1. Introduction

Rough-wall turbulent boundary layers have been studied extensively for nearly a century (Nikuradse Reference Nikuradse1933; Colebrook & White Reference Colebrook and White1937; Kempf Reference Kempf1937; Schlichting Reference Schlichting1937), however, reliable surface drag prediction remains a challenge. The central difficulty is the boundlessly varying surface morphologies which exist in nature and engineering applications. Though arduous, advancements in fluid dynamic experiments and modelling have steadily provided increased understanding and continue to further engineering capabilities (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021).

Initially the focus of study was drag prediction in pipe flows, but in the 1950s attention turned toward turbulent boundary layers and the search for universal scaling laws, allowing the collapse of a streamwise mean velocity profile onto a single function. That universal function has become known as the law of the wall. After over 50 years of rough-wall boundary layer research, Castro (Reference Castro2007) noted remarkable universality in the ability of the law of the wall to describe the turbulent boundary layer velocity profile across a wide range of rough surfaces. There are two immediate consequences of turbulent boundary layer universality. First, how can it be utilized to build practical engineering models? Second, what are the limits of universality? Both of these questions have been explored in recent years.

For the first question, turbulent boundary layer universality has given hope for the possibility of robust topographic drag prediction models. However, the essential element is understanding how rough surface topography affects roughness length, ![]() $y_0$, or the roughness function,

$y_0$, or the roughness function, ![]() $\Delta U^+$, or also sandgrain roughness,

$\Delta U^+$, or also sandgrain roughness, ![]() $k_s$, which are all measures of rough surface drag. Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) provides a recent review of studies contributing to this ongoing effort. Most studies have postulated or examined drag prediction algorithms successfully within a small parameter space, however, Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) highlights that further datasets are required for wider applicability and reduced uncertainty. Specifically, they note the need for an aggregation of systematic studies that sweep through the parameter space or test its limits (http://roughnessdatabase.org/).

$k_s$, which are all measures of rough surface drag. Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) provides a recent review of studies contributing to this ongoing effort. Most studies have postulated or examined drag prediction algorithms successfully within a small parameter space, however, Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) highlights that further datasets are required for wider applicability and reduced uncertainty. Specifically, they note the need for an aggregation of systematic studies that sweep through the parameter space or test its limits (http://roughnessdatabase.org/).

For the second question, these drag prediction models, as well as many reduced-order wall-bounded numerical models, implicitly rely on a level of turbulent boundary layer universality. Therefore, knowing the limits of the equation's applicability is vital for high reliability engineering applications. One important theory of turbulent boundary layer universality is Townsend's wall similarity hypothesis. It states that high Reynolds number, fully rough boundary layer turbulence outside of a small roughness layer is independent of the specific surface morphology and statistically similar when appropriately scaled (1976). This hypothesis implies what is known as outer-layer similarity (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991). Numerous studies have investigated this hypothesis and found significant supporting evidence (Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Schultz & Flack Reference Schultz and Flack2005; Volino, Schultz & Flack Reference Volino, Schultz and Flack2007; Flack & Schultz Reference Flack and Schultz2014), however, other studies have reported roughness effects well into the outer layer (Krogstad, Antonia & Browne Reference Krogstad, Antonia and Browne1992; Krogstad & Antonia Reference Krogstad and Antonia1999; Volino, Schultz & Flack Reference Volino, Schultz and Flack2011; Hong et al. Reference Hong, Katz, Meneveau and Schultz2012; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2018).

These studies give evidence that, at least under certain circumstances, Townsend's hypothesis does not hold. While researchers are actively working to identify universal criteria for which Townsend's hypothesis holds (Jiménez Reference Jiménez2004; Schultz & Flack Reference Schultz and Flack2005; Flack, Schultz & Shapiro Reference Flack, Schultz and Shapiro2005; Wu & Christensen Reference Wu and Christensen2007; Amir & Castro Reference Amir and Castro2011; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2018), the lack of well-established criteria highlights a lack of understanding of the physics linking surface characteristics to boundary layer statistics. This link is of fundamental scientific and engineering importance due to the prevalence of rough-wall boundary layers and may inform the construction and limits of future drag prediction models.

Very few studies have investigated the effect of regularly vs irregularly arranged roughness elements on the turbulent boundary layer. Researchers have generally focused on regular arrangements because it is easier to isolate important surface statistics or easier to manufacture such surfaces. However, it is not clear if the conclusions drawn from these studies are applicable to flow over random roughness, and irregular or random arrangements are very common in both engineering and nature. Mountainous and hilly topography in the atmospheric boundary layer and barnacles in a ship hull boundary layer are both roughness types that do not appear in the regular arrangements typically investigated. Wind farm inflow often develops over irregular terrain (Stevens & Meneveau Reference Stevens and Meneveau2017) and turbine arrangements often require irregularity due to topography or land use restrictions (Shapiro et al. Reference Shapiro, Starke, Meneveau and Gayme2019; Starke et al. Reference Starke, Meneveau, King and Gayme2021). Even engineered systems contain irregularities. The damaged turbine blade in Bons (Reference Bons2002) has been studied extensively (Wu & Christensen Reference Wu and Christensen2007, Reference Wu and Christensen2010; Mejia-Alvarez & Christensen Reference Mejia-Alvarez and Christensen2010, Reference Mejia-Alvarez and Christensen2013; Barros & Christensen Reference Barros and Christensen2014; Pathikonda & Christensen Reference Pathikonda and Christensen2017) but with little roughness parametric variation except Mejia-Alvarez & Christensen (Reference Mejia-Alvarez and Christensen2010). Research is just beginning to address these limitations. Forooghi et al. (Reference Forooghi, Stroh, Schlatter and Frohnapfel2018) recently conducted a direct numerical simulation (DNS) parametric study with randomly distributed roughness elements but was limited to low Reynolds number due to computational costs. Experimental data at higher Reynolds number are insufficient, and lack of data remains a current limitation in the understanding of rough-wall turbulent boundary layer behaviour.

In recent years, quite a few studies have focused on secondary flows as a way in which turbulent boundary layer universality breaks down. Secondary flows are mean flow features which manifest in the wall-normal spanwise plane (perpendicular to the dominant streamwise flow direction) and have long been studied in non-circular ducts (Nikuradse Reference Nikuradse1930; Hoagland Reference Hoagland1962; Hinze Reference Hinze1967, Reference Hinze1973). Secondary flows were perhaps first noted as a universality concern in rough-wall turbulent boundary layer wind tunnel experiments by Reynolds et al. (Reference Reynolds, Hayden, Castro and Robins2007), who observed spanwise-periodic velocity and turbulence intensity variations in measurements recorded at similar wall-normal distances over staggered cube surfaces. Further inspection revealed that the periodic variation was caused by secondary flow, counter-rotating vortical structures that seemed to correlate with periodic features on the rough surface below. These observations were used to caution about experimental studies with periodic surface features (Reynolds et al. Reference Reynolds, Hayden, Castro and Robins2007). Studies which were to have widely applicable results should try to avoid the presence of such seemingly atypical flow features.

Mostly, it was implicitly assumed that an irregular or random surface would not generate or sustain secondary flows. However, Mejia-Alvarez & Christensen (Reference Mejia-Alvarez and Christensen2013) observed what they described as high-momentum pathways (HMPs) and low-momentum pathways (LMPs) over a multi-scale irregular surface generated from a scaled replica of a damaged turbine blade. They believed that the surface roughness promoted preferential pathways for flow structures that were detectable in the mean flow statistics. Later, Barros & Christensen (Reference Barros and Christensen2014) used extensive stereoscopic (stereo) particle image velocimetry (PIV) data to generate plots of the mean structures in the wall-normal spanwise plane. They observed HMPs and LMPs in the mean streamwise velocity, reduced and enhanced Reynolds shear stress and turbulent kinetic energy in the HMPs and LMPs, respectively, and counter-rotating vortical structures in the signed swirl strength. Barros & Christensen further correlated these mean flow structures with relatively high and low upstream topography in the upstream fetch from the measurement plane. The Barros & Christensen (Reference Barros and Christensen2014) study prompted some important questions for rough-wall turbulence.

Anderson et al. (Reference Anderson, Barros, Christensen and Awasthi2015) provided a possible explanation of the fundamental fluid dynamic mechanisms responsible for generating and sustaining secondary flows within the turbulent boundary layer. In doing so, they were able to draw on the long history of research into non-circular duct secondary flows (Hinze Reference Hinze1967, Reference Hinze1973). Anderson et al. (Reference Anderson, Barros, Christensen and Awasthi2015) used the Reynolds-averaged turbulent kinetic energy balance equation to show that differences in the roughness across the span create spanwise regions that produce more and less turbulent kinetic energy. Their simulations show that HMP and LMP sustainment occurs when the spanwise heterogeneous wall roughness below is streamwise aligned.

