Glossary

- AFNOR

Association Française de Normalisation – French Standards Organization

- ALCA

Attributional Life-Cycle Assessment

- BOM

Bill of Materials

- CAPEX

Capital Expenditure

- CGE

Computable General Equilibrium

- CLCA

Consequential Life-Cycle Assessment

- EOL

End of Life

- GHG

Green House Gas

- LCA

Life-Cycle Assessment

- LCC

Life-Cycle Cost

- MFA

Material Flow Analysis

- OPEX

Operational Expenditure

- PLD

Product Line Design

- R&D

Research and Development

- ROI

Return on Investment

- SABEC

Stochastic-Activity-Based Energy Consumption

- SETAC

Society of Environmental Toxicology and Chemistry

- UNEP

United Nations Environment Programme

1 Introduction

Sustainability has steadily gained attention due to its overarching impact for evaluating and guiding designed systems and products across a wide variety of domains and disciplines. Sustainable design has become more complex as its field of applications has widened from consumer products to complex industrial systems. The scope of sustainability reaches beyond design and manufacturing stages to usage, maintenance and end-of-use stages, i.e., the entire life cycle leading to realization of circular economy. Design science – theory, methodology, guided tools etc. – has been central to recent advances, as evidenced in a wealth of literature and case studies (Papalambros Reference Papalambros2015).

While initial advances in sustainable design came from a desire to reduce environmental impacts during the life cycle, the recent focus has more comprehensively included all three aspects (‘pillars’) of sustainability, i.e., environmental, economic and societal (Kloepffer Reference Kloepffer2008). Rather than focusing on only one of the three, recent works combine economic and environmental aspects together or evaluate effectiveness from a society–community perspective.

Ecodesign serves as one of the main drivers for circular economy practices, whose connection to achieving the UN’s Sustainable Development Goals (SDGs) is documented in Schroeder, Anggraeni & Weber (Reference Schroeder, Anggraeni and Weber2018). Among the 17 SDGs, circular economy practices (enabled in part by ecodesign) have direct link to SDG 6 (Clean Water and Sanitation), 7 (Affordable and Clean Energy), 8 (Decent Work and Economic Growth), 12 (Responsible Consumption and Production) and 15 (Life on Land). In Perpignan et al. (Reference Perpignan, Robin, Baouch and Eynard2019), the authors also noted that the national effort in France to reduce green house gas (GHG) emission by 75% in 2050 has direct relevance to SDG 9 (Industry, Innovation, and Infrastructure) and SDG 12 (Responsible Consumption and Production).

Sustainability research has not only gained comprehensiveness by addressing all three pillars, it has also effectuated a shift in direction, for a number of reasons. First, the focus on product has been expanded to systems. Sustainability affects design and manufacturing processes for products and systems, which is expanded further in the areas of system operations, product usage, end of use, remanufacturing, etc. Second, new tools and themes are emerging with the advancement of computing capabilities and new awareness by policymakers and regulators. As a result, new areas of application are emerging for sustainability research and practice, such as design analytics, product take-back and recycling laws, regulatory guidelines and more.

Understanding a product’s usage in full detail has been a challenge due to the difficulties in gathering noisy and diverse real data. With advances in telematics systems enabled by manufacturers such as GM, Ford, Volvo, John Deere, Caterpillar and Rolls Royce, it is now possible to collect product usage data in real time. This kind of advancement has enabled new ways of approaching product design for sustainability, which in turn leads to new research themes, such as design analytics and data-driven design, for example.

This paper is intended as a position paper to identify new research themes in ecodesign (with concurrent environmental and economic focus) based on our recent observations from project experiences in diverse fields. We have compiled and studied a diverse set of cases to analyse and collect emerging themes and research areas. All these case studies have proven successful and meaningful as they have solved practical issues for companies, consortia or governments. They have used a diverse set of modelling, simulation and optimization methods, and most have resulted in academic publications. The paper is not intended as a systematic review and the case-study findings do not cover all relevant topics in sustainability research exhaustively, but our observations do provide relevant rationale for pursuing newly emerging research trends.

The paper is organized as follows. Section 2 describes the methodology process adopted for this research. Section 3 clarifies the identification of the 10 case studies and gives a brief description of each case by grouping them into three categories. Section 4 describes how our analysis of the case studies and relevant literature identified five ecodesign issues. Section 5 explores these five areas in detail. Section 6 discusses the results and summarizes a new set of newly emerging challenges. Section 7 sets out the conclusions and future perspectives.

2 Methodology

The methodology proposed in this paper is illustrated in Figure 1. It is composed of four steps, which are detailed in the following paragraphs.

Figure 1. Overview of the proposed methodology based on case-study analyses.

Step 1 – Identification of the 10 case studies. First, we identified 10 case studies considered as representative of their research activities in ecodesign in the past few years. These case studies concern different industrial sectors, scopes and objectives, as detailed in Section 3.

Step 2 – Identification of the 5 ecodesign issues. Second, we propose a framework to analyse the case studies based on five concurrent environmental and economic issues: (1) optimal resource use for less environmental impact, (2) managing lifespan, (3) understanding users and usage, (4) integrating data and analytics, and (5) defining system boundary and perimeter. These ecodesign issues form a common thread across many of the case studies, even though the cases are from diverse backgrounds and industries. The framework helps to understand the emerging issues in ecodesign research and serves to guide future directions. The choice of these 5 issues is justified and enriched with the literature. This step is described in Section 4.

Step 3 – Exploration of the 5 ecodesign issues. The 5 ecodesign issues are then explored in detail by illustrating the main scientific issues with the case studies. For each issue, we review the literature to confirm our vision with the state of the art. In this way, we identify what is being or has been done in each area and what issues remain for research. Section 5 details the exploration of the 5 issues.

Step 4 – Discussion of the main research challenges. On the basis of the 5 illustrated ecodesign issues, we deduce the main research perspectives in ecodesign from our point of view. We discuss each of these challenges and highlight whether they have already been discussed in the literature and whether our viewpoint is convergent. This discussion is proposed in Section 6.

3 Identification of the 10 case studies

3.1 Identification of the case studies

To shed light on emerging research trends in ecodesign, 10 recent ecodesign or sustainability case studies are presented in Table 1 and §§ A.1–A.10 and analysed according to five main ecodesign issues detailed in Section 4. These 10 case studies were selected from the authors’ past or current ecodesign research projects, from 2009 to 2017. We have limited the case pool to those with which we have in-depth prior or current experience and access to data and results. The case studies were chosen to be representative of our work, including our teams and collaborations. We set out to select case studies that demonstrate at least one of the following characteristics:

(i) Being ecodesign-centred with a strong stake in the environmental dimension leading to an assessment and improvement of environmental performance.

(ii) Dealing with business concerns and being representative of multiple industrial sectors.

(iii) Covering the entire life cycle.

(iv) Connected with the economic and social dimensions of sustainable design if possible.

(v) Being representative of multiscale ecodesign issues, from end user to entire value chain.

(vi) Covering different ecodesign approaches, methods and tools.

The case studies also span the three environmental, economic and social pillars of sustainable development (Kloepffer Reference Kloepffer2008). The case studies extensively contribute to the environmental and economic pillars (all of them for the environmental aspect; eight of them for the economic aspect), while less than half contribute to the social aspect. This imbalance in contributions to the three pillars may be due to different availabilities of metrics to assess them. The metrics to assess the environmental and economic aspects are well documented and widely adopted by many in academia and industry. However, the metric to assess the social aspect is not readily available in a quantitative form. This imbalance could present a potential opportunity for future research to link the social aspect to the other two aspects. Here, however, we focus only on the environmental and economic dimensions, leaving the social dimension as a perspective.

Table 1. Overview of the 10 case studies. The information in brackets is a perspective for addressing the issue that has been identified but not yet done

The cases cover multiple industrial sectors (heavy industry with metallurgy, automotive, heavy-duty equipment, agrifood, consumer electronics, building and architecture) with different contexts, objectives and design methods and tools. Cases 1 and 2 deal with metallurgy. Case 1 (aluminium substation) concerns the development of an adapted ecodesign process for complex industrial systems such as AC/DC conversion substations for aluminium smelters. Case 2 (forge furnace) compares the sustainable performance of forge furnace alternatives by integrating environment, costs, clients and operation context. Cases 3 (automotive axle) and 4 (automotive recycling chain) concern the automotive sector. Case 3 assesses the economic and environmental impacts of automotive part replacement, while Case 4 analyses possible scenarios to develop an automotive glazing recycling chain. Case 5 (cotton harvesting) studies different harvesting systems to assess and compare their environmental and economic impacts. Cases 6 (olive packaging) and 7 (pork value chain) deal with sustainability-pressured agrifood products and systems. Case 6 compares environmental impacts of different packaging alternatives taking into account consumer usage and country context, while Case 7 considers the sustainability impacts and performances of a French pork value chain. Case 8 (consumer electronics) models the time-varying advantage of remanufactured consumer electronics products. Finally, Cases 9 (building and externalities) and 10 (building and usage) concern the building and architecture sector by integrating sustainable externalities with occupant behaviour.

