No CrossRef data available.

Article contents

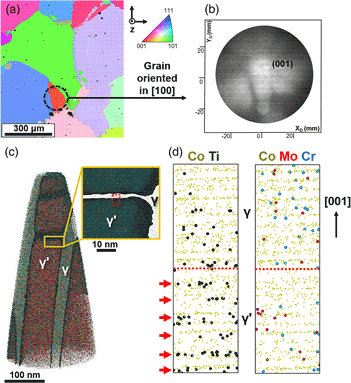

Elemental Sub-Lattice Occupation and Microstructural Evolution in γ/γ′ Co–12Ti–4Mo–Cr Alloys

Published online by Cambridge University Press: 23 April 2021

Abstract

We report on comparative atom probe tomography investigations of γ/γ′-forming Co–12Ti–4Mo–Cr alloys. Moderate additions of Cr (2 and 4 at%) reduced the γ/γ′ lattice misfit and increased the γ′ volume fraction of a Co–12Ti–4Mo alloy significantly. These microstructural changes were accompanied by changes in the elemental partitioning between γ and γ′ and site-occupancy in γ′. Spatial distribution maps revealed that Mo occupied both Co and Ti sub-lattice sites in γ′. In agreement with the experimental data, thermodynamic calculations predicted a stronger tendency for Mo to occupy the Co-sites than for Cr and an increase in Cr fraction on the Ti-sites with increasing Cr content.

Keywords

- Type

- Applications in Alloys

- Information

- Copyright

- Copyright © The Author(s), 2021. Published by Cambridge University Press on behalf of the Microscopy Society of America