Many other researchers have provided some answers to the question of what surface roughness conditions cause secondary flows to form (Willingham et al. Reference Willingham, Anderson, Christensen and Barros2014; Anderson et al. Reference Anderson, Barros, Christensen and Awasthi2015; Vanderwel & Ganapathisubramani Reference Vanderwel and Ganapathisubramani2015; Medjnoun, Vanderwel & Ganapathisubramani Reference Medjnoun, Vanderwel and Ganapathisubramani2018; Yang & Anderson Reference Yang and Anderson2018; Wangsawijaya et al. Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020). They have primarily looked at spanwise heterogeneity either in the form of elevated or recessed streamwise-aligned terrain or streamwise-aligned strips of alternating higher and lower drag-producing roughness. Parametric studies have probed the limits of the parameter space and found that, in general, turbulent boundary layer secondary flows occur when spanwise heterogeneous feature spacing is between approximately ![]() $\delta /2$ and

$\delta /2$ and ![]() $2\delta$, where

$2\delta$, where ![]() $\delta$ is the boundary layer thickness. When spanwise spacing is smaller, the features act as homogeneous roughness with effects confined to the roughness sublayer; and when spanwise spacing is larger, the features act as isolated flow perturbations (Vanderwel & Ganapathisubramani Reference Vanderwel and Ganapathisubramani2015; Yang & Anderson Reference Yang and Anderson2018; Wangsawijaya et al. Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021).

$\delta$ is the boundary layer thickness. When spanwise spacing is smaller, the features act as homogeneous roughness with effects confined to the roughness sublayer; and when spanwise spacing is larger, the features act as isolated flow perturbations (Vanderwel & Ganapathisubramani Reference Vanderwel and Ganapathisubramani2015; Yang & Anderson Reference Yang and Anderson2018; Wangsawijaya et al. Reference Wangsawijaya, Baidya, Chung, Marusic and Hutchins2020; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021).

The aim of this study is to examine the turbulent boundary layer over varying planform densities of regularly arranged (staggered) and randomly arranged roughness elements, with particular focus on outer similarity and the occurrence and properties of secondary flow structures. Eight planform densities of truncated cone roughness elements in a square staggered pattern were investigated and varied between 10 % and 78 % density. The same planform densities were also investigated with random arrangements of truncated cones. The effect of increasing density on the turbulent boundary layer is determined for both regular and irregular morphologies. No additional spanwise heterogeneity was imposed but is locally present within the random distribution of truncated cones.

Section 2 describes the experimental facility, roughness morphology and flow measuring equipment utilized. Section 3 reports spatially averaged results for both the staggered and random test series at all densities, and differences in turbulent boundary layer parameters are highlighted and examined. Section 4 presents measurements of HMPs and LMPs observed over the irregular arrangements of truncated cones that were not present over the regular staggered arrangements. HMP and LMP correlations with roughness topography are explored, and generation and sustainment mechanisms are discussed. In addition, HMP and LMP turbulent boundary layer parameters and statistics not previously reported in the literature are described. Conclusions are presented in § 5.

2. Experimental details

The experimental approach utilizes a boundary layer water tunnel (§ 2.1) and sixteen test surfaces of staggered and randomly arranged truncated cones (§ 2.2), while measurements are carried out with a laser Doppler velocimetry system described in § 2.3 and a stereo PIV system described in § 2.4.

2.1. Facility

Experiments were conducted at the Hydromechanics Laboratory at the United States Naval Academy in a recirculating boundary layer water tunnel. The test section is nominally 2.00 m long with a 0.20 m wide by 0.10 m tall cross-section at the inlet. The upper wall was adjusted to set a zero pressure gradient, and the resulting acceleration parameter, ![]() $K=(\nu /U_e^2)[\textrm {d}U_e/{\textrm {d} x}]$, where

$K=(\nu /U_e^2)[\textrm {d}U_e/{\textrm {d} x}]$, where ![]() $\nu$ is the kinematic viscosity, was less than

$\nu$ is the kinematic viscosity, was less than ![]() $5 \times 10^{-9}$ throughout the length of the test section for each test. All tests were conducted at a free-stream velocity of

$5 \times 10^{-9}$ throughout the length of the test section for each test. All tests were conducted at a free-stream velocity of ![]() $U_e = 1.25 \ \text {m}\ \text {s}^{-1}$. In this study, (

$U_e = 1.25 \ \text {m}\ \text {s}^{-1}$. In this study, (![]() $x, y, z$) were the streamwise, wall-normal and spanwise directions, respectively;

$x, y, z$) were the streamwise, wall-normal and spanwise directions, respectively; ![]() $y=0$ was located on the lower surface to which the roughness elements were attached, and

$y=0$ was located on the lower surface to which the roughness elements were attached, and ![]() $z=0$ was located at the centre of the spanwise cross-section. Test surfaces were mounted on the lower wall of the tunnel. A 0.8 mm diameter wire trip was located 0.20 m from the tunnel inlet and served as the streamwise origin,

$z=0$ was located at the centre of the spanwise cross-section. Test surfaces were mounted on the lower wall of the tunnel. A 0.8 mm diameter wire trip was located 0.20 m from the tunnel inlet and served as the streamwise origin, ![]() $x=0$. The roughness field began at

$x=0$. The roughness field began at ![]() $x_r=0.78\ \text {m}$ from the boundary layer trip, and velocity measurements were recorded at

$x_r=0.78\ \text {m}$ from the boundary layer trip, and velocity measurements were recorded at ![]() $x_0=1.50\ \text {m}$ from the trip which was approximately

$x_0=1.50\ \text {m}$ from the trip which was approximately ![]() $18\delta$ from the start of the roughness. A heat pump system controlled fluid temperature to

$18\delta$ from the start of the roughness. A heat pump system controlled fluid temperature to ![]() $20 \pm 1^{\circ }\text {C}$ during tests, which in some cases lasted over 50 h.

$20 \pm 1^{\circ }\text {C}$ during tests, which in some cases lasted over 50 h.

2.2. Roughness morphology

Sixteen test surfaces were constructed using high resolution additive manufacturing with a Stratasys Objet30 Pro 3D printer. The printer had a lateral resolution of ![]() $34\ \mathrm {\mu }\text {m}$ and elevation resolution of

$34\ \mathrm {\mu }\text {m}$ and elevation resolution of ![]() $16\ \mathrm {\mu }\text {m}$, which was reported in Flack, Schultz & Barros (Reference Flack, Schultz and Barros2020) from optical profilometer measurements. Since a single test surface exceeds the maximum printable dimensions, each test surface was split into three unique plates for production. Additionally, the subdivided test surfaces were designed with mating features so that there was no discontinuity in the intended topography.

$16\ \mathrm {\mu }\text {m}$, which was reported in Flack, Schultz & Barros (Reference Flack, Schultz and Barros2020) from optical profilometer measurements. Since a single test surface exceeds the maximum printable dimensions, each test surface was split into three unique plates for production. Additionally, the subdivided test surfaces were designed with mating features so that there was no discontinuity in the intended topography.

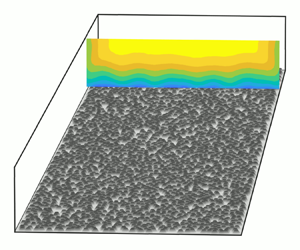

Examples of all sixteen surfaces with their designated names are shown in figure 1. Eight cases had varying planform densities of truncated cone elements in a square staggered pattern (figure 1a–h). In the most dense case, the truncated cone elements were touching but not overlapping at the base. The same eight planform densities were manufactured with random arrangements of the truncated cone elements with no repeating unit over the entire randomized test surface (figure 1i–p). In the random cases, the elements were allowed to overlap, but a minimum of 0.5 mm was maintained between the elements’ upper plateaus. Cases were named with an S for staggered or R for random and then two digit percentage for the planform density.

Figure 1. Test surfaces.

Selected surface statistics for all sixteen test cases are documented in table 1. Variable ![]() $h(x,z)$ is the local surface height. The table provides values for planform density (

$h(x,z)$ is the local surface height. The table provides values for planform density (![]() $\lambda _p$), frontal density (

$\lambda _p$), frontal density (![]() $\lambda _f$), effective slope, mean height

$\lambda _f$), effective slope, mean height ![]() $\left \langle h \right \rangle$, height standard deviation (

$\left \langle h \right \rangle$, height standard deviation (![]() $\sigma _h$), height skewness (

$\sigma _h$), height skewness (![]() $s_k$) and height flatness.

