1. Introduction

Convection between two superimposed horizontal immiscible fluid layers has received considerable attention since this process resembles multilayer turbulent convection, which occurs widely in nature (Olson, Silver & Carlson Reference Olson, Silver and Carlson1990; Neelin, Latif & Jin Reference Neelin, Latif and Jin1994; Tackley Reference Tackley2000). Previous works have suggested that convection in the Earth's mantle may occur in two layers separated by an interface at a depth of 600 km (Richter & Johnson Reference Richter and Johnson1974; Busse Reference Busse1981). The planetary mantle and buoyant lithosphere interact strongly with each other. In industrial applications, multilayer thermal convection is associated with the liquid-encapsulated crystal growth technique (Prakash & Koster Reference Prakash and Koster1994). Therefore, the study of Rayleigh–Bénard convections (RBCs) with multilayer fluids is crucial.

RBC, in which a fluid layer confined between two horizontal parallel plates is cooled from above and heated from below, has been studied extensively as an idealised model of thermal convection. The flow exhibits different properties in various regimes for a wide range of finely tuned parameters. In the conduction, convection, chaos, transition and turbulence regimes, the heat transport and flow structure of RBC have been studied experimentally and theoretically (for reviews, see Bodenschatz, Pesch & Ahlers Reference Bodenschatz, Pesch and Ahlers2000; Ahlers, Grossmann & Lohse Reference Ahlers, Grossmann and Lohse2009; Lohse & Xia Reference Lohse and Xia2010; Chillà & Schumacher Reference Chillà and Schumacher2012). The multilayer RBC system is similar to a traditional single-layer RBC in which different immiscible fluids are used that due to their different densities form multiple layers on top of each other. Since the temperature derivative of the interfacial tension is negative, in the system heated from below the local gradient of temperature can drive convective motion if viscous and thermal dissipation are overcome. Thus, thermocapillary forces are destabilising in the lower layer and buoyancy forces are destabilising in both layers since the system is unstably stratified. But in the upper layer thermocapillary forces are stabilising. The two-layer convection is also called Rayleigh–Bénard–Marangoni convection. The term Marangoni implies that surface tension plays an important role if the buoyancies of the fluid in both layers are in the same order and both dominate the flow.

To date, most previous studies on two-layer RBC have been conducted in the non-turbulent regime (see Nataf, Moreno & Cardin Reference Nataf, Moreno and Cardin1988; Prakash & Koster Reference Prakash and Koster1994; Juel et al. Reference Juel, Burgess, McCormick, Swift and Swinney2000; Busse & Petry Reference Busse and Petry2009; Diwakar et al. Reference Diwakar, Tiwari, Das and Sundararajan2014). In the non-turbulent regime, the mechanism leading to instability and the cellular patterns near the onset of convection are the main subjects of the previous work (see also Johnson & Narayanan (Reference Johnson and Narayanan1997, Reference Johnson and Narayanan1999) and references therein). The rich variety of phenomena occurring in the two-layer RBC results in part from their huge parameter space. Note that in the non-turbulent regime, two layers of fluid were usually confined in a gap with a thickness in the order of 1 mm. Theoretically, the onset of convection is a function of the height ratio and Marangoni number, but independent of the Prandtl number. This is generally studied with linear instability theory. The secondary instability or further instability is involved in weakly nonlinear instability theory. In liquid–gas system, also called Bénard–Marangoni convection, theories predict a subcritical bifurcation from conduction to convection (Scanlon & Segel Reference Scanlon and Segel1967; Schatz et al. Reference Schatz, VanHook, McCormick, Swift and Swinney1995) and the further evolution to planform patterns (Schatz et al. Reference Schatz, VanHook, McCormick, Swift and Swinney1999). In a two-liquid-layer system, the variety of convective mechanisms is greatly enhanced in the liquid–liquid system due to the interaction between the flows in each of the superposed liquid layers. When the two-liquid-layer system is heated either from above or below, the convective motion at the onset can be oscillatory (Clever & Busse Reference Clever and Busse1974). When thermocapillarity is negligible, thermal and viscous couplings between the convection rolls in each layer can compete to generate time-dependent behaviour (Renardy & Renardy Reference Renardy and Renardy1985; Rasenat, Busse & Rehberg Reference Rasenat, Busse and Rehberg1989; Degen, Colovas & Andereck Reference Degen, Colovas and Andereck1998). When thermocapillarity is dominant, generally in the two-layer RBC heated from the top, the competition between stabilising and destabilising forces in each layer may also lead to oscillatory convection at onset (Johnson & Narayanan Reference Johnson and Narayanan1999; Juel et al. Reference Juel, Burgess, McCormick, Swift and Swinney2000). The non-Boussinesq effect (Lyubimov et al. Reference Lyubimov, Lyubimova, Alexander and Lobov1998), the influence of surface deformation (Regnier, Dauby & Lebon Reference Regnier, Dauby and Lebon2000; Lyubimov et al. Reference Lyubimov, Lyubimova, Lobov and Alexander2018) has been analysed theoretically. As a comparison, in single-layer Rayleigh–Bénard systems, the onset of convection occurs as the heat transport grows through a supercritical bifurcation with increasing Ra (Hébert et al. Reference Hébert, Hufschmid, Scheel and Ahlers2010). Oscillatory convection is only found as a secondary instability (Clever & Busse Reference Clever and Busse1974; Croquette Reference Croquette1989). For a long time, Marangoni convection in two-liquid-layer systems was an interesting theoretical problem but too difficult to handle experimentally. The experimental results of the planform pattern were mainly obtained by the shadowgraph method. The deformation of the interface is difficult to observe.

Recently two-layer RBC in the turbulent regime has drawn a lot of attention. The investigation on turbulent two-layer RBC has been made through simulations and experiments in the sample with different geometries. In the turbulent regime, the thermal boundary layer (BL) is another important structure. The plumes are emitted and detached from thermal BL, and then a group of plumes is self-organised to form a quasi-two-dimensional structure, so-called large-scale circulation (LSC). The coupling mechanism between the LSC in each layer is the topic of the experiment by Xie & Xia (Reference Xie and Xia2013) and simulation by Yoshida & Hamano (Reference Yoshida and Hamano2016). Yoshida & Hamano (Reference Yoshida and Hamano2016) also determined the effect of viscosity contrast between two layers of fluid on the two-layer RBC. The simulations by Liu et al. (Reference Liu, Chong, Wang, Ng, Verzicco and Lohse2021) explored a case with interface breakup. Liu et al. (Reference Liu, Chong, Yang, Verzicco and Lohse2022) revealed the enhancement of heat transport in multiphase RBC with two-dimensional simulation. Huang et al. (Reference Huang, Xu, Wang, Wang, He and Tong2022) experimentally measured the thermal BL on the liquid–liquid surface in a two-layer RBC, in which both layers of fluid are fully developed turbulence. They found that the time-averaged temperature and the variance follow the theoretical result of RBC over a solid surface with a slip length. In the turbulent regime, there are more aspects of flow structures that need to be explored by the experiment.

Here we fill the gap in the research of two-layer RBC with an experiment, in which the lower layer of fluid undergoes the transition from conduction to convection and the upper layer of fluid has reached a turbulent regime. In the present work, in addition to the heat transport measurement, we also adopted a shadowgraph method to visualise the two-layer RBC from the side. The flow structure in each layer of fluid and the interface can be measured. In such a configuration, one might consider the interfacial surface for the lower layer as a free surface with a random driving force. The theoretical value of the critical Rayleigh number in RBC with a rigid boundary and a free surface can be verified experimentally. When the fluid of the lower layer is dominated by conduction or the convection is negligible, one can assume that the interfacial surface provides a slip boundary condition (BC). Then the effect of the slip BC on the turbulent RBC can be studied in such a configuration. In the present work, we studied the flow structures of silicone oil with no-slip BC at the top and slip BC above the interface. The experimental result showed that these two BCs cause two different shapes of plumes.

In the remainder of the paper, we define the parameters relevant to the system in § 2. The experimental apparatus is described in § 3. The experimental results and discussion are presented in § 4. In particular, we report the first experimental observation of the temperature at the interface with an abnormal oscillation. The heat transport and the flow field in two-layer RBC are also presented. A brief summary of the work is given in § 5.

2. Relevant parameters

We investigate a system of two layers of immiscible and incompressible liquids of thickness ![]() $h_{i}$ with densities

$h_{i}$ with densities ![]() $\rho _{i}$, kinematic viscosities

$\rho _{i}$, kinematic viscosities ![]() $\nu _{i}$, coefficients of volume expansion

$\nu _{i}$, coefficients of volume expansion ![]() $\alpha _{i}$, heat diffusivities

$\alpha _{i}$, heat diffusivities ![]() $\kappa _{i}$ and thermal conductivities

$\kappa _{i}$ and thermal conductivities ![]() $\lambda _{i}$, where the subscript

$\lambda _{i}$, where the subscript ![]() $i=1(2)$ denotes the lower (upper) fluid (see figure 1). The system is bounded in the vertical direction by two solid walls. The conducting bottom plate is regulated at temperature

$i=1(2)$ denotes the lower (upper) fluid (see figure 1). The system is bounded in the vertical direction by two solid walls. The conducting bottom plate is regulated at temperature ![]() $T_b$, while the top plate is controlled at temperature

$T_b$, while the top plate is controlled at temperature ![]() $T_t$. The temperature located at the centre of the initial interfacial surface is measured as

$T_t$. The temperature located at the centre of the initial interfacial surface is measured as ![]() $T_{int}$. The interfacial tension and the temperature coefficients are not known for liquid combinations. But they can be estimated using Antonow's rule (Casper Reference Casper1977), which states that the interfacial tension between two liquids is equal to the difference between their surface tensions in the air. Thus, we include the surface tension and its temperature coefficient for each liquid, when available. The interface between the two fluids is assumed to be flat and to lie in the

$T_{int}$. The interfacial tension and the temperature coefficients are not known for liquid combinations. But they can be estimated using Antonow's rule (Casper Reference Casper1977), which states that the interfacial tension between two liquids is equal to the difference between their surface tensions in the air. Thus, we include the surface tension and its temperature coefficient for each liquid, when available. The interface between the two fluids is assumed to be flat and to lie in the ![]() $x\unicode{x2013}y$ plane of the coordinate system.

