Article contents

A two-dimensional asymptotic model for capillary collapse

Published online by Cambridge University Press: 17 December 2020

Abstract

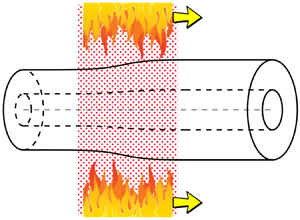

The collapse under surface tension of a long axisymmetric capillary, held at both ends and softened by a travelling heater, is used to determine the viscosity or surface tension of silica glasses. Capillary collapse is also used in the manufacture of some optical fibre preforms. Typically, a one-dimensional (1-D) model of the closure of a concentric fluid annulus is used to relate a measure of the change in the cross-sectional geometry, for example the external radius, to the desired information. We here show that a two-dimensional (2-D) asymptotic model developed for drawing of optical fibres, but with a unit draw ratio, may be used and yields analytic formulae involving a single dimensionless parameter, the scaled heater speed  $V$, equivalently a capillary number. For a capillary fixed at both ends, this 2-D model agrees with the 1-D model and offers the significant benefit that it enables determination of both the surface tension and viscosity from a single capillary-collapse experiment, provided the pulling tension in the capillary during collapse is measured. The 2-D model also enables our investigation of the situation where both ends of the capillary are not fixed, so that the capillary cannot sustain a pulling tension. Then the collapse of the capillary is markedly different from that predicted by the 1-D model and the ability to determine both surface tension and viscosity is lost.

$V$, equivalently a capillary number. For a capillary fixed at both ends, this 2-D model agrees with the 1-D model and offers the significant benefit that it enables determination of both the surface tension and viscosity from a single capillary-collapse experiment, provided the pulling tension in the capillary during collapse is measured. The 2-D model also enables our investigation of the situation where both ends of the capillary are not fixed, so that the capillary cannot sustain a pulling tension. Then the collapse of the capillary is markedly different from that predicted by the 1-D model and the ability to determine both surface tension and viscosity is lost.

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2020. Published by Cambridge University Press

References

REFERENCES

- 2

- Cited by