$s_k$) and height flatness.

Table 1. Test surface statistics.

Figure 2 illustrates the calculation of planform and frontal density. Planform density is best illustrated in the figure 2(a,c) top views. Planform density, λp, is calculated from the sum of all truncated cone faces (red, green and blue) projected on the base plane, ![]() $A_p$, then divided by the base lot area,

$A_p$, then divided by the base lot area, ![]() $A_0$, so that

$A_0$, so that ![]() $\lambda _p=A_p/A_0$. Frontal density,

$\lambda _p=A_p/A_0$. Frontal density, ![]() $\lambda_f$, is calculated by the sum of all upstream facing surfaces (red and green) projected on a plane normal to the streamwise direction,

$\lambda_f$, is calculated by the sum of all upstream facing surfaces (red and green) projected on a plane normal to the streamwise direction, ![]() $A_f$, then divided by the base lot area,

$A_f$, then divided by the base lot area, ![]() $A_0$, so that

$A_0$, so that ![]() $\lambda _f=A_f/A_0$. There are no differences between the red and green surfaces, the green surfaces were simply chosen to illustrate the area projection. Selected truncated cone upstream facing surfaces in green illustrate the projection on the plane normal to flow in the figure 2(b,d) isometric views. All upstream facing surfaces, regardless of whether they may be sheltered by the wake of upstream elements, are included in the frontal density calculation. As seen in figure 2(d) for random plates, truncated cones were allowed to overlap on the base lot area. This causes a solid surface occlusion of the front face of the downstream overlapping truncated cone. The occluded area is not included in the frontal density calculation as seen in the projection.

$\lambda _f=A_f/A_0$. There are no differences between the red and green surfaces, the green surfaces were simply chosen to illustrate the area projection. Selected truncated cone upstream facing surfaces in green illustrate the projection on the plane normal to flow in the figure 2(b,d) isometric views. All upstream facing surfaces, regardless of whether they may be sheltered by the wake of upstream elements, are included in the frontal density calculation. As seen in figure 2(d) for random plates, truncated cones were allowed to overlap on the base lot area. This causes a solid surface occlusion of the front face of the downstream overlapping truncated cone. The occluded area is not included in the frontal density calculation as seen in the projection.

Figure 2. Figures illustrate the planform and frontal density calculations in (a) a staggered surface top view, (b) a staggered surface isometric view, (c) a random surface top view and (d) a random surface isometric view. Black arrows indicate the streamwise direction. Red and green highlight upstream facing surfaces that are all included in the frontal area calculation. The green surfaces were selected to illustrate the frontal area projection, ![]() $A_f$, and have corresponding green projections that illustrate

$A_f$, and have corresponding green projections that illustrate ![]() $A_f$. The blue highlights wall-parallel and downstream faces that are included in the planform area,

$A_f$. The blue highlights wall-parallel and downstream faces that are included in the planform area, ![]() $A_p$, but not the frontal area,

$A_p$, but not the frontal area, ![]() $A_f$. The staggered repeating unit area,

$A_f$. The staggered repeating unit area, ![]() $A_0$, is shown in figure 4.

$A_0$, is shown in figure 4.

All truncated cone elements were identical, with the geometry documented in figure 3. Truncated cone dimensions were selected to idealize a single barnacle. Understanding boundary layers over barnacle roughness is important for informing drag prediction models and understanding ship propulsion requirements. However, these truncated cone elements may also be a proxy for low mountainous terrain in the atmospheric boundary layer. Specific truncated cone ratios were selected based on detailed barnacle statistics from Spivey (Reference Spivey1988). The ratio of height to base diameter is lower than the average reported by Spivey (Reference Spivey1988) but still falls within the standard deviation. Also, experimental and computational fluid dynamic studies which focused on barnacle elements were reported by Schultz, Kavanagh & Swain (Reference Schultz, Kavanagh and Swain1999) and Sadique (Reference Sadique2016). These studies measured barnacles with an average of ![]() $k=0.49D$ and

$k=0.49D$ and ![]() $k=0.37D$ respectively, where

$k=0.37D$ respectively, where ![]() $D$ is the base diameter and

$D$ is the base diameter and ![]() $k=\max (h)$ is the uniform height of the roughness crests. The ratio studied here falls between these two values.

$k=\max (h)$ is the uniform height of the roughness crests. The ratio studied here falls between these two values.

Figure 3. Truncated cone dimensions.

2.3. Laser Doppler velocimetry measurements

Detailed boundary layer velocity statistics were recorded with a TSI FSA3500 two-component laser Doppler velocimetry (LDV) system measuring streamwise and wall-normal velocity. A custom beam displacer and beam expander produce ellipsoidal measurement volumes that have a beam waist of ![]() $45 \ \mathrm {\mu } \text {m}$. The flow was seeded with

$45 \ \mathrm {\mu } \text {m}$. The flow was seeded with ![]() $2 \ \mathrm {\mu } \text {m}$ diameter silver coated glass spheres. For the square staggered cases, wall-normal profiles were recorded at nine locations over a repeating unit as seen in figure 4. Each of the nine staggered-case profiles contained 50 sampling locations in the wall-normal direction where velocity data were recorded for 180 s. The nine locations were representative of the entire repeating unit by utilizing mirroring and translation. Mirroring is the assumption that streamwise and wall-normal velocity component statistics on the left side of an upstream element are similar to those on the right side of the element. Translation is the assumption that velocity statistics from one profile are similar to another within the repeating unit that has the same relative position to a nearby elements (e.g. all profiles in the repeating unit centred over an element are similar). Then, an area weighting was used to create a spatial-averaged profile for all time-averaged statistics.

$2 \ \mathrm {\mu } \text {m}$ diameter silver coated glass spheres. For the square staggered cases, wall-normal profiles were recorded at nine locations over a repeating unit as seen in figure 4. Each of the nine staggered-case profiles contained 50 sampling locations in the wall-normal direction where velocity data were recorded for 180 s. The nine locations were representative of the entire repeating unit by utilizing mirroring and translation. Mirroring is the assumption that streamwise and wall-normal velocity component statistics on the left side of an upstream element are similar to those on the right side of the element. Translation is the assumption that velocity statistics from one profile are similar to another within the repeating unit that has the same relative position to a nearby elements (e.g. all profiles in the repeating unit centred over an element are similar). Then, an area weighting was used to create a spatial-averaged profile for all time-averaged statistics.

Figure 4. LDV profile locations over the staggered surface repeating unit. Red dots indicate LDV profile locations. The black box indicates the repeating unit. Flow is from left to right.

For the random cases, 12 wall-normal profiles were recorded and spaced at ![]() $1.5D$ across the span of the tunnel. The red profiles in figure 5 show these 12 locations. The spacing and number of profiles allowed independent profiles and well-converged spatial averages across the span. Additional wall-normal profiles were performed for the R17 and R39 cases with 23 profiles spaced at

$1.5D$ across the span of the tunnel. The red profiles in figure 5 show these 12 locations. The spacing and number of profiles allowed independent profiles and well-converged spatial averages across the span. Additional wall-normal profiles were performed for the R17 and R39 cases with 23 profiles spaced at ![]() $0.75D$ since these cases appeared less well converged when using 12 profiles. The additional 11 profiles for these test cases are depicted in blue on figure 5. Each of the 12 or 23 random-case profiles contained 50 sampling locations in the wall-normal direction where velocity data were recorded for 150 s. The field of view was

$0.75D$ since these cases appeared less well converged when using 12 profiles. The additional 11 profiles for these test cases are depicted in blue on figure 5. Each of the 12 or 23 random-case profiles contained 50 sampling locations in the wall-normal direction where velocity data were recorded for 150 s. The field of view was ![]() $115 \ \text {mm} \times 52 \ \text {mm}$ in the spanwise and wall-normal directions, respectively. All time-average statistics were calculated using a virtual saturable-detector scheme with

$115 \ \text {mm} \times 52 \ \text {mm}$ in the spanwise and wall-normal directions, respectively. All time-average statistics were calculated using a virtual saturable-detector scheme with ![]() $5\ \text {ms}$ saturation. Due to the amount of data sampled, all of these tests were over 24 h in duration.

$5\ \text {ms}$ saturation. Due to the amount of data sampled, all of these tests were over 24 h in duration.

Figure 5. LDV profile locations over the random surfaces. Red profiles were recorded on all random surfaces. Blue profiles were also recorded over the R17 and R39 surfaces. Flow is from bottom left to top right.