$x\unicode{x2013}y$ plane of the coordinate system.

Figure 1. (a) A diagram of the RBC cell. The various parts of the cell are explained in the text. (b) Photograph of the apparatus. (c) Photograph of the lower part of the cell. The red boxes indicate the thermistors, which are located at the interface and 10 mm above the interface.

The interface for the experiments presented here does not break up, which is supported by the shadowgraph image taken in the experiment. In the time-averaged sense, the temperature of the interface is assumed to be constant in the horizontal direction. The temperature of the interface then is measured by thermistors located at the centre of the interfacial surface ![]() $T_{int}$. The dimensionless control parameters of individual layers are described as the Prandtl number

$T_{int}$. The dimensionless control parameters of individual layers are described as the Prandtl number

the Rayleigh number

where ![]() $\varDelta _{i}$ is the temperature drops across each layer of fluid. The temperature drop across the lower layer is

$\varDelta _{i}$ is the temperature drops across each layer of fluid. The temperature drop across the lower layer is ![]() $\varDelta _{1}=T_{b}-T_{int}$. The temperature drop across the upper layer is

$\varDelta _{1}=T_{b}-T_{int}$. The temperature drop across the upper layer is ![]() $\varDelta _{2}=T_{int}-T_{t}$.

$\varDelta _{2}=T_{int}-T_{t}$.

The surface tension of the interface has a stronger influence on the lower layer of fluid than the upper layer. In contrast to the gas–liquid system, the surface tension ![]() $\gamma$ of the interface in liquid–liquid system is the competition of surface tension of two liquids

$\gamma$ of the interface in liquid–liquid system is the competition of surface tension of two liquids ![]() $\gamma =\lvert \gamma _{1}-\gamma _{2}\rvert$. To characterise the influence of the surface tension on the instability, here only the Marangoni number for the lower layer of fluid is defined as

$\gamma =\lvert \gamma _{1}-\gamma _{2}\rvert$. To characterise the influence of the surface tension on the instability, here only the Marangoni number for the lower layer of fluid is defined as

The Marangoni number compares the rate of transport due to Marangoni flows, with the rate of transport of diffusion.

The two-layer RBC can be described by an alternative non-dimensional control parameter, the Weber number is adopted from Huang et al. (Reference Huang, Xu, Wang, Wang, He and Tong2022) and it is defined as follows:

The ![]() $We$ is the ratio of inertial to surface tension. The work conducted by Liu et al. (Reference Liu, Chong, Wang, Ng, Verzicco and Lohse2021) has shown that the interface eventually breaks up when

$We$ is the ratio of inertial to surface tension. The work conducted by Liu et al. (Reference Liu, Chong, Wang, Ng, Verzicco and Lohse2021) has shown that the interface eventually breaks up when ![]() $We$ is larger than a critical value. In the present work, The We number is much smaller than the previous literature (Huang et al. Reference Huang, Xu, Wang, Wang, He and Tong2022) that claims the interface was not broken up.

$We$ is larger than a critical value. In the present work, The We number is much smaller than the previous literature (Huang et al. Reference Huang, Xu, Wang, Wang, He and Tong2022) that claims the interface was not broken up.

The exact definition of the Nusselt number is

Here ![]() $\langle {\cdot }\rangle _A$ denotes the average over (any) horizontal plane and over time, and

$\langle {\cdot }\rangle _A$ denotes the average over (any) horizontal plane and over time, and ![]() $u_z$ denotes the vertical component of the fluid velocity.

$u_z$ denotes the vertical component of the fluid velocity.

In the experiment of two-layer RBC, it is hard to calculate the Nusselt number of each layer over the liquid–liquid surface from the exact definition. On the solid–liquid surface in traditional RBC, the convective term ![]() $\langle u_z T\rangle _A$ equals 0 due to the no-slip BC. The solid plates are generally set to be isothermal due to the great thermal conductivity of metal material. In the individual layer of fluid in two-layer RBC, the temperature of the interface is assumed to be constant and independent of spatial position. Although the convective term

$\langle u_z T\rangle _A$ equals 0 due to the no-slip BC. The solid plates are generally set to be isothermal due to the great thermal conductivity of metal material. In the individual layer of fluid in two-layer RBC, the temperature of the interface is assumed to be constant and independent of spatial position. Although the convective term ![]() $\langle u_{z}T\rangle$ is not zero at the interface, the Nusselt number of individual layer is still calculated by the equation

$\langle u_{z}T\rangle$ is not zero at the interface, the Nusselt number of individual layer is still calculated by the equation

In the present work, measurement on a traditional RBC with only a single layer of silicone oil was also conducted for comparison. The subscript ‘![]() $i=0$’ is denoted to the quantities measured in traditional RBC with only silicone oil. The cell height is

$i=0$’ is denoted to the quantities measured in traditional RBC with only silicone oil. The cell height is ![]() $h_0 \equiv (h_1 + h_2)$.

$h_0 \equiv (h_1 + h_2)$.

3. Apparatus and performance

3.1. Apparatus

The convection cell has a design similar to that used by Huang & Xia (Reference Huang and Xia2016) and is shown in figure 1. Briefly, the convection cell has a rectangular sidewall (C) with length ![]() $L_{x} = 130$ mm, width

$L_{x} = 130$ mm, width ![]() $L_{y} = 13$ mm, and height

$L_{y} = 13$ mm, and height ![]() $h_0 = 258$ mm. The cooling (D) and heating plates (B) consist of

$h_0 = 258$ mm. The cooling (D) and heating plates (B) consist of ![]() $38$ mm thick copper and a nickel-coated surface. The cell is heated by a resistive heater attached to the back of the bottom plate, and the cell is cooled by a refrigerated circulator that passes temperature-controlled water through a chamber fitted to the top plate. Six thermistors (Honeywell, model 112-104KAJ-B01, with

$38$ mm thick copper and a nickel-coated surface. The cell is heated by a resistive heater attached to the back of the bottom plate, and the cell is cooled by a refrigerated circulator that passes temperature-controlled water through a chamber fitted to the top plate. Six thermistors (Honeywell, model 112-104KAJ-B01, with ![]() $\text {diameter} = 1.14$ mm) are embedded in the copper plates beneath the conducting surfaces, with three thermistors in each plate. The thermistors monitor the temperature across each plate and the temperature difference

$\text {diameter} = 1.14$ mm) are embedded in the copper plates beneath the conducting surfaces, with three thermistors in each plate. The thermistors monitor the temperature across each plate and the temperature difference ![]() $\varDelta$ across the cell. The sidewall consists of 2.85-mm-thick Plexiglas plates that are glued together to form a rectangular box. A groove is machined on the surface of the conducting plates, and an O-ring is placed in the groove to ensure a water-tight seal between the plates and the sidewall box. The top and bottom plates and the sidewall are held together by stainless steel posts (not shown in figure 1a). The cell was levelled to within 0.001 rad. To reduce the influence of surrounding temperature fluctuations and minimise heat leakage, the cell was wrapped with nitrile rubber sheets for thermal insulation and placed above a Nylon base (A) in a thermostat (F). The temperature of the thermostat was regulated by a water bath, and the temperature variation was less than

$\varDelta$ across the cell. The sidewall consists of 2.85-mm-thick Plexiglas plates that are glued together to form a rectangular box. A groove is machined on the surface of the conducting plates, and an O-ring is placed in the groove to ensure a water-tight seal between the plates and the sidewall box. The top and bottom plates and the sidewall are held together by stainless steel posts (not shown in figure 1a). The cell was levelled to within 0.001 rad. To reduce the influence of surrounding temperature fluctuations and minimise heat leakage, the cell was wrapped with nitrile rubber sheets for thermal insulation and placed above a Nylon base (A) in a thermostat (F). The temperature of the thermostat was regulated by a water bath, and the temperature variation was less than ![]() $0.1\,^{\circ }{\rm C}$. The temperature of the thermostat

$0.1\,^{\circ }{\rm C}$. The temperature of the thermostat ![]() $T_s$ was equal to the mean temperature

$T_s$ was equal to the mean temperature ![]() $T_{m}\equiv (T_{t}+T_{b})/2$.

$T_{m}\equiv (T_{t}+T_{b})/2$.

