1. Introduction

The problem of a particle or body that moves along or close to a surface is important for a range of industrial and natural flows, such as particle technology and sediment transport. One issue of particular importance is to determine of the hydrodynamic drag force applied to such a body, and hence predict the subsequent motion of the body.

For elementary particles with simplified geometry, such as a smooth sphere or cylinder rolling or translating along a plane wall, the hydrodynamic forces depend strongly on the magnitude of the gap between the particle and the wall (Goldman, Cox & Brenner Reference Goldman, Cox and Brenner1967; O'Neill & Stewartson Reference O'Neill and Stewartson1967; Merlen & Frankiewicz Reference Merlen and Frankiewicz2011). In particular, the drag force becomes infinite as the gap approaches zero, therefore a smooth sphere or cylinder would be unable to move while in contact with a smooth wall. In order for the particle to travel along the surface, a finite gap between the particle and the wall must be established, by cavitation (Prokunin Reference Prokunin2003; Ashmore, Del Pino & Mullin Reference Ashmore, Del Pino and Mullin2005), surface roughness (Smart, Beimfohr & Leighton Reference Smart, Beimfohr and Leighton1993; Galvin, Zhao & Davis Reference Galvin, Zhao and Davis2001; Thompson, Leweke & Hourigan Reference Thompson, Leweke and Hourigan2021; Houdroge et al. Reference Houdroge, Zhao, Leweke, Hourigan, Terrington and Thompson2023) or compressibility (Terrington, Thompson & Hourigan Reference Terrington, Thompson and Hourigan2022).

Once the hydrodynamic gap has been determined, the hydrodynamic forces and moments can be evaluated to predict the resulting motion of the body. For the rolling sphere, Ashmore et al. (Reference Ashmore, Del Pino and Mullin2005) and Kozlov, Prokunin & Slavin (Reference Kozlov, Prokunin and Slavin2007) predict the effective gap induced by cavitation, while Smart et al. (Reference Smart, Beimfohr and Leighton1993), Galvin et al. (Reference Galvin, Zhao and Davis2001) and Zhao, Galvin & Davis (Reference Zhao, Galvin and Davis2002) assume an average gap introduced by a sparse distribution of surface asperities on either the sphere or the wall. Assuming that inertial effects are negligible, these authors then use the Goldman et al. (Reference Goldman, Cox and Brenner1967) formulae for the drag and moment applied to a sphere in a Stokes flow to predict the motion of the sphere.

For slow-moving particles, the Stokes approximation can be used to predict the forces and moments applied to the rolling body, and in such cases, explicit expressions for the hydrodynamic forces and moments can be obtained. Dean & O'Neill (Reference Dean and O'Neill1963) and O'Neill (Reference O'Neill1964) use a bispherical coordinate transformation to obtain the forces and moments applied to spheres that either rotate or translate along a plane wall. However, their series solution suffers from poor numerical convergence when the gap between the sphere and the wall is small. For small gaps, asymptotic expressions for the forces and moments have been determined by Goldman et al. (Reference Goldman, Cox and Brenner1967), O'Neill & Stewartson (Reference O'Neill and Stewartson1967) and Cooley & O'Neill (Reference Cooley and O'Neill1968), using the method of matched asymptotic expansions. Similarly, solutions for the Stokes flow over the rolling cylinder were obtained using bipolar coordinates by Jeffery (Reference Jeffery1922), Wakiya (Reference Wakiya1975) and Jeffrey & Onishi (Reference Jeffrey and Onishi1981), while the asymptotic solution for small gaps was obtained using the method of matched asymptotic expansions by Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011).

For moderate and high Reynolds number flows, however, numerical simulations are required to predict the hydrodynamic forces and moments applied to the rolling body. Numerical simulations of the flow over a translating or rolling cylinder have been presented by Stewart et al. (Reference Stewart, Hourigan, Thompson and Leweke2006, Reference Stewart, Thompson, Leweke and Hourigan2010b), Rao et al. (Reference Rao, Stewart, Thompson, Leweke and Hourigan2011) and Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017, Reference Houdroge, Leweke, Hourigan and Thompson2020), while numerical simulations of the flow over a rolling sphere are presented by Zeng et al. (Reference Zeng, Najjar, Balachandar and Fischer2009), Stewart et al. (Reference Stewart, Thompson, Leweke and Hourigan2010a) and Houdroge et al. (Reference Houdroge, Leweke, Thompson and Hourigan2016, Reference Houdroge, Zhao, Leweke, Hourigan, Terrington and Thompson2023).

The forces and moments applied to a given body (either a cylinder or a sphere) depend on three parameters: the gap–diameter ratio ![]() $G/d$, the Reynolds number

$G/d$, the Reynolds number ![]() $Re = Ud/\nu$, and the slip coefficient

$Re = Ud/\nu$, and the slip coefficient ![]() $k = \varOmega d/(2U)$, where

$k = \varOmega d/(2U)$, where ![]() $d$ is the diameter of the body,

$d$ is the diameter of the body, ![]() $U$ and

$U$ and ![]() $\varOmega$ are the linear and angular velocities, respectively,

$\varOmega$ are the linear and angular velocities, respectively, ![]() $G$ is the gap between the body and the wall, and

