1. Introduction

Cilia are micro-scale hair-like organelles protruding from the surfaces of many kinds of cells. They can exhibit self-sustained oscillations and play crucial roles in flow transport (Sleigh, Blake & Liron Reference Sleigh, Blake and Liron1988; Chateau et al. Reference Chateau, Favier, D'Ortona and Poncet2017; Loiseau et al. Reference Loiseau, Gsell, Nommick, Jomard, Gras, Chanez, D'Ortona, Kodjabachian, Favier and Viallat2020), fluid mixing (Ding et al. Reference Ding, Nawroth, McFall-Ngai and Kanso2014; Shapiro et al. Reference Shapiro, Fernandez, Garren, Guasto, Debaillon-Vesque, Kramarsky-Winter, Vardi and Stocker2014) and locomotion (Brennen & Winet Reference Brennen and Winet1977) in nature. For instance, beating cilia can pump fluid and produce directional flow to facilitate the removal of mucus in the mucociliary clearance process (Chateau et al. Reference Chateau, Favier, D'Ortona and Poncet2017) as well as the transport of the female reproductive fluid and ovum in the fallopian tube (Fauci & Dillon Reference Fauci and Dillon2006). When covering the surface of a coral, cilia can generate arrays of counter-rotating vortices enhancing the exchange of nutrient and oxygen with the ambient fluid (Shapiro et al. Reference Shapiro, Fernandez, Garren, Guasto, Debaillon-Vesque, Kramarsky-Winter, Vardi and Stocker2014). If anchored on organisms, such as Paramecium and Ctenophore, their oscillatory motions can give rise to body locomotion (Brennen & Winet Reference Brennen and Winet1977; Matsumoto Reference Matsumoto1991). Due to its excellent performance in microscale flow transport, it inspired the design and the utilization of artificial cilia in some promising applications for fluid propulsion, such as lab-on-a-chip devices (Shields et al. Reference Shields, Fiser, Evans, Falvo, Washburn and Superfine2010; Hanasoge, Hesketh & Alexeev Reference Hanasoge, Hesketh and Alexeev2018). On these topics, Brennen & Winet (Reference Brennen and Winet1977), Fauci & Dillon (Reference Fauci and Dillon2006), Satir & Christensen (Reference Satir and Christensen2007), Gilpin, Bull & Prakash (Reference Gilpin, Bull and Prakash2020) and Ul Islam et al. (Reference Ul Islam2022) have given comprehensive reviews.

Typically, cilia beating motion results from their internal motile structure called the axoneme, which is composed of arrays of microtubule doublets and dynein molecular motors (Sartori et al. Reference Sartori, Geyer, Scholich, Jülicher and Howard2016). Nevertheless, the mechanisms for triggering the movement of the axoneme remain elusive. A popular hypothesis states that the motion is actuated by regulating dynein motors in spatial and temporal manners through geometric feedback control schemes (Sartori et al. Reference Sartori, Geyer, Scholich, Jülicher and Howard2016; Man, Ling & Kanso Reference Man, Ling and Kanso2020), such as sliding control (Jülicher & Prost Reference Jülicher and Prost1997; Chakrabarti & Saintillan Reference Chakrabarti and Saintillan2019), curvature control (Elgeti & Gompper Reference Elgeti and Gompper2013) and geometric clutch (Lindemann Reference Lindemann1994). Recently, Bayly & Dutcher (Reference Bayly and Dutcher2016) proposed that such regulation may not be necessary since dynein motors can supply sufficient axial stresses for the onset of the dynamic instability through a Hopf bifurcation, and hence induce sustained oscillations. When considering that cilia are expected to be curved in equilibrium states like flagella (Sartori et al. Reference Sartori, Geyer, Scholich, Jülicher and Howard2016), they can present realistic asymmetric beating patterns if they are instability driven, as demonstrated in a recent study (Ling, Guo & Kanso Reference Ling, Guo and Kanso2018). This mechanism is very attractive due to its extreme simplicity, as the sustained beating can emerge in the absence of any feedback control mechanism, and it could be potentially applied for actuating artificial cilia in microscale devices for flow transport. However, the performance of such cilia in the flow transport remains to be investigated.

Furthermore, the fluid around cilia usually exhibits various types of non-Newtonian behaviours, such as shear-dependent viscosity and viscoelastic behaviours (Dawson, Wirtz & Hanes Reference Dawson, Wirtz and Hanes2003; Vélez-Cordero & Lauga Reference Vélez-Cordero and Lauga2013; Vasquez et al. Reference Vasquez, Bowser, Swiderski, Walters and Kundu2014). For example, the airway liquid and the reproductive liquid can manifest viscoelastic, shear-thinning or slightly shear-thickening behaviours (Dawson et al. Reference Dawson, Wirtz and Hanes2003; Lauga Reference Lauga2007; Vasquez et al. Reference Vasquez, Bowser, Swiderski, Walters and Kundu2014), while all types of liquids could be encountered when using artificial cilia for flow transport. For simplification, however, the fluid is widely assumed as Newtonian (Shields et al. Reference Shields, Fiser, Evans, Falvo, Washburn and Superfine2010; Ding et al. Reference Ding, Nawroth, McFall-Ngai and Kanso2014; Chateau et al. Reference Chateau, Favier, D'Ortona and Poncet2017; Guo et al. Reference Guo, Fauci, Shelley and Kanso2018). As such, the effects of the non-Newtonian behaviours on the flow transport have not been fully understood, especially when the newly proposed instability-driven mechanism is assumed.

The purpose of this study is to bridge the aforementioned gaps and further our understandings on the flow transport of an instability-driven cilium in a non-Newtonian fluid flow. In particular, the cilium is modelled as an elastic filament. Three generalized Newtonian behaviours, i.e. the shear-thinning, Newtonian and shear-thickening behaviours, are taken into account. In nature, the Reynolds number (![]() $Re$) varies within a wide range, i.e. generally from around

$Re$) varies within a wide range, i.e. generally from around ![]() $O(10^{-5})$, such as for cilia in human lungs (Chateau et al. Reference Chateau, Favier, D'Ortona and Poncet2017), to

$O(10^{-5})$, such as for cilia in human lungs (Chateau et al. Reference Chateau, Favier, D'Ortona and Poncet2017), to ![]() $O(10^{2})$, such as for those of Ctenophore (Matsumoto Reference Matsumoto1991). In lab-on-a-chip devices,

$O(10^{2})$, such as for those of Ctenophore (Matsumoto Reference Matsumoto1991). In lab-on-a-chip devices, ![]() $Re$ can also vary across a broad range. Although it is usually set between

$Re$ can also vary across a broad range. Although it is usually set between ![]() $O(0.01)$ and

$O(0.01)$ and ![]() $O(1)$ (Shields et al. Reference Shields, Fiser, Evans, Falvo, Washburn and Superfine2010; Hanasoge et al. Reference Hanasoge, Hesketh and Alexeev2018; Milana et al. Reference Milana, Zhang, Vetrano, Peerlinck, De Volder, Onck, Reynaerts and Gorissen2020), it could get lower with the development of technologies. Herein, the ciliary transport at

$O(1)$ (Shields et al. Reference Shields, Fiser, Evans, Falvo, Washburn and Superfine2010; Hanasoge et al. Reference Hanasoge, Hesketh and Alexeev2018; Milana et al. Reference Milana, Zhang, Vetrano, Peerlinck, De Volder, Onck, Reynaerts and Gorissen2020), it could get lower with the development of technologies. Herein, the ciliary transport at ![]() $Re$ ranging from values close to zero to

$Re$ ranging from values close to zero to ![]() $O(1)$ is investigated in different ways. In particular, the direct numerical simulation (DNS) is adopted at

$O(1)$ is investigated in different ways. In particular, the direct numerical simulation (DNS) is adopted at ![]() $Re \sim O(0.01)$ to

$Re \sim O(0.01)$ to ![]() $O(1)$, while a scaling analysis is proposed at lower

$O(1)$, while a scaling analysis is proposed at lower ![]() $Re$ to circumvent the high numerical expense of DNS (Elgeti & Gompper Reference Elgeti and Gompper2013; Guo & Kanso Reference Guo and Kanso2017). The DNS is performed using a well-validated numerical framework, where the structure dynamics is simulated by the nonlinear finite element method and the fluid dynamics and its interaction with the structure are computed by the immersed-boundary lattice Boltzmann method.

$Re$ to circumvent the high numerical expense of DNS (Elgeti & Gompper Reference Elgeti and Gompper2013; Guo & Kanso Reference Guo and Kanso2017). The DNS is performed using a well-validated numerical framework, where the structure dynamics is simulated by the nonlinear finite element method and the fluid dynamics and its interaction with the structure are computed by the immersed-boundary lattice Boltzmann method.

The remainder of this paper is organized as follows. The problem set-up and numerical method are described in § 2. The simulation results at ![]() $Re \gtrsim O(0.01)$ are provided and discussed in § 3 and a scaling analysis at lower

$Re \gtrsim O(0.01)$ are provided and discussed in § 3 and a scaling analysis at lower ![]() $Re$ is performed in § 4, in which the filament dynamics, fluid dynamics and flow transport are revealed under a variety of conditions. A linear stability analysis is conducted to analyse how the filament dynamics is influenced in § 5, and a conclusion is given in § 6.

$Re$ is performed in § 4, in which the filament dynamics, fluid dynamics and flow transport are revealed under a variety of conditions. A linear stability analysis is conducted to analyse how the filament dynamics is influenced in § 5, and a conclusion is given in § 6.

2. Problem description and methodology

2.1. Problem description

In this study, a filament of diameter ![]() $D$ is placed in an initially quiescent generalized Newtonian fluid contained in a domain with the length

$D$ is placed in an initially quiescent generalized Newtonian fluid contained in a domain with the length ![]() $L$, height

$L$, height ![]() $H$ and width

$H$ and width ![]() $W$, as shown in figure 1. In the absence of external loading, the at-rest filament can exhibit a zero-stress shape which is modelled as a circular arc with the arc length

$W$, as shown in figure 1. In the absence of external loading, the at-rest filament can exhibit a zero-stress shape which is modelled as a circular arc with the arc length ![]() $L_c$ and arc angle

$L_c$ and arc angle ![]() $\theta$. Its base end (

$\theta$. Its base end (![]() $s=0$, where

$s=0$, where ![]() $s$ is the Lagrangian coordinate along the filament) is perpendicularly clamped at the centre of the bottom, while the other end (

$s$ is the Lagrangian coordinate along the filament) is perpendicularly clamped at the centre of the bottom, while the other end (![]() $s={L_c}$) is free. When a compressive follower force

$s={L_c}$) is free. When a compressive follower force ![]() ${\boldsymbol {F}_t}$ is tangentially imposed at the free end, the filament deforms, and the force keeps compressing the structure with its direction always tangential to the free end and with its magnitude unchanged. If the force is sufficiently large, it can trigger the dynamic instability of the filament which thus exhibits a self-sustained oscillation.