3.2. Fluid

Two immiscible fluid layers, namely, glycerol (AR, Jiangsu Qiangsheng Functional Chemistry Co., Ltd) and silicone oil (KF96L-2CS, Shin-Etsu Inc.), were used as the working fluids. The height of the glycerol was ![]() $h_{1} = 12.5$ mm, and the height of the silicone oil was

$h_{1} = 12.5$ mm, and the height of the silicone oil was ![]() $h_{2}= 245.5$ mm. Therefore, the height ratio of glycerol and whole cell is

$h_{2}= 245.5$ mm. Therefore, the height ratio of glycerol and whole cell is ![]() $h_{1}/h_{0}={0.048}$. The aspect ratios of the glycerol layer were

$h_{1}/h_{0}={0.048}$. The aspect ratios of the glycerol layer were ![]() $\varGamma _{xz,1}\equiv L_{x}/h_{1}=10.4$ and

$\varGamma _{xz,1}\equiv L_{x}/h_{1}=10.4$ and ![]() $\varGamma _{xy,1}\equiv L_{x}/L_{y}=10.0$. The aspect ratios of the silicone oil layer were

$\varGamma _{xy,1}\equiv L_{x}/L_{y}=10.0$. The aspect ratios of the silicone oil layer were ![]() $\varGamma _{xz, 2}= L_{x}/h_{2}=0.53$ and

$\varGamma _{xz, 2}= L_{x}/h_{2}=0.53$ and ![]() $\varGamma _{xy,2}= L_{x}/L_{y}=10.0$. The physical properties of the two fluids are given in table 1. The temperature difference across the glycerol layer was

$\varGamma _{xy,2}= L_{x}/L_{y}=10.0$. The physical properties of the two fluids are given in table 1. The temperature difference across the glycerol layer was ![]() $1.6 \sim 22\,^{\circ }{\rm C}$, and the mean temperature of the glycerol layer was in the range

$1.6 \sim 22\,^{\circ }{\rm C}$, and the mean temperature of the glycerol layer was in the range ![]() $25\sim 32\,^\circ {\rm C}$, resulting in the ranges of

$25\sim 32\,^\circ {\rm C}$, resulting in the ranges of ![]() $260< Ra_{1}<6000$ and

$260< Ra_{1}<6000$ and ![]() $3708< Pr_{1}<7000$. For the silicone oil layer, the temperature difference was

$3708< Pr_{1}<7000$. For the silicone oil layer, the temperature difference was ![]() $1.3<\varDelta _{2}<18\,^{\circ }{\rm C}$, and the mean temperature was

$1.3<\varDelta _{2}<18\,^{\circ }{\rm C}$, and the mean temperature was ![]() $14.5\sim 25\,^{\circ }{\rm C}$, resulting in the ranges

$14.5\sim 25\,^{\circ }{\rm C}$, resulting in the ranges ![]() $1.5\times 10^{9}< Ra_{2}<2.0\times 10^{10}$ and

$1.5\times 10^{9}< Ra_{2}<2.0\times 10^{10}$ and ![]() $28< Pr_{2}<33$.

$28< Pr_{2}<33$.

Table 1. Physical properties of the silicone oil and glycerol at ![]() $25\,^{\circ }{\rm C}$. The physical properties of glycerol are adopted from the reference physical and thermodynamic properties of pure chemicals, Data Compilation (Daubert & Danner Reference Daubert and Danner1989). The temperature coefficient

$25\,^{\circ }{\rm C}$. The physical properties of glycerol are adopted from the reference physical and thermodynamic properties of pure chemicals, Data Compilation (Daubert & Danner Reference Daubert and Danner1989). The temperature coefficient ![]() $\gamma _T$ of Glycerol is adopted from http://www.surface-tension.de/. All the physical properties of 2cS silicone oil were provided by Shin-Etsu. The physical properties except the surface tension were verified by independent measurements from a commercial company (Netzsch Inc.) (Li et al. Reference Li, He, Tian, Hao and Huang2021). The surface tension of 2cS silicone oil was measured by a commercial company.

$\gamma _T$ of Glycerol is adopted from http://www.surface-tension.de/. All the physical properties of 2cS silicone oil were provided by Shin-Etsu. The physical properties except the surface tension were verified by independent measurements from a commercial company (Netzsch Inc.) (Li et al. Reference Li, He, Tian, Hao and Huang2021). The surface tension of 2cS silicone oil was measured by a commercial company.

![]() $^a$

$^a$ ![]() $20\,^{\circ }{\rm C}$.

$20\,^{\circ }{\rm C}$.

![]() $^{b}$

$^{b}$ ![]() $30\,^{\circ }{\rm C}$.

$30\,^{\circ }{\rm C}$.

The surface tensions of the glycerol and silicone oil layers were ![]() $63.4\ {\rm mN}\ {\rm m}^{-1}$ at

$63.4\ {\rm mN}\ {\rm m}^{-1}$ at ![]() $20\,^\circ {\rm C}$ and

$20\,^\circ {\rm C}$ and ![]() $16\ {\rm mN}\ {\rm m}^{-1}$ at

$16\ {\rm mN}\ {\rm m}^{-1}$ at ![]() $20\,^{\circ }{\rm C}$, respectively. Because the glycerol has a considerably stronger surface tension than the silicone oil, the edge of the interface curves down, as shown in figure 1(c). The Weber number in the present work with the value at temperature

$20\,^{\circ }{\rm C}$, respectively. Because the glycerol has a considerably stronger surface tension than the silicone oil, the edge of the interface curves down, as shown in figure 1(c). The Weber number in the present work with the value at temperature ![]() $20\,^{\circ }{\rm C}$ is

$20\,^{\circ }{\rm C}$ is ![]() $We=(\rho _1g\alpha _1\Delta H^2)/\lvert \gamma _1 - \gamma _2\rvert \approx 82$ for

$We=(\rho _1g\alpha _1\Delta H^2)/\lvert \gamma _1 - \gamma _2\rvert \approx 82$ for ![]() $\varDelta =10\,^{\circ }{\rm C}$. The Marangoni number has a value of 42.6 for

$\varDelta =10\,^{\circ }{\rm C}$. The Marangoni number has a value of 42.6 for ![]() $\varDelta _1=10\,^{\circ }{\rm C}$. For the reader's reference, the

$\varDelta _1=10\,^{\circ }{\rm C}$. For the reader's reference, the ![]() $We$ in Huang et al. (Reference Huang, Xu, Wang, Wang, He and Tong2022) was about 300 with Water and FC770 in both turbulent regimes.

$We$ in Huang et al. (Reference Huang, Xu, Wang, Wang, He and Tong2022) was about 300 with Water and FC770 in both turbulent regimes.

3.3. Temperature measurement

In the fluid, two high-sensitivity metal oxide NTC thermistors with diameters of 0.3 mm and accuracies of ![]() $\pm 0.01\,^{\circ }{\rm C}$ (AB6E3-B07, GE Measurement and Control Inc.) are used to measure the temperature of the convecting fluid. As shown in figure 1, the small thermistors were fixed on a stainless steel rod and separated by 10.0 mm. To measure the heat transport characteristics, the two thermistors were located at the interface and 10.0 mm above the interface. The temperatures of the interface and centre of the silicone oil layer were then determined. All the thermistors were calibrated in a separate calibration facility against a platinum probe (Hart Scientific, model 5626), which in turn had been calibrated against various fixed points on the ITS-90 temperature scale by the Hart Scientific Division of Fluke Corporation. Consistency between all these thermometers is excellent; at the same temperature corresponding to

$\pm 0.01\,^{\circ }{\rm C}$ (AB6E3-B07, GE Measurement and Control Inc.) are used to measure the temperature of the convecting fluid. As shown in figure 1, the small thermistors were fixed on a stainless steel rod and separated by 10.0 mm. To measure the heat transport characteristics, the two thermistors were located at the interface and 10.0 mm above the interface. The temperatures of the interface and centre of the silicone oil layer were then determined. All the thermistors were calibrated in a separate calibration facility against a platinum probe (Hart Scientific, model 5626), which in turn had been calibrated against various fixed points on the ITS-90 temperature scale by the Hart Scientific Division of Fluke Corporation. Consistency between all these thermometers is excellent; at the same temperature corresponding to ![]() $\varDelta =0\,^{\circ }{\rm C}$, their readings all agree within

$\varDelta =0\,^{\circ }{\rm C}$, their readings all agree within ![]() $\pm 0.01\,^{\circ }{\rm C}$. For the heat transport measurement, the resistances of the thermistors in the fluid and plates were collected at a sampling rate of 0.27 Hz. For the temperature profile measurement, the resistances of the thermistors in the fluid were collected at a sampling rate of 1.28 Hz.

$\pm 0.01\,^{\circ }{\rm C}$. For the heat transport measurement, the resistances of the thermistors in the fluid and plates were collected at a sampling rate of 0.27 Hz. For the temperature profile measurement, the resistances of the thermistors in the fluid were collected at a sampling rate of 1.28 Hz.

3.4. Visualisation method and image analysis

The shadowgraph technique was utilised in our measurements (Xi, Lam & Xia Reference Xi, Lam and Xia2004). As shown in figure 2, the shadowgraph technique consists of a light source and two cameras. A white light point source (WenCe S2700E) was placed in front of the thermostat. From the point light source, the light was guided by optical fibres to two collimators, and two beams of collimated light were projected to the thermostat. A piece of oil paper was placed behind the cell but in front of two digital cameras. At the top placed a digital camera (Canon, model EOS6D) with an ![]() $f=50$ mm lens, and the image was collected at a rate of 25 Hz and in the size of

$f=50$ mm lens, and the image was collected at a rate of 25 Hz and in the size of ![]() $1080\times 1920$ pixel. At the bottom placed another digital camera (Canon, model EOS6D) with a Canon 24–105 mm lens. The image at the bottom was collected at a rate of 30 Hz and in the size of

$1080\times 1920$ pixel. At the bottom placed another digital camera (Canon, model EOS6D) with a Canon 24–105 mm lens. The image at the bottom was collected at a rate of 30 Hz and in the size of ![]() $1080\times 1920$ pixels. The flow field below the top plate, the cellular patterns of the glycerol layer, and the flow above the interfacial surface were recorded simultaneously. The duration of image recording lasts more than 24 h for each run. Since the temperature of the heated fluid parcel is higher than the ambient fluid, the intensity of transmitted light reflects the second derivative of temperature qualitatively.