2.4. Stereoscopic PIV measurements

In order to investigate mean flow structures, stereoscopic PIV measurements were employed in the wall-normal spanwise (![]() $y, z$) plane at

$y, z$) plane at ![]() $x=1.55\ \text {m}$ downstream of the trip, which approximately matches the downstream location used in the LDV measurements. Measurements were recorded over the least dense and most dense cases for both staggered and random surfaces (S10, S78, R10, R78).

$x=1.55\ \text {m}$ downstream of the trip, which approximately matches the downstream location used in the LDV measurements. Measurements were recorded over the least dense and most dense cases for both staggered and random surfaces (S10, S78, R10, R78).

For each surface, a wall-normal spanwise plane was acquired at the spanwise centre of the test section. The flow was seeded with the same particles used in the LDV measurements. For each plane, 1000 image pairs were acquired using two CCD cameras with ![]() $3320 \times 2496$ pixel arrays. The acquisition frequency was low (approximately

$3320 \times 2496$ pixel arrays. The acquisition frequency was low (approximately ![]() $3\ \text {Hz}$), so the image pairs were statistically independent. The time interval between images in each pair was

$3\ \text {Hz}$), so the image pairs were statistically independent. The time interval between images in each pair was ![]() $200 \ \mathrm {\mu } \text {s}$, which at the free-stream velocity corresponds to a

$200 \ \mathrm {\mu } \text {s}$, which at the free-stream velocity corresponds to a ![]() $0.25 \ \text {mm}$ displacement in the streamwise direction. Velocity vectors were obtained with TSI Insight 4G software using 32 pixel square windows with 50 % overlap. The field of view was

$0.25 \ \text {mm}$ displacement in the streamwise direction. Velocity vectors were obtained with TSI Insight 4G software using 32 pixel square windows with 50 % overlap. The field of view was ![]() $81 \ \text {mm} \times 40 \ \text {mm}$ in the spanwise and wall-normal directions, respectively. The spatial resolution of the PIV velocity vectors was 0.4 mm, which compares with the

$81 \ \text {mm} \times 40 \ \text {mm}$ in the spanwise and wall-normal directions, respectively. The spatial resolution of the PIV velocity vectors was 0.4 mm, which compares with the ![]() $300\ \mathrm {\mu }\text {m}$ length of the LDV probe volume.

$300\ \mathrm {\mu }\text {m}$ length of the LDV probe volume.

3. Spatial-averaged results

This section presents spatial-averaged results for all staggered and random truncated cone surfaces. Spatial averaging is computed over the basic repeating tile for the staggered cases and in the spanwise direction for the random cases. Friction velocity, roughness length and zero-plane displacement are determined as functions of the planform density parameter space and trends are discussed. Two existing a priori drag prediction models are evaluated against the results. The section concludes by highlighting differences between turbulent boundary layer profiles and parameters between the staggered and random surfaces which indicated a breakdown in outer-layer similarity.

3.1. Spatial-averaged boundary layer profile results

Spatial-averaged experimental boundary layer profiles were analysed with the comprehensive shear stress (CSS) method described in Womack, Meneveau & Schultz (Reference Womack, Meneveau and Schultz2019). The CSS method calculates several important turbulent boundary layer parameters appearing in the log-law equation. The log-law equation with the wake function is

In this equation, ![]() $U$ is the mean streamwise velocity. The velocity scaling parameter is the friction velocity,

$U$ is the mean streamwise velocity. The velocity scaling parameter is the friction velocity, ![]() $u_\tau$, and the

$u_\tau$, and the ![]() $+$ superscript indicates normalization by

$+$ superscript indicates normalization by ![]() $u_\tau$;

$u_\tau$; ![]() $\kappa =0.384$ is the Kármán constant used throughout this study with corresponding smooth-wall intercept,

$\kappa =0.384$ is the Kármán constant used throughout this study with corresponding smooth-wall intercept, ![]() $A=4.17$ (Chauhan, Nagib & Monkewitz Reference Chauhan, Nagib and Monkewitz2007). Zero-plane displacement,

$A=4.17$ (Chauhan, Nagib & Monkewitz Reference Chauhan, Nagib and Monkewitz2007). Zero-plane displacement, ![]() $d$, is a shift in the effective origin of the log law due to roughness;

$d$, is a shift in the effective origin of the log law due to roughness; ![]() $y_0$ is known as the roughness length and is related to the roughness function by

$y_0$ is known as the roughness length and is related to the roughness function by ![]() $\Delta U^+ = A + (1/\kappa ) \ln { ( y_0 u_\tau /\nu )}$ or to the equivalent sandgrain roughness by

$\Delta U^+ = A + (1/\kappa ) \ln { ( y_0 u_\tau /\nu )}$ or to the equivalent sandgrain roughness by ![]() $k_s = y_0 \textrm {e}^{8.5 \kappa }$ (Jiménez Reference Jiménez2004; Castro Reference Castro2007; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). Friction velocity (

$k_s = y_0 \textrm {e}^{8.5 \kappa }$ (Jiménez Reference Jiménez2004; Castro Reference Castro2007; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). Friction velocity (![]() $u_\tau$), wall shear stress (

$u_\tau$), wall shear stress (![]() $\tau _w$) and skin friction (

$\tau _w$) and skin friction (![]() $c_f$), will all be used interchangeably based on application and are related by definition

$c_f$), will all be used interchangeably based on application and are related by definition ![]() $u_\tau \equiv \sqrt {\tau _w/\rho } \equiv U_e \sqrt {c_f/2}$, where

$u_\tau \equiv \sqrt {\tau _w/\rho } \equiv U_e \sqrt {c_f/2}$, where ![]() $U_e$ is the free-stream velocity and

$U_e$ is the free-stream velocity and ![]() $\rho$ is the fluid density. The wake function,

$\rho$ is the fluid density. The wake function, ![]() $W(y/\delta )$, models the outer-region deviation from the log law and scales with the boundary layer thickness. This study will use the most common definition of the boundary layer thickness,

$W(y/\delta )$, models the outer-region deviation from the log law and scales with the boundary layer thickness. This study will use the most common definition of the boundary layer thickness, ![]() $\delta$, namely the wall-normal distance where velocity reaches 99 % of the free-stream velocity (so that

$\delta$, namely the wall-normal distance where velocity reaches 99 % of the free-stream velocity (so that ![]() $U(\delta ) =0.99U_e$). The wake strength parameter,

$U(\delta ) =0.99U_e$). The wake strength parameter, ![]() $\varPi$, measures the strength of the deviation by

$\varPi$, measures the strength of the deviation by ![]() $\varPi = ({\kappa }/{2}) \max [ U^+ ( y ) - ({1}/{\kappa }) \ln ( y/y_0 ) ]$.

$\varPi = ({\kappa }/{2}) \max [ U^+ ( y ) - ({1}/{\kappa }) \ln ( y/y_0 ) ]$.

The extended Volino & Schultz equation is a reformulated total shear stress balance and was fit in the range of ![]() $0.15 < (y-d)/(\delta -d) < 0.30$ to determine

$0.15 < (y-d)/(\delta -d) < 0.30$ to determine ![]() $u_\tau$, and the log-law equation was fit in the range of

$u_\tau$, and the log-law equation was fit in the range of ![]() $0.07 < y/\delta < 0.15$ to determine

$0.07 < y/\delta < 0.15$ to determine ![]() $y_0$ and

$y_0$ and ![]() $d$ in each iteration (Volino & Schultz Reference Volino and Schultz2018; Womack et al. Reference Womack, Meneveau and Schultz2019). An iterative solution process is required since both equations have dependencies in all three variables. The convergence criteria for each profile were three significant digits in

$d$ in each iteration (Volino & Schultz Reference Volino and Schultz2018; Womack et al. Reference Womack, Meneveau and Schultz2019). An iterative solution process is required since both equations have dependencies in all three variables. The convergence criteria for each profile were three significant digits in ![]() $u_\tau$,

$u_\tau$, ![]() $y_0$ and

$y_0$ and ![]() $d$ or 10 iterations. Table 2 contains results from the CSS method as well as other relevant profile parameters for each surface's average profile. Displacement thickness,

$d$ or 10 iterations. Table 2 contains results from the CSS method as well as other relevant profile parameters for each surface's average profile. Displacement thickness, ![]() $\delta ^*$, and momentum thickness,

$\delta ^*$, and momentum thickness, ![]() $\theta$, were calculated assuming an extrapolation of the log law between

$\theta$, were calculated assuming an extrapolation of the log law between ![]() $y=y_0+d$ and the nearest measurement point to the wall (Castro Reference Castro2007). Also, relative roughness height,

$y=y_0+d$ and the nearest measurement point to the wall (Castro Reference Castro2007). Also, relative roughness height, ![]() $k/\delta$ is reported and shows that the relative roughness height is between

$k/\delta$ is reported and shows that the relative roughness height is between ![]() $0.08 < k/\delta < 0.10$ in all cases. Finally, friction Reynolds number,

$0.08 < k/\delta < 0.10$ in all cases. Finally, friction Reynolds number, ![]() ${\textit {Re}}_\tau \equiv \delta ^+ \equiv u_\tau \delta / \nu$ is reported for each case.