$G$ is the gap between the body and the wall, and ![]() $\nu$ is the kinematic viscosity of the fluid. Existing numerical studies have not considered the entirety of this parameter space. Stewart et al. (Reference Stewart, Hourigan, Thompson and Leweke2006, Reference Stewart, Thompson, Leweke and Hourigan2010a,Reference Stewart, Thompson, Leweke and Houriganb), Rao et al. (Reference Rao, Stewart, Thompson, Leweke and Hourigan2011) and Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017) consider only a single gap ratio, noting that the flow far from the gap is approximately independent of the gap ratio. While the gap ratio effect is considered by Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2020, Reference Houdroge, Zhao, Leweke, Hourigan, Terrington and Thompson2023), these studies are restricted to cylinders and spheres that roll without slipping (

$\nu$ is the kinematic viscosity of the fluid. Existing numerical studies have not considered the entirety of this parameter space. Stewart et al. (Reference Stewart, Hourigan, Thompson and Leweke2006, Reference Stewart, Thompson, Leweke and Hourigan2010a,Reference Stewart, Thompson, Leweke and Houriganb), Rao et al. (Reference Rao, Stewart, Thompson, Leweke and Hourigan2011) and Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017) consider only a single gap ratio, noting that the flow far from the gap is approximately independent of the gap ratio. While the gap ratio effect is considered by Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2020, Reference Houdroge, Zhao, Leweke, Hourigan, Terrington and Thompson2023), these studies are restricted to cylinders and spheres that roll without slipping (![]() $k = 1$). Slip has been observed experimentally, for both spheres (Smart et al. Reference Smart, Beimfohr and Leighton1993; Yang et al. Reference Yang, Seddon, Mullin, Del Pino and Ashmore2006) and cylinders (Seddon & Mullin Reference Seddon and Mullin2006), for certain ranges of the governing parameters, therefore a complete dynamical model for the motion of the particle requires the dependence of the force and moment coefficients against all three parameters:

$k = 1$). Slip has been observed experimentally, for both spheres (Smart et al. Reference Smart, Beimfohr and Leighton1993; Yang et al. Reference Yang, Seddon, Mullin, Del Pino and Ashmore2006) and cylinders (Seddon & Mullin Reference Seddon and Mullin2006), for certain ranges of the governing parameters, therefore a complete dynamical model for the motion of the particle requires the dependence of the force and moment coefficients against all three parameters: ![]() $G/d$,

$G/d$, ![]() $k$ and

$k$ and ![]() $Re$. To cover this entire parameter space directly requires significant computational expense.

$Re$. To cover this entire parameter space directly requires significant computational expense.

The small gap ratios that occur in many experiments pose further difficulty in simulating numerically the flow over a rolling body. As the gap ratio is reduced, a progressively finer numerical mesh is needed to capture adequately the interstitial flow, therefore numerical simulations become impractical for a sufficiently small gap ratio. For example, Houdroge et al. (Reference Houdroge, Zhao, Leweke, Hourigan, Terrington and Thompson2023) perform simulations of the rolling sphere to a minimum gap ratio ![]() $2\times 10^{-4}$, which is substantially larger than the gap ratios of order

$2\times 10^{-4}$, which is substantially larger than the gap ratios of order ![]() $10^{-6}$ required to match their experimental measurements. Therefore, numerical simulation of the entire flow, including both the outer flow and the interstitial flow, is impractical for many experimental conditions.

$10^{-6}$ required to match their experimental measurements. Therefore, numerical simulation of the entire flow, including both the outer flow and the interstitial flow, is impractical for many experimental conditions.

To avoid these numerical difficulties, the present paper applies the method of matched asymptotic expansions, which has been used to solve the Stokes flow over rolling bodies (Goldman et al. Reference Goldman, Cox and Brenner1967; O'Neill & Stewartson Reference O'Neill and Stewartson1967; Merlen & Frankiewicz Reference Merlen and Frankiewicz2011), to the inertial flow over a rolling body. Under this approach, the flow is separated conceptually into inner and outer domains. The inner flow describes the flow in the narrow interstice between the rolling body and the wall, and is given by an analytical solution obtained using lubrication theory. The outer flow is the flow far from the interstice, which is independent of ![]() $G/d$. Since an analytical solution is obtained for the inner flow, numerical simulations are performed only for the outer flow, thereby avoiding the numerical difficulties associated with a small gap ratio. Moreover, since the outer flow depends only weakly on

$G/d$. Since an analytical solution is obtained for the inner flow, numerical simulations are performed only for the outer flow, thereby avoiding the numerical difficulties associated with a small gap ratio. Moreover, since the outer flow depends only weakly on ![]() $G/d$, the parameter space that must be covered by numerical simulations is reduced to only two variables,

$G/d$, the parameter space that must be covered by numerical simulations is reduced to only two variables, ![]() $Re$ and

$Re$ and ![]() $k$, significantly reducing the computational work required to model the dynamics of the particle.

$k$, significantly reducing the computational work required to model the dynamics of the particle.

In the present work, this framework is applied to the two-dimensional flow over an infinite circular cylinder translating and rolling near a plane wall. The solution for the outer flow is obtained numerically as a function of ![]() $Re$ and

$Re$ and ![]() $k$. By combining the outer solution with the lubrication solution for the inner flow, the total force and moment coefficients are evaluated as functions of the three parameters

$k$. By combining the outer solution with the lubrication solution for the inner flow, the total force and moment coefficients are evaluated as functions of the three parameters ![]() $G/d$,

$G/d$, ![]() $Re$ and

$Re$ and ![]() $k$. We introduce the wake force and moment coefficients – defined as the difference in the force and moment coefficients between inertial and Stokes flow – to characterise the effects of inertia on the forces and moments applied to the cylinder. The wake drag and moment coefficients are found to be insensitive to

$k$. We introduce the wake force and moment coefficients – defined as the difference in the force and moment coefficients between inertial and Stokes flow – to characterise the effects of inertia on the forces and moments applied to the cylinder. The wake drag and moment coefficients are found to be insensitive to ![]() $G/d$, and can therefore be determined directly from the outer-flow solution. The wake lift coefficient decreases linearly with

$G/d$, and can therefore be determined directly from the outer-flow solution. The wake lift coefficient decreases linearly with ![]() $\sqrt {G/d}$, and an upper limit for the wake lift coefficient can be determined directly from the outer solution.