$1080\times 1920$ pixels. The flow field below the top plate, the cellular patterns of the glycerol layer, and the flow above the interfacial surface were recorded simultaneously. The duration of image recording lasts more than 24 h for each run. Since the temperature of the heated fluid parcel is higher than the ambient fluid, the intensity of transmitted light reflects the second derivative of temperature qualitatively.

Figure 2. Schematic diagram of the shadowgraph method used in the present work: 1, light source; 2, optical fibre; 3, collimator; 4, thermostat; 5, motor; 6, stainless-steel rod with thermistors attached; 7, RBC cell; 8, oil paper; 9, cameras.

3.5. Procedure and performance

The measurements were made using glycerol and 2cS silicone oil. The glycerol was injected through a capillary tube into the sample first. Then silicone oil was siphoned through another capillary tube to the sample above the glycerol layer. After this procedure, a visual inspection of the sample showed a complete absence of any bubbles. The stainless-steel rod with thermistors fixed was placed inside the sample, and two thermistors were positioned at the interface and 10 mm above the interface.

The heat transport of two-layer RBC was measured from small temperature drops to large temperature drops. In the end, we measured the heat flux through the empty cell placed in the thermostat for each set of ![]() $T_b$,

$T_b$, ![]() $T_t$ and

$T_t$ and ![]() $T_s$ to account for the heat lost into the apparatus. Although the air was kept in the empty cell, the air was considered to be acquiescent and no convection occurred in the empty cell. Then this heat flux through the empty cell was subtracted from the measured heat flux through the two-layer fluid. The heat current through the empty cell is 63 % to 85 % of the two-layer measured heat flux. For comparison, we also conducted a similar heat flux measurement for a one-layer RBC filled with silicone oil. The correction ranged from approximately 35 % to approximately 50 % of the one-layer measured heat flux. The temperature profile in the traditional one-layer RBC was later measured. The temperature of the bottom plate, top plate, and thermostat was set as the value of

$T_s$ to account for the heat lost into the apparatus. Although the air was kept in the empty cell, the air was considered to be acquiescent and no convection occurred in the empty cell. Then this heat flux through the empty cell was subtracted from the measured heat flux through the two-layer fluid. The heat current through the empty cell is 63 % to 85 % of the two-layer measured heat flux. For comparison, we also conducted a similar heat flux measurement for a one-layer RBC filled with silicone oil. The correction ranged from approximately 35 % to approximately 50 % of the one-layer measured heat flux. The temperature profile in the traditional one-layer RBC was later measured. The temperature of the bottom plate, top plate, and thermostat was set as the value of ![]() $T_{int}$ and

$T_{int}$ and ![]() $T_t$ and

$T_t$ and ![]() $T_s$ used in two-layer RBC.

$T_s$ used in two-layer RBC.

Data points were obtained by holding constant both the top- and bottom-plate temperatures. For the bottom plate, this was done by adjusting the heat power in a digital feedback loop using the mean temperature of the bottom plate ![]() $T_b$. For the top plate, a constant temperature was achieved by circulating temperature-controlled water. The heat current applied to the bottom plate and all three thermistors in each plate were monitored for a minimum of 8 h and on occasion for 10 days for temperature profile measurement under nominally constant external conditions.

$T_b$. For the top plate, a constant temperature was achieved by circulating temperature-controlled water. The heat current applied to the bottom plate and all three thermistors in each plate were monitored for a minimum of 8 h and on occasion for 10 days for temperature profile measurement under nominally constant external conditions.

The currents and temperatures recorded after the first several hours were time-averaged. The three averaged temperatures for each plate were averaged to give our best estimate of the top- and bottom-plate temperatures. A correction to these temperatures was made for the temperature change across the copper layers between the fluid and the thermistor heads. This correction was estimated to be 0.5 % (0.2 %) of ![]() $\varDelta$ for

$\varDelta$ for ![]() $\varDelta = 3$

$\varDelta = 3$ ![]() $(20)\,^{\circ }{\rm C}$. The results for

$(20)\,^{\circ }{\rm C}$. The results for ![]() $T_t$ and

$T_t$ and ![]() $T_b$ yielded the final values of

$T_b$ yielded the final values of ![]() $T_{m}=(T_b+T_t)/2$, and of the value of

$T_{m}=(T_b+T_t)/2$, and of the value of ![]() $\varDelta _1=T_b-T_{int}$ and

$\varDelta _1=T_b-T_{int}$ and ![]() $\varDelta _2=T_{int}-T_{t}$ used to compute

$\varDelta _2=T_{int}-T_{t}$ used to compute ![]() $Nu_1$ and

$Nu_1$ and ![]() $Nu_2$.

$Nu_2$.

Another source of system error comes from the temperature measurement. In figures 3(a) and 3(d), we show the horizontal temperature differences ![]() $T_{t,k}-T_t$ or

$T_{t,k}-T_t$ or ![]() $T_{b,k}- T_b(k=1,2,3)$ between thermistors 1–3 from left to right and the mean temperature of plate, normalised by the applied vertical temperature difference

$T_{b,k}- T_b(k=1,2,3)$ between thermistors 1–3 from left to right and the mean temperature of plate, normalised by the applied vertical temperature difference ![]() $\varDelta _i$. In this case,

$\varDelta _i$. In this case, ![]() $(T_{t,k}-T_t)/\varDelta$ and

$(T_{t,k}-T_t)/\varDelta$ and ![]() $(T_{b,k}-T_b)/\varDelta$ are at most of the order of a few per cent. For the determination of the Nusselt numbers, we used the average of all the thermistors in a given plate. We would estimate that this horizontal inhomogeneity of the temperature at the fluid boundary could introduce a systematic error of the order of 1.5 % into the results for

$(T_{b,k}-T_b)/\varDelta$ are at most of the order of a few per cent. For the determination of the Nusselt numbers, we used the average of all the thermistors in a given plate. We would estimate that this horizontal inhomogeneity of the temperature at the fluid boundary could introduce a systematic error of the order of 1.5 % into the results for ![]() $Nu$. The temperature of the interface was determined by only one thermistor. In the experiment, the interface is subject to constant heat-flux condition instead of constant temperature condition as in traditional RBC. In general, the temperature

$Nu$. The temperature of the interface was determined by only one thermistor. In the experiment, the interface is subject to constant heat-flux condition instead of constant temperature condition as in traditional RBC. In general, the temperature ![]() $T_{int}$ shows a fluctuation

$T_{int}$ shows a fluctuation ![]() $s_{int}$ around the time-averaged value in the steady state. The value

$s_{int}$ around the time-averaged value in the steady state. The value ![]() $\sigma _{int}/\varDelta _{i}$ are plotted in figures 3(b) and 3(c), and the values are less than 1 %. In the present work, the effect of the finite conductivity of the conducting plate and the effect of non-OB (Oberbeck-Boussinesq) are negligible compared with the heat loss through the thermostat discussed previously.

$\sigma _{int}/\varDelta _{i}$ are plotted in figures 3(b) and 3(c), and the values are less than 1 %. In the present work, the effect of the finite conductivity of the conducting plate and the effect of non-OB (Oberbeck-Boussinesq) are negligible compared with the heat loss through the thermostat discussed previously.

Figure 3. (a) Horizontal temperature differences ![]() $(T_{b,k}-T_{b})/\varDelta _1$ for the bottom plate against

$(T_{b,k}-T_{b})/\varDelta _1$ for the bottom plate against ![]() $\varDelta _1$ for glycerol layer. (b) Normalised temperature standard deviation at interface

$\varDelta _1$ for glycerol layer. (b) Normalised temperature standard deviation at interface ![]() $\sigma _{int}/\varDelta _1$ against

$\sigma _{int}/\varDelta _1$ against ![]() $\varDelta _{1}$. (c) Plot of

$\varDelta _{1}$. (c) Plot of ![]() $\sigma _{int}/\varDelta _2$ against

$\sigma _{int}/\varDelta _2$ against ![]() $\varDelta _{2}$. (d) Horizontal temperature differences

$\varDelta _{2}$. (d) Horizontal temperature differences ![]() $(T_{t,k}-T_{t})/\varDelta _2$ for the top plate against

$(T_{t,k}-T_{t})/\varDelta _2$ for the top plate against ![]() $\varDelta _2$ for the silicone oil layer. The subscripts

$\varDelta _2$ for the silicone oil layer. The subscripts ![]() $k=1, 2, 3$ label the thermistors from left to right when viewed from the side.

$k=1, 2, 3$ label the thermistors from left to right when viewed from the side.

Visualisation was made after the heat transport measurement and the black thermal-insulating rubber was removed. Visualisation was made for ![]() $\varDelta =6$, 14 and

$\varDelta =6$, 14 and ![]() $30\,^{\circ }{\rm C}$ in order. The

$30\,^{\circ }{\rm C}$ in order. The ![]() $Ra$ and

$Ra$ and ![]() $Pr$ numbers for each layer of fluid were listed in table 2.

$Pr$ numbers for each layer of fluid were listed in table 2.

Table 2. Parameters for the visualization runs.