${\textit {Re}}_\tau \equiv \delta ^+ \equiv u_\tau \delta / \nu$ is reported for each case.

Table 2. Experimental profile parameters for spatial-averaged LDV measurements.

The friction velocity is one of the most important parameters to determine. The CSS method determines friction velocity indirectly, so it is prudent to check results against expectations. Figure 6 shows the spatial-averaged LDV results for skin friction plotted against the skin-friction law first derived by Clauser (Reference Clauser1954) and Rotta (Reference Rotta1962) from the log-law equation. The skin-friction law can be written, as in Castro (Reference Castro2007), as

\begin{equation} \sqrt{\frac{2}{c_f}}={-}\frac{1}{\kappa}\ln{\left ( \frac{1}{H}\sqrt{\frac{c_f}{2}} \right )}+\frac{1}{\kappa}\ln{\left ( \frac{\theta}{y_0} \right )} + \frac{2\varPi}{\kappa} - \frac{1}{\kappa}\ln{ \left( \frac{1+\varPi}{\kappa} \right)}, \end{equation}

\begin{equation} \sqrt{\frac{2}{c_f}}={-}\frac{1}{\kappa}\ln{\left ( \frac{1}{H}\sqrt{\frac{c_f}{2}} \right )}+\frac{1}{\kappa}\ln{\left ( \frac{\theta}{y_0} \right )} + \frac{2\varPi}{\kappa} - \frac{1}{\kappa}\ln{ \left( \frac{1+\varPi}{\kappa} \right)}, \end{equation}

and provides a relationship between skin friction and the momentum thickness normalized by roughness length. Here, ![]() $H$ is the shape factor defined as

$H$ is the shape factor defined as ![]() $H=\delta ^*/\theta$. The two plotted curves, one with

$H=\delta ^*/\theta$. The two plotted curves, one with ![]() $\varPi =0.55$ and one with

$\varPi =0.55$ and one with ![]() $\varPi =0.70$, require an assumed wake function to solve for shape factor and are described in detail in Castro (Reference Castro2007) and Womack et al. (Reference Womack, Meneveau and Schultz2019). The random cases’ results are observed to be closer to the

$\varPi =0.70$, require an assumed wake function to solve for shape factor and are described in detail in Castro (Reference Castro2007) and Womack et al. (Reference Womack, Meneveau and Schultz2019). The random cases’ results are observed to be closer to the ![]() $\varPi =0.55$ curve, and the staggered cases’ results tend to lie closer to the

$\varPi =0.55$ curve, and the staggered cases’ results tend to lie closer to the ![]() $\varPi =0.70$ curve. This is consistent with the wake strength results found in table 2 which shows the random cases tend to have results near

$\varPi =0.70$ curve. This is consistent with the wake strength results found in table 2 which shows the random cases tend to have results near ![]() $\varPi =0.55$ and the staggered cases tend to have higher wake strengths in the spatial-averaged profiles.

$\varPi =0.55$ and the staggered cases tend to have higher wake strengths in the spatial-averaged profiles.

Figure 6. Variation of ![]() $c_f$ as a function of

$c_f$ as a function of ![]() $\theta /y_0$ for all surfaces.

$\theta /y_0$ for all surfaces.

Inner-normalized, spatial-averaged mean streamwise velocity profiles are plotted in figure 7. Figure 7(a) shows the staggered cases, and figure 7(b) shows the random cases. The dashed black line shows the smooth-wall log law. All profiles show the expected downward shift due to roughness effects. The S10, R10, S17 and R17 cases have clearly less downward shift than the other cases, which plot together more closely. All sixteen average profiles exhibit a log–linear region with slope of approximately ![]() $1/\kappa$ between approximately

$1/\kappa$ between approximately ![]() $0.07 < y/\delta < 0.15$ (approximately

$0.07 < y/\delta < 0.15$ (approximately ![]() $100 \lesssim (y-d)^+ \lesssim 300$). The existence of a linear region in the spatial-averaged profile with this roughness height to boundary layer thickness ratio or larger has been seen in other recent studies such as Cheng & Castro (Reference Cheng and Castro2002), Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015, Reference Placidi and Ganapathisubramani2018) and Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016) among others. The process of solving for

$100 \lesssim (y-d)^+ \lesssim 300$). The existence of a linear region in the spatial-averaged profile with this roughness height to boundary layer thickness ratio or larger has been seen in other recent studies such as Cheng & Castro (Reference Cheng and Castro2002), Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015, Reference Placidi and Ganapathisubramani2018) and Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016) among others. The process of solving for ![]() $y_0$ and

$y_0$ and ![]() $d$ assumed this linear region existed, however, the extent of such a region is not necessarily guaranteed in all cases.

$d$ assumed this linear region existed, however, the extent of such a region is not necessarily guaranteed in all cases.

Figure 7. Mean streamwise velocity profiles in inner scaling for (a) staggered cases and (b) random cases.

Figure 8 shows inner-normalized spatial-averaged mean Reynolds shear stress profiles for all sixteen cases. Staggered cases are in figure 8(a), and random cases are in figure 8(b). The profiles appear consistent with data from other rough surfaces such as Cheng & Castro (Reference Cheng and Castro2002), Flack, Schultz & Connelly (Reference Flack, Schultz and Connelly2007), Flack & Schultz (Reference Flack and Schultz2014) and Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015, Reference Placidi and Ganapathisubramani2018, Reference Placidi and Ganapathisubramani2019). However, there are notable differences between the cases in the near-wall region, ![]() $(y-d)/(\delta -d)<0.15$. This is attributed to the significant spatial heterogeneity found in this turbulence statistic in the roughness sublayer, defined as the region where local Reynolds shear stresses differ by greater than 10 %. Flack et al. (Reference Flack, Schultz and Connelly2007) and Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) both report that the roughness sublayer in their experiments extended up to

$(y-d)/(\delta -d)<0.15$. This is attributed to the significant spatial heterogeneity found in this turbulence statistic in the roughness sublayer, defined as the region where local Reynolds shear stresses differ by greater than 10 %. Flack et al. (Reference Flack, Schultz and Connelly2007) and Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) both report that the roughness sublayer in their experiments extended up to ![]() $y\approx 5k$. It is likely that the nine profiles of the staggered cases and twelve (or 23) profiles of the random cases do not provide a fine enough resolution to capture a well-converged spatial-averaged Reynolds shear stress in this region, similar to the results of Cheng & Castro (Reference Cheng and Castro2002) and Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015). The CSS method, which was used to calculate

$y\approx 5k$. It is likely that the nine profiles of the staggered cases and twelve (or 23) profiles of the random cases do not provide a fine enough resolution to capture a well-converged spatial-averaged Reynolds shear stress in this region, similar to the results of Cheng & Castro (Reference Cheng and Castro2002) and Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015). The CSS method, which was used to calculate ![]() $u_\tau$,

$u_\tau$, ![]() $y_0$ and

$y_0$ and ![]() $d$, avoids uncertainty in the region by only fitting the extended Volino & Schultz equation to Reynolds shear stress and dispersive shear stress in the range of

$d$, avoids uncertainty in the region by only fitting the extended Volino & Schultz equation to Reynolds shear stress and dispersive shear stress in the range of ![]() $0.15 < (y-d)/(\delta -d) < 0.30$.

$0.15 < (y-d)/(\delta -d) < 0.30$.

Figure 8. Turbulent shear stress profiles in inner scaling for (a) staggered cases and (b) random cases.

Reynolds number independence of the rough surface drag was not checked directly, however, several important reviews consider rough-wall boundary layers Reynolds number independent when ![]() $k_s^+ \gtrsim 100$ (Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Flack et al. Reference Flack, Schultz and Shapiro2005). Table 2 shows that all cases from this study are at least 45 % greater than this threshold, so Reynolds number independence is expected and

$k_s^+ \gtrsim 100$ (Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Flack et al. Reference Flack, Schultz and Shapiro2005). Table 2 shows that all cases from this study are at least 45 % greater than this threshold, so Reynolds number independence is expected and ![]() $y_0$ and

$y_0$ and ![]() $k_s$ are solely a function of the surface roughness.

$k_s$ are solely a function of the surface roughness.