$\sqrt {G/d}$, and an upper limit for the wake lift coefficient can be determined directly from the outer solution.

While the present paper considers only the two-dimensional flow over a circular cylinder, we anticipate that the approach used can be applied to other rolling body flows, such as rolling spheres or finite cylinders (wheels). For example, Goldman et al. (Reference Goldman, Cox and Brenner1967), O'Neill & Stewartson (Reference O'Neill and Stewartson1967) and Cooley & O'Neill (Reference Cooley and O'Neill1968) decompose the Stokes flow over a sphere near a wall into inner and outer solutions. Therefore, a similar decomposition likely exists for inertial flows, and the method proposed in this paper should allow for efficient numerical computation of the forces and moments applied to the sphere.

For the rolling sphere, many relevant physical effects, such as cavitation (Prokunin Reference Prokunin2003), compressibility and surface roughness (Smart et al. Reference Smart, Beimfohr and Leighton1993), are relevant only in the inner region (Terrington et al. Reference Terrington, Thompson and Hourigan2022), and one might expect the same to be true of the rolling cylinder flow. Assuming that this is the case, the present study separates these effects from those of inertia, which are significant only in the outer region. For example, this would allow the forces and moments applied to a cylinder in an inertial and cavitating flow to be determined by combining the inertial, but non-cavitating, outer solution, with a cavitating, but non-inertial, inner solution.

The structure of this paper is as follows. First, in § 2, we present the theoretical analysis that justifies the decomposition into inner and outer solutions. Next, in § 3, we discuss the numerical approach used to obtain the outer-flow solution. Finally, the force and moment coefficients are computed using the inner and outer solutions, in § 4. Concluding remarks are made in § 5.

2. Inner and outer solutions for the rolling cylinder

Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) compute the forces and moments applied to a rolling circular cylinder in a Stokes flow by using the method of matched asymptotic expansions, where the flow is decomposed conceptually into inner and outer flows. This section extends their analysis to inertial flows. The structure of this section is as follows. First, in § 2.1, we present the geometry and problem description. Next, in § 2.2, we discuss the computation of the outer flow. Then, in § 2.3, we review the lubrication solution for the inner flow. Finally, in § 2.4, we show that the inner and outer solutions are matched asymptotically when ![]() $G/d$ is small.

$G/d$ is small.

2.1. Problem description

As shown in figure 1, we consider the flow over a circular cylinder of diameter ![]() $d$, which travels along a plane wall with linear velocity

$d$, which travels along a plane wall with linear velocity ![]() $U$ and angular velocity

$U$ and angular velocity ![]() $\varOmega$. Due to surface roughness, cavitation or compressibility, the cylinder is separated from the wall by an effective hydrodynamic gap

$\varOmega$. Due to surface roughness, cavitation or compressibility, the cylinder is separated from the wall by an effective hydrodynamic gap ![]() $G$. The density of the fluid is denoted by

$G$. The density of the fluid is denoted by ![]() $\rho$, while the dynamic and kinematic viscosities are denoted by

$\rho$, while the dynamic and kinematic viscosities are denoted by ![]() $\mu$ and

$\mu$ and ![]() $\nu$, respectively. The fluid exerts a drag force

$\nu$, respectively. The fluid exerts a drag force ![]() $D$, lift force

$D$, lift force ![]() $L$ and moment

$L$ and moment ![]() $M$ on the cylinder.

$M$ on the cylinder.

Figure 1. Problem considered in this work. A cylinder of diameter ![]() $d$ travels along a plane wall with translational and angular velocities

$d$ travels along a plane wall with translational and angular velocities ![]() $U$ and

$U$ and ![]() $\varOmega$, respectively, while maintaining a gap

$\varOmega$, respectively, while maintaining a gap ![]() $G$ between the cylinder and the wall. The hydrodynamic lift, drag and moment are given by

$G$ between the cylinder and the wall. The hydrodynamic lift, drag and moment are given by ![]() $L$,

$L$, ![]() $D$ and

$D$ and ![]() $M$, respectively. Finally,

$M$, respectively. Finally, ![]() $k$ is the slip coefficient.

$k$ is the slip coefficient.

Three dimensionless parameters are required to characterise the flow: the Reynolds number ![]() $Re = U d/\nu$, the slip coefficient

$Re = U d/\nu$, the slip coefficient ![]() $k = \varOmega d/2U$, and the gap-to-diameter ratio

$k = \varOmega d/2U$, and the gap-to-diameter ratio ![]() $G/d$. This study aims to determine the functional dependence of the force and moment coefficients

$G/d$. This study aims to determine the functional dependence of the force and moment coefficients

against ![]() $Re$,

$Re$, ![]() $k$ and

$k$ and ![]() $G/d$. As indicated previously, this is achieved by separating the flow into inner and outer regions. The outer flow depends only on

$G/d$. As indicated previously, this is achieved by separating the flow into inner and outer regions. The outer flow depends only on ![]() $Re$ and

$Re$ and ![]() $k$, while the inner flow is determined analytically using lubrication theory.

$k$, while the inner flow is determined analytically using lubrication theory.