An extended description of each case study is given in §§ A.1 to A.10. Each case study is also detailed in standard breakdown sheets available online. The web link is provided in appendix A. At this stage, we would urge the reader to carefully read at least the short case descriptions in §§ A.1 to A.10 if not the detailed descriptions found by following the URL links, to get a deeper understanding of this paper and process of coding and analysing the 10 use cases.

Next we group the 10 case studies into three categories as they cover all or some of the life-cycle phases of a product or system. Some of them concern the entire life cycle (Section 3.2), while some are mainly focused on the use phase (Section 3.3) and others mainly deal with end of life (EOL; Section 3.4). For each of these three categories, we give a ‘big picture’ to illustrate the case studies concerned, and a detailed picture in one particular case to highlight the issues raised and analysed in Section 4. Detailed descriptions of all 10 case studies can be found in appendix A, and further details can be found in Table 1. The whole life-cycle-oriented case studies (Cases 1, 2 and 7) investigate sustainability issues spanning the entire life of a product or system – design/manufacturing, distribution, usage, maintenance, and EOL management. They cover a wide variety of large-scale systems where the sustainability issues are considered not just for a particular life-cycle phase but more comprehensively for the entire life cycle. The scope of these case studies therefore tends to be larger than for those for a single product or system. The use-phase-oriented case studies (Cases 5, 6, 9 and 10) focus on how a product or system is used and how to capture the usage in the context of sustainability. Once a product or system is in operational use, it is important to understand the context and pattern of usage and gather data associated with diverse usage environments. Emerging technologies such as telematics systems have become increasingly important for capturing this usage data, as further explained in the case studies. The EOL-oriented case studies (Cases 3, 4 and 8) mainly focus on reuse, recycling and remanufacturing aspects of a product or system at the end of the life cycle. In line with the five sustainability issues in our framework, EOL operations carry clear benefits.

3.2 Life-cycle-oriented case studies

Life-cycle thinking, or the life-cycle approach (see for example the Life Cycle Initiative proposed conjointly by UNEP and SETAC; UNEP & SETAC 2012), considers the impacts generated throughout a product’s life cycle – from design/manufacturing through distribution, usage and maintenance and on to EOL management – in order to monitor and improve them in a structured way. Companies are increasingly implementing this paradigm, but considering and improving a product or system’s life-cycle-long environmental performances remains a challenge, so they often find it helpful to focus on particular phases. However, 3 of the 10 case studies presented in this paper consider every phase of the entire life cycle equally (Cases 1, 2 and 7).

Case 2 (forge furnace) deals with the selection of forge furnace technologies in a given context (location, client, energy supply). LCA results and life-cycle costs (LCC) are sensitive to the client’s profile (Leroy, Cluzel & Lamé Reference Leroy, Cluzel and Lamé2014). Different profiles have been defined to study how decisions could evolve according to these profiles, which are defined by environmental awareness and priority given to CAPEX or OPEX (does the client prefer a short-term perspective with little expenditure or prefer low operational costs?). Manufacturing, distribution and use phases are explicitly taken into account to estimate LCC and environmental impacts, but the shortage of data makes it difficult to include the EOL phase.

Case 7 explores the French pork value chain. Consumers increasingly want more information on the origin and quality of the food they buy: information on origin, breeding conditions and animal welfare, substances absorbed during the animal’s life (antibiotics, genetically modified organisms), carbon footprint etc. Case 7 shows which kinds of data are already captured in a food value chain and considers every phase of the life cycle, whether the product or system under study is the food source or the associated industrial value chain (Petit et al. Reference Petit, Bertoluci, Trystram, Lecomte and Chapdaniel2014). An LCA model has been developed and alternative scenarios for new solutions have been evaluated and used for decision-making between the actors of the value chain.

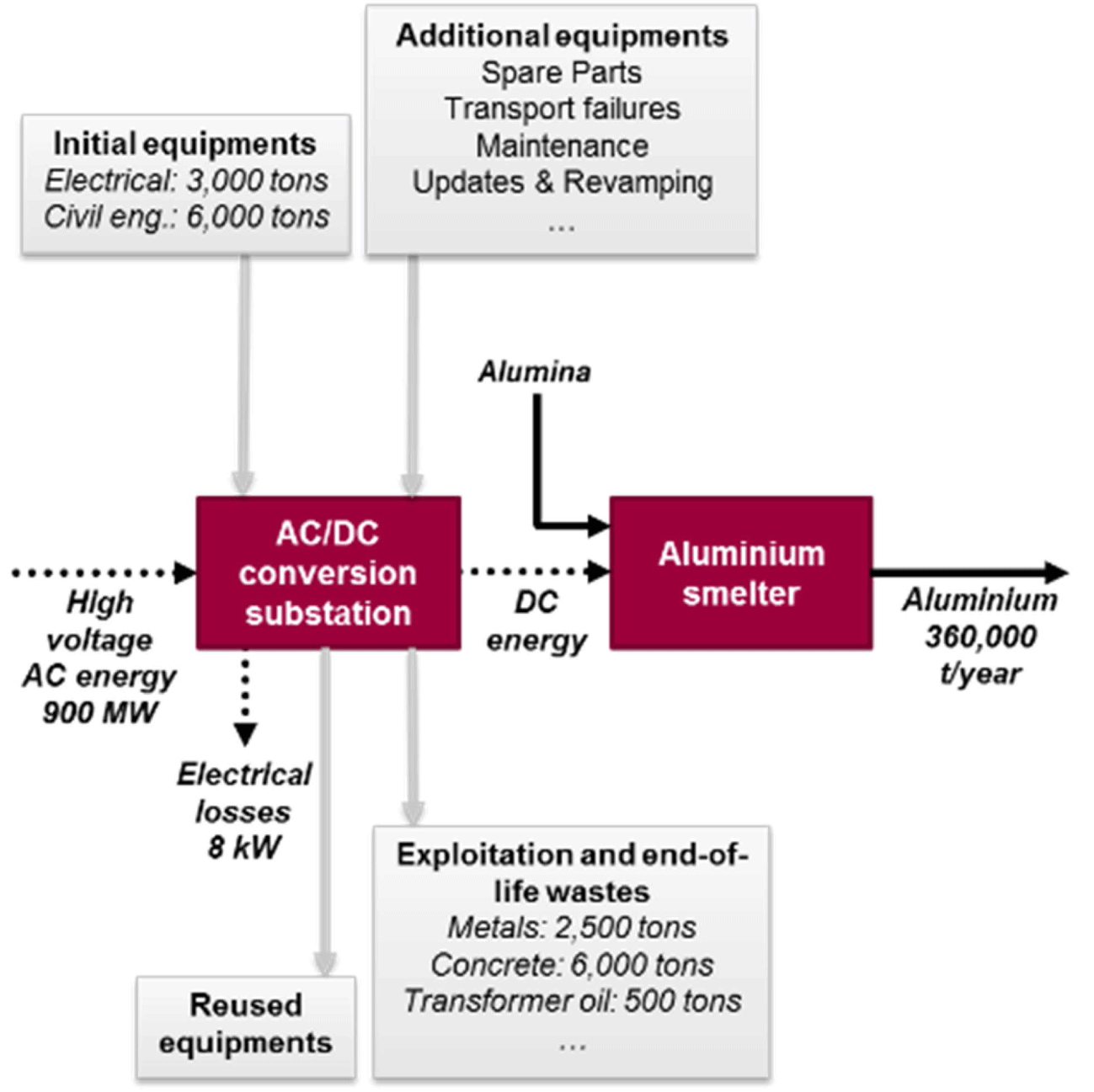

The life-cycle-oriented Case 1 (aluminium substation) considers the entire life cycle of a complex industrial system, namely an AC/DC conversion substation (described in Figure 2) used to convert energy for massive energy-consuming aluminium smelters. The design of these substations was independent of their future location, i.e., mainly where energy is abundant and cheap, namely in the Nordic countries with hydropower like Canada, Iceland or Russia, or in the Gulf countries or China, which use fossil energies. However, varied facility locations result in widely varied industry contexts: local electrical mix, distance to clients, client-led management of industrial systems (preventive versus corrective maintenance, updates and revamps), operating conditions in terms of temperature or humidity, regulations or practices for managing EOL components or systems and so on. Ecodesigning this type of industrial system requires consideration of industry-specific parameters and entire life-cycle scenarios.