Normalized roughness length, ![]() $y_0/k$, as a function of planform density,

$y_0/k$, as a function of planform density, ![]() $\lambda _p$, was investigated and results are plotted in figure 9. Normalized roughness length for staggered and random cases at equivalent planform densities plot closely together for all but one density,

$\lambda _p$, was investigated and results are plotted in figure 9. Normalized roughness length for staggered and random cases at equivalent planform densities plot closely together for all but one density, ![]() $\lambda _p=0.70$. Specific selection of the linear range used to fit the log-law equation is the largest source of error for determination of these average profile parameters. Therefore, error bars were generated by varying the region in which the linear regression was fit to the log law during iteration in the CSS method. Those assumed linear regions also fit in the CSS method were:

$\lambda _p=0.70$. Specific selection of the linear range used to fit the log-law equation is the largest source of error for determination of these average profile parameters. Therefore, error bars were generated by varying the region in which the linear regression was fit to the log law during iteration in the CSS method. Those assumed linear regions also fit in the CSS method were: ![]() $0 < y/\delta < 0.15$,

$0 < y/\delta < 0.15$, ![]() $0.10 < y/\delta < 0.15$,

$0.10 < y/\delta < 0.15$, ![]() $0 < y/\delta < 0.19$,

$0 < y/\delta < 0.19$, ![]() $0.07 < y/\delta < 0.19$ and

$0.07 < y/\delta < 0.19$ and ![]() $0.10 < y/\delta < 0.19$. As noted by Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) and Womack et al. (Reference Womack, Meneveau and Schultz2019), fitting of (3.1) for

$0.10 < y/\delta < 0.19$. As noted by Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) and Womack et al. (Reference Womack, Meneveau and Schultz2019), fitting of (3.1) for ![]() $y_0$ and

$y_0$ and ![]() $d$ carries significant uncertainty, however, it is still common to use a fitting procedure due to lack of a better alternative when only velocity profile measurements are available. Additionally, using a consistent fitting procedure allows for comparison among cases which provides valuable insight into roughness length trends. Varying the region in which the extended Volino & Schultz equation was fitted had a much smaller effect and was not included in the results presented here.

$d$ carries significant uncertainty, however, it is still common to use a fitting procedure due to lack of a better alternative when only velocity profile measurements are available. Additionally, using a consistent fitting procedure allows for comparison among cases which provides valuable insight into roughness length trends. Varying the region in which the extended Volino & Schultz equation was fitted had a much smaller effect and was not included in the results presented here.

Figure 9. Normalized roughness length, ![]() $y_0/k$, as a function of

$y_0/k$, as a function of ![]() $\lambda _p$. Data from Sadique (Reference Sadique2016) are obtained from table 3.6 in § 3.2.2.2 of the thesis.

$\lambda _p$. Data from Sadique (Reference Sadique2016) are obtained from table 3.6 in § 3.2.2.2 of the thesis.

Since staggered and random cases plot so close together, the results suggest that normalized roughness length is more a function of the density and element shape rather than their particular arrangement. This may be due to relatively comparable average distances between elements at each density in the staggered and random configurations. The correlation could break down if there was significant element clustering or directionality at the same density (Forooghi et al. Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017; Anderson Reference Anderson2020; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). Truncated cone surfaces tested in this study show increasing normalized roughness length in the range ![]() $0 < \lambda _p \lesssim 0.4$. Then a gradual decrease above

$0 < \lambda _p \lesssim 0.4$. Then a gradual decrease above ![]() $\lambda _p \gtrsim 0.4$. To the authors’ knowledge, the only truncated cone data that provide comparison over a range of planform densities are found in Sadique (Reference Sadique2016). He conducted large eddy simulations over staggered and aligned truncated cones at several planform densities. The comparison study's repeating truncated cone had height

$\lambda _p \gtrsim 0.4$. To the authors’ knowledge, the only truncated cone data that provide comparison over a range of planform densities are found in Sadique (Reference Sadique2016). He conducted large eddy simulations over staggered and aligned truncated cones at several planform densities. The comparison study's repeating truncated cone had height ![]() $k=0.5D$ and plateau diameter equal to

$k=0.5D$ and plateau diameter equal to ![]() $0.5D$, making it slightly taller and wider than the truncated cone in this study. The results compare well with the present study given the differences in truncated cone shape. The normalized roughness length magnitudes are generally consistent, and if a curve were drawn though these points, it would seem to indicate a peak normalized roughness length around

$0.5D$, making it slightly taller and wider than the truncated cone in this study. The results compare well with the present study given the differences in truncated cone shape. The normalized roughness length magnitudes are generally consistent, and if a curve were drawn though these points, it would seem to indicate a peak normalized roughness length around ![]() $\lambda _p \approx 0.4$ as the current experimental data suggest.

$\lambda _p \approx 0.4$ as the current experimental data suggest.

Most other studies which have systematically varied planform density have used cubes, rectangular prisms or rectangular LEGO® blocks including Hall, Macdonald & Walker (Reference Hall, Macdonald and Walker1996), Cheng et al. (Reference Cheng, Hayden, Robins and Castro2007), Hagishima et al. (Reference Hagishima, Tanimoto, Nagayama and Meno2009), Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015, Reference Placidi and Ganapathisubramani2018), Yang et al. (Reference Yang, Sadique, Mittal and Meneveau2016) and Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017). Most of these studies suggest a peak drag at a density of ![]() $\lambda _p \approx 0.15$ and marked drop in drag at higher densities, so the curve shape is not similar to the results reported here or in Sadique (Reference Sadique2016). Additionally, most a priori analytical models were designed and evaluated against these rectangular prism surface morphologies (often called urban-like roughness) and were not found to be easily adaptable to truncated cone surface elements.

$\lambda _p \approx 0.15$ and marked drop in drag at higher densities, so the curve shape is not similar to the results reported here or in Sadique (Reference Sadique2016). Additionally, most a priori analytical models were designed and evaluated against these rectangular prism surface morphologies (often called urban-like roughness) and were not found to be easily adaptable to truncated cone surface elements.

A roughness length model in Macdonald, Griffiths & Hall (Reference Macdonald, Griffiths and Hall1998), however, was found to be adaptable to the truncated cone shape when provided an a priori estimate for the coefficient of drag, ![]() $C_{DH}$, and zero-plane displacement height,

$C_{DH}$, and zero-plane displacement height, ![]() $d$. Two relevant coefficient of drag measurements were found in a literature survey. Sadique (Reference Sadique2016) reports

$d$. Two relevant coefficient of drag measurements were found in a literature survey. Sadique (Reference Sadique2016) reports ![]() $C_D=0.23$ from DNS on truncated cones in a laminar boundary layer;

$C_D=0.23$ from DNS on truncated cones in a laminar boundary layer; ![]() $C_D$ corresponds with

$C_D$ corresponds with ![]() $C_{DH}=0.27$ when using the Blasius laminar profile solution to estimate velocity at the roughness crests,

$C_{DH}=0.27$ when using the Blasius laminar profile solution to estimate velocity at the roughness crests, ![]() $U_H$, from reported simulation details. Additionally, Schultz et al. (Reference Schultz, Kavanagh and Swain1999) reported a coefficient of drag of

$U_H$, from reported simulation details. Additionally, Schultz et al. (Reference Schultz, Kavanagh and Swain1999) reported a coefficient of drag of ![]() $C_D=0.52$ for natural barnacle specimens in a turbulent boundary layer;

$C_D=0.52$ for natural barnacle specimens in a turbulent boundary layer; ![]() $C_D$ corresponds with

$C_D$ corresponds with ![]() $C_{DH}=0.65$ when using reported information to estimate

$C_{DH}=0.65$ when using reported information to estimate ![]() $U_H$ in a turbulent boundary layer. Neither reported coefficient of drag was an ideal match for this study. Sadique (Reference Sadique2016) had a similar truncated cone element but differing laminar flow regime. Schultz et al. (Reference Schultz, Kavanagh and Swain1999) had a similar turbulent flow regime but differing natural barnacle element. Therefore, both were used for comparative results. Details on the adaption of the Macdonald et al. (Reference Macdonald, Griffiths and Hall1998) model and a priori estimation of

$U_H$ in a turbulent boundary layer. Neither reported coefficient of drag was an ideal match for this study. Sadique (Reference Sadique2016) had a similar truncated cone element but differing laminar flow regime. Schultz et al. (Reference Schultz, Kavanagh and Swain1999) had a similar turbulent flow regime but differing natural barnacle element. Therefore, both were used for comparative results. Details on the adaption of the Macdonald et al. (Reference Macdonald, Griffiths and Hall1998) model and a priori estimation of ![]() $d$ for truncated cones are included in Appendix A.