4. Results and discussion

In the present work, we first obtain the results of global heat transport. The global heat transport ![]() $Q_{f}\sim \varDelta$ showed three ranges with different behaviours. This was mainly caused by different flow structures in the glycerol layer, which was revealed by the shadowgraph method. To quantify the control parameters in each layer of fluid, the temperature and partial slip condition of the interface shall be determined and justified first. In the following we show the temperature profile along the centreline first. Then we show the results of temperature trace and typical flow structures in three ranges, and six videos for the shadowgraph results are provided as supplementary movies available at https://doi.org/10.1017/jfm.2023.982. In the end, we provide the results of global heat transport and

$Q_{f}\sim \varDelta$ showed three ranges with different behaviours. This was mainly caused by different flow structures in the glycerol layer, which was revealed by the shadowgraph method. To quantify the control parameters in each layer of fluid, the temperature and partial slip condition of the interface shall be determined and justified first. In the following we show the temperature profile along the centreline first. Then we show the results of temperature trace and typical flow structures in three ranges, and six videos for the shadowgraph results are provided as supplementary movies available at https://doi.org/10.1017/jfm.2023.982. In the end, we provide the results of global heat transport and ![]() $Nu$ in each layer of fluid.

$Nu$ in each layer of fluid.

4.1. The temperature of the interface

The interface was assumed as a flat and isothermal surface without breaking up. In figures 4 and 5, we first show the temperature profiles along the centreline and the time-averaged shadowgraph images to justify this assumption. The measurements were taken at run E3. In figure 4(a), the time-averaged temperatures ![]() $\langle T \rangle$ were plotted. Obviously, the temperature has two different gradients above and below the interface. For

$\langle T \rangle$ were plotted. Obviously, the temperature has two different gradients above and below the interface. For ![]() $z< h_{1}$,

$z< h_{1}$, ![]() $\langle T \rangle$ decreases as

$\langle T \rangle$ decreases as ![]() $z$ increases. For

$z$ increases. For ![]() $h_{1}< z< 14.0$ mm, the temperature

$h_{1}< z< 14.0$ mm, the temperature ![]() $\langle T\rangle$ decreases from

$\langle T\rangle$ decreases from ![]() $22.9\,^{\circ }{\rm C}$ to

$22.9\,^{\circ }{\rm C}$ to ![]() $20.9\,^{\circ }{\rm C}$. The intersection of two fitted lines is located at the interface

$20.9\,^{\circ }{\rm C}$. The intersection of two fitted lines is located at the interface ![]() $z=12.5$ mm. It means that our measurement of position is accurate. Meanwhile the standard deviation of temperature

$z=12.5$ mm. It means that our measurement of position is accurate. Meanwhile the standard deviation of temperature ![]() $\sigma _{T}$ increases from

$\sigma _{T}$ increases from ![]() $0.02\,^{\circ }{\rm C}$ near the bottom plate to

$0.02\,^{\circ }{\rm C}$ near the bottom plate to ![]() $0.63\,^{\circ }{\rm C}$ at

$0.63\,^{\circ }{\rm C}$ at ![]() $z=14.0$ mm and then decreases to

$z=14.0$ mm and then decreases to ![]() $0.24\,^{\circ }{\rm C}$ at

$0.24\,^{\circ }{\rm C}$ at ![]() $z=20.9$ mm. This is different from the traditional BL over the liquid–solid surface (Scheel, Kim & White Reference Scheel, Kim and White2012; Shishkina et al. Reference Shishkina, Horn, Wagner and Ching2015). As a comparison, the

$z=20.9$ mm. This is different from the traditional BL over the liquid–solid surface (Scheel, Kim & White Reference Scheel, Kim and White2012; Shishkina et al. Reference Shishkina, Horn, Wagner and Ching2015). As a comparison, the ![]() $\langle T \rangle$ and

$\langle T \rangle$ and ![]() $\sigma _{T}$ beneath the top plate were also plotted in figures 4(c) and 4(d). However, the data cannot be fitted well by analytic expression in Ahlers, Bodenschatz & He (Reference Ahlers, Bodenschatz and He2014) and Huang et al. (Reference Huang, Xu, Wang, Wang, He and Tong2022) due to the scattering of data. It is well known that there exists a thermal BL beneath the top plate. As measurements are moving away from the top conducting plate,

$\sigma _{T}$ beneath the top plate were also plotted in figures 4(c) and 4(d). However, the data cannot be fitted well by analytic expression in Ahlers, Bodenschatz & He (Reference Ahlers, Bodenschatz and He2014) and Huang et al. (Reference Huang, Xu, Wang, Wang, He and Tong2022) due to the scattering of data. It is well known that there exists a thermal BL beneath the top plate. As measurements are moving away from the top conducting plate, ![]() $\langle T \rangle$ increases greatly across the BL and then reaches a constant in the bulk. The

$\langle T \rangle$ increases greatly across the BL and then reaches a constant in the bulk. The ![]() $\sigma _{T}$ increases from

$\sigma _{T}$ increases from ![]() $0\,^{\circ }{\rm C}$ to a maximum value of

$0\,^{\circ }{\rm C}$ to a maximum value of ![]() $0.96\,^{\circ }{\rm C}$ and then sharply decreases to

$0.96\,^{\circ }{\rm C}$ and then sharply decreases to ![]() $0.15\,^{\circ }{\rm C}$ in the bulk. Although the trends of

$0.15\,^{\circ }{\rm C}$ in the bulk. Although the trends of ![]() $\langle T \rangle$ and

$\langle T \rangle$ and ![]() $\sigma _{T}$ over the interface are similar to those beneath the top plate, they still show differences. The maximum value of

$\sigma _{T}$ over the interface are similar to those beneath the top plate, they still show differences. The maximum value of ![]() $\sigma _{T}$ over the interface with slip BC is much smaller than that under the top plate with no-slip BC. In this part, the main focus is to examine the temperature at the liquid–liquid interface

$\sigma _{T}$ over the interface with slip BC is much smaller than that under the top plate with no-slip BC. In this part, the main focus is to examine the temperature at the liquid–liquid interface ![]() $z=h_1$. It is known that at

$z=h_1$. It is known that at ![]() $z=0$ mm the fluid is subject to no-slip condition over the solid surface. The

$z=0$ mm the fluid is subject to no-slip condition over the solid surface. The ![]() $\sigma _{T}$ approaches

$\sigma _{T}$ approaches ![]() $0\,^{\circ }{\rm C}$ as

$0\,^{\circ }{\rm C}$ as ![]() $z$ approaches to 0 mm. But

$z$ approaches to 0 mm. But ![]() $\sigma _{T}$ has a value of

$\sigma _{T}$ has a value of ![]() $0.12\,^{\circ }{\rm C}$ at

$0.12\,^{\circ }{\rm C}$ at ![]() $z=h_{1}$. This value is much larger than the accuracy of the thermometer. The non-zero

$z=h_{1}$. This value is much larger than the accuracy of the thermometer. The non-zero ![]() $\sigma _{T}$ at

$\sigma _{T}$ at ![]() $z=h_{1}$ is evident that the interface is subject to a slip condition.

$z=h_{1}$ is evident that the interface is subject to a slip condition.

Figure 4. (a,c) Vertical position ![]() $z$ against time-averaged temperature

$z$ against time-averaged temperature ![]() $\langle T\rangle$. In (a) the dot-dashed line is for

$\langle T\rangle$. In (a) the dot-dashed line is for ![]() $z=37.6 - 1.08\langle T\rangle$ and the dashed line is for

$z=37.6 - 1.08\langle T\rangle$ and the dashed line is for ![]() $z=21 - 0.40\langle T\rangle$. (b,d) Plots of

$z=21 - 0.40\langle T\rangle$. (b,d) Plots of ![]() $z$ against the standard deviation of temperature

$z$ against the standard deviation of temperature ![]() $\sigma _{t}$. The measurements were taken at run E3.

$\sigma _{t}$. The measurements were taken at run E3.

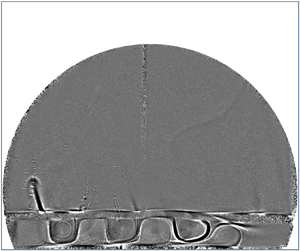

Figure 5. (a) Shadowgraph image as the background without temperature drops across the cell. (b) Time-averaged image. (c) Result of the background image subtracting the time-averaged image. The measurements were taken at run E3.

The other assumption of the interface is that the temperature in the time-averaged sense is constant along the horizontal direction. To validate this assumption, we show the shadowgraph image without any temperature drops across the cell in figure 5(a). This figure is also chosen as the background image to be subtracted in a later section. The vertical probe projects a dark thick line in the centreline. The horizontal interface also appears as a dark thick line. In figure 5(b), we also show the time-averaged image of the flow field in the run E3. Here we only discuss the shape of the interface. The interface in figure 5(b) shows a thicker dark line. To study the spatial dependence of temperature at the interface, we use figure 5(b) to subtract the background in figure 5(a), and the result is shown in figure 5(c). The white stripe at the interface has a near-constant intensity in the horizontal direction, so we can assume that the interface is isothermal horizontally.

4.2. Flow field in two-layer RBC

4.2.1. Range I: two-layer RBC with conductive glycerol layer

A time series of the temperature of conducting plates and interface for E1 were shown in figures 6(a) and 6(b). Figure 6(c) also showed the times series of total heat flux. The total duration for this run is about ![]() $2\times 10^{5}$ s (2 days). We found that the temperatures at conducting plates and the heat flux reached constant values after 500 s. The temperature

$2\times 10^{5}$ s (2 days). We found that the temperatures at conducting plates and the heat flux reached constant values after 500 s. The temperature ![]() $T_{int}$ of the interface reached a mean value of

$T_{int}$ of the interface reached a mean value of ![]() ${25.35}\,^{\circ }{\rm C}$ with a standard deviation of

${25.35}\,^{\circ }{\rm C}$ with a standard deviation of ![]() ${0.03}\,^\circ {\rm C}$.