${\boldsymbol {F}_t}$ is tangentially imposed at the free end, the filament deforms, and the force keeps compressing the structure with its direction always tangential to the free end and with its magnitude unchanged. If the force is sufficiently large, it can trigger the dynamic instability of the filament which thus exhibits a self-sustained oscillation.

Figure 1. Schematic of a filament located at the centre of the computational domain (not to scale). Here, ![]() $L$,

$L$, ![]() $H$ and

$H$ and ![]() $W$ are the length, height, width of the domain, respectively,

$W$ are the length, height, width of the domain, respectively, ![]() $D$ is the filament diameter,

$D$ is the filament diameter, ![]() $L_c$ is the filament length,

$L_c$ is the filament length, ![]() $\theta$ is the filament arc angle,

$\theta$ is the filament arc angle, ![]() $s$ is the Lagrangian coordinate along the filament and

$s$ is the Lagrangian coordinate along the filament and ![]() $\boldsymbol {F}_t$ is the compressive follower force imposed at the filament free end.

$\boldsymbol {F}_t$ is the compressive follower force imposed at the filament free end.

Although cilium beating motion is intrinsically three-dimensional, which may further benefit fluid transport, it is found that the fundamental mechanisms of generating a directional flow remain the same if it beats two-dimensionally (Eloy & Lauga Reference Eloy and Lauga2012; Elgeti & Gompper Reference Elgeti and Gompper2013; Ding et al. Reference Ding, Nawroth, McFall-Ngai and Kanso2014). For simplification, therefore, it is extensively assumed that the cilium only undergoes two-dimensional deformation (Ding et al. Reference Ding, Nawroth, McFall-Ngai and Kanso2014; Chateau et al. Reference Chateau, Favier, D'Ortona and Poncet2017; Guo et al. Reference Guo, Fauci, Shelley and Kanso2018; Mesdjian et al. Reference Mesdjian, Wang, Gsell, D'Ortona, Favier, Viallat and Loiseau2022). For the same reason, this assumption is also made in this study, and the filament is only allowed to deform in the ![]() $y=0$ plane, as shown in figure 1. Furthermore, cilia are slender bodies in nature, since their diameters are much smaller than their lengths. For instance, the diameter-to-length ratio usually varies from 0.03 to 0.05 in human lungs (Sleigh et al. Reference Sleigh, Blake and Liron1988). Hence, the filament can be simplified as a slender body, whose dynamics is typically governed by (Favier, Revell & Pinelli Reference Favier, Revell and Pinelli2014; Wang et al. Reference Wang, Wang, Zhao, Qi, Lockington, Ramaesh, Stewart, Luo and Tang2022)

$y=0$ plane, as shown in figure 1. Furthermore, cilia are slender bodies in nature, since their diameters are much smaller than their lengths. For instance, the diameter-to-length ratio usually varies from 0.03 to 0.05 in human lungs (Sleigh et al. Reference Sleigh, Blake and Liron1988). Hence, the filament can be simplified as a slender body, whose dynamics is typically governed by (Favier, Revell & Pinelli Reference Favier, Revell and Pinelli2014; Wang et al. Reference Wang, Wang, Zhao, Qi, Lockington, Ramaesh, Stewart, Luo and Tang2022)

\begin{equation} {\rho}_{c}{A}\frac{{\partial}^{2}{\boldsymbol{X}}}{{\partial}{t}^{2}} -\frac{\partial}{{\partial}{s}}\left[{EA}\left(1-\left| \frac{{\partial}{\boldsymbol{X}}}{{\partial}{s}}\right|^{{-}1} \right)\frac{{\partial}{\boldsymbol{X}}}{{\partial}{s}}\right] +\frac{{\partial}^{2}}{{\partial}{s}^{2}}\left[{EI} \left(\frac{{\partial}^{2}{\boldsymbol{X}}}{{\partial}{s}^{2}}- \frac{{\partial}^{2}{\boldsymbol{X}}^{0}}{{\partial}{s}^{2}}\right)\right] = {\boldsymbol{F}_e}, \end{equation}

\begin{equation} {\rho}_{c}{A}\frac{{\partial}^{2}{\boldsymbol{X}}}{{\partial}{t}^{2}} -\frac{\partial}{{\partial}{s}}\left[{EA}\left(1-\left| \frac{{\partial}{\boldsymbol{X}}}{{\partial}{s}}\right|^{{-}1} \right)\frac{{\partial}{\boldsymbol{X}}}{{\partial}{s}}\right] +\frac{{\partial}^{2}}{{\partial}{s}^{2}}\left[{EI} \left(\frac{{\partial}^{2}{\boldsymbol{X}}}{{\partial}{s}^{2}}- \frac{{\partial}^{2}{\boldsymbol{X}}^{0}}{{\partial}{s}^{2}}\right)\right] = {\boldsymbol{F}_e}, \end{equation}

where ![]() $\rho _c$ is the filament density,

$\rho _c$ is the filament density, ![]() $E$ is the Young's modulus,

$E$ is the Young's modulus, ![]() $A$ is the cross-section area of the filament (

$A$ is the cross-section area of the filament (![]() $A = {{\rm \pi} }{D}^{2}/{4}$),

$A = {{\rm \pi} }{D}^{2}/{4}$), ![]() $I$ is the moment of inertia (

$I$ is the moment of inertia (![]() $I={{\rm \pi} }{D}^{4}/{64}$),

$I={{\rm \pi} }{D}^{4}/{64}$), ![]() $EA$ and

$EA$ and ![]() $EI$ can be considered as the stretching and bending stiffnesses, respectively,

$EI$ can be considered as the stretching and bending stiffnesses, respectively, ![]() ${\boldsymbol {X}}$ is the filament's position,

${\boldsymbol {X}}$ is the filament's position, ![]() ${\boldsymbol {X}}^{0}$ denotes the zero-stress shape of the filament and

${\boldsymbol {X}}^{0}$ denotes the zero-stress shape of the filament and ![]() ${\boldsymbol {F}_e}$ is the external loading acting on the filament.

${\boldsymbol {F}_e}$ is the external loading acting on the filament.

The dynamics of the incompressible flow can be described by the continuity and momentum equations as follows:

where ![]() $\boldsymbol {\nabla }$ is the gradient operator,

$\boldsymbol {\nabla }$ is the gradient operator, ![]() $\boldsymbol {v}$ is the flow velocity,

$\boldsymbol {v}$ is the flow velocity, ![]() $\rho _f$ is the fluid density,

$\rho _f$ is the fluid density, ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\boldsymbol {f}_{e}$ is the external force per unit volume and

$\boldsymbol {f}_{e}$ is the external force per unit volume and ![]() $\boldsymbol {\tau }$ is the deviatoric stress tensor which is given by

$\boldsymbol {\tau }$ is the deviatoric stress tensor which is given by

for the generalized-Newtonian fluid, ![]() $\mu$ is the fluid dynamic viscosity, and

$\mu$ is the fluid dynamic viscosity, and ![]() $\boldsymbol {S}$ is the strain rate tensor defined as

$\boldsymbol {S}$ is the strain rate tensor defined as

As such, the momentum equation, i.e. (2.3), can be rewritten as

Since one objective of this study is to investigate the effects of the shear-thinning and shear-thickening behaviours, a power-law model is applied to represent these generalized-Newtonian behaviours, where the dynamic viscosity is given by (Chai et al. Reference Chai, Shi, Guo and Rong2011)

![]() $\kappa$ is the power-law consistency index,

$\kappa$ is the power-law consistency index, ![]() $n$ is the power-law index of the fluid (

$n$ is the power-law index of the fluid (![]() $n < 1$ for shear-thinning flow,

$n < 1$ for shear-thinning flow, ![]() $n=1$ for Newtonian flow and

$n=1$ for Newtonian flow and ![]() $n > 1$ for shear-thickening flow), and

$n > 1$ for shear-thickening flow), and ![]() $\dot {\gamma }$ is the shear rate, which can be expressed as

$\dot {\gamma }$ is the shear rate, which can be expressed as

To parameterize this fluid–structure interaction (FSI) system, ![]() ${L}_{c}$ and

${L}_{c}$ and ![]() ${\rho }_{f}$ are chosen as the repeating variables. The reference time scale is chosen as

${\rho }_{f}$ are chosen as the repeating variables. The reference time scale is chosen as

\begin{equation} {T}_{r}=\left(\frac{\kappa {L_c^4}}{EI}\right)^{{1}/{n}}, \end{equation}

\begin{equation} {T}_{r}=\left(\frac{\kappa {L_c^4}}{EI}\right)^{{1}/{n}}, \end{equation}

which corresponds to the balancing between the fluid viscosity and the filament elasticity, and is selected as the third repeating variable for the parameterization. When ![]() $n=1$,

$n=1$, ![]() ${T}_{r}$ recovers the reference time scale proposed in Guo et al. (Reference Guo, Fauci, Shelley and Kanso2018). As such, the dimensionless forms of (2.1), (2.2) and (2.6) can be written as

