Article contents

A comparative investigation of long-term oxidation behavior of selective laser melting–fabricated Inconel 718 at 650 °C

Published online by Cambridge University Press: 26 May 2020

Abstract

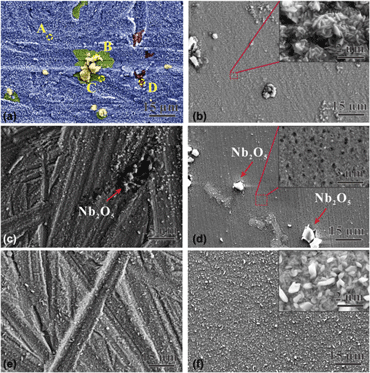

The oxidation behavior of the selective laser melting (SLM)–fabricated Inconel 718 was investigated through isothermal oxidation testing at 650 °C for 500 h and compared with that of the as-cast and as-forged specimens at the same testing conditions. The effect of microstructure and surface roughness on the oxidation behavior of the SLM-fabricated, as-cast, and as-forged Inconel 718 specimens was examined. The result shows that Inconel 718 fabricated by SLM with the unique layer structure exhibited a better resistance to the 500 h oxidation at 650 °C compared with as-cast and as-forged 718 with coarse dendritic structure and uniform equiaxed grain microstructure, respectively. The influence of the surface roughness on the long-time oxidation resistance of SLM specimens is not pronounced compared with that of as-cast and as-forged specimens. The tiny dendrites instead of grain boundaries are a major influencing factor for the oxidation process of SLM specimens. The surface roughness has more evident influence on the oxidation resistance of as-forged specimens than that of the as-cast ones subjected to the 500 h oxidation at 650 °C.

Keywords

- Type

- Article

- Information

- Journal of Materials Research , Volume 35 , Issue 15: Focus Issue: Additive Manufacturing of Metals: Complex Microstructures and Architecture Design , 14 August 2020 , pp. 2036 - 2045

- Copyright

- Copyright © Materials Research Society 2020

References

- 5

- Cited by