${0.03}\,^\circ {\rm C}$.

Figure 6. (a) Time series of mean temperature ![]() $T_t$ at the top plate (blue) and

$T_t$ at the top plate (blue) and ![]() $T_b$ at the bottom plate (red). (b) Time series of mean temperature

$T_b$ at the bottom plate (red). (b) Time series of mean temperature ![]() $T_{int}$ at the interface. (c) Time series of heat flux

$T_{int}$ at the interface. (c) Time series of heat flux ![]() $Q_{tot}$ measured at the bottom plate. The measurements were taken for run E1.

$Q_{tot}$ measured at the bottom plate. The measurements were taken for run E1.

In figure 7, we showed the instantaneous images, the time average and the standard deviation of images beneath the top plate and above the bottom plate. These two instantaneous images in figures 7(a) and 7(d) were taken at the same moment. There is no obvious cellular pattern or other structures in the glycerol layer. This indicates that the glycerol layer was mainly at rest in such a condition. We did not observe the deformation of the interface. The total heat flux across the interface is the same as that across the top plate. It is surprising that many cold plumes were emitting from the top plate but no hot plume appeared above the interface in the silicone oil layer in figures 7(a) and 7(d). The different flow structures under the top plate and above the interface are attributed to the different velocity conditions applied on the top/bottom of silicone oil. The silicone oil is subjected to no-slip BC beneath the top plate, but it is subjected to slip BC on the interface.

Figure 7. (a,d) Instantaneous background-divided snapshot. (b,e) Time-averaged and contrast-enhanced image. (c,f) Standard-deviation and contrast-enhanced image. Panels (a–c) were taken below the top plate and panels (d–f) are taken above the bottom plate. The measurements were taken for run E1.

The cold plumes in figure 7(a) have greater brightness than the background. There are at least six bright vertical stems attaching the top plate at the instantaneous moment. After detachment, the bright streaks were distributed almost everywhere. It is difficult to distinguish individual cold plumes. The cold plumes emerged into larger structures. The average speed of cold plumes in figure 7(a) was about ![]() $3\ {\rm mm}\ {\rm s}^{-1}$. Most of the cold plumes do not disappear before they sink out of the illuminated area.

$3\ {\rm mm}\ {\rm s}^{-1}$. Most of the cold plumes do not disappear before they sink out of the illuminated area.

In addition to the plume in the silicone oil layer, the turbulent mixing also enhances heat transport. But we cannot evaluate the portion of heat flux due to the turbulent mixing with the shadowgraph method. In fact, even the heat flux carried by plumes cannot be evaluated in the present work for the temperature of plumes is hard to determine.

To evaluate the degree of mixing of plumes, we calculate the time-averaged and standard-deviation images for run E1 as shown in figures 7(b), 7(c), 7(e) and 7(f). Under the top plate, the time-averaged image is similar to the image without heating. The bright area under the top plate of the standard-deviation image in figure 7(c) indicated that cold plumes were evenly detached from the top plate. Above the bottom plate, there is no motion of fluid observed. The standard-deviation image in the figure 7(f) was mainly caused by the fluctuation of the light source and the background.

4.2.2. Range II: two-layer RBC with oscillatory glycerol layer

For most temperature drops, the heat transport and flow field reach a steady state after a certain interval. However, there are special cases. Figures 8(a), 8(b), 8(c), 8(d) and 8(e) plot the time series of the temperature and measured heat flux ![]() $Q_{tot}$. The temperature drops were set as

$Q_{tot}$. The temperature drops were set as ![]() $\varDelta =16\,^{\circ }{\rm C}$. One sees that the temperatures at conducting plates reach a steady state in 6000 s. The temperature difference in the bottom plate increases from

$\varDelta =16\,^{\circ }{\rm C}$. One sees that the temperatures at conducting plates reach a steady state in 6000 s. The temperature difference in the bottom plate increases from ![]() $0.04\,^{\circ }{\rm C}$ to about

$0.04\,^{\circ }{\rm C}$ to about ![]() $0.06\,^{\circ }{\rm C}$ at

$0.06\,^{\circ }{\rm C}$ at ![]() $t=5000$ s and decreases back to

$t=5000$ s and decreases back to ![]() $0.04\,^{\circ }{\rm C}$ at

$0.04\,^{\circ }{\rm C}$ at ![]() $t=15\,000$ s. At

$t=15\,000$ s. At ![]() $t=20\,000$ s this temperature difference in the bottom plate starts to slowly decrease, and then it increases from

$t=20\,000$ s this temperature difference in the bottom plate starts to slowly decrease, and then it increases from ![]() $0.01\,^{\circ }{\rm C}$ at

$0.01\,^{\circ }{\rm C}$ at ![]() $t=41\,000$ s and reaches a constant value

$t=41\,000$ s and reaches a constant value ![]() $0.04\,^{\circ }{\rm C}$ at

$0.04\,^{\circ }{\rm C}$ at ![]() $t=55\,000$ s.

$t=55\,000$ s.

Figure 8. Temperature time series at the top plate (a), ![]() $10$ mm above the interface (b), at the interface (c) and at the bottom plate (d), and the total heat flux

$10$ mm above the interface (b), at the interface (c) and at the bottom plate (d), and the total heat flux ![]() $Q_{tot}$ time series (e). The plots in (f) show the corresponding power spectra for the segments of

$Q_{tot}$ time series (e). The plots in (f) show the corresponding power spectra for the segments of ![]() $T_i$ in (c). These measurements were acquired at

$T_i$ in (c). These measurements were acquired at ![]() $\varDelta =16\,^{\circ }{\rm C}$. The corresponding

$\varDelta =16\,^{\circ }{\rm C}$. The corresponding ![]() $Ra_{1}=1529$ and

$Ra_{1}=1529$ and ![]() $Ra_{2}=6.72\times 10^9$.

$Ra_{2}=6.72\times 10^9$.

The temperatures at the interface ![]() $T_{int}$ and 10 mm above the interface

$T_{int}$ and 10 mm above the interface ![]() $T_{c}$ reach a steady state in a long time of 10 000 s. Then the temperatures at the interface and conducting plates remain constant for an extended period of 10 000 s. The

$T_{c}$ reach a steady state in a long time of 10 000 s. Then the temperatures at the interface and conducting plates remain constant for an extended period of 10 000 s. The ![]() $T_c$ value in the silicone oil layer fluctuates slightly around a mean value, which indicates that the flow in the cell is in a steady state. Then

$T_c$ value in the silicone oil layer fluctuates slightly around a mean value, which indicates that the flow in the cell is in a steady state. Then ![]() $T_{c}$ slightly decreases at

$T_{c}$ slightly decreases at ![]() $t=20\,000$ s when the temperature difference of the bottom plate starts decreasing slowly. At this point,

$t=20\,000$ s when the temperature difference of the bottom plate starts decreasing slowly. At this point, ![]() $T_{int}$ is equal to

$T_{int}$ is equal to ![]() $23.6\,^{\circ }{\rm C}$. At

$23.6\,^{\circ }{\rm C}$. At ![]() $t=35\,000$ s,

$t=35\,000$ s, ![]() $T_{int}$ starts to oscillate, and the magnitude of this oscillation increases over time, as shown in figure 8(c). At

$T_{int}$ starts to oscillate, and the magnitude of this oscillation increases over time, as shown in figure 8(c). At ![]() $t=40\,700$ s,

$t=40\,700$ s, ![]() $T_{int}$ reaches

$T_{int}$ reaches ![]() $24.8\,^{\circ }{\rm C}$ and oscillates with a greater magnitude of

$24.8\,^{\circ }{\rm C}$ and oscillates with a greater magnitude of ![]() $1.5\,^{\circ }{\rm C}$. At

$1.5\,^{\circ }{\rm C}$. At ![]() $t=50\,000$ s,

$t=50\,000$ s, ![]() $T_{int}$ still oscillates; however, the magnitude and period of the oscillation are not constant. The power spectra of

$T_{int}$ still oscillates; however, the magnitude and period of the oscillation are not constant. The power spectra of ![]() $T_{int}$ for these three segments are plotted in figure 8(f). The individual power spectra peak at different frequencies.

$T_{int}$ for these three segments are plotted in figure 8(f). The individual power spectra peak at different frequencies.

The oscillation frequency decreases from ![]() $1.742\times 10^{-3}$ Hz to

$1.742\times 10^{-3}$ Hz to ![]() $9.955\times 10^{-4}$ Hz before decreasing further to

$9.955\times 10^{-4}$ Hz before decreasing further to ![]() $7.466\times 10^{-4}$ Hz. These frequencies are equivalent to periods of 574, 1004 and 1339 s. These are much greater than the typical lifetime of the thermal plume in the silicone oil layer. The envelope of

$7.466\times 10^{-4}$ Hz. These frequencies are equivalent to periods of 574, 1004 and 1339 s. These are much greater than the typical lifetime of the thermal plume in the silicone oil layer. The envelope of ![]() $T_{int}$ gradually increases starting at

$T_{int}$ gradually increases starting at ![]() $t=35\,000$ s. The temperature

$t=35\,000$ s. The temperature ![]() $T_{c}$ gradually increases from

$T_{c}$ gradually increases from ![]() $21.5\,^{\circ }{\rm C}$ at

$21.5\,^{\circ }{\rm C}$ at ![]() $t=40\,000$ s to

$t=40\,000$ s to ![]() $22.0\,^{\circ }{\rm C}$ at

$22.0\,^{\circ }{\rm C}$ at ![]() $t=67\,500$ s. The temperature

$t=67\,500$ s. The temperature ![]() $T_{c}$ also oscillates at

$T_{c}$ also oscillates at ![]() $t=40\,000$ s with the same frequency of

$t=40\,000$ s with the same frequency of ![]() $T_{int}$, but the amplitude of

$T_{int}$, but the amplitude of ![]() $T_{c}$ is much smaller than that of

$T_{c}$ is much smaller than that of ![]() $T_{int}$.