2.2. Outer flow

When ![]() $G/d$ is small, the flow far from the interstice is approximately independent of the gap ratio (Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2020). This suggests that a gap-ratio-independent outer flow can be obtained by assuming

$G/d$ is small, the flow far from the interstice is approximately independent of the gap ratio (Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2020). This suggests that a gap-ratio-independent outer flow can be obtained by assuming ![]() $G/d = 0$, as is done by Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) for Stokes flow.

$G/d = 0$, as is done by Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) for Stokes flow.

The geometry and coordinate systems for the outer flow are presented in figure 2(a). The outer flow is made non-dimensional by the cylinder diameter, translational velocity and fluid density, so that in non-dimensional units, the cylinder has diameter ![]() $1$, linear velocity

$1$, linear velocity ![]() $1$ and angular velocity

$1$ and angular velocity ![]() $k$. Three different coordinate systems are used for the outer flow: a Cartesian coordinate system

$k$. Three different coordinate systems are used for the outer flow: a Cartesian coordinate system ![]() $(x,y)$ centred at the contact point, polar coordinates

$(x,y)$ centred at the contact point, polar coordinates ![]() $(r,\phi )$ also centred at the contact point, and a second polar coordinate system

$(r,\phi )$ also centred at the contact point, and a second polar coordinate system ![]() $(r_2,\theta )$ with its origin at the centre of the cylinder.

$(r_2,\theta )$ with its origin at the centre of the cylinder.

Figure 2. Geometry and coordinate systems for (a) the outer flow, and (b) the inner flow.

We assume that flow is governed by the incompressible continuity and Navier–Stokes equations, which are expressed in non-dimensional form as

where ![]() $\boldsymbol {u} = \boldsymbol {u}^*/U$ is the dimensionless velocity, and

$\boldsymbol {u} = \boldsymbol {u}^*/U$ is the dimensionless velocity, and ![]() $p = (\,p^* - p^*_\infty )/\rho U^2$ is the dimensionless pressure. Here, asterisks (

$p = (\,p^* - p^*_\infty )/\rho U^2$ is the dimensionless pressure. Here, asterisks (![]() $^*$) denote dimensional quantities, and

$^*$) denote dimensional quantities, and ![]() $p^*_\infty$ is the free-stream pressure.

$p^*_\infty$ is the free-stream pressure.

The boundary conditions for (2.4) and (2.5) are as follows: we assume that there is no slip between the fluid and the cylinder (![]() $u_x = k \cos \theta$ and

$u_x = k \cos \theta$ and ![]() $u_y = k \sin \theta$ on the cylinder), as well as between the fluid and the lower wall (

$u_y = k \sin \theta$ on the cylinder), as well as between the fluid and the lower wall (![]() $u_x = 1$ and

$u_x = 1$ and ![]() $u_y = 0$ on the wall). Finally, the free-stream conditions far from the cylinder are

$u_y = 0$ on the wall). Finally, the free-stream conditions far from the cylinder are ![]() $u_x = 1$,

$u_x = 1$, ![]() $u_y = 0$ and

$u_y = 0$ and ![]() $p = 0$.

$p = 0$.

Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) consider the solution to the outer flow under the Stokes flow approximation (![]() $Re = 0$), and for steady flow (

$Re = 0$), and for steady flow (![]() $\partial \boldsymbol {u} /\partial t = 0$). Under these approximations, (2.5) reduces to

$\partial \boldsymbol {u} /\partial t = 0$). Under these approximations, (2.5) reduces to

where ![]() $p_2 = (\,p^* - p^*_\infty )/(\mu U /d)$ is a non-dimensional pressure defined for Stokes flow, which is related to the non-dimensionalisation for inertial flows as

$p_2 = (\,p^* - p^*_\infty )/(\mu U /d)$ is a non-dimensional pressure defined for Stokes flow, which is related to the non-dimensionalisation for inertial flows as ![]() $p_2= \lim _{Re \rightarrow 0} (Re\,p)$. Using the

$p_2= \lim _{Re \rightarrow 0} (Re\,p)$. Using the ![]() $(r,\phi,z)$ coordinates, the analytic solution to this problem is (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011)

$(r,\phi,z)$ coordinates, the analytic solution to this problem is (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011)

where ![]() $\xi = r/\sin \phi$. To allow for comparisons between the inertial and Stokes flow solutions at finite

$\xi = r/\sin \phi$. To allow for comparisons between the inertial and Stokes flow solutions at finite ![]() $Re$, the pressure in (2.9) is expressed in the non-dimensional form corresponding to inertial flow. While this results in an infinite pressure

$Re$, the pressure in (2.9) is expressed in the non-dimensional form corresponding to inertial flow. While this results in an infinite pressure ![]() $p$ at

$p$ at ![]() $Re = 0$, the corresponding Stokes flow pressure

$Re = 0$, the corresponding Stokes flow pressure ![]() $p_2 = \lim _{Re \rightarrow 0} (Re\,p)$ remains finite.

$p_2 = \lim _{Re \rightarrow 0} (Re\,p)$ remains finite.

On the surface of the cylinder (![]() $\xi = 1$), the pressure distribution is given by (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011)

$\xi = 1$), the pressure distribution is given by (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011)

while the wall shear stress distribution on the cylinder is

which are also non-dimensionalised according to the inertial flow variables. Importantly, both the pressure and wall stress distributions are singular at the contact point (![]() $\phi = 0$), so that the drag and moment applied to the cylinder are infinite when

$\phi = 0$), so that the drag and moment applied to the cylinder are infinite when ![]() $G/d = 0$ (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011). For finite gap ratios, however, the outer-flow solution is invalid near the contact point. Lubrication theory is used to obtain the inner-flow solution, which is matched asymptotically to the outer-flow solution (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011), and the resulting drag and moment are finite.

