No CrossRef data available.

Article contents

Analytical STEM Investigations of Nozzle Vane Surfaces after Turbine Engine Operation

Published online by Cambridge University Press: 30 July 2021

Abstract

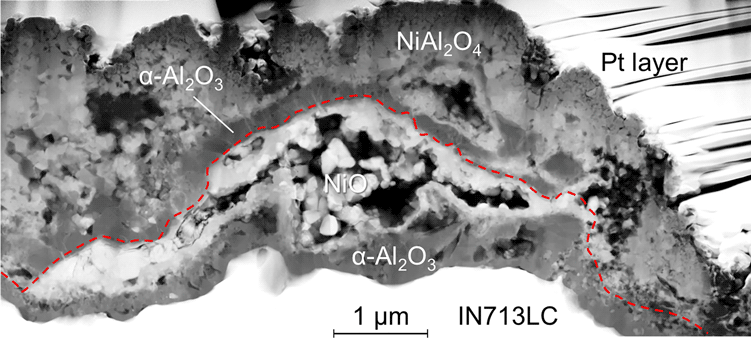

The scope of this work includes detailed microstructural investigations using high-resolution scanning transmission electron microscopy of the oxide scales and deposits formed on nozzle ring vanes made of IN713LC alloy during the operation of an auxiliary power unit under real conditions. The paper presents the differences of oxidation processes between the suction and the pressure sides of the vanes. It has been shown that in the pressure side of the vane, where a greater flow of exhaust gases from the combustion chamber is present, the oxidation process is accompanied by a deposition of among others (i.a.) Fe, Mg, Ca, Na, and P, while on the suction side of the vane, the thermal stresses and the mechanical loading most likely lead to a cracking of the oxide scale. A segregation of Cr, Ni, Ta, and Ti to the boundaries of α-Al2O3 grains is observed, which may indicate their diffusion from a metal to a gas atmosphere.

Keywords

- Type

- The XVIIth International Conference on Electron Microscopy (EM2020)

- Information

- Copyright

- Copyright © The Author(s), 2021. Published by Cambridge University Press on behalf of the Microscopy Society of America