Article contents

Crystallographic and Compositional Evolution of Ordered B2 and Disordered BCC Phases During Isothermal Annealing of Refractory High-Entropy Alloys

Published online by Cambridge University Press: 10 June 2022

Abstract

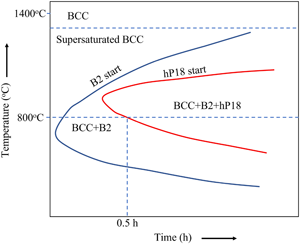

Refractory high-entropy alloys (RHEAs) are promising candidates for next-generation high-temperature materials. RHEAs containing Al, often exhibit a checkered pattern microstructure comprising a combination of disordered BCC and ordered B2 phases. Since the ordered B2 phase is based on the BCC parent matrix, distinguishing these two phases can be rather challenging. Advanced characterization techniques are necessary for a reliable qualitative and quantitative analysis of BCC and B2 phases in RHEAs. Additionally, there is a tendency for transformation of the ordered B2 phase into more complex ordered-omega type phases that are usually deleterious to mechanical properties. The current study focuses on the phase stability of a candidate RHEA, Al0.5Mo0.5NbTa0.5TiZr. Correlative transmission electron microscopy (TEM) and atom probe tomography (APT) have been employed to investigate the phase stability and transformation pathway of this RHEA when isothermally annealed at 800°C. The results show that a metastable two-phase BCC + B2 microstructure formed at the early stages of decomposition, eventually transforming into a three-phase BCC + B2 + hP18 microstructure. The hP18 phase is an ordered omega derivative of the ordered B2 phase. The correlative microscopy techniques (TEM and APT) reveal a very interesting interplay of compositional partitioning between the different phases and their respective stability.

Keywords

- Type

- Original Article

- Information

- Copyright

- Copyright © The Author(s), 2022. Published by Cambridge University Press on behalf of the Microscopy Society of America

References

- 3

- Cited by