${T}_{r}$ recovers the reference time scale proposed in Guo et al. (Reference Guo, Fauci, Shelley and Kanso2018). As such, the dimensionless forms of (2.1), (2.2) and (2.6) can be written as

\begin{gather} \begin{aligned} & {m}^{*}{Re}\frac{{\partial}^{2}{\boldsymbol{X}^{*}}}{{\partial}{t}^{*2}} - \frac{\partial}{{\partial}{s}^{*}}\left[{E}^{*}{A}^{*}\left(1-\left| \frac{{\partial}{\boldsymbol{X}}^{*}}{{\partial}{s}^{*}}\right|^{{-}1} \right)\frac{{\partial}{\boldsymbol{X}}^{*}}{{\partial}{s}^{*}}\right]\\ & \quad +\frac{{\partial}^{2}}{{\partial}{s}^{*2}} \left[{E}^{*}{I}^{*}\left( \frac{{\partial}^{2}{\boldsymbol{X}^{*}}}{{\partial}{s}^{*2}}- \frac{{\partial}^{2}{\boldsymbol{X}^{0*}}}{{\partial}{s}^{*2}}\right)\right] = {{\boldsymbol{F}}_e^{*}}, \end{aligned} \end{gather}

\begin{gather} \begin{aligned} & {m}^{*}{Re}\frac{{\partial}^{2}{\boldsymbol{X}^{*}}}{{\partial}{t}^{*2}} - \frac{\partial}{{\partial}{s}^{*}}\left[{E}^{*}{A}^{*}\left(1-\left| \frac{{\partial}{\boldsymbol{X}}^{*}}{{\partial}{s}^{*}}\right|^{{-}1} \right)\frac{{\partial}{\boldsymbol{X}}^{*}}{{\partial}{s}^{*}}\right]\\ & \quad +\frac{{\partial}^{2}}{{\partial}{s}^{*2}} \left[{E}^{*}{I}^{*}\left( \frac{{\partial}^{2}{\boldsymbol{X}^{*}}}{{\partial}{s}^{*2}}- \frac{{\partial}^{2}{\boldsymbol{X}^{0*}}}{{\partial}{s}^{*2}}\right)\right] = {{\boldsymbol{F}}_e^{*}}, \end{aligned} \end{gather}For ease of reference, the definitions of the dimensionless parameters in (2.10)–(2.12) are shown in table 1 alphabetically. Furthermore, some other dimensionless parameters, such as the length, width and height of the computational domain and the follower-force magnitude, are also included in this table.

Table 1. Definitions and selected values of dimensionless parameters in this study. Here, ![]() $\theta = 0$ means that the filament is straight in its zero-stress state. Symbol ‘-’ indicates that the corresponding parameter is updated during the simulation.

$\theta = 0$ means that the filament is straight in its zero-stress state. Symbol ‘-’ indicates that the corresponding parameter is updated during the simulation.

To satisfy the slender-body condition, the dimensionless filament diameter (![]() $D^*$) is set to 0.1 throughout this study. Thus, the dimensionless moment of inertia (

$D^*$) is set to 0.1 throughout this study. Thus, the dimensionless moment of inertia (![]() $I^*$) is equal to

$I^*$) is equal to ![]() $4.91 \times {10}^{-6}$. Substituting (2.9) into the definition of the dimensionless Young's modulus, i.e.

$4.91 \times {10}^{-6}$. Substituting (2.9) into the definition of the dimensionless Young's modulus, i.e. ![]() ${E}^{*}=E{{T}_{r}^{n}}/{\kappa }$, yields

${E}^{*}=E{{T}_{r}^{n}}/{\kappa }$, yields ![]() $E^*=1/I^* = 2.04 \times {10}^{5}$. As

$E^*=1/I^* = 2.04 \times {10}^{5}$. As ![]() ${\rho }_{c}$ is close to

${\rho }_{c}$ is close to ![]() ${\rho }_{f}$ in nature, they are assumed to be equal.

${\rho }_{f}$ in nature, they are assumed to be equal.

Similar to Chateau et al. (Reference Chateau, Favier, D'Ortona and Poncet2017), the filament dynamics and flow transport in this study are quantified by several dimensionless quantities, mainly including the beating frequency (![]() $\,f^*$), time-averaged flux (

$\,f^*$), time-averaged flux (![]() $\bar {Q}^{*}$) across the computational domain, time-averaged input power per unit area (

$\bar {Q}^{*}$) across the computational domain, time-averaged input power per unit area (![]() $\bar {P}^{*}$), transport efficiency (

$\bar {P}^{*}$), transport efficiency (![]() $\eta$) and mean effectiveness (

$\eta$) and mean effectiveness (![]() $\xi$) quantifying the time-averaged directional pushing efficiency. Specifically,

$\xi$) quantifying the time-averaged directional pushing efficiency. Specifically, ![]() $\,f^*$ is defined as

$\,f^*$ is defined as

where ![]() $f$ is the dimensional beating frequency. Also,

$f$ is the dimensional beating frequency. Also, ![]() $\bar {Q}^{*}$ is given by

$\bar {Q}^{*}$ is given by

\begin{equation} \bar{Q}^{*} = \frac{\displaystyle \int_{{T}^{*}}{Q}^{*}\, {\rm d} {t}^{*}}{{H}^{*}{W}^{*}{T}^{*}}, \end{equation}

\begin{equation} \bar{Q}^{*} = \frac{\displaystyle \int_{{T}^{*}}{Q}^{*}\, {\rm d} {t}^{*}}{{H}^{*}{W}^{*}{T}^{*}}, \end{equation}

where ![]() ${Q}^{*} = {Q}/{{\rho }_{f}}{{U}_{r}}{{L}_{c}^{2}}$ is the instantaneous dimensionless flow rate in the

${Q}^{*} = {Q}/{{\rho }_{f}}{{U}_{r}}{{L}_{c}^{2}}$ is the instantaneous dimensionless flow rate in the ![]() $x$ direction,

$x$ direction, ![]() ${U}_{r}$ is the reference velocity defined as

${U}_{r}$ is the reference velocity defined as ![]() ${U}_{r}={L_c}/{T_r}$ and

${U}_{r}={L_c}/{T_r}$ and ![]() ${T}^{*}$ is the dimensionless beating period defined by

${T}^{*}$ is the dimensionless beating period defined by ![]() ${T}^{*}=1/f^*$.

${T}^{*}=1/f^*$. ![]() $\bar {P}^{*}$ is expressed as

$\bar {P}^{*}$ is expressed as

\begin{equation} \bar{P}^{*} = \frac{\displaystyle \int_{{T}^{*}}{({P^*})}_{p} \, {\rm d}{t}^{*}}{{L}^{*}{W}^{*}{T}^{*}}, \end{equation}

\begin{equation} \bar{P}^{*} = \frac{\displaystyle \int_{{T}^{*}}{({P^*})}_{p} \, {\rm d}{t}^{*}}{{L}^{*}{W}^{*}{T}^{*}}, \end{equation}

where ![]() ${P}^{*}$ is the dimensionless input power defined as

${P}^{*}$ is the dimensionless input power defined as ![]() ${P}^{*} = {\boldsymbol {F}_{t}^{*}} \boldsymbol {\cdot } {\boldsymbol {v}_{t}^{*}}$,

${P}^{*} = {\boldsymbol {F}_{t}^{*}} \boldsymbol {\cdot } {\boldsymbol {v}_{t}^{*}}$, ![]() $\boldsymbol {v}_{t}^{*}$ is the dimensionless filament-tip velocity defined by

$\boldsymbol {v}_{t}^{*}$ is the dimensionless filament-tip velocity defined by ![]() $\boldsymbol {v}_{t}^{*}=\boldsymbol {v}_{t}/{U}_{r}$ and

$\boldsymbol {v}_{t}^{*}=\boldsymbol {v}_{t}/{U}_{r}$ and ![]() $\boldsymbol {v}_{t}$ is the dimensional counterpart of

$\boldsymbol {v}_{t}$ is the dimensional counterpart of ![]() $\boldsymbol {v}_{t}^{*}$. In this study, negative input power implies that energy is transferred from the filament to the actuation system. Since this part of energy may not be recovered, only positive input power represented by

$\boldsymbol {v}_{t}^{*}$. In this study, negative input power implies that energy is transferred from the filament to the actuation system. Since this part of energy may not be recovered, only positive input power represented by ![]() ${({P}^{*})}_{p}$ is taken into account. Since the flow horizontally passes through the surfaces normal to the

${({P}^{*})}_{p}$ is taken into account. Since the flow horizontally passes through the surfaces normal to the ![]() $x$ direction, the flux

$x$ direction, the flux ![]() $\bar {Q}^{*}$ is equal to the time-averaged flow rate divided by the corresponding area, i.e.

$\bar {Q}^{*}$ is equal to the time-averaged flow rate divided by the corresponding area, i.e. ![]() $H^*W^*$. In contrast,

$H^*W^*$. In contrast, ![]() $\bar {P}^{*}$ corresponds to the time-averaged power normalized by the area of the bottom surface where the filament is located, i.e.

$\bar {P}^{*}$ corresponds to the time-averaged power normalized by the area of the bottom surface where the filament is located, i.e. ![]() $L^*W^*$.

$L^*W^*$. ![]() $\eta$ is defined as

$\eta$ is defined as

![]() $\xi$ is written as

$\xi$ is written as

\begin{equation} {\xi} = \frac{{\bar Q}^{*}_{p}-{\bar Q}^{*}_{n}}{{\bar Q}^{*}_{p}+{\bar Q}^{*}_{n}}, \end{equation}

\begin{equation} {\xi} = \frac{{\bar Q}^{*}_{p}-{\bar Q}^{*}_{n}}{{\bar Q}^{*}_{p}+{\bar Q}^{*}_{n}}, \end{equation}

where ![]() ${\bar Q}^{*}_{p}$ and

${\bar Q}^{*}_{p}$ and ![]() ${\bar Q}^{*}_{n}$ are the positive and negative time-averaged flux evaluated by

${\bar Q}^{*}_{n}$ are the positive and negative time-averaged flux evaluated by

\begin{gather} \bar{Q}^{*}_{p} = \frac{\displaystyle \int_{{T}^{*}}({Q}^{*})_{p}\, {\rm d} {t}^{*}}{{H}^{*}{W}^{*}{T}^{*}}, \end{gather}

\begin{gather} \bar{Q}^{*}_{p} = \frac{\displaystyle \int_{{T}^{*}}({Q}^{*})_{p}\, {\rm d} {t}^{*}}{{H}^{*}{W}^{*}{T}^{*}}, \end{gather} \begin{gather}\bar{Q}^{*}_{n} = \frac{\displaystyle \int_{{T}^{*}}({Q}^{*})_{n}\, {\rm d} {t}^{*}}{{H}^{*}{W}^{*}{T}^{*}}, \end{gather}

\begin{gather}\bar{Q}^{*}_{n} = \frac{\displaystyle \int_{{T}^{*}}({Q}^{*})_{n}\, {\rm d} {t}^{*}}{{H}^{*}{W}^{*}{T}^{*}}, \end{gather}

the subscripts ‘![]() $p$’ and ‘

$p$’ and ‘![]() $n$’ mean that only the positive or negative flow rate is considered in the integral. Therefore,

$n$’ mean that only the positive or negative flow rate is considered in the integral. Therefore, ![]() $\xi$ quantifies the filament capability of consistently pushing the fluid towards a certain direction. Specifically, when

$\xi$ quantifies the filament capability of consistently pushing the fluid towards a certain direction. Specifically, when ![]() $\xi =-1$ and 1, the fluid is always transported in the negative and positive

$\xi =-1$ and 1, the fluid is always transported in the negative and positive ![]() $x$ directions throughout the whole beating period, respectively, while the flow direction changes occasionally when

$x$ directions throughout the whole beating period, respectively, while the flow direction changes occasionally when ![]() $-1 < \xi < 1$.