Figure 2. Overview of mass and energy flows for an aluminium substation (Cluzel et al. Reference Cluzel, Yannou, Millet and Leroy2014).

First, a scenario-based LCA model was proposed to capture the environmental impacts of the entire life cycle despite the lack of data and the variability of exploitation contexts (Cluzel et al. Reference Cluzel, Yannou, Millet and Leroy2014). This semi-quantitative approach highlights for example that the best-case scenario in a particular context (substations supplied by hydroelectricity in a Nordic country) can decrease the environmental impacts by 70% compared to the worst-case scenario. The LCA model embracing the entire life cycle thus leads to different ecodesign actions (for example, decreasing masses of components but increasing electrical losses versus decreasing electrical losses by increasing masses of components) in a specific exploitation context.

Further, these LCA results were used to lead an eco-innovation approach based on a multidisciplinary working group composed of experts from different departments of the company (Cluzel et al. Reference Cluzel, Yannou, Millet and Leroy2016). The main deliverable of this working group was a portfolio of eco-innovative R&D to build the company’s strategic R&D road map. The method ensures a balanced portfolio, i.e., including projects with short-, mid- or long-term deadlines, projects dealing with components, subsystems, systems or supersystems, projects involving organizational, technological or methodological actions and projects considering different life-cycle phases of the system.

3.3 Use-phase-oriented case studies

In a number of cases, the use phase dramatically impacts a system’s ecodesign performance (Throne-Holst, Stø & Strandbakken Reference Throne-Holst, Stø and Strandbakken2007). However, real use emerges after the design and product launch phase. This is why user/usage profiles/patterns and sales prediction models are needed to integrate these nontrivial data models into LCA simulations.

Nine of the ten case studies highlighted in this paper, i.e., studies 2–10, directly consider – or could consider – users and usage to inform the ecodesign. This is especially true for case studies 5 (cotton harvesting), 6 (olive packaging), 9 (building and externalities) and 10 (building and usage).

The use-phase-oriented Case 10 is explained in more detail below. Building stock accounts for between 16 and 50 percent of national energy consumption worldwide (Saidur, Masjuki & Jamaluddin Reference Saidur, Masjuki and Jamaluddin2007; Hoes et al. Reference Hoes, Hensen, Loomans, De Vries and Bourgeois2009a,Reference Hoes, Hensen, Loomans, de Vries and Bourgeoisb; Masoso & Grobler Reference Masoso and Grobler2010). Governments around the world are thus rolling out energy directives, national regulations and energy-efficiency labels that set minimum requirements for building performances and promote the construction of ‘green’ buildings. Building stakeholders have thereby started dealing with buildings as products with services rather than just simple products. Services may for instance include energy monitoring or equipment maintenance during a building’s use phase. Moreover, new market expectations such as ‘energy performance contracts’ have started to emerge in a number of countries. Such services and offers thus require a better control of performance variability during a building’s life cycle. Consequently, a better understanding and consideration of the key determinants of energy performance has become essential for building design and marketing processes. Occupant behaviour is a substantial source of uncertainty in energy consumption, as inter-individual behavioural variations can account by as much as 100% for a given dwelling (Guerra-Santin et al. Reference Guerra-Santin, Romero Herrera, Cuerda and Keyson2016). The reasons are that different people generate different numbers of activities and may own more or less eco-efficient electrical appliances, both of which depend on household composition, lifestyle and socio-demographic background (Reinhart Reference Reinhart2004; Yun, Tuohy & Steemers Reference Yun, Tuohy and Steemers2009; Haldi & Robinson Reference Haldi and Robinson2011; Langevin, Gurian & Wen Reference Langevin, Gurian and Wen2015). This is why Zaraket et al. proposed an activity-based model for forecasting household energy and water consumption for residential building design (Zaraket, Yannou & Leroy Reference Zaraket, Yannou and Leroy2014). A user-centred statistics-driven approach correlates occupants’ profiles (socio-economic and -demographic) to quantities of domestic activities, appliance ownership and energy and water footprints. This model generates more accurate energy and water consumption forecasts and gives a means to assess usage-trend disparities in domestic consumption (Zaraket et al. Reference Zaraket, Yannou, Leroy, Minel and Chapotot2012). In total, 28 domestic energy- and water-consuming activities have been modelled as illustrated in Figure 3. These consumption models are expressed with approximately 20 parameters featuring household composition. Each activity was modelled in an Excel spreadsheet by a subset of influential household variables, a causal graph of influence starting from these household variables and ending with activity quantities via a number of quantitative intermediate variables (e.g., occupancy rate, number of weekly meals, laundry weight, etc.), modelling assumptions, data inputs from statistical databases or national consumption data and procedures used for model fitting to national consumption data. Figure 3 depicts the model architecture. These simulations of energy and water consumption based on different household profiles make it possible to

(i) refine or increase the accuracy of energy performance contracts;

(ii) simulate the influence of certain in-frame technical solutions (e.g., effectiveness or number of pre-installed washing machines);

(iii) obtain heat gain estimates per activity that are useful inputs for more accurate dynamic thermal simulations.

The originality of this work is the per-activity breakdown of domestic electricity consumption, which is vital, as occupants made aware can monitor and regulate their activities. This model could serve to build graphical displays helping occupants voluntarily reduce their consumption (via incentives, social-network emulation, diagnostics and action plan support etc.). Other similar approaches that link usage conditions to energy consumption can be found in the literature. As an illustration to highlight a couple of relevant use-phase-focused examples, Telenko (Telenko Reference Telenko2012; Telenko & Seepersad Reference Telenko and Seepersad2014) used probabilistic graphical models – a type of Bayesian network – to represent usage context as a network of factors characterized by local conditional probability distributions. Ma (Reference Ma2015) recently proposed collecting large-scale sensor data on product operation to mine usage patterns and build a usage model for LCA. He developed a predictive usage mining for life-cycle assessment (PUMLCA) algorithm to segment usage patterns and provide a more accurate estimation of environmental impact.

Figure 3. The SABEC model architecture (left side) applied to 28 activities of water and energy consumption.

Another project (Case 9) noted that ambitious building retrofits – positive externalities – to improve energy performance are often barely justified by energy savings alone. Indeed, the ROI to halve a building’s energy consumption is more than 25 years, which often discourages investors. Energy efficiency thus needs to be considered differently to be economically justified, which prompted a consortium of big French construction companies and academic partners to co-develop a new methodology called DECADIESE (Cluzel, Yannou & Costa Reference Cluzel, Yannou and Da Costa2015). Broader than an energy-efficiency focus only, DECADIESE aims to capture the sustainable value of a building with an original focus beyond the scope of classical analytic methods, by extending the perimeter of associated stakeholders to enable ambitious building projects.

Going further, Bertoluci, Leroy & Olsson (Reference Bertoluci, Leroy and Olsson2014) showed how collecting product use-phase information is crucial to determine whether a product or system is sustainable and eco-friendly. Abi Akle, Bertoluci & Minel (Reference Abi Akle, Bertoluci and Minel2013) showed that concentrated detergents branded as ‘green’ are actually slightly less environmentally friendly in practice as uninformed consumers tend to overdose them. In Case 6 (Bertoluci et al. Reference Bertoluci, Leroy and Olsson2014), it was shown that the environmental impact of olive packaging type was different in different countries depending on their packaging recycling rates, consumer food habits and olive loss rates related to packaging types.

Last, in Case 5, John Deere developed a new cotton harvesting system with a revolutionary cotton-stripping and module-making design (Quan et al. Reference Quan, Kim, Knight, Nelson and Finamore2015) that reduces harvest loss while enabling flexible configuration of cotton collection modules. Quan et al. (Reference Quan, Kim, Knight, Nelson and Finamore2015) showed that the environmental impact of a cotton field harvest depends on a series of configurations, i.e., composition of multiple machinery and equipment to ‘get the job done’ and harvesting task strategy, which is why harvester ecodesign is dependent on the ability to simulate all usage configurations and strategies.

3.4 EOL-oriented case studies

Environmental regulations have urged stronger product stewardship in product retirement and maintenance, which has resulted in a wealth of literature and industrial practices in the area of product recovery for reuse, repair, refurbishment and recycling. Successful recovery operations enable companies to gain economic advantage while complying with environmental regulations. In other words, the objective of the recovery operations is usually twofold: to maximize recovery profit and minimize adverse environmental impacts.

The nature of recovery operations, however, depends on an array of factors including product design, assembly/disassembly processes, buyback, reverse logistics, production planning, pricing of new and remanufactured products, managing product take-back timing, design upgrades etc. If remanufacturing is pursued as a viable recovery operation, for example, setting the prices for buyback and for remanufactured products directly affects total profit. In addition to pricing decisions, production planning – matching supply plan to demand plan, details of disassembly operations and production quantity – affects total profit as well.