$d$ for truncated cones are included in Appendix A.

Results for these two values of ![]() $C_{DH}$ are shown in figure 9. The curve, which utilizes

$C_{DH}$ are shown in figure 9. The curve, which utilizes ![]() $C_{DH}=0.65$, performs well below

$C_{DH}=0.65$, performs well below ![]() $\lambda _p \approx 0.4$ but does not peak there as the experimental data suggest. Instead, it seems to calculate a fairly flat peak around

$\lambda _p \approx 0.4$ but does not peak there as the experimental data suggest. Instead, it seems to calculate a fairly flat peak around ![]() $\lambda _p \approx 0.55$ which is above the measurements and outside of their uncertainty. The curve which utilizes

$\lambda _p \approx 0.55$ which is above the measurements and outside of their uncertainty. The curve which utilizes ![]() $C_{DH}=0.27$ consistently plots below the experimental results. This confirms that the model is sensitive to an accurate estimate of an individual element's coefficient of drag and limits the a priori reliability of the model on many surface morphologies where the coefficient of drag is not known well or roughness shapes are not consistent.

$C_{DH}=0.27$ consistently plots below the experimental results. This confirms that the model is sensitive to an accurate estimate of an individual element's coefficient of drag and limits the a priori reliability of the model on many surface morphologies where the coefficient of drag is not known well or roughness shapes are not consistent.

Surface statistical models provide another possible a priori prediction of normalized roughness length. These types of models have the advantage of not requiring estimation of surface parameters like ![]() $C_{DH}$ and

$C_{DH}$ and ![]() $d$. Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017), inspired by the contribution of Flack & Schultz (Reference Flack and Schultz2010), provides an explicit expression for

$d$. Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017), inspired by the contribution of Flack & Schultz (Reference Flack and Schultz2010), provides an explicit expression for ![]() $y_0$ as a function of the surface standard deviation and skewness,

$y_0$ as a function of the surface standard deviation and skewness,

\begin{equation} y_0 \left( \sigma_h {, } s_k \right) = \begin{cases} \alpha \sigma_h \left( 1 + \beta s_k \right) {,} & \sigma_h/ \left\langle h \right\rangle < 1.15 \\ \alpha \sigma_h \left( 1 + s_k \right)^\beta {,} & \sigma_h/ \left\langle h \right\rangle \geqslant 1.15 \end{cases}{,} \end{equation}

\begin{equation} y_0 \left( \sigma_h {, } s_k \right) = \begin{cases} \alpha \sigma_h \left( 1 + \beta s_k \right) {,} & \sigma_h/ \left\langle h \right\rangle < 1.15 \\ \alpha \sigma_h \left( 1 + s_k \right)^\beta {,} & \sigma_h/ \left\langle h \right\rangle \geqslant 1.15 \end{cases}{,} \end{equation}

where constants ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$ are

$\beta$ are ![]() $0.1$ and

$0.1$ and ![]() $0.9$, respectively. The truncated cone surfaces tested in this study have a slightly different standard deviation and skewness at each density due to the overlapping truncated cones on the random plates. Therefore, this model produces a range of results for the planform densities tested. This range is plotted in figure 9 as the dark grey shaded area. The Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017) equation roughly matches the slope of the current experiments but underestimates the normalized roughness length above

$0.9$, respectively. The truncated cone surfaces tested in this study have a slightly different standard deviation and skewness at each density due to the overlapping truncated cones on the random plates. Therefore, this model produces a range of results for the planform densities tested. This range is plotted in figure 9 as the dark grey shaded area. The Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017) equation roughly matches the slope of the current experiments but underestimates the normalized roughness length above ![]() $\lambda _p \gtrsim 0.4$. It also does not seem to capture the shape of the curve well and overestimates the normalized roughness length below

$\lambda _p \gtrsim 0.4$. It also does not seem to capture the shape of the curve well and overestimates the normalized roughness length below ![]() $\lambda _p \lesssim 0.4$. For sparse distributions of individual elements, a simple calculation in the limit

$\lambda _p \lesssim 0.4$. For sparse distributions of individual elements, a simple calculation in the limit ![]() $\lambda _p \to 0$ shows that

$\lambda _p \to 0$ shows that ![]() $\sigma ^2 \to k^2 \lambda _p$ while

$\sigma ^2 \to k^2 \lambda _p$ while ![]() $s_k \sim \lambda _p^{-1/2}$. Thus the predicted

$s_k \sim \lambda _p^{-1/2}$. Thus the predicted ![]() $y_0$ based on the skewness,

$y_0$ based on the skewness, ![]() $s_k$, does not tend to zero when

$s_k$, does not tend to zero when ![]() $\lambda _p \to 0$ but to a constant fraction of

$\lambda _p \to 0$ but to a constant fraction of ![]() $k$ (for

$k$ (for ![]() $\beta =1$), consistent with the Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017) results shown in figure 9.

$\beta =1$), consistent with the Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017) results shown in figure 9.

Since (3.3) seems to match the shape of the profile and Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017) report ![]() $\alpha \approx 0.1$, it seems reasonable to attempt to tune

$\alpha \approx 0.1$, it seems reasonable to attempt to tune ![]() $\alpha$ for a better fit. Additionally, Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017) cite several studies where

$\alpha$ for a better fit. Additionally, Zhu et al. (Reference Zhu, Iungo, Leonardi and Anderson2017) cite several studies where ![]() $0.1 < \alpha < 0.17$ bounds the reported values. Equation (3.3) yields a good fit to the data above

$0.1 < \alpha < 0.17$ bounds the reported values. Equation (3.3) yields a good fit to the data above ![]() $\lambda \gtrsim 0.4$ when

$\lambda \gtrsim 0.4$ when ![]() $\alpha =0.14$ as seen by the light grey shaded area in figure 9.

$\alpha =0.14$ as seen by the light grey shaded area in figure 9.

Given the success of the Macdonald et al. and Zhu et al. models at different surface densities and their different underlying assumptions, it is reasonable to postulate that the truncated cone surface is exhibiting two different flow regimes. The Macdonald et al. model assumes a coefficient of drag for individual elements while the Zhu et al. model attempts to characterize the surface with surface statistics. Below ![]() $\lambda _p \lesssim 0.4$ the flow is characteristic of flow around isolated elements, while above

$\lambda _p \lesssim 0.4$ the flow is characteristic of flow around isolated elements, while above ![]() $\lambda _p \gtrsim 0.4$ the flow is characteristic of skimming flow over a rough surface with the transition happening at the point of peak drag. Such a transition was expected as this type of behaviour has been observed before in other studies such as Grimmond & Oke (Reference Grimmond and Oke1999) and Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015). However, proposed flow regime prediction parameters such as ratios of roughness height to average distance between elements are difficult to apply to truncated cones. This is due to their varying cross-section with height, which gives rise to different flow behaviour as

$\lambda _p \gtrsim 0.4$ the flow is characteristic of skimming flow over a rough surface with the transition happening at the point of peak drag. Such a transition was expected as this type of behaviour has been observed before in other studies such as Grimmond & Oke (Reference Grimmond and Oke1999) and Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015). However, proposed flow regime prediction parameters such as ratios of roughness height to average distance between elements are difficult to apply to truncated cones. This is due to their varying cross-section with height, which gives rise to different flow behaviour as ![]() $\lambda _p \to 1$. Cubes tend to a smooth wall as

$\lambda _p \to 1$. Cubes tend to a smooth wall as ![]() $\lambda _p \to 1$ leading to skimming behaviour whereas truncated cones have a dense rough surface as

$\lambda _p \to 1$ leading to skimming behaviour whereas truncated cones have a dense rough surface as ![]() $\lambda _p \to 1$ with evidence of limited sheltering at the tested dimensional ratios.

$\lambda _p \to 1$ with evidence of limited sheltering at the tested dimensional ratios.

Normalized zero-plane displacement height, ![]() $d/k$, is plotted in figure 10. Based on flow physics and previous studies, it is expected that

$d/k$, is plotted in figure 10. Based on flow physics and previous studies, it is expected that ![]() $d/k$ increases with planform density Grimmond & Oke (Reference Grimmond and Oke1999). Such a trend is visible at larger

$d/k$ increases with planform density Grimmond & Oke (Reference Grimmond and Oke1999). Such a trend is visible at larger ![]() $\lambda _p$ while the trend is somewhat noisy at

$\lambda _p$ while the trend is somewhat noisy at ![]() $\lambda _p<0.4$.

$\lambda _p<0.4$.

Figure 10. Normalized zero-plane displacement, ![]() $d/k$, as a function of

$d/k$, as a function of ![]() $\lambda _p$.

$\lambda _p$.