$G/d = 0$ (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011). For finite gap ratios, however, the outer-flow solution is invalid near the contact point. Lubrication theory is used to obtain the inner-flow solution, which is matched asymptotically to the outer-flow solution (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011), and the resulting drag and moment are finite.

Equations (2.7)–(2.12) are valid for Stokes flow, and do not apply when ![]() $Re$ is non-zero. Instead, the solution to (2.4) and (2.5) must be obtained numerically. However, the inertial solution should approach the Stokes flow solution near the contact point (

$Re$ is non-zero. Instead, the solution to (2.4) and (2.5) must be obtained numerically. However, the inertial solution should approach the Stokes flow solution near the contact point (![]() $\phi = 0$). The characteristic length scale associated with the flow near the contact point is the film thickness

$\phi = 0$). The characteristic length scale associated with the flow near the contact point is the film thickness

The corresponding film thickness Reynolds number,

approaches zero as ![]() $\phi \rightarrow 0$, therefore the solution to the finite

$\phi \rightarrow 0$, therefore the solution to the finite ![]() $Re$ outer flow is expected to approach the Stokes flow solution (2.7)–(2.9) as the contact point is approached. This is validated using numerical simulations in § 3.

$Re$ outer flow is expected to approach the Stokes flow solution (2.7)–(2.9) as the contact point is approached. This is validated using numerical simulations in § 3.

2.3. Inner flow

We now turn our attention to the lubrication flow in the narrow gap between the cylinder and the wall. The geometry for the inner flow is shown in figure 2(b). Assuming that ![]() $G/d$ is small, the cylinder can be approximated by a parabolic shape, so that the film thickness

$G/d$ is small, the cylinder can be approximated by a parabolic shape, so that the film thickness ![]() $h$ is given by

$h$ is given by

Additionally, the velocity of the lower wall is approximated by ![]() $U_1 = U$, and the velocity of the upper wall (cylinder) is approximated as

$U_1 = U$, and the velocity of the upper wall (cylinder) is approximated as ![]() $U_2 = kU$.

$U_2 = kU$.

Since the film thickness is small, the standard assumptions of lubrication theory apply (Ghosh, Majumdar & Sarangi Reference Ghosh, Majumdar and Sarangi2014): flow is laminar; inertial effects are negligible; pressure gradients across the film thickness are negligible; and velocity gradients along the film are negligible compared to velocity gradients across the film thickness. We also assume that the interstitial flow is two-dimensional, so that there are no velocity or pressure gradients in the ![]() $z$-direction, and the inner flow is steady in time.

$z$-direction, and the inner flow is steady in time.

Under these assumptions, the streamwise velocity profile is given by

which gives a volume flow rate

The interstitial pressure distribution is obtained by solving the Reynolds equation,

For the present case, this equation is written as

For the inner flow, we introduce a new set of non-dimensional parameters:

Note that the non-dimensional position ![]() $\hat {x}$ and pressure

$\hat {x}$ and pressure ![]() $\hat {p}$ in the inner region differ from the corresponding non-dimensional forms

$\hat {p}$ in the inner region differ from the corresponding non-dimensional forms ![]() $x$ and

$x$ and ![]() $p$ used in the outer flow. Using this non-dimensionalisation, (2.19) becomes

$p$ used in the outer flow. Using this non-dimensionalisation, (2.19) becomes

and using the boundary conditions ![]() $\hat {p}(\infty ) = \hat {p}(-\infty ) = 0$, the solution of (2.21) is

$\hat {p}(\infty ) = \hat {p}(-\infty ) = 0$, the solution of (2.21) is

in agreement with Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011). When non-dimensionalised by outer flow variables, the pressure is written as

Finally, the wall shear stress on the cylinder is given by

which is written in non-dimensional form, using outer-flow variables, as

2.4. Asymptotic matching of the inner and outer flows

In order for the decomposition into inner and outer solutions to be valid, the inner and outer solutions must be asymptotically matched. This requires there to be an overlap region where both the inner and outer solutions are in agreement. In this subsection, we demonstrate that the Stokes flow solution to the outer flow is matched asymptotically to the inner lubrication solution. Since the inertial solution to the outer flow is expected to approach the Stokes flow solution near the contact point (![]() $\phi = 0$), we expect the inner and outer flow solutions to also be matched for inertial flows. This assumption is validated using numerical simulations in § 3.

$\phi = 0$), we expect the inner and outer flow solutions to also be matched for inertial flows. This assumption is validated using numerical simulations in § 3.

We first estimate the domains where the inner and outer solutions are valid. Consider terms of up to fourth order in the Maclaurin series expansion for the film thickness near the interstice:

In computing the outer solution, we assume ![]() $G = 0$, which is valid when

$G = 0$, which is valid when ![]() $|x^*| \gg \sqrt {Gd}$. The inner solution was evaluated assuming a parabolic profile, which requires

$|x^*| \gg \sqrt {Gd}$. The inner solution was evaluated assuming a parabolic profile, which requires ![]() ${x^*}^2 \ll d^2$. Therefore, the inner and outer solutions can be simultaneously valid only in the region

${x^*}^2 \ll d^2$. Therefore, the inner and outer solutions can be simultaneously valid only in the region

The asymptotic matching region, if it exists, must be located in the domain given by (2.27). Note that the inequality in (2.27) cannot be satisfied for ![]() $G/d \gtrsim 10^{-2}$, therefore the decomposition into inner and outer solutions will not be valid for gap ratios above this value.