The EOL-oriented case studies (Cases 3, 4 and 8) mainly focus on the reuse, recycling and remanufacturing aspect of a product or a system at the end of the life cycle. Cases 3 and 4 are from the automotive industry, where a part replacement decision is investigated in the remanufacturing context (Case 3) and a large-scale national level of automotive glass recycling is studied and optimized along with recycling network design (Case 4). Case 8 is for consumer electronics where product design and timing of remanufacturing were co-considered to gain economic and environmental advantages. These case studies illustrate the wide variety of products and relevant manufacturing and logistics issues considered in the EOL study category. While keeping the EOL context as the common thread in this subsection, additional details of Case 8 are provided next for illustration.

One of the core questions in EOL operations is whether product recovery operations truly benefit the company when evaluated by the sustainability pillars. A typical question could be Is a remanufactured product better than a brand-new product? (Kwak and Kim Reference Kwak and Kim2016). Case 8 offers an approach to estimating the economic and environmental benefits of EOL operations, in particular remanufacturing. Remanufacturing has time-varying benefit (i.e., timing of product take-back and remanufacturing) due to physical deterioration and technological obsolescence.

The framework in Case 8 provides a quantitative link between the nature of the product (e.g., product specification, physical and technological characteristics of each part, production costs) and the time-varying value of remanufacturing from the remanufacturer’s perspective. More specifically, the case answers the following questions:

(i) Is a remanufactured product better (both economically and environmentally) than a brand-new version of the product?

(ii) How does timing of remanufacturing affect the advantages of a remanufactured product?

(iii) How do market conditions (e.g., market preferences for a remanufactured product and customer requirements for product specifications) influence any advantages from remanufacturing?

The model incorporates two critical aspects – physical deterioration and technological obsolescence – to construct the framework for optimal production planning. It considers both economic and environmental aspects by capturing unit production cost and environmental impact savings from remanufacturing in comparison to manufacturing brand-new products. The perceived utility by customers diminishes from initial sales to EOL. After remanufacturing, the utility is increased to the level of significant improvement, although it may be lower than that at the time of the initial sale. When the product becomes a remanufactured product, the pattern of diminishing utility repeats, but possibly with a different rate of change. The logic of this model in explained in Figure 4.

Figure 4. Two components of optimal product design for life-cycle profit: initial product design and design upgrade at the EOL stage (Kwak & Kim Reference Kwak and Kim2015a).

The model specifically introduces the price ratio ( $\unicode[STIX]{x1D6FD}$;

$\unicode[STIX]{x1D6FD}$;  $0\leqslant \unicode[STIX]{x1D6FD}\leqslant 1$) of the remanufactured product to the equivalent brand-new product, which was simulated under various product recovery operations. Two distinct scenarios can be optimized with this model. First, if the price ratio is set as a certain number (e.g.,

$0\leqslant \unicode[STIX]{x1D6FD}\leqslant 1$) of the remanufactured product to the equivalent brand-new product, which was simulated under various product recovery operations. Two distinct scenarios can be optimized with this model. First, if the price ratio is set as a certain number (e.g.,  $\unicode[STIX]{x1D6FD}=0.7$, i.e., the price of the remanufactured product is 70% of the brand-new price), the model calculates the product generation up to which the net-profit advantage is maintained (e.g.,

$\unicode[STIX]{x1D6FD}=0.7$, i.e., the price of the remanufactured product is 70% of the brand-new price), the model calculates the product generation up to which the net-profit advantage is maintained (e.g.,  $t=7$), i.e., if a product is older than 7th generation ago, do not remanufacture. Second, if the age of the product is given as a fixed value, the model calculates the

$t=7$), i.e., if a product is older than 7th generation ago, do not remanufacture. Second, if the age of the product is given as a fixed value, the model calculates the  $\unicode[STIX]{x1D6FD}$ ratio for remanufactured product pricing. Additional sensitivity analysis can also be performed depending on cost and environmental impact changes for each part or manufacturing operation.

$\unicode[STIX]{x1D6FD}$ ratio for remanufactured product pricing. Additional sensitivity analysis can also be performed depending on cost and environmental impact changes for each part or manufacturing operation.

The next section proposes five ecodesign issues abstracted from the case studies and the literature as a framework to analyse the 10 case studies.

4 Identification of the five ecodesign issues

4.1 Analysis of the case studies

After sharing in-depth knowledge about each case listed above, we identified the common and major issues. We consider the following issues as representative of recent developments and new trends in ecodesign research, although we do acknowledge there may be others that are outside the scope of the case studies. We do not claim these five issues are exhaustive nor fully independent. Rather, the intent is to provide an overview to help identify common threads and lay the ground for future research topics. The five ‘ecodesign issues’ that we have identified are as follows:

(1) Optimal resource use to reduce environmental impact

(2) Managing lifespan

(3) Understanding users and usage

(4) Integrating data and analytics

(5) Defining system boundary and perimeter

4.2 Confirmation with the literature

Four of these ecodesign issues (numbers 1–3 and 5) were also identified by Pigosso, Mcaloon & Rozenfeld (Reference Pigosso, Mcaloon and Rozenfeld2015) who characterized the state of the art and future trends in ecodesign from a bibliometric analysis covering the period 1996–2015. Managing lifespan had already started to surface in the literature in the period 2006–2010, but these four issues are reported by Pigosso et al. as a subset of nine trends for future ecodesign research. Resource efficiency (issue 1) and managing lifespan (issue 2) were classified in the trend ‘Development of products and services’. Development of product–service systems is assumed to lead to high dematerialization. The main consequences will be an increase of product lifespan and optimized resource consumption. Concern to use resources optimally (issue 1) is also covered by the ‘Circular economy’ trend, where waste management and design for EOL are predominant. Pigosso et al. (Reference Pigosso, Mcaloon and Rozenfeld2015) reports issues 3 and 4 as being part of the ‘Systems thinking’ trend. The necessity to characterize interactions among subsystems requires first defining or redefining system boundaries, and second acquiring more robust information on users, usages and user behaviours. These five issues are detailed in Section 5 and then discussed in Section 6.

The fact that the case studies presented in this paper match the state of the art by Pigosso et al. serves to validate the major categories of sustainable design reported in the literature. Here, in addition to validation, we intend the in-depth knowledge and insight from our case studies to provide a more specific picture of current ecodesign practices and trends along with the perspectives for future efforts described in Sections 5 and 6. Sections 5 and 6 bring core contributions of this position paper for future research directions based on in-depth analysis of the five ecodesign issues.

5 Exploration of the five ecodesign issues

After analysis of the 10 case studies and following the analysis framework proposed in Section 2, we identified five main ecodesign issues that we go on to explain in more detail in the next subsections. Table 2 gives a roll-up of all the contributions of the 10 case studies to these five ecodesign issues.

