Article contents

Study of Cu–In–Ga precursor for Cu(In,Ga)Se2 thin film prepared by the two-stage process

Published online by Cambridge University Press: 11 July 2012

Abstract

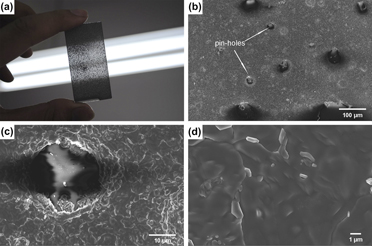

Cu–In–Ga precursor thin films were deposited onto soda lime glass by magnetron cosputtering CuIn and CuGa alloy targets. After that, Cu(In,Ga)Se2(CIGSe) absorbers were formed by selenizing those alloy precursors with Se vapor at 550 °C. The influence of the precursor temperature on the properties of CIGSe thin film was investigated. The results show that a lot of pinholes existed in the CIGSe thin film produced by selenizing the Cu–In–Ga alloy precursor, which was sputtering deposited at ambient temperature. After sputtering substrate temperature of 250 °C was applied, pinholes were avoided. The surface roughness of Cu–In–Ga precursor increased with the increase of sputtering substrate temperature. Due to the volume expansion of selenization process, even the precursor with high surface roughness could be converted to smooth and compact CIGSe thin film.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2012

References

REFERENCES

- 4

- Cited by