$G/d \gtrsim 10^{-2}$, therefore the decomposition into inner and outer solutions will not be valid for gap ratios above this value.

We now show that the pressure distributions on the surface of the cylinder from the inner and outer solutions are matched asymptotically. Since, on the surface of the cylinder, we have

the pressure distribution for the outer solution (2.10) becomes

Since ![]() $y \approx (G/d) \hat {x}^2$ and

$y \approx (G/d) \hat {x}^2$ and ![]() $x \approx (G/d)^{1/2}\hat {x}$ in the matching region, this becomes

$x \approx (G/d)^{1/2}\hat {x}$ in the matching region, this becomes

and since ![]() $\hat {x} \gg 1$, for

$\hat {x} \gg 1$, for ![]() $k \neq -1$, this reduces to

$k \neq -1$, this reduces to

Similarly, when ![]() $\hat {x} \gg 1$, the inner pressure distribution (2.23) becomes

$\hat {x} \gg 1$, the inner pressure distribution (2.23) becomes

Equations (2.31) and (2.32) are equal, therefore the inner and outer pressure distributions are matched asymptotically.

Asymptotic matching between the pressure profiles for the inner and outer solutions is shown in figure 3. Figure 3(a) shows the pressure profiles for both the inner and outer solutions, normalised in inner variables. The asymptotic solution given by (2.31) and (2.32) is also shown. The inner solution differs from the asymptotic prediction when ![]() $\hat {x}$ is small, but approaches the asymptotic profile when

$\hat {x}$ is small, but approaches the asymptotic profile when ![]() $\hat {x}\gg 1$. The outer solution differs from the asymptotic region for large

$\hat {x}\gg 1$. The outer solution differs from the asymptotic region for large ![]() $\hat {x}$, but follows the asymptotic profile when

$\hat {x}$, but follows the asymptotic profile when ![]() $\hat {x} \ll 1/\sqrt {Gd}$. Importantly, for

$\hat {x} \ll 1/\sqrt {Gd}$. Importantly, for ![]() $G/d \leq 10^{-3}$, there exists an asymptotic matching region, given by (2.27), where both the inner and outer solutions are asymptotically matched.

$G/d \leq 10^{-3}$, there exists an asymptotic matching region, given by (2.27), where both the inner and outer solutions are asymptotically matched.

Figure 3. Asymptotic matching between the inner (2.23) and outer (2.10) pressure distributions for Stokes flow, expressed in (a) inner and (b) outer variables, respectively. The asymptotic limit of the inner and outer pressure profiles in the matching region ((2.31) and (2.32)) is also shown in (a).

Figure 3(b) presents the pressure profiles for the inner and outer solutions normalised in outer variables. For large values of ![]() $\theta$, the inner and outer solutions differ, and only the outer solution is valid. The inner solution approaches the outer solution as

$\theta$, the inner and outer solutions differ, and only the outer solution is valid. The inner solution approaches the outer solution as ![]() $\theta$ is decreased, and the inner and outer solutions are approximately equal in the asymptotic matching region. Finite-gap effects become significant as

$\theta$ is decreased, and the inner and outer solutions are approximately equal in the asymptotic matching region. Finite-gap effects become significant as ![]() $\theta$ is decreased further, and the inner solution begins to deviate from the outer solution. The maximum

$\theta$ is decreased further, and the inner solution begins to deviate from the outer solution. The maximum ![]() $\theta$ for which finite-gap effects are significant decreases as the gap ratio

$\theta$ for which finite-gap effects are significant decreases as the gap ratio ![]() $G/d$ is decreased.

$G/d$ is decreased.

We can also show that the wall shear stress distributions from the inner and outer solutions are matched asymptotically. The ![]() $x$-wall shear stress in the outer region (2.11) becomes, in the asymptotic matching region,

$x$-wall shear stress in the outer region (2.11) becomes, in the asymptotic matching region,

where we have assumed that ![]() $G/d \ll 1$. For

$G/d \ll 1$. For ![]() $\hat {x}\gg 1$, the wall shear from the inner region (2.25) is given by

$\hat {x}\gg 1$, the wall shear from the inner region (2.25) is given by

Equations (2.33) and (2.34) are equal, therefore the wall shear stress distributions are also matched asymptotically.

3. Numerical methodology

This section discusses the numerical method used to solve for the inertial flow over a circular cylinder near a plane wall. Two different numerical approaches are considered. First, we consider the conventional approach, where the solution is obtained numerically using a single computational domain that includes both the inner and outer regions. The second approach is to simulate numerically only the outer flow, by setting ![]() $G/d = 0$, and use the analytic lubrication solution for the inner region.

$G/d = 0$, and use the analytic lubrication solution for the inner region.

The structure of this section is as follows. First, in § 3.1, we discuss the conventional approach to obtaining the finite gap ratio solution over a single computational domain. Then, in § 3.2, the results of the single-domain computation are interpreted using the decomposition into inner and outer flows. Next, in § 3.3, we discuss the combined numerical–analytical approach, where the numerically obtained, ![]() $G/d$-independent outer flow is matched with the inner lubrication solution. Finally, the possibility of applying the combined numerical–analytical approach to other rolling body problems is discussed in § 3.4.

$G/d$-independent outer flow is matched with the inner lubrication solution. Finally, the possibility of applying the combined numerical–analytical approach to other rolling body problems is discussed in § 3.4.

