Article contents

Palladium seeded GaAs nanowires

Published online by Cambridge University Press: 14 January 2016

Abstract

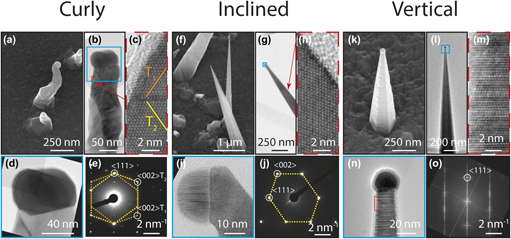

In this work, we present a detailed investigation of the growth of palladium-seeded GaAs nanowires. Nanowires grown on GaAs (111)B substrates consist of three different morphologies, denoted as curly (containing multiple kinks), inclined (relative to the substrate, such as 〈001〉), and vertical. We show that the relative yield of the different types is controllable by a combination of V/III ratio and temperature, where vertical and inclined nanowires are promoted by a high temperature and low V/III ratio. These growth conditions are expected to promote a higher Ga incorporation into the Pd particle, which is confirmed by energy dispersive x-ray analysis. We propose that the observed relationship between particle composition and nanowire morphology may be related to the particle phase, with liquid particles promoting straight nanowire growth. In addition, particles at the tips of nanowires are sometimes observed to be smaller than the initial particle size, suggesting that Pd has been lost during the growth process. Finally, we demonstrate the importance of initial particle size-control to interpret diameter changes after growth.

Keywords

- Type

- Invited Feature Paper

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 10

- Cited by