Article contents

Fabrication of dense alumina layer on Ti alloy hybrid by cold metal transfer and micro-arc oxidation methods

Published online by Cambridge University Press: 03 April 2017

Abstract

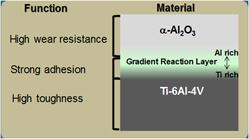

Recent advances in alumina ceramics are focused toward innovative processing routes to improve their mechanical reliability while retaining their superior wear resistance, which might be possible if a thin layer of dense alumina can be formed on a metallic substrate such as Ti–6Al–4V with high mechanical strength. For this purpose, we propose a new two-step process in which a dense layer of Al deposited on the Ti alloy by cold metal transfer method, formed a dense Al3Ti gradient reaction layer at their interface to improve adhesion in a single step. Subsequent micro-arc oxidation treatment transformed Al layer to a graded alumina layer in which γ-alumina decreased and α-alumina increased with increasing depth. Abrasion of outer regions revealed underlying pure α-alumina regions with high Vickers hardness matching with that of sintered alumina. The designed alumina/Ti alloy hybrid can be a potential candidate for wear resistance applications.

Keywords

- Type

- Invited Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 17: Focus Issue: Achieving Superior Ceramics and Coating Properties through Innovative Processing , 14 September 2017 , pp. 3415 - 3424

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Eugene Medvedovski

References

REFERENCES

- 7

- Cited by