Article contents

Kinetics of length-scale dependent plastic deformation of gold microspheres

Published online by Cambridge University Press: 22 June 2017

Abstract

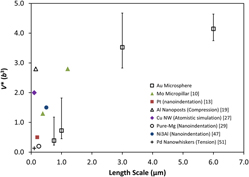

The size and strain-rate dependence of plastic deformation in Au microspheres of diameter ranging from 0.8 to 6.0 µm was investigated at room-temperature using flat-punch micro-compression testing. The contact yield stress was observed to increase with decreasing microsphere diameter. The apparent activation volume, V*, associated with the rate dependent plastic deformation remained essentially constant between 4 and 6b 3 for 0.8 and 1.0 µm spheres over strains up to 20% whereas it increased from 12 to 42b 3 for the larger 3.0 and 6.0 µm diameter specimens. The initiation of plastic deformation within the microspheres was also found to be highly dependent upon sphere diameter and strain rate with associated V*, and apparent activation energy, Q*, values of 0.4b 3 and 0.02 eV for 0.8 µm diameter spheres increasing to 4.1b 3 and 0.16 eV for 6.0 µm diameter spheres. These values indicate that initial plasticity is controlled by heterogeneous nucleation events that are consistent with a surface self-diffusion mechanism.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Mathias Göken

References

REFERENCES

- 5

- Cited by