Table 2. Contribution of the 10 case studies to the five ecodesign issues

5.1 Optimal resource use for less environmental impact

5.1.1 Context

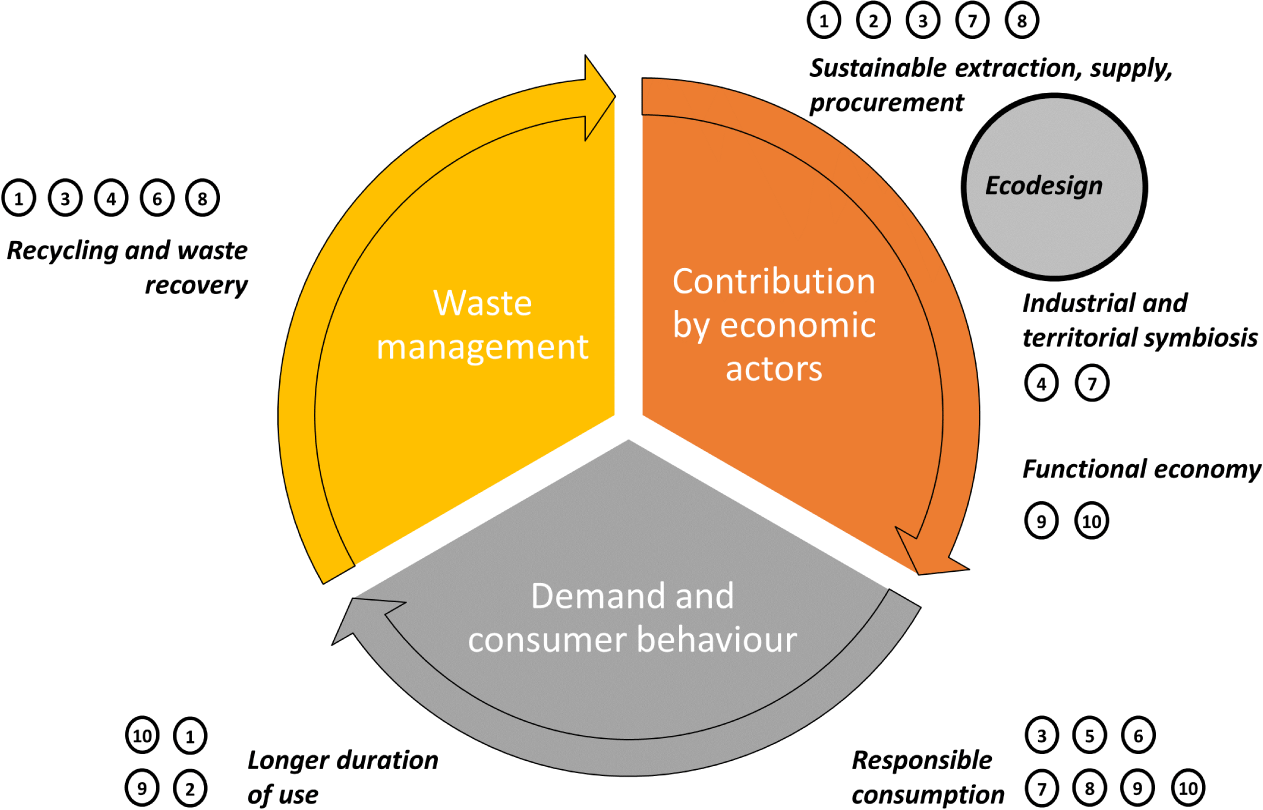

Using resources – materials and energy – optimally is one of the most obvious concerns when ecodesigning products, systems and services. As resources are finite, the simplest way to make more sustainable products and systems is to use less resource, but also to reuse and recycle existing resources where and when possible. Doing more and better with less is broadly the core concept of the circular economy, defined as an ‘economic system of exchange and production that aims to efficiently reduce the environmental impact of resource use throughout the product/service life cycle’ by the French environment and energy management agency (ADEME 2014), which subdivides the circular economy into seven axes – one of which is ecodesign (ADEME 2014):

(i) Offer of economic actors

(1) Sustainable extraction, supply, procurement

(2) Ecodesign (products and processes)

(3) Industrial and territorial symbiosis

(4) Functional economy

(ii) Demand and consumer behaviour

(5) Responsible consumption

(6) Longer duration of use

(iii) Waste management

(7) Recycling and waste recovery

Axes (5) and (6) related to consumption, demand and behaviour are directly connected with other sustainable design issues proposed in this paper: Integrating data and analytics, Understanding users and usage and Managing lifespan. From a design perspective, the other axes emerge spontaneously when we consider the question of how to promote optimal use of resources at the product or system design stage. Different strategies can be envisioned to answer this question. First, ecodesign (Axis 2) aims to minimize the environmental impact of a product throughout its life cycle. Ecodesign approaches may be seen as being mostly internal to one company and as involving one product or process – through lean and green approaches for example (Cluzel et al. Reference Cluzel, Yannou, Leroy and Millet2012) – that the company generates or uses. However, a company is likely part of a larger ecosystem encompassing other companies, territories, sectors etc. The industrial ecology (Axis 3) perspective reaches outside the traditional perimeter of a company to envision the optimization of material and energy flows across a territory. Sustainable supply (Axis 1) is another perspective that considers the origin of resources used to produce goods. Significant environmental burdens are then generated later at product EOL. Another perspective dealing with optimal resource use is of course waste management, with the ability to reintroduce secondary resources to produce new products and then to close the loop (Axis 7). The last strategy, a functional economy (Axis 4), consists in fostering a move from ownership to usage with the idea of selling services instead of products, which would hopefully mean less material intensiveness. All these strategies are closely linked and interdependent.

Decreasing resource use answers two main challenges. The first is the fact that Earth’s resources, in particular, metal and fossil resources, are finite yet depleting. Using less resources and promoting circular economies is manifestly a necessity. The second challenge is to minimize the environmental impact of products throughout their life cycle to address major environmental concerns such as climate change, ozone layer depletion, soil acidification and water eutrophication. Identifying the environmental impacts generated by products is thus a crucial task, for which there are numerous methods and tools, the most widely used being Life Cycle Assessment (LCA; International Organization for Standardization 2006).

5.1.2 Analysis of the case studies

Figure 5 shows the positioning of the 10 case studies on the seven ‘Circular Economy’ axes proposed by the ADEME. Ecodesign is of course the common denominator of these 10 cases, but this graph shows that all other axes are involved in at least two case studies, highlighting a high variety of possible strategies for ecodesign.

Figure 5. Positioning of the 10 case studies on the ADEME’s circular economy diagram.

It shows that Optimal resource use for less environmental impact is a major consideration in all 10 studies. Along with Defining system boundary and perimeter, it is the only common issue shared across all the case studies, and is thus an inescapable part of sustainable design. The other issues may be seen as directions that are complementary or emerging – but not necessarily less important – to complement or reinforce a product’s sustainable performance.

Going further, LCA is clearly predominant in case studies dealing with optimal resource use. LCA has become the major method for quantifying environmental impacts and then identifying critical areas to improve environmental performance (Millet et al. Reference Millet, Bistagnino, Lanzavecchia, Camous and Poldma2007), as done in Cases 1, 2, 3, 5, 6, 8 and 9. For example, LCA is used in Case 1 with a scenario-based approach to evaluate the environmental impacts of a set of operations scenarios (best case, most likely scenario, worst case) for large AC/DC conversion substations for aluminium smelters (Cluzel et al. Reference Cluzel, Yannou, Millet and Leroy2014). LCA results are then used as inputs to inform an eco-innovation process whose goal is to identify a set of eco-innovative R&D projects that could be deployed in the coming years (Cluzel et al. Reference Cluzel, Yannou, Millet and Leroy2016). Another example is Case 6 where LCA is used to compare three olive packaging alternatives (doypack, glass jar and steel can) in different countries (Bertoluci et al. Reference Bertoluci, Leroy and Olsson2014). Usages are taken into account to identify environmental impacts and set recommendations for the most ecodesigned solution in a specific country.

Other methods for considering optimal resource use employ simulations centred on specific indicators such as energy consumption (Cases 7 and 10), GHG emissions (Case 4) or environmental externalities that are broader than (but also include) classical LCA impact categories (Case 10). For instance, Case 4 simulates the emergence of a recycling value chain for automotive glazing. Performance indicators used to evaluate the model include not only economic aspects and material recovery but also lowering GHG emissions via energy savings. Simulations are performed using linear programming and system dynamics (Farel, Yannou & Bertoluci Reference Farel, Yannou and Bertoluci2013a; Farel et al. Reference Farel, Yannou, Ghaffari and Leroy2013b). Case 9 goes beyond the classical scope of LCA by considering more general environmental, social and economic externalities associated with a building construction or retrofit (Cluzel et al. Reference Cluzel, Yannou and Da Costa2015; Nösperger, Mazoyer & Vitt Estelle Reference Nösperger and Mazoyer2015). Positive externalities can be considered to extend the perimeter of stakeholders ready to finance part of the building, leading to more ambitious sustainable buildings with optimal use of resources and less environmental impact.

5.1.3 Confirmation with the literature

Optimal resource use for less environmental impact is undoubtedly the core concept or the raison d’ être of ecodesign. However, in classical design perspectives, the use phase is rarely considered in detail and rarely fully integrated in studies. Considering usage is an emerging field of research in building ecodesign for example (Hoes et al. Reference Hoes, Hensen, Loomans, De Vries and Bourgeois2009a,Reference Hoes, Hensen, Loomans, de Vries and Bourgeoisb). The use phase of a wide range of products (energy-using products, buildings etc.) is characterized by high variability of users’ behaviour, leading to large uncertainties.