$-1 < \xi < 1$.

2.2. Methodology

To solve the aforementioned FSI problem, a co-rotational finite element formulation (Doyle Reference Doyle2013) is applied to solve the structure dynamics governed by (2.10). The multiple-relaxation-time lattice Boltzmann method (Chai et al. Reference Chai, Shi, Guo and Rong2011) is adopted for solving the three-dimensional generalized-Newtonian flow. To solve the interplay between the flow and structure dynamics, the immersed-boundary method (IBM) (Peskin Reference Peskin2002) is incorporated to impose the no-slip boundary condition on the structure surface as well as accurately evaluate the fluid stresses. Similar to prior works (Chateau et al. Reference Chateau, Favier, D'Ortona and Poncet2017; Han & Peskin Reference Han and Peskin2018), the filament radius is assumed equal to half the support length of the Dirac delta function adopted in the IBM. Details on the current numerical algorithm and its validation can be found in our previous works (Favier et al. Reference Favier, Revell and Pinelli2014; Li et al. Reference Li, Favier, D'Ortona and Poncet2016; Wang & Tang Reference Wang and Tang2018, Reference Wang and Tang2019; Gsell, D'Ortona & Favier Reference Gsell, D'Ortona and Favier2019).

According to (2.7), the dynamic viscosity ![]() $\mu$ turns to infinity as the shear rate

$\mu$ turns to infinity as the shear rate ![]() $\dot {\gamma }$ approaches zero if the power-law index

$\dot {\gamma }$ approaches zero if the power-law index ![]() $n<1$, which poses a critical numerical issue. To overcome this problem, the lower limit of

$n<1$, which poses a critical numerical issue. To overcome this problem, the lower limit of ![]() $\dot {\gamma }$ is arbitrarily set as a value close to zero herein, i.e.

$\dot {\gamma }$ is arbitrarily set as a value close to zero herein, i.e. ![]() $\dot {\gamma }_{min}=10^{-14}$. It is confirmed that this value is sufficiently small, so that when another value of similar order of magnitude is selected, the simulation results are nearly unaffected.

$\dot {\gamma }_{min}=10^{-14}$. It is confirmed that this value is sufficiently small, so that when another value of similar order of magnitude is selected, the simulation results are nearly unaffected.

In this study, the no-slip boundary condition is imposed on the bottom wall representing the substrate from which the filament protrudes. The periodic boundary condition is applied in the ![]() $x$ and

$x$ and ![]() $y$ directions, meaning that an infinite number of filaments beat in phase in the domain which is infinitely large in these two directions. In contrast, the domain height (

$y$ directions, meaning that an infinite number of filaments beat in phase in the domain which is infinitely large in these two directions. In contrast, the domain height (![]() $H^*$) is finite, and the free-slip boundary condition is imposed on the top wall at

$H^*$) is finite, and the free-slip boundary condition is imposed on the top wall at ![]() $z^*=H^*$. This setting can represent different physical scenarios. One can be where a free surface presents on the top boundary, and another one can be where the current computational domain is only one half of a channel symmetric about the plane at

$z^*=H^*$. This setting can represent different physical scenarios. One can be where a free surface presents on the top boundary, and another one can be where the current computational domain is only one half of a channel symmetric about the plane at ![]() $z^*=H^*$. However, it does not correspond to the scenario with a semi-infinite domain.

$z^*=H^*$. However, it does not correspond to the scenario with a semi-infinite domain.

Although the dimensions of the computational domain could affect the quantities of interest to different extents, their effects are not explored in this study, but they are fixed as follows. The length and width are set the same as the filament length, i.e. ![]() ${L}^{*}={W}^{*}=1$, the height is selected as three times the filament length, i.e.

${L}^{*}={W}^{*}=1$, the height is selected as three times the filament length, i.e. ![]() ${H}^{*}=3$. According to the convergence test conducted in the Appendix, the mesh spacing (

${H}^{*}=3$. According to the convergence test conducted in the Appendix, the mesh spacing (![]() ${{\rm \Delta} }x$) and the time step (

${{\rm \Delta} }x$) and the time step (![]() ${{\rm \Delta} }{t}$) depend on the Reynolds number (

${{\rm \Delta} }{t}$) depend on the Reynolds number (![]() $Re$) and

$Re$) and ![]() $n$, as given in table 3. Hence, different

$n$, as given in table 3. Hence, different ![]() ${{\rm \Delta} }{x}$ and

${{\rm \Delta} }{x}$ and ![]() ${{\rm \Delta} }{t}$ are adopted for the cases with different

${{\rm \Delta} }{t}$ are adopted for the cases with different ![]() $Re$ and

$Re$ and ![]() $n$.

$n$.

2.3. Case summary

As shown in § 2.1, the filament dynamics and flow transport depend on the power-law index (![]() $n$), Reynolds number (

$n$), Reynolds number (![]() $Re$), arc angle (

$Re$), arc angle (![]() $\theta$) and follower-force magnitude (

$\theta$) and follower-force magnitude (![]() $F_t^*$). To cover the shear-thinning and shear-thickening behaviours and also to make a comprehensive investigation,

$F_t^*$). To cover the shear-thinning and shear-thickening behaviours and also to make a comprehensive investigation, ![]() $n$ is selected from 0.75 to 1.5 with an interval of 0.25.

$n$ is selected from 0.75 to 1.5 with an interval of 0.25. ![]() $Re$ is chosen from both low-

$Re$ is chosen from both low-![]() $Re$ and

$Re$ and ![]() $Re \approx 0$ regimes. In particular,

$Re \approx 0$ regimes. In particular, ![]() $Re$ is selected as 0.04, 0.2, 1 and 5 in the low-

$Re$ is selected as 0.04, 0.2, 1 and 5 in the low-![]() $Re$ regime, where inertial effects are exhibited in the domain, as will be shown in § 3.2.5. Due to extremely high computational demand, however, the investigations in the

$Re$ regime, where inertial effects are exhibited in the domain, as will be shown in § 3.2.5. Due to extremely high computational demand, however, the investigations in the ![]() $Re \approx 0$ regime where viscous effects are overwhelmingly dominant are not conducted numerically, but are performed through a scaling analysis. In addition, two

$Re \approx 0$ regime where viscous effects are overwhelmingly dominant are not conducted numerically, but are performed through a scaling analysis. In addition, two ![]() $\theta$ values are considered, i.e.

$\theta$ values are considered, i.e. ![]() $\theta =0$ and

$\theta =0$ and ![]() $3{\rm \pi} /4$. When

$3{\rm \pi} /4$. When ![]() $\theta = 0$ the filament is completely straight in its zero-stress state and usually exhibits symmetric beating, and it presents asymmetric beating when

$\theta = 0$ the filament is completely straight in its zero-stress state and usually exhibits symmetric beating, and it presents asymmetric beating when ![]() $\theta = 3{\rm \pi} /4$. Furthermore,

$\theta = 3{\rm \pi} /4$. Furthermore, ![]() $F_t^*$ varies in the range of 20 to 60 with an interval of 10, whose lower bound is roughly equal to the critical value to trigger the dynamic instability of a straight filament in vacuum (Timoshenko & Gere Reference Timoshenko and Gere1961). For ease of reference, the above selected values of these four dimensionless parameters are listed in table 1.

$F_t^*$ varies in the range of 20 to 60 with an interval of 10, whose lower bound is roughly equal to the critical value to trigger the dynamic instability of a straight filament in vacuum (Timoshenko & Gere Reference Timoshenko and Gere1961). For ease of reference, the above selected values of these four dimensionless parameters are listed in table 1.

3. Flow transport in the low- $Re$ regime

$Re$ regime

3.1. Symmetric beating

Figure 2 gives an overview of the beating frequency (![]() $\,f^*$) for the straight-filament cases. To numerically trigger the dynamic instability, a small constant force, i.e. a force whose magnitude is

$\,f^*$) for the straight-filament cases. To numerically trigger the dynamic instability, a small constant force, i.e. a force whose magnitude is ![]() $1\,\%$ of the follower-force magnitude (

$1\,\%$ of the follower-force magnitude (![]() ${F}_t^*$), is initially imposed on the filament tip in the

${F}_t^*$), is initially imposed on the filament tip in the ![]() $x$ direction and is removed after ten time steps of simulation in all cases. It is found that

$x$ direction and is removed after ten time steps of simulation in all cases. It is found that ![]() ${F}_t^*$ of 20 is not sufficiently large for the onset of the dynamic instability. Thus, the filament remains stationary and straight. As

${F}_t^*$ of 20 is not sufficiently large for the onset of the dynamic instability. Thus, the filament remains stationary and straight. As ![]() ${F}_t^*$ approaches 30, the instability sets in, as shown in figure 2(a). Additionally, it is seen that

${F}_t^*$ approaches 30, the instability sets in, as shown in figure 2(a). Additionally, it is seen that ![]() $\,f^*$ increases with

$\,f^*$ increases with ![]() ${F}_t^*$. At each

${F}_t^*$. At each ![]() ${F}_t^*$,

${F}_t^*$, ![]() $\,f^*$ decreases with the power-law index (

$\,f^*$ decreases with the power-law index (![]() $n$) and the Reynolds number (

$n$) and the Reynolds number (![]() $Re$). As such,

$Re$). As such, ![]() $\,f^*$ approaches the maximum when

$\,f^*$ approaches the maximum when ![]() ${F}_t^*=60$,

${F}_t^*=60$, ![]() $n=0.75$ and

$n=0.75$ and ![]() $Re=0.04$.

$Re=0.04$.

