No CrossRef data available.

Article contents

Convenient synthesis of inorganic fullerene-like WS2 self-lubricating films and their tribological behaviors

Published online by Cambridge University Press: 07 April 2020

Abstract

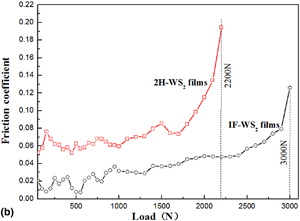

In the present work, an efficient route has been further explored to achieve the batch synthesis of inorganic fullerene (IF)-WS2 nanoparticles, and the self-lubricating film is conveniently prepared by coating these nanoparticles on the surface of metal substrates. The as-synthesized IF-WS2 nanoparticles have a closed hollow structure with an average particle size of about 50 nm and are evenly distributed in the self-lubricating film. Further friction tests show that the film has excellent friction properties, with its lowest friction coefficient of approximately 0.008, which can be mainly attributed to the unique hollow cage structure and a smaller particle size of the IF-WS2 nanoparticles.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2020