$T_{int}$.

Similar oscillations in ![]() $T_{int}$ are also observed for the case with

$T_{int}$ are also observed for the case with ![]() $\varDelta =17\,^{\circ }{\rm C}$ in figure 9. In figures 9(a) and 9(d), the temperatures in conducting plates reach a steady state in 6000 s. The temperature

$\varDelta =17\,^{\circ }{\rm C}$ in figure 9. In figures 9(a) and 9(d), the temperatures in conducting plates reach a steady state in 6000 s. The temperature ![]() $T_{int}$ remains oscillating with a decreasing amplitude and decreasing frequency. As shown in figure 9(f), the oscillating frequency of

$T_{int}$ remains oscillating with a decreasing amplitude and decreasing frequency. As shown in figure 9(f), the oscillating frequency of ![]() $T_{int}$ from

$T_{int}$ from ![]() $t=0$ s to

$t=0$ s to ![]() $t=6500$ s is

$t=6500$ s is ![]() $2.490\times 10^{-4}$ Hz, while the oscillating frequency of

$2.490\times 10^{-4}$ Hz, while the oscillating frequency of ![]() $T_{int}$ from

$T_{int}$ from ![]() $t=6500$ s to

$t=6500$ s to ![]() $t=27\,000$ s is

$t=27\,000$ s is ![]() $1.244\times 10^{-4}$ Hz. The oscillation of temperature

$1.244\times 10^{-4}$ Hz. The oscillation of temperature ![]() $T_{int}$ ceases at

$T_{int}$ ceases at ![]() $t=27\,000$ s. These oscillation frequencies are corresponding to a period of 4016 and 8037 s. The temperatures in the bottom plate show large fluctuations from

$t=27\,000$ s. These oscillation frequencies are corresponding to a period of 4016 and 8037 s. The temperatures in the bottom plate show large fluctuations from ![]() $t=10\,000$ s to 15 000 s in figure 9(d). The temperature difference in the bottom plate varies from

$t=10\,000$ s to 15 000 s in figure 9(d). The temperature difference in the bottom plate varies from ![]() $0.04\,^{\circ }{\rm C}$ to

$0.04\,^{\circ }{\rm C}$ to ![]() $0.08\,^{\circ }{\rm C}$. The heat flux

$0.08\,^{\circ }{\rm C}$. The heat flux ![]() $Q$ also varies at the same time because the temperature of the bottom plate is controlled by a proportional–integral–derivative (PID) electric loop. But the temperatures inside the cell and at the conducting plate and the heat flux reach a steady state after

$Q$ also varies at the same time because the temperature of the bottom plate is controlled by a proportional–integral–derivative (PID) electric loop. But the temperatures inside the cell and at the conducting plate and the heat flux reach a steady state after ![]() $t=30\,000$ s.

$t=30\,000$ s.

Figure 9. Temperature time series at the top plate (a), ![]() $10$ mm above the interface (b), at the interface (c) and at the bottom plate (d), and the total heat flux

$10$ mm above the interface (b), at the interface (c) and at the bottom plate (d), and the total heat flux ![]() $Q_{tot}$ time series (e). The plots in (f) show the corresponding power spectra for the segments of

$Q_{tot}$ time series (e). The plots in (f) show the corresponding power spectra for the segments of ![]() $T_i$ in (c). These measurements were acquired at

$T_i$ in (c). These measurements were acquired at ![]() $\varDelta =17\,^{\circ }{\rm C}$. The corresponding

$\varDelta =17\,^{\circ }{\rm C}$. The corresponding ![]() $Ra_{1}=1621$ and

$Ra_{1}=1621$ and ![]() $Ra_{2}=7.41\times 10^9$.

$Ra_{2}=7.41\times 10^9$.

To reveal the flow structure causing this oscillatory temperature in the interface, we later removed the rubber around the sidewall to obtain the shadowgraph image. The temperature drop across the cell was set to zero to set the fluid into a motionless state. Then the temperature drop ![]() $\varDelta =14\,^{\circ }{\rm C}$ was set. The temperatures of conducting plates and the interface for run E2 were plotted in figures 10(a) and 10(b). The time series of measured heat flux provided by the electric heater was also plotted in figure 10(c). The temperatures of conducting plates and the heat flux reached constant values after 3000 s. But the temperature measured at the interface starts to oscillate from 8000 s. The amplitude of this oscillation is about

$\varDelta =14\,^{\circ }{\rm C}$ was set. The temperatures of conducting plates and the interface for run E2 were plotted in figures 10(a) and 10(b). The time series of measured heat flux provided by the electric heater was also plotted in figure 10(c). The temperatures of conducting plates and the heat flux reached constant values after 3000 s. But the temperature measured at the interface starts to oscillate from 8000 s. The amplitude of this oscillation is about ![]() $1.1\,^{\circ }{\rm C}$ but it is not a constant value. The period of oscillation is about 2200 s (36 min). After 57 700 s, the temperature at the interface remains the oscillation with the amplitude

$1.1\,^{\circ }{\rm C}$ but it is not a constant value. The period of oscillation is about 2200 s (36 min). After 57 700 s, the temperature at the interface remains the oscillation with the amplitude ![]() $1.4\,^{\circ }{\rm C}$ and a period of 2580 s (43 min).

$1.4\,^{\circ }{\rm C}$ and a period of 2580 s (43 min).

Figure 10. (a) Time series of temperature ![]() $T_t$ (blue) and

$T_t$ (blue) and ![]() $T_b$ (red). (b) Time series of the interface temperature

$T_b$ (red). (b) Time series of the interface temperature ![]() $T_{int}$ at the interface. (c) Time series of

$T_{int}$ at the interface. (c) Time series of ![]() $Q_{tot}$ at the bottom plate. The measurements were taken for run E2.

$Q_{tot}$ at the bottom plate. The measurements were taken for run E2.

We chose five moments corresponding to three successive troughs and two successive crests of ![]() $T_{int}$. The corresponding images of the glycerol layer were shown in figure 11. We observed that square rolls keep moving to the right. The left side of each square roll has a larger temperature while the right side of the roll has a lower temperature. On the left corner of the glycerol layer, a small roll was formed. The size of the roll gradually increased as the roll moved to the right. Once the roll passes through the thermistor at the centre of the interface, the lower side of the roll gradually lifts upwards, and the shape of the roll gradually evolves to an elliptic shape. When the roll reached

$T_{int}$. The corresponding images of the glycerol layer were shown in figure 11. We observed that square rolls keep moving to the right. The left side of each square roll has a larger temperature while the right side of the roll has a lower temperature. On the left corner of the glycerol layer, a small roll was formed. The size of the roll gradually increased as the roll moved to the right. Once the roll passes through the thermistor at the centre of the interface, the lower side of the roll gradually lifts upwards, and the shape of the roll gradually evolves to an elliptic shape. When the roll reached ![]() $L_{x}/4$ away from the right side of the cell, a secondary roll appeared in the lower right position next to the roll. In the end, the roll disappeared before it reached the right side of the cell. The size of the roll increased from 0.05

$L_{x}/4$ away from the right side of the cell, a secondary roll appeared in the lower right position next to the roll. In the end, the roll disappeared before it reached the right side of the cell. The size of the roll increased from 0.05![]() $L_{x}$ at the left corner to 0.12

$L_{x}$ at the left corner to 0.12![]() $L_{x}$ at the centre of the bottom plate. The separation between successive rolls is 0.12

$L_{x}$ at the centre of the bottom plate. The separation between successive rolls is 0.12![]() $L_{x}$. The average speed of the roll is

$L_{x}$. The average speed of the roll is ![]() $0.012\ {\rm mm}\ {\rm s}^{-1}$. The visualisation in figure 11 confirmed that the oscillatory temperature in the interface was a result of the movement of the periodical cellular pattern in the glycerol.

$0.012\ {\rm mm}\ {\rm s}^{-1}$. The visualisation in figure 11 confirmed that the oscillatory temperature in the interface was a result of the movement of the periodical cellular pattern in the glycerol.

Figure 11. (a,c,e,g,i) Instantaneous background-divided and contrast-enhanced images for five moments labelled in the previous figure. (b,d,f,h,j) Cartoon of the images on the left column. The red color indicates that the sides of the roll with greater temperature than the background, and the blue color represents a colder temperature. The measurements were taken for run E2.

We also observed the hot plumes emitted from the interface and cold plumes under the top plate in figure 12. In figures 12(a) and 12(d), the flow fields were taken at the same moment. The cold plumes in figure 12(a) are much more chaotic than the hot plumes in figure 12(d). There are at least six bright vertical stems attaching the top plate at the instantaneous moment. After detachment, the bright streaks were distributed almost everywhere. It is difficult to distinguish individual cold plumes. The cold plumes emerged into larger structures. The average speed of cold plumes in figure 12(a) was about ![]() $6\ {\rm mm}\ {\rm s}^{-1}$. Most of the cold plumes do not disappear before they sink out of the illuminated area.

$6\ {\rm mm}\ {\rm s}^{-1}$. Most of the cold plumes do not disappear before they sink out of the illuminated area.