Figure 2. Interpolated contours of the dimensionless beating frequency (![]() $\,f^*$) of the straight filament (the arc angle

$\,f^*$) of the straight filament (the arc angle ![]() $\theta =0$) when the follower force

$\theta =0$) when the follower force ![]() ${F}_t^*=30$ (a),

${F}_t^*=30$ (a), ![]() ${F}_t^*=40$ (b),

${F}_t^*=40$ (b), ![]() ${F}_t^*=50$ (c) and

${F}_t^*=50$ (c) and ![]() ${F}_t^*=60$ (d). Transparent symbols denote DNS data points.

${F}_t^*=60$ (d). Transparent symbols denote DNS data points.

Since the filament is straight and vertically clamped in its zero-stress state, its beating pattern is spatially symmetric. Under this condition, the beating filament only causes an oscillatory flow with zero mean flux, i.e. ![]() $\bar {Q}^{*}=0$, in all cases. Hence, the transport efficiency (

$\bar {Q}^{*}=0$, in all cases. Hence, the transport efficiency (![]() ${\eta }$) and the mean effectiveness (

${\eta }$) and the mean effectiveness (![]() ${\xi }$) are zero. All of these can be illustrated by one representative case, i.e. the case with

${\xi }$) are zero. All of these can be illustrated by one representative case, i.e. the case with ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$. Figure 3 shows that the filament beating pattern is symmetric with respect to the

$Re=0.2$. Figure 3 shows that the filament beating pattern is symmetric with respect to the ![]() $x^*=0$ plane and the trajectory of the filament tip forms a symmetric figure ‘8’ in this case. Under these circumstances, the flow rate (

$x^*=0$ plane and the trajectory of the filament tip forms a symmetric figure ‘8’ in this case. Under these circumstances, the flow rate (![]() ${Q}^{*}$) varies almost sinusoidally with the amplitude of 5.5 as well as with

${Q}^{*}$) varies almost sinusoidally with the amplitude of 5.5 as well as with ![]() $\bar {Q}^{*}=0$, as shown in figure 4, where the time origin

$\bar {Q}^{*}=0$, as shown in figure 4, where the time origin ![]() ${t}^{*}=0$ is set as the instant when the

${t}^{*}=0$ is set as the instant when the ![]() $x$ position of the filament tip reaches its minimum after the periodic steady state of the flow has been achieved. The variation of

$x$ position of the filament tip reaches its minimum after the periodic steady state of the flow has been achieved. The variation of ![]() ${Q}^{*}$ originates from the periodically oscillating flow forced by the beating filament, while the zero mean flux is due to the spatio-temporal symmetry of the flow–structure response, as shown in figure 5. Furthermore, comparing figures 4 and 5 reveals that

${Q}^{*}$ originates from the periodically oscillating flow forced by the beating filament, while the zero mean flux is due to the spatio-temporal symmetry of the flow–structure response, as shown in figure 5. Furthermore, comparing figures 4 and 5 reveals that ![]() ${Q}^{*}$ always lags behind the filament motion due to the flow inertia. For instance, at

${Q}^{*}$ always lags behind the filament motion due to the flow inertia. For instance, at ![]() $t^*=0$ the mid-portion of the filament starts to flap rightward, while the flow above the filament still moves leftward, as shown in figure 5(a), yielding the negative

$t^*=0$ the mid-portion of the filament starts to flap rightward, while the flow above the filament still moves leftward, as shown in figure 5(a), yielding the negative ![]() ${Q}^{*}$, as shown in figure 4. Note that for consistent comparison, the colour bar scale in figure 5 is adopted throughout this study. However, the

${Q}^{*}$, as shown in figure 4. Note that for consistent comparison, the colour bar scale in figure 5 is adopted throughout this study. However, the ![]() $x$ velocity could exceed the scale range (especially in the shear-thinning case). To represent the fluid and filament velocities precisely under this condition, velocity vectors are also plotted in scale in the contour figures.

$x$ velocity could exceed the scale range (especially in the shear-thinning case). To represent the fluid and filament velocities precisely under this condition, velocity vectors are also plotted in scale in the contour figures.

Figure 3. Beating pattern of the straight filament in the case with ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$. The blue dashed line represents the filament-tip trajectory.

$Re=0.2$. The blue dashed line represents the filament-tip trajectory.

Figure 4. Time history of the flow rate (![]() $Q^*$) in the case with

$Q^*$) in the case with ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$. The dashed line represents the time-averaged flux (

$Re=0.2$. The dashed line represents the time-averaged flux (![]() $\bar {Q}^*$).

$\bar {Q}^*$).

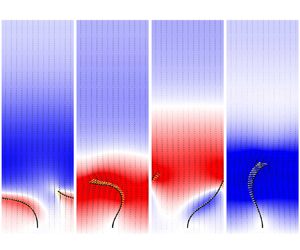

Figure 5. Contour of the ![]() $x$ velocity (

$x$ velocity (![]() $u^*$) in the

$u^*$) in the ![]() $y^*=0$ plane in the case with

$y^*=0$ plane in the case with ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$ at the instant

$Re=0.2$ at the instant ![]() $t^*/T^*=0$ (a),

$t^*/T^*=0$ (a), ![]() $t^*/T^*=0.25$ (b),

$t^*/T^*=0.25$ (b), ![]() $t^*/T^*=0.5$ (c) and

$t^*/T^*=0.5$ (c) and ![]() $t^*/T^*=0.75$ (d).

$t^*/T^*=0.75$ (d).

3.2. Asymmetric beating

3.2.1. Overview of results

Figure 6 provides an overview of the simulation results for the curved-filament cases. It is found that the critical follower force (![]() ${F}_t^*$) to trigger the dynamic instability is the same for the straight and curved filaments. In addition, the beating frequency (

${F}_t^*$) to trigger the dynamic instability is the same for the straight and curved filaments. In addition, the beating frequency (![]() $\,f^*$) and its variation with

$\,f^*$) and its variation with ![]() ${F}_t^*$, the power-law index (

${F}_t^*$, the power-law index (![]() $n$) and the Reynolds number (

$n$) and the Reynolds number (![]() $Re$) are generally the same when the filament is straight and curved, as shown in figure 2 and the first row of figure 6. This implies that the filament dynamics is not largely changed when its zero-stress shape is altered from straight to arc.

$Re$) are generally the same when the filament is straight and curved, as shown in figure 2 and the first row of figure 6. This implies that the filament dynamics is not largely changed when its zero-stress shape is altered from straight to arc.

Figure 6. Interpolated contours of the (the first row) dimensionless beating frequency (![]() $\,f^*$), (the second row) time-averaged flux (

$\,f^*$), (the second row) time-averaged flux (![]() $\bar {Q}^{*}$), (the third row) time-averaged input power per unit area (

$\bar {Q}^{*}$), (the third row) time-averaged input power per unit area (![]() $\bar {P}^{*}$), (the fourth row) transport efficiency (

$\bar {P}^{*}$), (the fourth row) transport efficiency (![]() $\eta$) and (the last row) mean effectiveness (

$\eta$) and (the last row) mean effectiveness (![]() $\xi$) of the curved filament with the arc angle

$\xi$) of the curved filament with the arc angle ![]() $\theta =3{\rm \pi} /4$ when the follower force

$\theta =3{\rm \pi} /4$ when the follower force ![]() ${F}_t^*=30$ (a),

${F}_t^*=30$ (a), ![]() ${F}_t^*=40$ (b),

${F}_t^*=40$ (b), ![]() ${F}_t^*=50$ (c) and

${F}_t^*=50$ (c) and ![]() ${F}_t^*=60$ (d). Transparent symbols denote DNS data points.

${F}_t^*=60$ (d). Transparent symbols denote DNS data points.

When the filament is curved, the time-averaged flux (![]() $\bar {Q}^{*}$) is no longer zero due to the breaking of the spatial symmetry, as shown in the second row of figure 6. Although the filament is curved rightward in its zero-stress state (see figure 1), it is bent leftward more largely after the self-sustained oscillation is achieved (see figure 7). As such, the overall flow is leftward in most cases, corresponding to negative

$\bar {Q}^{*}$) is no longer zero due to the breaking of the spatial symmetry, as shown in the second row of figure 6. Although the filament is curved rightward in its zero-stress state (see figure 1), it is bent leftward more largely after the self-sustained oscillation is achieved (see figure 7). As such, the overall flow is leftward in most cases, corresponding to negative ![]() $\bar {Q}^{*}$. If comparing the first three rows of figure 6, it is found that the effects of

$\bar {Q}^{*}$. If comparing the first three rows of figure 6, it is found that the effects of ![]() ${F}_t^*$,

${F}_t^*$, ![]() $n$ and

$n$ and ![]() $Re$ on

$Re$ on ![]() $\bar {Q}^{*}$ and the time-averaged input power per unit area (

$\bar {Q}^{*}$ and the time-averaged input power per unit area (![]() $\bar {P}^{*}$) are similar to those on

$\bar {P}^{*}$) are similar to those on ![]() $\,f^*$, indicating that

$\,f^*$, indicating that ![]() $\bar {Q}^*$ and

$\bar {Q}^*$ and ![]() $\bar {P}^*$ are closely correlated with

$\bar {P}^*$ are closely correlated with ![]() $\,f^*$. However, the contour patterns of

$\,f^*$. However, the contour patterns of ![]() $\bar {Q}^{*}$ and

$\bar {Q}^{*}$ and ![]() $\bar {P}^{*}$ are different at the same

$\bar {P}^{*}$ are different at the same ![]() ${F}_t^*$, meaning that they are not influenced by

${F}_t^*$, meaning that they are not influenced by ![]() $n$ and

$n$ and ![]() $Re$ in the same way. In particular,

$Re$ in the same way. In particular, ![]() $\bar {P}^{*}$ is reduced roughly by the same amount when

$\bar {P}^{*}$ is reduced roughly by the same amount when ![]() $Re$ increases from 0.04 to 5 and when

$Re$ increases from 0.04 to 5 and when ![]() $n$ increases from 0.75 to 1.5. By contrast,

$n$ increases from 0.75 to 1.5. By contrast, ![]() $\bar {Q}^{*}$ mainly changes with

$\bar {Q}^{*}$ mainly changes with ![]() $n$ instead of

$n$ instead of ![]() $Re$, as shown in the second and third rows of figure 6. This results in a quite different variation of the transport efficiency (

$Re$, as shown in the second and third rows of figure 6. This results in a quite different variation of the transport efficiency (![]() $\eta$) with

