Article contents

Semi-solid slurry preparation, rheo-die casting and rheo-squeeze casting of an AZ91–2Ca–1.5Ce ignition-proof magnesium alloy by gas-bubbling process

Published online by Cambridge University Press: 20 January 2017

Abstract

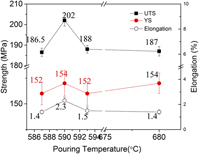

In present study, the semi-solid slurry of the AZ91–2Ca–1.5Ce alloy was firstly prepared by gas-bubbling processing and then was formed by die casting and squeeze casting, respectively. The influence of processing parameters on microstructure and mechanical properties of the alloy was investigated. The results show that increase of gas-flow rate and appropriate pouring temperature can improve the quality of the semi-solid slurry and change the morphology of primary α-Mg particles to rosette-like shape or roundness. Meanwhile, the addition of calcium and cerium refines the as-cast microstructure and dramatically improves the tensile properties, also the strengthening phase Al4Ce exists around the grain boundary. The peak ultimate tensile strength (UTS), yield strength, and elongation of rheo-die casting AZ91–2Ca–1.5Ce alloy are 202 MPa, 154 MPa, and 2.3%, respectively. Especially, compared with conventional liquid die-casting, the UTS and elongation of rheo-die casting AZ91–2Ca–1.5Ce alloy were improved by 8% and 64%, respectively. Meanwhile, the rheo-die casting alloy also showed higher mechanical properties than rheo-squeeze casting alloy, since the higher speed that die casting provided could induce more compact microstructure and remain the semi-solid characteristic better.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

References

REFERENCES

- 5

- Cited by