For many authors, ecodesign has now become a core strategy of the circular economy, which is an economic system that represents a ‘change of paradigm in the way that human society is interrelated with nature and aims to prevent the depletion of resources [and] close energy and material loops’ (Prieto-Sandoval, Jaca & Ormazabal Reference Prieto-Sandoval, Jaca and Ormazabal2018). Ecodesign is now seen as an essential design strategy guided by LCA to diminish the environmental impacts often located at the distribution and use phases (Prieto-Sandoval et al. Reference Prieto-Sandoval, Jaca and Ormazabal2018) in the broader scope of the circular economy. The scientific literature has now moved towards strategies, methods and tools for developing the circular economy (see for example Gaustad et al. Reference Gaustad, Krystofik, Bustamante and Badami2018; Kalmykova, Sadagopan & Rosado Reference Kalmykova, Sadagopan and Rosado2018) to use resources optimally, especially through product design (Bocken et al. Reference Bocken, De Pauw, Bakker and van der Grinten2016). Researchers recently started to observe how ecodesign fits and serves the transition towards a circular economy (den Hollander, Bakker & Hultink Reference den Hollander, Bakker and Hultink2017; Richet et al. Reference Richet, Perry, Vautier and Roche2019). While the scholarship’s central message is still to decrease environmental impacts by decreasing or at least rationalizing resource use, this shift of vocabulary also shows that decision makers (in the industrial and political spheres) have started to more seriously consider these issues, even if the road is still long. Cultural barriers are considered the main bottlenecks for the circular economy in terms of consumer interest (driven by markets) and company culture (Kirchherr et al. Reference Kirchherr, Piscicelli, Bour, Kostense-Smit, Muller, Huibrechtse-Truijens and Hekkert2018). While Optimal resource use for less environmental impact is intuitively an obvious issue that the research community has long been tackling, constant effort is still needed to make it more tangible in industry.

While optimal resource use now appears to be a well-established direction in sustainable design approaches, Integrating data and analytics, Understanding users and usage and Managing lifespan are emerging research fields with the potential to fully incorporate the use phase in sustainable design. Finally, in order to make environmental impact assessments more reliable, particularly when involving increasingly complex systems, research on Defining system boundary and perimeter is also crucial. These four issues are expanded below.

5.2 Managing lifespan

5.2.1 Context

Managing lifespan, i.e., the lifetime of a product or system, is critical to achieving sustainability for economic and environmental reasons. Two main stakeholders – manufacturer and customer – have different perspectives that need to be evaluated when making lifetime decisions. These lifetime decisions include the following concerns:

(i) When is it time to retire a product by declaring the end-of-use stage?

(ii) What are the end-of-use options (reuse, remanufacturing, recycling or disposal) to choose from after retirement?

(iii) What are the benefits (economic or environmental) to consider?

(iv) What is the role of regulators?

(v) What are the indications from the usage data?

(vi) What are the product-specific considerations (e.g., size, weight, normal lifespan etc.)?

Take the example case of end-of-use product management: ‘Cash For Clunkers’, a government-driven car allowance rebate programme in the United States in 2009 (US DOT 2015). Different cash rebates were allowed depending on vehicle type and specifications. While the programme was widely popular, it is not clear how the rebate criteria were determined, particularly in terms of sustainability, which underlines the importance of managing a product or system’s lifespan.

One of the main challenges in managing a product or system’s lifespan is the transient aspect of time or pseudo-time (e.g., product generation; Guide et al. Reference Guide, Souza, Van Wassenhove and Blackburn2006; Bras Reference Bras2014). The nature of the product drives end-of-use decisions such as remanufacturing, recycling or disposal (Hauser & Lund Reference Hauser and Lund2003; Kwak Reference Kwak2012). However, the optimal lifetime decision may change as the advantage evolves over time (or over product generation). Remanufacturing may be more profitable and environmentally friendly at one point in time, but this profitability may shift as the value and benefit of remanufacturing change over time. At the end of product usage, a carefully planned remanufacturing scheme, with upgrades for example, could increase the utility perceived by customers. If no action is taken with prolonged usage of product, the utility diminishes without prolonging the product’s useful life. Results show the benefit of lifetime management in the context of sustainable design.

5.2.2 Analysis of the case studies

Individual case studies show different aspects of lifespan management and its challenges: uncertainties in defining the lifetime of a system (Case 1), time-dependent nature of value and preference (Case 3), uncertainty in demand evolution for recycled cullet from automotive glazing (Case 4), normalizing the lifetimes of multiple systems for a fair comparison (Case 5), trade-off between waste reduction and energy consumption (Case 7), optimal lifetime identification for higher economic value recovery (Case 8) or a long time horizon to realize the ROI (Case 9). In that sense, Figure 6 positions the 10 case studies according to the type of consideration they lend to lifespan management. Most of the cases (2, 5, 6, 9 and 10) broadly seek to extend the duration of the use phase. Cases 3 and 8 are more focused on taking the right decisions when the system product is reaching the end of a ‘first’ use phase (second life or not). Case 4 is dedicated to recycling scenarios to imagine reusing glazing in other applications. Finally, Cases 1 and 7 attempt to optimize the entire life cycle of a system or a value chain, including considerations on lifespan optimization.

Figure 6. Main concerns surrounding lifespan decisions with the 10 case studies positioned.

The importance of managing a product’s lifespan is evident when a product or system shows the following characteristics:

(i) Uncertainty in end-of-use status and timing to retire a product due to obsolescence or part failures.

(ii) Deterioration of economic or environmental characteristics: continuing usage has a significant economic or environmental downside, often due to regulations or wear and tear.

(iii) Potential benefit of end-of-use treatment: remanufacturing may bring economic benefit for the manufacturers by expanding market coverage for remanufactured products while sustaining new product sales.

Following these observations, a few of the case studies are further detailed below to highlight the importance of managing lifespan.

In the harvester case (Case 5), product lifespan tends to be long (usually more than 10 years). The life cycle of a harvester consists of manufacturing, usage, maintenance, and end-of-use treatment, where economic and environmental impact is present at every stage. There has been a wealth of LCA literature where the primary goal is to analyse the environmental impact of a product or a system (Hauser & Lund Reference Hauser and Lund2003; Smith & Keoleian Reference Smith and Keoleian2004; Gutowski et al. Reference Gutowski, Sahni, Boustani and Graves2011; Kwak Reference Kwak2012; Bras Reference Bras2014). However, few studies have compared two or more heterogeneous systems on their environmental impact due to the additional layer of complexity needed for a fair comparison. The harvester case study brings a unique contribution in this regard (Quan et al. Reference Quan, Kim, Knight, Nelson and Finamore2015). Two different sets of product systems (old versus new harvester models) sharing the same objective (harvesting cotton crops) were compared on environmental impact to show which system is better and why. Old and new systems are composed of different sets of machinery and equipment, which makes it difficult for a fair comparison between the two. The harvester case study provides a common task to be completed, and each contributing machine’s impact is measured with consideration of the entire life cycle.

In the consumer electronics case (Case 8), product lifespan tends to be short (e.g., 12–24 months for cell phones). Compared to the harvester case, technological obsolescence has a much more significant role to play in sustainable product design and remanufacturing decisions (Bras Reference Bras2014; Kwak Reference Kwak2016). New generations of consumer electronics with emerging technological features make it to market at a much faster pace than for agricultural equipment. As a result, in making end-of-use treatment decisions, it is critical to factor in the time-varying aspect of product value (Guide et al. Reference Guide, Souza, Van Wassenhove and Blackburn2006; Kwak & Kim Reference Kwak and Kim2011). For example, remanufacturing may be desired for a cell phone, but if the phone is too old, it will be difficult to sell at a profit in the remanufacturing market. Both consumers and manufacturers therefore need to recognize that there is a window of opportunity in making product retirement decisions. The consumer electronics case study provides a quantitative framework to guide optimizing this type of remanufacturing decision by ensuring economic profitability and environmental friendliness (Kwak and Kim 2016).

The automotive axle case (Case 3) showed that the time frame of a maintenance operation determines the type of sustainable options available and the role of regulators. Unlike the harvester and consumer electronics cases, the automotive axle case concerns replacing a part rather than a whole product. Vehicle owners tend to prefer a new replacement part when the product is relatively new but prefer a remanufactured part when the product’s residual value is low (i.e., on older vehicles; Ovchinnikov Reference Ovchinnikov2011; Ovchinnikov, Blass & Raz Reference Ovchinnikov, Blass and Raz2014). The challenge is that a remanufactured product brings environmental benefit but with a loss of economic benefit, i.e., a remanufacturer loses money by selling a remanufactured axle due to its lower price (Mitra Reference Mitra2007; Vadde, Kamarthi & Gupta Reference Vadde, Kamarthi and Gupta2007; Kwak & Kim Reference Kwak and Kim2012). For this particular case study, the data was collected for the Korean automotive market, where the government is looking to promote the remanufacturing business. With remanufacturers clearly losing money, the government needs to determine the amount of subsidy to give them, which is calculated based on sensitivity analysis. The axle case study provides a quantitative framework by which regulators can decide whether any economic incentive should be provided and how much subsidy to allocate for a particular industry or market.

5.2.3 Confirmation with the literature

In addition to the cases described above, recent papers confirm the importance of managing product lifespan for sustainable design. Product lifespan management for sustainability includes reuse of the product itself, maintenance, repair, and technology upgrades for remanufacturing (and/or refurbishment) (Bocken et al. Reference Bocken, De Pauw, Bakker and van der Grinten2016). Below we cite the notable recent work on this topic.