$\eta$) with ![]() ${F}_t^*$,

${F}_t^*$, ![]() $n$ and

$n$ and ![]() $Re$, as shown in the fourth row of figure 6. Specifically,

$Re$, as shown in the fourth row of figure 6. Specifically, ![]() $\eta$ reduces with

$\eta$ reduces with ![]() ${F}_t^*$. At each

${F}_t^*$. At each ![]() ${F}_t^*$,

${F}_t^*$, ![]() $\eta$ generally increases with

$\eta$ generally increases with ![]() $Re$ but decreases with

$Re$ but decreases with ![]() $n$. The last row of figure 6 shows that the mean effectiveness (

$n$. The last row of figure 6 shows that the mean effectiveness (![]() $\xi$) remains at

$\xi$) remains at ![]() $-1$ roughly at

$-1$ roughly at ![]() $Re \ge 1$ and

$Re \ge 1$ and ![]() $n<1.25$, where thus the instantaneous flow is always along the negative

$n<1.25$, where thus the instantaneous flow is always along the negative ![]() $x$ direction. In the other cases,

$x$ direction. In the other cases, ![]() $\xi$ falls between

$\xi$ falls between ![]() $-$1 and 0, meaning that the flow is not unidirectional over each beating period. Overall, figure 6 shows that as

$-$1 and 0, meaning that the flow is not unidirectional over each beating period. Overall, figure 6 shows that as ![]() $n$ decreases,

$n$ decreases, ![]() $\bar {Q}^{*}$,

$\bar {Q}^{*}$, ![]() $\eta$ and

$\eta$ and ![]() ${\xi }$ can be improved simultaneously at all

${\xi }$ can be improved simultaneously at all ![]() ${F}_t^*$, suggesting that the shear-thinning behaviour is more beneficial to the flow transport.

${F}_t^*$, suggesting that the shear-thinning behaviour is more beneficial to the flow transport.

Figure 7. Beating pattern of the curved filament in the baseline case where ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$.

$Re=0.2$.

In the following, the case with ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$ is selected as the baseline case for unveiling the filament dynamics, fluid dynamics and flow transport in detail. Afterwards, more cases are selected and discussed to further reveal the effects of

$Re=0.2$ is selected as the baseline case for unveiling the filament dynamics, fluid dynamics and flow transport in detail. Afterwards, more cases are selected and discussed to further reveal the effects of ![]() ${F}_t^*$,

${F}_t^*$, ![]() $n$ and

$n$ and ![]() $Re$.

$Re$.

3.2.2. Baseline case

In the baseline case, the curved filament beats asymmetrically with its tip trajectory forming a figure ‘8’, as shown in figure 7. Similar to that in nature, the beating pattern consists of two strokes, i.e. the power and recovery strokes. However, unlike in nature where the duration of the power stroke is usually around half that of the recovery one, these two strokes last for roughly the same amount of time. Since the power stroke occurs when the filament flaps leftward, the resulting overall flow is along the negative ![]() $x$ direction, yielding the time-averaged flux

$x$ direction, yielding the time-averaged flux ![]() $\bar {Q}^{*}=-0.97$, as shown in figure 6(b-ii).

$\bar {Q}^{*}=-0.97$, as shown in figure 6(b-ii).

Due to the successive alternation of the power and recovery strokes, the flow rate (![]() $Q^*$) varies in a sinusoidal manner while the input power (

$Q^*$) varies in a sinusoidal manner while the input power (![]() $P^*$) changes with two peaks and two troughs appearing over each beating period, as shown in figure 8. Such variations of

$P^*$) changes with two peaks and two troughs appearing over each beating period, as shown in figure 8. Such variations of ![]() $Q^*$ and

$Q^*$ and ![]() $P^*$ are determined by the filament dynamics and the corresponding unsteady flow field.

$P^*$ are determined by the filament dynamics and the corresponding unsteady flow field.

Figure 8. Time histories of the (a) flow rate (![]() $Q^*$) and (b) input power (

$Q^*$) and (b) input power (![]() $P^*$) in the baseline case where

$P^*$) in the baseline case where ![]() ${F}_t^*=40$ and the cases with

${F}_t^*=40$ and the cases with ![]() ${F}_t^*=30$, 50 and 60 when

${F}_t^*=30$, 50 and 60 when ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$.

$Re=0.2$.

At the instant ![]() $t^*/T^*=0$, the filament is undergoing the stroke reversal from the power to the recovery one. During this period, the filament reaches its leftmost position and is starting to flap rightward, as shown in figure 9(a). Under this condition, the filament moves slowly, resulting in the local minimum

$t^*/T^*=0$, the filament is undergoing the stroke reversal from the power to the recovery one. During this period, the filament reaches its leftmost position and is starting to flap rightward, as shown in figure 9(a). Under this condition, the filament moves slowly, resulting in the local minimum ![]() $P^*$ at around this instant, as shown in figure 8(b). Due to the flow inertia, only the flow closely wrapping the filament is along the positive

$P^*$ at around this instant, as shown in figure 8(b). Due to the flow inertia, only the flow closely wrapping the filament is along the positive ![]() $x$ direction, while that in the rest region goes in the opposite direction. Hence,

$x$ direction, while that in the rest region goes in the opposite direction. Hence, ![]() $Q^*$ approaches a large negative value, i.e.

$Q^*$ approaches a large negative value, i.e. ![]() $Q^*=-6.38$, at this instant, as shown in figure 8(a).

$Q^*=-6.38$, at this instant, as shown in figure 8(a).

Figure 9. Contours of the ![]() $x$ velocity (

$x$ velocity (![]() $u^*$) in the

$u^*$) in the ![]() $y^*=0$ plane (first row) and in the

$y^*=0$ plane (first row) and in the ![]() $z^*=0.7$ plane (second row) in the baseline case where

$z^*=0.7$ plane (second row) in the baseline case where ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$ at the instant

$Re=0.2$ at the instant ![]() $t^*/T^*=0$ (a),

$t^*/T^*=0$ (a), ![]() $t^*/T^*=0.25$ (b),

$t^*/T^*=0.25$ (b), ![]() $t^*/T^*=0.5$ (c) and

$t^*/T^*=0.5$ (c) and ![]() $t^*/T^*=0.75$ (d).

$t^*/T^*=0.75$ (d).

As time advances to ![]() $t^*/T^*=0.25$, the filament is beating rightward roughly with the maximum speed during the recovery stroke, as shown in figure 9(b). This leads to the local maximum

$t^*/T^*=0.25$, the filament is beating rightward roughly with the maximum speed during the recovery stroke, as shown in figure 9(b). This leads to the local maximum ![]() $P^*$ at around this instant, as shown in figure 8(b). Compared with that at the instant

$P^*$ at around this instant, as shown in figure 8(b). Compared with that at the instant ![]() $t^*/T^*=0$, more flow is directed by the filament towards the positive

$t^*/T^*=0$, more flow is directed by the filament towards the positive ![]() $x$ direction with larger speed. Meanwhile, the negative

$x$ direction with larger speed. Meanwhile, the negative ![]() $x$-direction flow is slowed down and the corresponding region shrinks. As such, the flow rate reduces to

$x$-direction flow is slowed down and the corresponding region shrinks. As such, the flow rate reduces to ![]() $Q^*=-0.81$ at this instant.

$Q^*=-0.81$ at this instant.

At around the instant ![]() $t^*/T^*=0.5$, the filament approaches the other stroke reversal, as shown in figure 9(c). Accordingly,

$t^*/T^*=0.5$, the filament approaches the other stroke reversal, as shown in figure 9(c). Accordingly, ![]() $P^*$ reaches the other local minimum, as shown in figure 8(b). Compared with that at around

$P^*$ reaches the other local minimum, as shown in figure 8(b). Compared with that at around ![]() $t^*/T^*=0.25$, the interface between the positive and negative

$t^*/T^*=0.25$, the interface between the positive and negative ![]() $x$-direction flow regions approximately rises to

$x$-direction flow regions approximately rises to ![]() $z^*=1.8$, while the flow in both regions becomes slower. As a result, the overall flow goes in the positive

$z^*=1.8$, while the flow in both regions becomes slower. As a result, the overall flow goes in the positive ![]() $x$ direction with

$x$ direction with ![]() $Q^* = 2.03$ at this instant. This explains why the mean effectiveness

$Q^* = 2.03$ at this instant. This explains why the mean effectiveness ![]() $\xi =-0.75$ rather than

$\xi =-0.75$ rather than ![]() $-$1 in this case, as given in figure 6(b-v).

$-$1 in this case, as given in figure 6(b-v).

As time progresses to ![]() $t^*/T^*=0.75$, the filament is beating leftward approximately with the maximum speed during the power stroke, as shown in figure 9(d). As such,

$t^*/T^*=0.75$, the filament is beating leftward approximately with the maximum speed during the power stroke, as shown in figure 9(d). As such, ![]() $P^*$ approaches the other local maximum at around this instant, as shown in figure 8(b). Since the filament is the least bent and the most vertical at around this instant, it generally produces the strongest nearby flow within the whole beating period, if comparing the

$P^*$ approaches the other local maximum at around this instant, as shown in figure 8(b). Since the filament is the least bent and the most vertical at around this instant, it generally produces the strongest nearby flow within the whole beating period, if comparing the ![]() $x$-velocity contours at the four selected instants shown in figure 9. Moreover, the flow within the entire domain moves in the negative

$x$-velocity contours at the four selected instants shown in figure 9. Moreover, the flow within the entire domain moves in the negative ![]() $x$ direction. Hence,

$x$ direction. Hence, ![]() $Q^*$ rapidly reaches the negative maximum, i.e.

$Q^*$ rapidly reaches the negative maximum, i.e. ![]() $Q^*=-8.44$, at

$Q^*=-8.44$, at ![]() $t^*/T^*=0.87$, as shown in figure 8(a).

$t^*/T^*=0.87$, as shown in figure 8(a).