3.1. Finite gap ratio

We first discuss the conventional approach for simulating numerically the inertial flow over a cylinder at a finite gap ratio. This approach considers a single computational domain that encompasses both the inner and outer regions. Importantly, no explicit decomposition into inner and outer solutions is made.

The computational domain and coordinate systems for this approach are as illustrated in figure 4(a). Non-dimensional coordinates are used, so that the cylinder diameter is ![]() $d = 1$. The inlet is located a distance

$d = 1$. The inlet is located a distance ![]() $10d$ upstream from the centre of the cylinder, while the outlet is positioned

$10d$ upstream from the centre of the cylinder, while the outlet is positioned ![]() $25d$ downstream from the cylinder. Finally, the domain is bounded by an upper wall located at vertical position

$25d$ downstream from the cylinder. Finally, the domain is bounded by an upper wall located at vertical position ![]() $y = 25d$ above the lower wall. Simulations are performed in a Galilean reference frame co-translating the cylinder.

$y = 25d$ above the lower wall. Simulations are performed in a Galilean reference frame co-translating the cylinder.

Figure 4. Schematic illustration of (a) the computational domain and (b) the block mesh scheme, for the finite gap ratio cylinder. The variables ![]() $N_y$ and

$N_y$ and ![]() $\Delta x$ denote the number of cells across the film thickness, and minimum cell spacing in the streamwise direction, respectively. Diagrams are not to scale, and the representative mesh is much coarser than those used for numerical simulations.

$\Delta x$ denote the number of cells across the film thickness, and minimum cell spacing in the streamwise direction, respectively. Diagrams are not to scale, and the representative mesh is much coarser than those used for numerical simulations.

The computational domain was meshed with a block-structured mesh, using the commercial software package ICEM CFD. A schematic illustration of the blocking scheme is shown in figure 4(b). A finer mesh resolution is used near the cylinder and in the wake, while a coarser resolution is used elsewhere. The cylinder is surrounded by an ‘O’-grid block, which passes through the interstice, allowing a good mesh quality in the interstice.

Numerical simulations are performed using the commercial finite-volume solver ANSYS FLUENT. Spatial derivatives were discretised using the least squares cell-based formulation, with the second-order upwind scheme used for the momentum equation, and second-order central differencing used for all other equations. For transient simulations, the second-order implicit time-stepping scheme was used. The small cell size and large pressure magnitudes in the interstice result in a relatively stiff set of equations, therefore the coupled solver was used for improved robustness.

As ![]() $G/d$ is decreased, the element size needed to resolve the inner lubrication flow decreases, posing increased difficulty for numerical simulations. In the present work, numerical instabilities were encountered for

$G/d$ is decreased, the element size needed to resolve the inner lubrication flow decreases, posing increased difficulty for numerical simulations. In the present work, numerical instabilities were encountered for ![]() $G/d = 10^{-5}$, therefore simulations are performed to a minimum gap ratio

$G/d = 10^{-5}$, therefore simulations are performed to a minimum gap ratio ![]() $G/d = 10^{-4}$. We also remark that if an explicit scheme were used, then the time-step restrictions due to the Courant–Friedrichs–Lewy (CFL) condition would provide additional limits on the minimum gap ratio. In the present work, the CFL limitations are avoided by using an implicit scheme. While large Courant numbers also imply a loss of temporal accuracy, the interstitial flow is time-steady, therefore relatively large Courant numbers can be tolerated in the interstice.

$G/d = 10^{-4}$. We also remark that if an explicit scheme were used, then the time-step restrictions due to the Courant–Friedrichs–Lewy (CFL) condition would provide additional limits on the minimum gap ratio. In the present work, the CFL limitations are avoided by using an implicit scheme. While large Courant numbers also imply a loss of temporal accuracy, the interstitial flow is time-steady, therefore relatively large Courant numbers can be tolerated in the interstice.

Boundary conditions for the fluid are as follows. A constant velocity ![]() $u_x = 1$,

$u_x = 1$, ![]() $u_y = 0$ was specified at the inlet, while a constant pressure

$u_y = 0$ was specified at the inlet, while a constant pressure ![]() $p = 0$ was specified at the outlet. The stress-free condition was applied to the upper boundary. Finally, both the cylinder and lower wall are no-slip boundaries, with velocities

$p = 0$ was specified at the outlet. The stress-free condition was applied to the upper boundary. Finally, both the cylinder and lower wall are no-slip boundaries, with velocities ![]() $u_x = 1$ and

$u_x = 1$ and ![]() $u_y = 0$ on the wall, and

$u_y = 0$ on the wall, and ![]() $u_x = k \cos \theta$ and

$u_x = k \cos \theta$ and ![]() $u_y = k \sin \theta$ on the cylinder.

$u_y = k \sin \theta$ on the cylinder.

A grid resolution study was performed to determine the resolution needed to obtain converged solutions. A single case with ![]() $Re = 200$,

$Re = 200$, ![]() $k = 1$ and

$k = 1$ and ![]() $G/d = 10^{-4}$ was considered. Table 1 lists statistics for the three meshes used for the resolution study, including the total number of cells in each mesh (

$G/d = 10^{-4}$ was considered. Table 1 lists statistics for the three meshes used for the resolution study, including the total number of cells in each mesh (![]() $N_c$), the number of cells across the film thickness (

$N_c$), the number of cells across the film thickness (![]() $N_y$), and the minimum streamwise cell spacing in the interstice (

$N_y$), and the minimum streamwise cell spacing in the interstice (![]() $\Delta x$). The time-mean and root-mean-square (r.m.s.) wake drag lift and moment coefficients (the wake force/moment coefficients are defined in § 4) are also provided. Differences between the predicted force and moment coefficients evaluated using mesh 2 and mesh 3 are below 1.1 %, therefore mesh 2 is sufficient to resolve the force and moment coefficients.