3.2. Differences in spatial-averaged staggered and random surface profiles

Local outer-normalized mean streamwise velocity profiles for the S78 staggered case are plotted in figure 11(a), and local outer-normalized mean streamwise velocity profiles for the R78 random case are plotted in figure 11(b). Cases S78 and R78 were selected to showcase the trends seen for all staggered and random cases, respectively. The spatial average is plotted with a thick black line. It is clear from figure 11(a) that the various S78 local profiles converge within one roughness height, ![]() $k$, above the roughness crests (

$k$, above the roughness crests (![]() $(k-d)/(\delta -d)=0.12$ for this case). Reynolds shear stress profiles (not shown) converge within

$(k-d)/(\delta -d)=0.12$ for this case). Reynolds shear stress profiles (not shown) converge within ![]() $2k$ above the roughness crests. This is the result for all staggered cases and consistent with other studies that report convergence above

$2k$ above the roughness crests. This is the result for all staggered cases and consistent with other studies that report convergence above ![]() $y > 5k$ (Flack et al. Reference Flack, Schultz and Connelly2007; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2015). In contrast, figure 11(b) shows visual differences in the local profiles all the way to the edge of the boundary layer.

$y > 5k$ (Flack et al. Reference Flack, Schultz and Connelly2007; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2015). In contrast, figure 11(b) shows visual differences in the local profiles all the way to the edge of the boundary layer.

Figure 11. All outer-normalized (a) S78 local profiles and (b) R78 local profiles plotted in colour. The thick black line is the spatial-average profile for the case. Other staggered and random cases were similar to S78 and R78, respectively.

Inner-normalized mean streamwise velocity profiles in defect form are included for all staggered cases in figure 12(a) and for all random cases in figure 12(b). DNS at ![]() ${\textit {Re}}_\tau \approx 2000$ from Sillero, Jiménez & Moser (Reference Sillero, Jiménez and Moser2013) is included as the thick black dotted line for reference in both plots. It can be observed that all staggered cases except S10 plot above the DNS reference in figure 12(a), and all random cases plot near the DNS reference in figure 12(b). Additionally, there is a greater visual spread in the profiles at low

${\textit {Re}}_\tau \approx 2000$ from Sillero, Jiménez & Moser (Reference Sillero, Jiménez and Moser2013) is included as the thick black dotted line for reference in both plots. It can be observed that all staggered cases except S10 plot above the DNS reference in figure 12(a), and all random cases plot near the DNS reference in figure 12(b). Additionally, there is a greater visual spread in the profiles at low ![]() $(y-d)/(\delta -d)$ for the staggered cases when compared with the random cases.

$(y-d)/(\delta -d)$ for the staggered cases when compared with the random cases.

Figure 12. (a) Staggered surface profiles and (b) random surface profiles shown in inner-normalized mean streamwise velocity defect form. The thick dotted black line is the smooth-wall DNS result at ![]() ${\textit {Re}}_\tau \approx 2000$ from Sillero et al. (Reference Sillero, Jiménez and Moser2013).

${\textit {Re}}_\tau \approx 2000$ from Sillero et al. (Reference Sillero, Jiménez and Moser2013).

Further evidence of the differences seen in figure 12 is observed in the column of ![]() $\varPi$ values in table 2. For the staggered cases, wake strength is in the range

$\varPi$ values in table 2. For the staggered cases, wake strength is in the range ![]() $\varPi =0.53 - 0.79$ compared with

$\varPi =0.53 - 0.79$ compared with ![]() $\varPi =0.51 - 0.66$ for the random cases, and the differences in wake strength are largely outside of the experimental uncertainty when compared at similar

$\varPi =0.51 - 0.66$ for the random cases, and the differences in wake strength are largely outside of the experimental uncertainty when compared at similar ![]() $\lambda _p$, as seen in figure 13(a). Additional comparison with other surface morphologies such as the mesh, cubes, rectangular blocks and sandgrain surfaces from Castro (Reference Castro2007) in figure 13(b) reveals that the staggered cases seem to show wake strengths commensurate with the roughness function. However, the random cases appear to have reduced wake strength by comparison.

$\lambda _p$, as seen in figure 13(a). Additional comparison with other surface morphologies such as the mesh, cubes, rectangular blocks and sandgrain surfaces from Castro (Reference Castro2007) in figure 13(b) reveals that the staggered cases seem to show wake strengths commensurate with the roughness function. However, the random cases appear to have reduced wake strength by comparison.

Figure 13. Plots of wake strength, ![]() $\varPi$, as a function of (a) planform density,

$\varPi$, as a function of (a) planform density, ![]() $\lambda _p$, and (b) roughness function,

$\lambda _p$, and (b) roughness function, ![]() $\Delta U^+$, for staggered and random surfaces.

$\Delta U^+$, for staggered and random surfaces.

As suggested by the varying wake strength, outer-layer similarity in the spatially averaged profiles is not observed across the range of densities of either the staggered or random arrangements of truncated cones. Neither the criterion from Jiménez (Reference Jiménez2004) of ![]() $k/\delta <0.025$ or the criterion from Flack et al. (Reference Flack, Schultz and Shapiro2005) of

$k/\delta <0.025$ or the criterion from Flack et al. (Reference Flack, Schultz and Shapiro2005) of ![]() $k_s/\delta <0.025$ would have predicted outer-layer similarity. However, Amir & Castro (Reference Amir and Castro2011) suggest that boundary layers exhibit outer-layer similarity when

$k_s/\delta <0.025$ would have predicted outer-layer similarity. However, Amir & Castro (Reference Amir and Castro2011) suggest that boundary layers exhibit outer-layer similarity when ![]() $k/\delta <0.15$, and the present measurements do meet this criterion. Furthermore, each staggered case, when compared with the random case at the same density in figure 13(a), show roughly equivalent measures of

$k/\delta <0.15$, and the present measurements do meet this criterion. Furthermore, each staggered case, when compared with the random case at the same density in figure 13(a), show roughly equivalent measures of ![]() $k/\delta$ or

$k/\delta$ or ![]() $k_s/\delta$ but have values of

$k_s/\delta$ but have values of ![]() $\varPi$ which are different (see table 2). The findings here are consistent with Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2018), where outer-layer similarity did not solely depend on

$\varPi$ which are different (see table 2). The findings here are consistent with Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2018), where outer-layer similarity did not solely depend on ![]() $k/\delta$ or

$k/\delta$ or ![]() $k_s/\delta$ but must also depend on other characteristics of the surface morphology. The presently observed differences in the outer layer over surfaces with similar densities and roughness height ratios adds interesting new evidence to the salient surface morphology parameters which generate or disrupt outer-layer similarity.

$k_s/\delta$ but must also depend on other characteristics of the surface morphology. The presently observed differences in the outer layer over surfaces with similar densities and roughness height ratios adds interesting new evidence to the salient surface morphology parameters which generate or disrupt outer-layer similarity.

Notably, the observations in figures 12 and 13 were formed on spatial-averaged profiles. However, there was significant spatial variation across the horizontal tunnel span (![]() $z$-direction) on all random surface cases that was illustrated by the R78 case in figure 11(b). In contrast, the staggered surface cases, as shown in the S78 case in figure 11(a), showed variation only in the near-wall region consistent with other studies (Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Flack et al. Reference Flack, Schultz and Shapiro2005; Amir & Castro Reference Amir and Castro2011). The lack of collapse of the profiles in figure 11(b) outside of the inner layer is striking given that all of these profiles were recorded over a similar surface at the same Reynolds number,

$z$-direction) on all random surface cases that was illustrated by the R78 case in figure 11(b). In contrast, the staggered surface cases, as shown in the S78 case in figure 11(a), showed variation only in the near-wall region consistent with other studies (Raupach et al. Reference Raupach, Antonia and Rajagopalan1991; Jiménez Reference Jiménez2004; Flack et al. Reference Flack, Schultz and Shapiro2005; Amir & Castro Reference Amir and Castro2011). The lack of collapse of the profiles in figure 11(b) outside of the inner layer is striking given that all of these profiles were recorded over a similar surface at the same Reynolds number, ![]() ${\textit {Re}}_x = U_e x/\nu$. Taken together, these observations indicate a breakdown in outer-layer similarity warranting further analysis. In § 4, it will be shown that these differences can be attributed to secondary flows which create HMPs and LMPs and disrupt outer-layer similarity.

${\textit {Re}}_x = U_e x/\nu$. Taken together, these observations indicate a breakdown in outer-layer similarity warranting further analysis. In § 4, it will be shown that these differences can be attributed to secondary flows which create HMPs and LMPs and disrupt outer-layer similarity.

4. Secondary flow structures and their characteristics