Article contents

Effect of a traveling magnetic field on freckle formation of directionally solidified Pb–Sn alloys

Published online by Cambridge University Press: 13 February 2017

Abstract

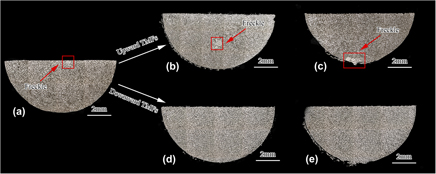

Effects of traveling magnetic field (TMF) on freckle formation of directionally solidified Pb–Sn alloys were investigated experimentally and numerically. The experimental results demonstrated that freckles could form without any magnetic field and with the upward TMF. In the former case, the formation location is the center. In the latter case, it diverted from the center to the surface with the increasing intensity of TMF. However, freckle could not form under the downward TMF. Numerical results indicated that the change of the formation location under upward TMF should be attributed to the different solid/liquid interface shape, and no formation under downward TMF should be attributed to the convection intensity driven by TMF. These magnetic fields are used to modulate melt flow, which is similar to the effects of the gravity. For eliminating freckle, a microgravity environment can be established under the suitable downward TMF.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Michael E. McHenry

References

REFERENCES

- 2

- Cited by