3.2.3. Effects of follower-force magnitude

Figure 10 shows the beating patterns in the baseline case where the follower force ![]() ${F}_t^*=40$ as well as three other cases with

${F}_t^*=40$ as well as three other cases with ![]() ${F}_t^*=30$, 50 and 60 when the power-law index

${F}_t^*=30$, 50 and 60 when the power-law index ![]() $n=1$ and the Reynolds number

$n=1$ and the Reynolds number ![]() $Re=0.2$. It is seen that, as

$Re=0.2$. It is seen that, as ![]() ${F}_t^*$ increases, the filament beating pattern becomes wider in the

${F}_t^*$ increases, the filament beating pattern becomes wider in the ![]() $x$ direction and slightly shorter in the

$x$ direction and slightly shorter in the ![]() $z$ direction. This variation is the most obvious when

$z$ direction. This variation is the most obvious when ![]() ${F}_t^*$ augments from 30 to 40, whereas it turns less visible for larger

${F}_t^*$ augments from 30 to 40, whereas it turns less visible for larger ![]() ${F}_t^*$, as it is constrained by the negligible extensibility of the filament. Accordingly, the time-averaged flux (

${F}_t^*$, as it is constrained by the negligible extensibility of the filament. Accordingly, the time-averaged flux (![]() $\bar {Q}^{*}$) is enhanced from

$\bar {Q}^{*}$) is enhanced from ![]() $-$0.64 to

$-$0.64 to ![]() $-$0.97 as

$-$0.97 as ![]() $F_t^*$ increases from 30 to 40, while it remains at around

$F_t^*$ increases from 30 to 40, while it remains at around ![]() $-$1.0 as

$-$1.0 as ![]() $F_t^*$ further rises, as shown in the second row of figure 6. This implies that

$F_t^*$ further rises, as shown in the second row of figure 6. This implies that ![]() $|\bar {Q}^{*}|$ is positively correlated with the beating amplitude, and the effects of

$|\bar {Q}^{*}|$ is positively correlated with the beating amplitude, and the effects of ![]() $F_t^*$ on them become saturated when it is sufficiently large. Furthermore, a larger

$F_t^*$ on them become saturated when it is sufficiently large. Furthermore, a larger ![]() $F_t^*$ can drive the filament to beat faster, which causes the stronger oscillation of the flow rate (

$F_t^*$ can drive the filament to beat faster, which causes the stronger oscillation of the flow rate (![]() $Q^*$) and the higher input power (

$Q^*$) and the higher input power (![]() $P^*$), as shown in figure 8.

$P^*$), as shown in figure 8.

Figure 10. Beating patterns of the curved filament in the cases with ![]() $F_t^*=30$ (a),

$F_t^*=30$ (a), ![]() $F_t^*=40$ (b),

$F_t^*=40$ (b), ![]() $F_t^*=50$ (c) and

$F_t^*=50$ (c) and ![]() $F_t^*=60$ (d) when

$F_t^*=60$ (d) when ![]() $n=1$ and

$n=1$ and ![]() $Re=0.2$. Note that the filament number in each panel is arbitrary and is not related to

$Re=0.2$. Note that the filament number in each panel is arbitrary and is not related to ![]() $\,f^*$. The same applies to the other figures showing filament beating patterns.

$\,f^*$. The same applies to the other figures showing filament beating patterns.

3.2.4. Effects of power-law index

To unveil the influences of the power-law index (![]() $n$), the baseline case (where

$n$), the baseline case (where ![]() $n=1$ and the flow is Newtonian) as well as two representative non-Newtonian cases, i.e. the cases with

$n=1$ and the flow is Newtonian) as well as two representative non-Newtonian cases, i.e. the cases with ![]() $n=0.75$ and

$n=0.75$ and ![]() $n=1.5$ (corresponding to the shear-thinning and shear-thickening flows, respectively) when the follower force

$n=1.5$ (corresponding to the shear-thinning and shear-thickening flows, respectively) when the follower force ![]() ${F}_t^*=40$ and the Reynolds number

${F}_t^*=40$ and the Reynolds number ![]() $Re=0.2$, are selected for detailed investigation.

$Re=0.2$, are selected for detailed investigation.

Figure 11 shows that the filament beating pattern is similar but the beating amplitude increases as ![]() $n$ increases from 0.75 to 1.5. The reason can be revealed from figure 12 through examining the competition of three types of forces in the

$n$ increases from 0.75 to 1.5. The reason can be revealed from figure 12 through examining the competition of three types of forces in the ![]() $x$ direction along which the major deformation of the filament occurs, namely, the

$x$ direction along which the major deformation of the filament occurs, namely, the ![]() $x$-component follower force (

$x$-component follower force (![]() ${F}_{tx}^{*}$), the dimensionless drag force (

${F}_{tx}^{*}$), the dimensionless drag force (![]() ${{F}_{D}^{*}}$) and the

${{F}_{D}^{*}}$) and the ![]() $x$-component inertial force which can be represented by that at the filament tip (

$x$-component inertial force which can be represented by that at the filament tip (![]() ${F}_{ix}^{*}$).

${F}_{ix}^{*}$). ![]() ${{F}_{D}^{*}} = {F}_{D}{{T}_{r}^{n}}/{\kappa }{{L}_{c}^{2}}$, where

${{F}_{D}^{*}} = {F}_{D}{{T}_{r}^{n}}/{\kappa }{{L}_{c}^{2}}$, where ![]() ${F}_{D}$ is the

${F}_{D}$ is the ![]() $x$ component of the hydrodynamic force acting on the filament and is evaluated through the IBM (Gsell et al. Reference Gsell, D'Ortona and Favier2019), and

$x$ component of the hydrodynamic force acting on the filament and is evaluated through the IBM (Gsell et al. Reference Gsell, D'Ortona and Favier2019), and ![]() ${F}_{ix}^{*} = -{m}^{*}{Re}({{\partial }^{2}{X^{*}_{1}}}/{{\partial }{t}^{*2}})$, where

${F}_{ix}^{*} = -{m}^{*}{Re}({{\partial }^{2}{X^{*}_{1}}}/{{\partial }{t}^{*2}})$, where ![]() $X^{*}_{1}$ is the

$X^{*}_{1}$ is the ![]() $x$ coordinate of the filament tip according to the first term of (2.10).

$x$ coordinate of the filament tip according to the first term of (2.10).

Figure 11. Beating patterns of the curved filament in the cases with ![]() $n=0.75$ (a) and

$n=0.75$ (a) and ![]() $n=1.5$ (c) as well as the baseline case where

$n=1.5$ (c) as well as the baseline case where ![]() $n=1$ (b) when

$n=1$ (b) when ![]() ${F}_t^*=40$ and

${F}_t^*=40$ and ![]() $Re=0.2$.

$Re=0.2$.

Figure 12. Time histories of (a) the ![]() $x$-component follower force (

$x$-component follower force (![]() $F_{tx}^*$), (b) the

$F_{tx}^*$), (b) the ![]() $x$-component inertial force at the filament tip (

$x$-component inertial force at the filament tip (![]() $F_{ix}^*$) and (c) the drag force (

$F_{ix}^*$) and (c) the drag force (![]() $F_{D}^*$) in the cases with

$F_{D}^*$) in the cases with ![]() $n=0.75$, 1 and 1.5 when

$n=0.75$, 1 and 1.5 when ![]() $Re=0.2$ and

$Re=0.2$ and ![]() ${F}_t^*=40$.

${F}_t^*=40$.

In these cases, ![]() ${F}_{tx}^{*}$ is roughly independent of

${F}_{tx}^{*}$ is roughly independent of ![]() $n$, while

$n$, while ![]() ${F}_{D}^{*}$ is nearly anti-phase with

${F}_{D}^{*}$ is nearly anti-phase with ![]() ${F}_{tx}^{*}$ and generally has an amplitude comparable to that of

${F}_{tx}^{*}$ and generally has an amplitude comparable to that of ![]() ${F}_{tx}^{*}$, as shown in figure 12. In contrast,

${F}_{tx}^{*}$, as shown in figure 12. In contrast, ![]() ${F}_{ix}^{*}$ is greatly dependent of

${F}_{ix}^{*}$ is greatly dependent of ![]() $n$, and its amplitude decreases with

$n$, and its amplitude decreases with ![]() $n$, as shown in figure 12(b). This stems from the fact that the drag-force amplitude can be generally scaled as

$n$, as shown in figure 12(b). This stems from the fact that the drag-force amplitude can be generally scaled as ![]() ${F}_{DA}^{*} \sim ({\zeta }{u}_{m}^{*})^{n}$, where

${F}_{DA}^{*} \sim ({\zeta }{u}_{m}^{*})^{n}$, where ![]() ${u}_{m}^{*}$ is the maximum nominal filament beating speed in the

${u}_{m}^{*}$ is the maximum nominal filament beating speed in the ![]() $x$ direction, and

$x$ direction, and ![]() ${\zeta }$ is a constant determined by the filament geometry, as will be shown in § 5. If assuming that the filament generally undergoes a sinusoidal oscillation with the nominal beating amplitude of half the filament length,

${\zeta }$ is a constant determined by the filament geometry, as will be shown in § 5. If assuming that the filament generally undergoes a sinusoidal oscillation with the nominal beating amplitude of half the filament length, ![]() ${u}_{m}^{*} \sim {\rm \pi}f^*$, where

${u}_{m}^{*} \sim {\rm \pi}f^*$, where ![]() $\,f^*$ is the beating frequency. Hence,

$\,f^*$ is the beating frequency. Hence, ![]() ${F}_{DA}^{*} \sim ({{\rm \pi} }{\zeta }f^{*})^{n}$. As such, when the drag-force amplitude is the same, the filament has to beat faster in the shear-thinning flow (

${F}_{DA}^{*} \sim ({{\rm \pi} }{\zeta }f^{*})^{n}$. As such, when the drag-force amplitude is the same, the filament has to beat faster in the shear-thinning flow (![]() $n<1$) and slower in the shear-thickening (

$n<1$) and slower in the shear-thickening (![]() $n > 1$) flow than in the Newtonian flow (

$n > 1$) flow than in the Newtonian flow (![]() $n=1$), as also evidenced by figures 9, 13 and 14 (refer to § 5 for more accurate and detailed explanations). Since a faster beating commonly corresponds to a larger acceleration and thus a greater inertial force, it is reasonable to see that the

$n=1$), as also evidenced by figures 9, 13 and 14 (refer to § 5 for more accurate and detailed explanations). Since a faster beating commonly corresponds to a larger acceleration and thus a greater inertial force, it is reasonable to see that the ![]() ${F}_{ix}^{*}$ amplitude decreases with

${F}_{ix}^{*}$ amplitude decreases with ![]() $n$. As

$n$. As ![]() ${F}_{tx}^{*}$ and

${F}_{tx}^{*}$ and ![]() ${F}_{ix}^{*}$ are roughly anti-phase, their resultant force, which can be regarded as the effective actuation force, generally increases with

${F}_{ix}^{*}$ are roughly anti-phase, their resultant force, which can be regarded as the effective actuation force, generally increases with ![]() $n$. Thus, a wider beating pattern presents at a higher

$n$. Thus, a wider beating pattern presents at a higher ![]() $n$. These analyses show that the increase of

$n$. These analyses show that the increase of ![]() $n$ is equivalent to that of

$n$ is equivalent to that of ![]() $F_t^*$ when the structure inertia is not negligible.

