Article contents

Low-temperature failure mechanism of [001] niobium micropillars under uniaxial tension

Published online by Cambridge University Press: 23 September 2020

Abstract

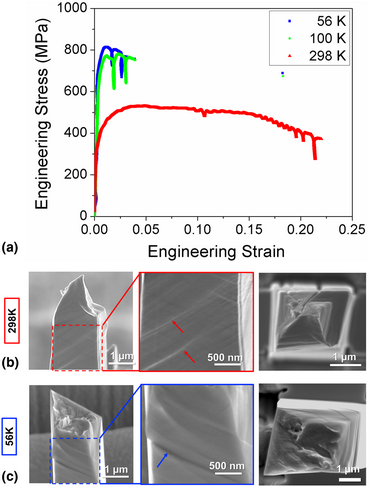

The plasticity of body-centered cubic (bcc) metals is dependent of temperature as well as sample dimension at the micrometer scale, but the effects of cryogenic temperature on the plasticity and the related failure process in micron-sized bcc metals have not been studied under uniaxial tension. In this work, we utilized in situ cryogenic micro-tensile tests, transmission electron microscopy, and dislocation dynamic simulations to examine the plasticity and failure processes of [001]-oriented bcc niobium micropillars. Our study reveals that a strong suppression of cross-slip at low temperatures prevents dislocation multiplication and leads to a dislocation starvation state, at which no mobile dislocation exists due to the rapid annihilation of dislocations at free surfaces. New dislocations are then nucleated until stress concentration at a slip step creates a micro-crack, the propagation of which leads to catastrophic failure. This unique failure process results from the combined effects of sample dimension and temperature.

Keywords

- Type

- Invited Paper

- Information

- Copyright

- Copyright © The Author(s), 2020. Published by Cambridge University Press on behalf of Materials Research Society

References

- 7

- Cited by