Aydin, Kwong & Ji (Reference Aydin, Kwong and Ji2015) provided a methodology to consider new and remanufactured products simultaneously in product line design (PLD) to acquire maximum profit and product market share. The method determines the specifications of new and remanufactured products and the time for launching remanufactured products. Aydin, Kwong & Ji (Reference Aydin, Kwong and Ji2016) also focused on PLD for which supply chain partners work with remanufacturers to maximize total profit from new and remanufactured products.

Bobba, Ardente & Mathieux (Reference Bobba, Ardente and Mathieux2016) proposed a set of indicators, called ‘Pro-EnDurAncE’ to assess product durability from both environmental and economic perspectives. The indicators capture various relevant aspects such as impact and cost of keeping and replacing products, maintenance and repair, lifetime extension and use of energy and auxiliary materials during operation. Based on the indicators, the decision whether to replace a product or extend its life was evaluated in terms of environmental and economic benefits.

Iraldo, Facheris & Nucci (Reference Iraldo, Facheris and Nucci2017) investigated whether extended durability is beneficial both environmentally and economically. LCA and LCC were applied to compare scenarios of durable versus standard options for managing life-cycle length. For the case studies of a refrigerator and electric oven (i.e., energy-using products), increased durability (i.e., extending life) was shown to be practically always economically beneficial, while the environmental impact of manufacturing and EOL treatment determines whether increased durability is a preferred option.

Kwak (Reference Kwak2016) proposed an index to measure the ‘greenness’ of product lifetime extension. The greenness index reflects the nature of a product, including the intensity of remanufacturing, technological trends and their influence on product design and user satisfaction, and the intensity of customer use in terms of environmental impact. The index provides a more comprehensive assessment as to the effectiveness of extending product lifetimes, which could be used to evaluate a variety of products.

Kim & Moon (Reference Kim and Moon2017) utilized the benefits of a product family to prolong the lifespan of a product by sharing new and remanufactured modules. The sustainability was mathematically modelled by considering the three pillars of sustainability: economic, environmental and social performance. Also, Wang et al. (Reference Wang, Tang, Li, Yang, Salido, Giret and Zhu2019) presented an optimization model to determine product family design and remanufactured products’ configuration designs to maximize the total profit and the total GHG emission from production.

Kwak (Reference Kwak2018) proposed an optimal way to differentiate new and remanufactured products’ configuration designs that can overcome the effects of potential cannibalization of new product sales and technological obsolescence of used products, which are barriers to remanufacturing, while maximizing total profit and market share.

Ma & Kremer (Reference Ma and Kremer2015) provided a systematic method for evaluating the EOL options of components considering the sustainability and subjective perception of the designer’s sustainability. Cong, Zhao & Sutherland (Reference Cong, Zhao and Sutherland2019) proposed a methodology to determine recovery strategies for end-of-use components and optimal new product design to improve product recyclability for circular economy.

Wang et al. (Reference Wang, Wang, Mo and Tseng2017) showed the impact of component commonality decisions in product family design on component reuse in remanufacturing with respect to introduction time of the second generation of product family and durability of components. Kim & Kim (Reference Kim and Kim2019) applied the benefits of generational commonality to prolong the lifespan of components by sharing components between successive generations. This study investigated the impact of generational commonality of short-life-cycle products in manufacturing and remanufacturing processes.

Mesa, Esparragoza & Maury (Reference Mesa, Esparragoza and Maury2018) proposed a set of indicators to measure sustainability performance in product families for a robust framework for sustainable product design. The indicators were expanded to cover product families, unlike those for a single product that was presented in previous studies, which are mainly classified as sustainability performance indicators and functional performance indicators. Such indicators are measured sustainability of product families that encourages the implementation of the circular economy model.

This recent literature demonstrates that managing product lifespan is a relevant issue. The highlights above provide insight into the breadth and depth of lifetime management. While the insights come from observations of recent case studies, there are also other interesting research questions and opportunities. Section 5 identifies and expands on a new set of research challenges.

5.3 Understanding users and usage

5.3.1 Context

Understanding users and usage contexts is hugely important for making sure that designed products and services are effectively ecodesigned. Due to various restrictions and limitations, companies usually have little information available to answer the following questions:

(i) What is the average (or distribution of) product lifespan? Are products always as reliable and used as much as expected?

(ii) Are products disposed of due to real obsolescence or perceived obsolescence?

(iii) What are the reasons for EOL: not repairable, repairable but too expensive, and real/perceived/planned obsolescence? Does the market assign some value to a second life of the product? Are the products properly returned by users and effectively collected for adequate dismantling and recycling?

(iv) Do users properly maintain their products, i.e., follow maintenance guidelines?

(v) Do users responsibly eco-operate their high-energy-consumption products?

But the sustainability property of a product or service often surfaces later on in real usage, which mirrors the durability and recyclability conditions with a high degree of variability and uncertainty. This is why product sustainability requires investigation into users, usage situations and product usage modes.

5.3.2 Analysis of the case studies

Usage scenarios are known to be made of usage context and user profile to simulate product performance in the specific issue settings described above in the questions on modelling and simulating product lifespans, perceived or real/planned product obsolescence, product maintenance, product use and reasons for product end of use and product disposal. Each of these issues warrants consideration to assess the environmental impact of a product line in its category and to determine whether a product family is ecodesigned. These issues appear in Figure 7, where the 10 case studies are positioned. Note some cases deal with maintenance and obsolescence considerations. There is explicit reflection on lifespan in 6 out of the 10 case studies, in accordance with Section 4, while EOL and disposal are considered in 5 case studies. However, 8 of the 10 case studies explicitly give focus to user habits and how they influence the environmental impacts of a product or system, revealing a real focus for research.

Figure 7. Main concerns dealing with usage, and position of the 10 case studies.

Most of the 10 case studies presented in this paper directly consider users and usage. However, we can distinguish two different perspectives. The first considers end users, consumer behaviours and preferences. The approaches concerned deal for example with user observation, preference elicitation and statistical models in order to make products more sustainable regardless of their usage context. This is shown in case studies 3, 5, 6, 7, 8, 9 and 10.

The second is a manufacturer (or company) perspective, as shown in case studies 2 and 4, where the companies consider client data and market conditions. This perspective therefore deals with more collective, large-scale user and usage data in the intermediate value-chain stage.

In the automotive axle case study (Case 3), both new and remanufactured parts (CV joints) are available to customers, at different prices (i.e., cheaper for remanufactured parts). For CV joints, consumer preference was captured through market demand data in Korea. Remanufactured CV joints bring environmental benefit, but at lower profit as remanufactured CV joints are cheaper to buy. Current market data on sales prices of new and remanufactured CV joints shows that without regulatory subsidization, pursuing remanufacturing business is beneficial for the environment at the expense of profitability. Market sensitivity analysis in Case 3 shows how customers’ preferences affect potential business strategy and regulatory policy.

In the forge furnace case study (Case 2), different customer profiles were modelled to study the variability of potential environmental impacts in different operation contexts. Three profiles were considered, from a customer with no environmental stakes and a short-term economic vision to another considered as an environmental champion with a long-term economic vision, and a third profile midway between the two. These profiles impact the importance customers give to the costs (CAPEX and OPEX) and different environmental categories (global warming potential, ozone layer depletion, human toxicity, fossil depletion, and recycling/reuse). Even if these profiles are theoretical, results show that the manufacturer would recommend different decisions on the best technology to choose according to these profiles, showing the importance of considering industrial usages in the exploitation of industrial systems.

5.3.3 Confirmation with the literature

In addition to the cases described above, the recent literature confirms the importance of understanding users and usage for sustainable design. Below we cite the most notable recent works on this topic.

The recent scholarship has started modelling user habits. Green et al. (Reference Green, Tan, Linsey, Seepersad and Wood2005) emphasized the importance of understanding and representing usage contexts for simulating a product’s design performances. Yannou et al. (Reference Yannou, Chen, Wang, Hoyle, Drayer, Rianantsoa, Alizon and Mathieu2009) and He et al. (Reference He, Chen, Hoyle and Yannou2012) showed how to identify a series of key variables for featuring usage scenarios that influence performance and utility. This new usage-centred market segmentation approach was used to build a market share prediction model for a hybrid car model by the choice modelling technique in He et al. (Reference He, Chen, Hoyle and Yannou2012) and by collecting human appraisals in different usage contexts, which was named usage-context-based design. Yannou et al. (Reference Yannou, Yvars, Hoyle and Chen2013) proposed the usage coverage model based on physics-based performance simulations under usage scenarios. Constraint programming techniques were used to compute usage coverage indicators under physical and behavioural uncertainties and usage segment domains.