$F_t^*$ when the structure inertia is not negligible.

Figure 13. Contours of the ![]() $x$ velocity (

$x$ velocity (![]() $u^*$) in the

$u^*$) in the ![]() $y^*=0$ plane (first row) and in the

$y^*=0$ plane (first row) and in the ![]() $z^*=0.7$ plane (second row) in the case with

$z^*=0.7$ plane (second row) in the case with ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=0.75$ and

$n=0.75$ and ![]() $Re=0.2$ at the instant

$Re=0.2$ at the instant ![]() $t^*/T^*=0$ (a),

$t^*/T^*=0$ (a), ![]() $t^*/T^*=0.25$ (b),

$t^*/T^*=0.25$ (b), ![]() $t^*/T^*=0.5$ (c) and

$t^*/T^*=0.5$ (c) and ![]() $t^*/T^*=0.75$ (d).

$t^*/T^*=0.75$ (d).

Figure 14. Contours of the ![]() $x$ velocity (

$x$ velocity (![]() $u^*$) in the

$u^*$) in the ![]() $y^*=0$ plane (first row) and in the

$y^*=0$ plane (first row) and in the ![]() $z^*=0.7$ plane (second row) in the case with

$z^*=0.7$ plane (second row) in the case with ![]() ${F}_t^*=40$,

${F}_t^*=40$, ![]() $n=1.5$ and

$n=1.5$ and ![]() $Re=0.2$ at the instant

$Re=0.2$ at the instant ![]() $t^*/T^*=0$ (a),

$t^*/T^*=0$ (a), ![]() $t^*/T^*=0.25$ (b),

$t^*/T^*=0.25$ (b), ![]() $t^*/T^*=0.5$ (c) and

$t^*/T^*=0.5$ (c) and ![]() $t^*/T^*=0.75$ (d).

$t^*/T^*=0.75$ (d).

Due to the different fluid-filament dynamics, the time histories of the flow rate (![]() ${Q}^{*}$) and input power (

${Q}^{*}$) and input power (![]() ${P}^{*}$) are distinct in these cases, as shown in figure 15. In particular, as the filament beating speed in the case with

${P}^{*}$) are distinct in these cases, as shown in figure 15. In particular, as the filament beating speed in the case with ![]() $n=0.75$ is much larger than that in the baseline case,

$n=0.75$ is much larger than that in the baseline case, ![]() ${P}^*$ is generally larger (see figure 15b) and the ambient fluid speed is higher in the case with

${P}^*$ is generally larger (see figure 15b) and the ambient fluid speed is higher in the case with ![]() $n=0.75$. Owning to the shear-thinning behaviour, however, the fluid velocity decays much faster in space in the case with

$n=0.75$. Owning to the shear-thinning behaviour, however, the fluid velocity decays much faster in space in the case with ![]() $n=0.75$, suggesting a smaller viscous length scale, as shown in figure 13. Therefore, only the flow closely surrounding the filament is evidently directed, and the oscillation of

$n=0.75$, suggesting a smaller viscous length scale, as shown in figure 13. Therefore, only the flow closely surrounding the filament is evidently directed, and the oscillation of ![]() ${Q}^{*}$ is weaker. Also for this reason, a strong unidirectional flow right above the filament is developed in the case with

${Q}^{*}$ is weaker. Also for this reason, a strong unidirectional flow right above the filament is developed in the case with ![]() $n=0.75$, which does not emerge in the baseline case. Consequently, the flow is always in the negative

$n=0.75$, which does not emerge in the baseline case. Consequently, the flow is always in the negative ![]() $x$ direction in the case with

$x$ direction in the case with ![]() $n=0.75$, as shown in figure 15(a).

$n=0.75$, as shown in figure 15(a).

Figure 15. Time histories of the (a) flow rate (![]() $Q^*$) and (b) input power (

$Q^*$) and (b) input power (![]() $P^*$) in the baseline case where

$P^*$) in the baseline case where ![]() $n=1$ and the cases with

$n=1$ and the cases with ![]() $n=0.75$ and 1.5 when

$n=0.75$ and 1.5 when ![]() ${F}_t^*=40$ and

${F}_t^*=40$ and ![]() $Re=0.2$.

$Re=0.2$.

The influences of the shear-thickening behaviour on the filament and fluid dynamics are opposite to those of the shear-thinning one, as demonstrated in figures 9, 13 and 14. In the case with ![]() $n=1.5$, the filament beats the most slowly, leading to the smallest

$n=1.5$, the filament beats the most slowly, leading to the smallest ![]() ${P}^*$, as shown in figure 15(b). While a unidirectional flow is observed above the filament in the cases with

${P}^*$, as shown in figure 15(b). While a unidirectional flow is observed above the filament in the cases with ![]() $n=0.75$ and 1, in that with

$n=0.75$ and 1, in that with ![]() $n=1.5$ the viscous length scale is larger and the flow is oscillating across the whole domain. However, a clear phase lag develops in the

$n=1.5$ the viscous length scale is larger and the flow is oscillating across the whole domain. However, a clear phase lag develops in the ![]() $z$ direction, as shown in figure 14. The flow rate is generally smaller with larger oscillations than those in the other two cases, indicating that the flow transport is the least effective in the case with

$z$ direction, as shown in figure 14. The flow rate is generally smaller with larger oscillations than those in the other two cases, indicating that the flow transport is the least effective in the case with ![]() $n=1.5$, as shown in figure 15.

$n=1.5$, as shown in figure 15.

Although it is expected that the increase of the beating amplitude could enhance the absolute time-averaged flux (![]() $|\bar {Q}^{*}|$), as discussed in § 3.2.3, the opposite is true in this section. This implies the existence of a mechanism enhancing the flow transport in the shear-thinning case, despite the smaller beating amplitude. It could be related to the drastic variation of the viscous length scale with

$|\bar {Q}^{*}|$), as discussed in § 3.2.3, the opposite is true in this section. This implies the existence of a mechanism enhancing the flow transport in the shear-thinning case, despite the smaller beating amplitude. It could be related to the drastic variation of the viscous length scale with ![]() $n$, as shown in figures 9, 13 and 14. In the shear-thinning case, the length scale is the smallest, resulting in the presence of the unidirectional flow right above the filament and maximizing

$n$, as shown in figures 9, 13 and 14. In the shear-thinning case, the length scale is the smallest, resulting in the presence of the unidirectional flow right above the filament and maximizing ![]() $|\bar {Q}^{*}|$.

$|\bar {Q}^{*}|$.

3.2.5. Effects of Reynolds number

Figure 16 shows the filament beating pattern in the cases with the Reynolds number ![]() $Re=0.04$, 0.2, 1 and 5 when the follower force

$Re=0.04$, 0.2, 1 and 5 when the follower force ![]() ${F}_t^*=40$ and the power-law index

${F}_t^*=40$ and the power-law index ![]() $n=1$. It is noted that the beating amplitude and the time-averaged flux (

$n=1$. It is noted that the beating amplitude and the time-averaged flux (![]() $\bar {Q}^{*}$) generally decrease with

$\bar {Q}^{*}$) generally decrease with ![]() $Re$. This stems from that the

$Re$. This stems from that the ![]() $x$-component follower force (

$x$-component follower force (![]() ${F}_{tx}^{*}$) is roughly independent of

${F}_{tx}^{*}$) is roughly independent of ![]() $Re$, while the

$Re$, while the ![]() $x$-component inertial force (

$x$-component inertial force (![]() ${F}_{ix}^{*}$) is generally anti-phase with

${F}_{ix}^{*}$) is generally anti-phase with ![]() ${F}_{tx}^{*}$ and its strength increases with

${F}_{tx}^{*}$ and its strength increases with ![]() $Re$. As such, their resultant force, i.e. the effective actuation force, diminishes with

$Re$. As such, their resultant force, i.e. the effective actuation force, diminishes with ![]() $Re$, as shown in figure 17. Hence, the increase of

$Re$, as shown in figure 17. Hence, the increase of ![]() $Re$ is similar to reducing

$Re$ is similar to reducing ![]() ${F}_t^*$ in § 3.2.3. Also for this reason, the filament beats slowly when

${F}_t^*$ in § 3.2.3. Also for this reason, the filament beats slowly when ![]() $Re$ is large, and the oscillation amplitude of the input power (

$Re$ is large, and the oscillation amplitude of the input power (![]() $P^*$) turns smaller with

$P^*$) turns smaller with ![]() $Re$, as shown in figure 18(b).

$Re$, as shown in figure 18(b).

Figure 16. Beating patterns of the curved filament in the cases with ![]() $Re=0.04$ (a),

$Re=0.04$ (a), ![]() $Re=0.2$ (b),

$Re=0.2$ (b), ![]() $Re=1$ (c) and

$Re=1$ (c) and ![]() $Re=5$ (d) when

$Re=5$ (d) when ![]() $n=1$ and

$n=1$ and ![]() $F_t^*=40$.

$F_t^*=40$.

Figure 17. Time histories of (a) the ![]() $x$-component follower force (

$x$-component follower force (![]() $F_{tx}^*$) and (b) the

$F_{tx}^*$) and (b) the ![]() $x$-component inertial force at the filament tip (

$x$-component inertial force at the filament tip (![]() $F_{ix}^*$) in the cases with

$F_{ix}^*$) in the cases with ![]() $Re=0.04$, 0.2, 1 and 5 when

$Re=0.04$, 0.2, 1 and 5 when ![]() $n=1$ and

$n=1$ and ![]() ${F}_t^*=40$.

${F}_t^*=40$.

Figure 18. Time histories of the (a) flow rate (![]() $Q^*$) and (b) input power (

$Q^*$) and (b) input power (![]() $P^*$) in the cases with

$P^*$) in the cases with ![]() $Re=0.04$, 0.2, 1 and 5 when