Article contents

Film thickness dependent microstructural changes of thick copper metallizations upon thermal fatigue

Published online by Cambridge University Press: 13 June 2017

Abstract

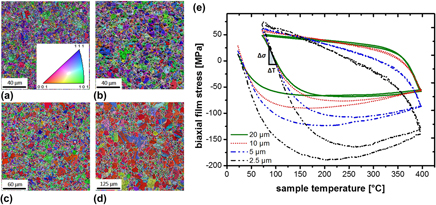

With increasing performance requirements in power electronics, the necessity has emerged to investigate the thermo-mechanical behavior of thick Cu metallizations (≥5 µm). Cu films on rigid substrates in the range of 5–20 µm were thermally cycled between 170 and 400 °C by a fast laser device. Compared to the initial microstructures, a texture transition toward the {100} out-of-plane orientation with increasing film thickness was observed during thermo-mechanical cycling, along with an abnormal grain growth in the {100}-oriented grains and a gradual development of substructures in a crystallographic arrangement. Compared to the well-studied thin Cu film counterparts (≤5 µm), the surface damage showed a 1/hf dependency. Transition from an orientation independent (hf = 5 µm) to an orientation specific thermo-mechanical fatigue damage (hf = 10, 20 µm) was observed following a higher damager tolerance in {100} oriented grains.

Keywords

- Type

- Invited Papers

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: George M. Pharr

References

REFERENCES

- 7

- Cited by