Tuarob & Tucker (Reference Tuarob and Tucker2015) presented an automated approach to lead user product-feature identification. Their study assumed that the product features desired by lead users do not yet exist but will be desired by the general customer. It is also assumed that the lead users can be found through social media. The authors collected social media messages from the United States during a period of 31 months to determine whether lead user preferences are relevant to next-generation cell phone designs.

Zhou, Jiao & Linsey (Reference Zhou, Jiao and Linsey2015) proposed a two-layer model for latent customer needs elicitation through use case reasoning. The first layer is to identify explicit needs from online product reviews. The second layer is to identify implicit needs by reasoning the semantics of use cases.

Fuge & Agogino (Reference Fuge and Agogino2015) led a study on identifying appropriate design methods to uncover user needs and preferences in an unfamiliar context, especially in developing regions. They applied a series of statistical techniques to learn how user research methods are used in practice in the developing regions, and found that certain methods are consistently used in certain types of problems and that certain methods complement each other.

Wang & Chen (Reference Wang and Chen2015) introduced a data-driven network analysis based approach to predict individual choice sets for customer choice modelling in engineering design. The analysis consists of the following major steps: (1) classify customers into clusters based on their profile attributes; (2) construct a product association network that reflects the similarity of products in customers’ perceptual space; and (3) predict choice sets for individual customers using a probabilistic sampling approach.

Zaraket et al. (Reference Zaraket, Yannou, Leroy, Minel and Chapotot2015) proposed an activity-based model for forecasting household energy and water consumption and discussed how such an occupant-focused model could integrate a user-focused design for residential buildings. The consumption prediction is closer to reality compared to the standard averaged energy consumption profiles.

Cor et al. (Reference Cor, Domingo, Brissaud and Zwolinski2014), Cor & Zwolinski (Reference Cor and Zwolinski2015) developed a protocol to integrate user behaviour into the ecodesign of low-complexity consumer products. The protocol is composed of the following steps: (1) identify critical environmental aspects in use; (2) support designers to select a design strategy for sustainable behaviour after analysis of the use phase; and (3) test the selected strategy with product-in-use observations. Polizzi di Sorrentino, Woelbert & Sala (Reference Polizzi di Sorrentino, Woelbert and Sala2016) also used behavioural science to better model use phase in LCA and come up with realistic scenarios as basis for a behaviour-driven ecodesign and eco-innovation.

Sabbaghi & Behdad (Reference Sabbaghi and Behdad2017) investigated the impact of component deterioration profiles and consumer repair decisions on device lifespans and assessed the anticipated life-cycle environmental impact. The life-cycle characteristics were estimated by Monte Carlo simulation. In the same manner, Popoff, Millet & Pialot (Reference Popoff, Millet and Pialot2016) investigated the impact of usage ecodrifts, i.e., nonoptimal use of a product by the users, on energy overconsumption (real-time impacts) and abnormal wear and tear of parts of the product (delayed impacts).

Many studies have explored the effects of behavioural changes while the development of digital devices has increased (Pothitou, Hanna & Chalvatzis Reference Pothitou, Hanna and Chalvatzis2016). Others have studied how design could be used to influence consumer behaviour towards more sustainable practices. For instance, Lilley (Reference Lilley2009) proposed three strategies to incentivize sustainable behaviour: eco-feedback, behaviour steering and persuasive technology. The expression Design for Sustainable Behaviour (DfSB) is used by Boks (Reference Boks, Matsumoto, Umeda, Masui and Fukushige2012) and Daae & Boks (Reference Daae and Boks2015).

Picon et al. (Reference Picon, Yannou, Zaraket, Minel, Bertoluci, Cluzel and Farel2013) proposed a principle of residence-level mapping and storing of household consumption data as well as indications on geo-localized complaints on a residence map. This mapping may be useful for monitoring energy and water consumption of any household in (real) time and comparing it to that of comparable households for potential renovation projects by building designers. Capturing a household’s electricity and water usage data in the cloud or organizing a residence memory may in return provide useful information feedbacks to the consumers themselves. All the actors – residents, building administrator, construction/renovation company – need to voluntarily adopt the proposed renovation and design for the next generation of buildings. Kuo et al. (Reference Kuo, Tseng, Lin, Wang and Lee2018) used smart meters to provide energy information on real-time consumption and explore energy consumer behaviour with socio-demographics, pro-environmental behaviour and goal-directed behaviour.

We are undoubtedly at the beginning of an era in which data will be managed for designing adapted and energy-frugal products (i.e., zero energy use) and for monitoring product usage phases. This takes us to the next subsection.

5.4 Integrating data and analytics

5.4.1 Context

Data from various life-cycle stages of products and systems are becoming readily available, and data analytics is now more critical than ever for sustainable design. Measuring performance along the three sustainability pillars is becoming more affordable due to advancements in sensor technologies, which in turn leads to further improvement in sustainable product and system designs. Several approaches, such as carbon footprint measurement, LCA, LCC, activity-based costing, social life-cycle assessment or hybridization of tools, all provide useful solutions. However, the downside of measuring sustainable performance is that it creates issues with acquiring, managing and analysing the data. The main issues in dealing with data are charted in Figure 8, where the case studies are positioned according to the analysis proposed below.

Figure 8. Main problems arising from data acquisition in the 10 case studies with different approaches (LCA, value-chain assessment or other types of eco-evaluation).

Life-cycle decisions usually integrate the entire life cycle of a product, service or system. In order to support such decision-making processes, several kinds of information need to be collected throughout the life cycle. First, bills of materials are a requisite for assessing the environmental impact of a system. Nature and amount of materials contained and consumed or emitted by the system are used to calculate the environmental impact. Cases 1, 2, 3, 5, 6, 8 and 9 evaluated this environmental impact, as all of them performed LCAs. In an open and global market, where components come from several locations to be assembled and where systems are sold in other locations, it is difficult to know the exact material content of components and the associated manufacturing processes. The information required essentially spans raw material extraction through to manufacturing life-cycle stages. Traceability and data exchange between stakeholders, e.g., producers/suppliers, suppliers/suppliers or producers/end users, is a prerequisite for more systematic evaluation. The next subsection briefly summarizes the case studies in terms of data and analytics context and then looks at other recent papers on this topic.

5.4.2 Analysis of the case studies

Data traceability is particularly challenging when it involves consumer consumption and demographic data. This issue is particularly significant for food production and its final clients (Case 7). One of the main challenges revolves around how to share confidential information and sustainable benefits between economic partners in a value chain or their stakeholders (Sarkis, Zhu & Lai Reference Sarkis, Zhu and Lai2011; Grimm, Hofstetter & Sarkis Reference Grimm, Hofstetter and Sarkis2014). The issue of data availability is a common thread across all the life-cycle stages, including packaging, transport, usage and EOL management. Public or commercial databases usually help overcome the data availability issue by providing specific life-cycle inventories (Finnveden et al. Reference Finnveden, Hauschild, Ekvall, Guinée, Heijungs, Hellweg, Koehler, Pennington and Suh2009). This practice will gain more traction in coming years thanks to increased awareness of environmental issues, animal well-being, local production or sustainable fair trade. In order to accommodate the demand for more transparency and environmental information, industries are increasingly leveraging environmental communications instruments such as ecolabels (Thøgersen, Haugaard & Olesen Reference Thøgersen, Haugaard and Olesen2010). These approaches force them first to evaluate their own products and processes, second to communicate with their economic partners and third to generate and disseminate up-to-date information.

Although data may be accessible for existing systems, acquiring massive-scale data is still bottlenecked (Reap et al. Reference Reap, Roman, Duncan and Bras2008; Pryshlakivsky & Searcy Reference Pryshlakivsky and Searcy2013), chiefly by the static aspect of the data, the lack of knowledge or detailed information about some life-cycle stages and relevancy when moving from generic to specific data and from global to local context.

The static aspect of data generated by most of the existing tools and approaches and the major data collection effort required for tackling sustainability issues are often sources of data inaccuracy. Information may be obsolete and limited to a specific system, area or operational conditions. In addition, as collecting information is expensive, it is not unusual to only have access to a single value for one parameter instead of a complete statistical dataset (Leroy & Froelich Reference Leroy and Froelich2010). As a result, uncertainty is still high, which has prompted practitioners to develop several strategies to overcome the uncertainty. In Case 1 for example, where the lifespan of the substation and its use phase are uncertain, the authors performed scenario-based analysis to capture the range of environmental performances (Cluzel et al. Reference Cluzel, Yannou, Millet and Leroy2014). The use of expert data, assumptions, estimations and approximations is also common practice to overcome data gaps. The life-cycle inventory, i.e., the energy and material streams consumed and emitted by the system during its entire life cycle, for example the oxy-fuel system in Case 2 or the profitability model in Case 3, is also based on estimations.