivatives as promising In-vitro bio-imaging platforms.

Scientific Reports,

Vol. 10,

Issue. 1,

VELMURUGAN, C.

and

SENTHILKUMAR, V.

2021.

EFFECTS OF PARTICLE SIZE AND SINTERING TEMPERATURE ON SUPERELASTICITY BEHAVIOR OF NiTi SHAPE MEMORY ALLOY USING NANOINDENTATION.

Surface Review and Letters,

Vol. 28,

Issue. 05,

p.

2150024.

Zhang, Mingyang

Yu, Qin

Wang, Huamiao

Zhang, Jian

Wang, Faheng

Zhang, Yining

Xu, Dake

Liu, Zengqian

Zhang, Zhefeng

and

Ritchie, Robert O.

2022.

Phase-transforming Ag-NiTi 3-D interpenetrating-phase composite with high recoverable strain, strength and electrical conductivity.

Applied Materials Today,

Vol. 29,

Issue. ,

p.

101639.

Rezaee-Hajidehi, Mohsen

Tůma, Karel

and

Stupkiewicz, Stanisław

2023.

Indentation-induced martensitic transformation in SMAs: Insights from phase-field simulations.

International Journal of Mechanical Sciences,

Vol. 245,

Issue. ,

p.

108100.

Chen, Ximing

Wang, Bing

Ying, Penghua

and

Zhang, Jin

2024.

Indentation Depth‐Dependent Hardness of Metal‐Organic Framework Crystals: The Effect of Local Amorphization Induced by Indentation.

ChemPhysChem,

Vol. 25,

Issue. 1,

Ben Fraj, Boutheina

and

Zghal, Slim

2024.

Correlation between Hardness Behavior, Shape Memory, and Superelasticity in Ni-Rich NiTi Shape Memory Alloy.

Journal of Materials Engineering and Performance,