Figure 12. (a,d) Instantaneous background-divided snapshot. (b,e) Time-averaged and contrast-enhanced image. (c,f) Standard-deviation and contrast-enhanced image. Panels (a–c) are taken below the top plate and panels (d–f) are taken above the bottom plate. The measurements were taken for run E2.

In figure 12(d), several hot vertical thermals appear at the same time. The largest structure above the interface is a dark mushroom-shaped plume on the left side. Initially, the stem erupts from a position ![]() $0.4L_{x}$ away from the left sidewall on the interfacial surface. As time varies the stem grows upwards and moves to the left slowly. The width of the stem slowly increases from 0 to about 5 mm and then the plume disappears. The lifetime of a stem is about 23 s. Note that we do not observe the detachment of the stem. The height of the stem grows from 0 to 20 mm. The average speed of hot plumes is about

$0.4L_{x}$ away from the left sidewall on the interfacial surface. As time varies the stem grows upwards and moves to the left slowly. The width of the stem slowly increases from 0 to about 5 mm and then the plume disappears. The lifetime of a stem is about 23 s. Note that we do not observe the detachment of the stem. The height of the stem grows from 0 to 20 mm. The average speed of hot plumes is about ![]() $2\ {\rm mm}\ {\rm s}^{-1}$. The interface showed a sinusoidal shape. The wave number of the sinusoidal interface is

$2\ {\rm mm}\ {\rm s}^{-1}$. The interface showed a sinusoidal shape. The wave number of the sinusoidal interface is ![]() $m=4$. It seems that the crest is dark and the trough is bright.

$m=4$. It seems that the crest is dark and the trough is bright.

The time-averaged and standard deviation images for run E2 were shown in figures 12(b), 12(c), 12(e) and 12(f). Under the top plate, the time-averaged image is similar to the image without heating. The bright area of figure 12(c) showed the detachment of cold plumes beneath the top plate. The time-averaged image in figure 12(e) showed a thin bright streak over the interface with a thickness of 1 mm. The standard deviation image in figure 12(f) also showed a bright streak over the interface. Obviously, the thickness of the bright streak is greater at the position closer to the sidewall. This indicated that the hot plumes appeared at these positions more frequently. In the glycerol layer, the movement of cellular rolls causes bright areas. The brightest area appears in the right corner, where the cellular rolls mix and disappear.

4.2.3. Range III: two-layer RBC with convective glycerol layer

In figure 13, we show a time series of the temperatures and the heat flux for run E3. The temperature drop across the cell increases from zero to a constant value in 1000 s. There is no oscillation observed in ![]() $T_{int}$. In figure 14, we showed the instantaneous, time-averaged and standard-deviation images of the two-layer RBC under the top plate and over the bottom plate. In figure 14(a), we observed the cluster of cold plumes. The average width of cold plumes in present

$T_{int}$. In figure 14, we showed the instantaneous, time-averaged and standard-deviation images of the two-layer RBC under the top plate and over the bottom plate. In figure 14(a), we observed the cluster of cold plumes. The average width of cold plumes in present ![]() $\varDelta$ is thinner than cold plumes for smaller

$\varDelta$ is thinner than cold plumes for smaller ![]() $\Delta T$ in run E2. In figure 14(d), more than four mushroom-shaped hot plumes are emitted from the interface. The width of the hot plume is about 12 mm. The average lifetime of hot plumes is 10 s, shorter than that of hot plumes for E2 with a smaller

$\Delta T$ in run E2. In figure 14(d), more than four mushroom-shaped hot plumes are emitted from the interface. The width of the hot plume is about 12 mm. The average lifetime of hot plumes is 10 s, shorter than that of hot plumes for E2 with a smaller ![]() $\varDelta$. The average speed of hot plumes is about

$\varDelta$. The average speed of hot plumes is about ![]() $5\ {\rm mm}\ {\rm s}^{-1}$, and it is much greater than that for E2. In the lower layer, three obvious dark wavelets were formed above the bottom plate. This is the wavy variation of the temperature with horizontal distance from the left side of the cell. There are four vertical dark pillars formed at the troughs of the wavelets above the bottom plate. The height of the pillars is 8 mm and the width is 5 mm. The pattern in the glycerol layer is time-independent so the standard deviation image showed no obvious pattern in the glycerol layer. The wave number of the pattern and the shape of the interface is

$5\ {\rm mm}\ {\rm s}^{-1}$, and it is much greater than that for E2. In the lower layer, three obvious dark wavelets were formed above the bottom plate. This is the wavy variation of the temperature with horizontal distance from the left side of the cell. There are four vertical dark pillars formed at the troughs of the wavelets above the bottom plate. The height of the pillars is 8 mm and the width is 5 mm. The pattern in the glycerol layer is time-independent so the standard deviation image showed no obvious pattern in the glycerol layer. The wave number of the pattern and the shape of the interface is ![]() $m=4$. Beneath the top plate, the cold plumes showed more complicated shapes. The cold plumes were inclined to elongate into larger structures or emerge into larger structures. We also observed that hot plumes rise toward the top plate. The average speed of the cold plumes is about

$m=4$. Beneath the top plate, the cold plumes showed more complicated shapes. The cold plumes were inclined to elongate into larger structures or emerge into larger structures. We also observed that hot plumes rise toward the top plate. The average speed of the cold plumes is about ![]() $10\ {\rm mm}\ {\rm s}^{-1}$. This is much greater than that of the cold plume for E2 with a smaller

$10\ {\rm mm}\ {\rm s}^{-1}$. This is much greater than that of the cold plume for E2 with a smaller ![]() $\varDelta$ and it is also much greater than hot plumes.

$\varDelta$ and it is also much greater than hot plumes.

Figure 13. (a) Time series of ![]() $T_{t}$ (blue) and

$T_{t}$ (blue) and ![]() $T_b$ (red). (b) Time series of

$T_b$ (red). (b) Time series of ![]() $T_{int}$. (c) Time series of

$T_{int}$. (c) Time series of ![]() $Q_{tot}$. The measurements were taken for the run E3.

$Q_{tot}$. The measurements were taken for the run E3.

Figure 14. (a,d) Instantaneous background-divided snapshot. (b,e) Time-averaged and contrast-enhanced image. (c,f) Standard-deviation and contrast-enhanced image. Panels (a–c) are taken below the top plate and panels (d–f) are taken above the bottom plate. The measurements were taken for the run E3.

4.3. Heat transport in two-layer RBC

In two-layer RBC, the temperature drop ![]() $\varDelta$ across the whole cell can be set as constant values. The global heat flux

$\varDelta$ across the whole cell can be set as constant values. The global heat flux ![]() $Q_{f}$ transferred through the fluid reaches a statistically steady value. With increasing

$Q_{f}$ transferred through the fluid reaches a statistically steady value. With increasing ![]() $\varDelta$ (equivalent to thermal-driven force), the global effective heat transport quantity

$\varDelta$ (equivalent to thermal-driven force), the global effective heat transport quantity ![]() $Q_{f}/\varDelta$ grows as shown in figure 15. The data were plotted in both logarithmic scales. Power laws were fitted into data in different ranges to yield exponents of 0.8, 2.4, 4.2 and 1.68, respectively. Two vertical lines

$Q_{f}/\varDelta$ grows as shown in figure 15. The data were plotted in both logarithmic scales. Power laws were fitted into data in different ranges to yield exponents of 0.8, 2.4, 4.2 and 1.68, respectively. Two vertical lines ![]() $\varDelta =7\,^{\circ }{\rm C}$ and

$\varDelta =7\,^{\circ }{\rm C}$ and ![]() $19\,^{\circ }{\rm C}$ divided the data into three ranges. It is noted that the temperature inside the fluid is not involved in the global quantity

$19\,^{\circ }{\rm C}$ divided the data into three ranges. It is noted that the temperature inside the fluid is not involved in the global quantity ![]() $Q_{f}/\varDelta$. The flow structures in the glycerol layer in different ranges were attributed to different heat transport.

$Q_{f}/\varDelta$. The flow structures in the glycerol layer in different ranges were attributed to different heat transport.

Figure 15. Heat flux through the fluid ![]() $Q_{f}$ against

$Q_{f}$ against ![]() $\varDelta$. The vertical lines represent

$\varDelta$. The vertical lines represent ![]() $\varDelta ={7}\,^{\circ }{\rm C}$ and

$\varDelta ={7}\,^{\circ }{\rm C}$ and ![]() ${19}\,^{\circ }{\rm C}$. From left to right, the solid lines are

${19}\,^{\circ }{\rm C}$. From left to right, the solid lines are ![]() $Q_f=0.0118 \varDelta ^{0.8\pm 0.1}$,

$Q_f=0.0118 \varDelta ^{0.8\pm 0.1}$, ![]() $Q_f=5.6\times 10^{-4}\varDelta ^{2.4\pm 0.1}$,

$Q_f=5.6\times 10^{-4}\varDelta ^{2.4\pm 0.1}$, ![]() $Q_f=2.4 \times 10^{-6}\varDelta ^{4.2\pm 0.7}$ and

$Q_f=2.4 \times 10^{-6}\varDelta ^{4.2\pm 0.7}$ and ![]() $Q_f=4.2\times 10^{-4} \varDelta ^{1.68\pm 0.04}$.

$Q_f=4.2\times 10^{-4} \varDelta ^{1.68\pm 0.04}$.

To characterise global heat transport, the temperature of interface ![]() $T_{int}$ is required. With

$T_{int}$ is required. With ![]() $T_{int}$, the temperature drops across each layer of fluid are obtained in figure 16(a). For a given