$\Delta x$). The time-mean and root-mean-square (r.m.s.) wake drag lift and moment coefficients (the wake force/moment coefficients are defined in § 4) are also provided. Differences between the predicted force and moment coefficients evaluated using mesh 2 and mesh 3 are below 1.1 %, therefore mesh 2 is sufficient to resolve the force and moment coefficients.

Table 1. Comparison between the mean and r.m.s. wake force and moment coefficients for ![]() $Re = 200$,

$Re = 200$, ![]() $k = 1$ and

$k = 1$ and ![]() $G/d = 10^{-4}$ evaluated using different grid resolutions. The relative differences between the mesh 2 and mesh 3 predictions are given in parentheses.

$G/d = 10^{-4}$ evaluated using different grid resolutions. The relative differences between the mesh 2 and mesh 3 predictions are given in parentheses.

Finally, we compare our predicted force and moment coefficients to results from previous numerical investigations, which are presented in table 2. First, we compare the predicted mean drag and lift coefficients at ![]() $k=1$,

$k=1$, ![]() $Re = 100$ and

$Re = 100$ and ![]() $G/d=0.005$ to results from Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017). Excellent agreement is observed, with errors below 0.6 %. Next, we compare the mean drag and lift coefficients at

$G/d=0.005$ to results from Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017). Excellent agreement is observed, with errors below 0.6 %. Next, we compare the mean drag and lift coefficients at ![]() $k=1$,

$k=1$, ![]() $Re = 60$ and

$Re = 60$ and ![]() $G/d=0.0025$ to results presented in Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011). Good agreement is observed, with errors below 2.3 %. Therefore, the present numerical results are validated successfully against previous results.

$G/d=0.0025$ to results presented in Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011). Good agreement is observed, with errors below 2.3 %. Therefore, the present numerical results are validated successfully against previous results.

Table 2. Comparison between the force and moment coefficients predicted using the present numerical approach and previous numerical investigations: Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017) at ![]() $Re = 100$,

$Re = 100$, ![]() $k=1$ and

$k=1$ and ![]() $G/d = 0.005$, and Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) at

$G/d = 0.005$, and Merlen & Frankiewicz (Reference Merlen and Frankiewicz2011) at ![]() $Re = 60$,

$Re = 60$, ![]() $k= 1$ and

$k= 1$ and ![]() $G/d = 0.0025$.

$G/d = 0.0025$.

3.2. The inner and outer solutions for inertial flow

As discussed in § 2, the flow over a cylinder at small gap ratios can be separated conceptually into an outer flow, which is independent of ![]() $G/d$, and an inner lubrication flow, where gap ratio effects are significant. In this subsection, the results of the single-domain, finite gap ratio simulations are interpreted and analysed using this decomposition into inner and outer flows, to demonstrate that the outer flow is independent of

$G/d$, and an inner lubrication flow, where gap ratio effects are significant. In this subsection, the results of the single-domain, finite gap ratio simulations are interpreted and analysed using this decomposition into inner and outer flows, to demonstrate that the outer flow is independent of ![]() $G/d$, and that the lubrication solution is applicable in the inner region.

$G/d$, and that the lubrication solution is applicable in the inner region.

Simulations are performed at ![]() $Re = 100$ and

$Re = 100$ and ![]() $k = 1$, for a range of gap ratios between

$k = 1$, for a range of gap ratios between ![]() $G/d = 10^{-2}$ and

$G/d = 10^{-2}$ and ![]() $G/d = 10^{-4}$. For these parameters, the unconstrained wake is typically three-dimensional (Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017). For simplicity, however, only two-dimensional simulations are considered in this work. For two-dimensional flow at

$G/d = 10^{-4}$. For these parameters, the unconstrained wake is typically three-dimensional (Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017). For simplicity, however, only two-dimensional simulations are considered in this work. For two-dimensional flow at ![]() $Re = 100$ and

$Re = 100$ and ![]() $k = 1$, the wake features periodic vortex shedding (Stewart et al. Reference Stewart, Thompson, Leweke and Hourigan2010b; Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017). We remark that the wake dynamics and transitions have been studied in great detail by Stewart et al. (Reference Stewart, Thompson, Leweke and Hourigan2010b) and Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017), and are not the main focus of this work. The present work is concerned with determining the force and moment coefficients as functions of

$k = 1$, the wake features periodic vortex shedding (Stewart et al. Reference Stewart, Thompson, Leweke and Hourigan2010b; Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017). We remark that the wake dynamics and transitions have been studied in great detail by Stewart et al. (Reference Stewart, Thompson, Leweke and Hourigan2010b) and Houdroge et al. (Reference Houdroge, Leweke, Hourigan and Thompson2017), and are not the main focus of this work. The present work is concerned with determining the force and moment coefficients as functions of ![]() $Re$,

$Re$, ![]() $G/d$ and

$G/d$ and ![]() $k$, using the decomposition into inner and outer flows.

$k$, using the decomposition into inner and outer flows.

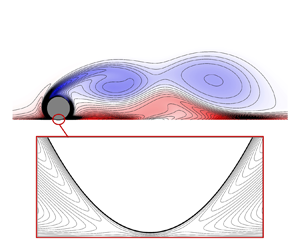

Figure 5 presents vorticity contours for the rolling cylinder at ![]() $Re = 100$ and

$Re = 100$ and ![]() $k = 1$, for gap ratios

$k = 1$, for gap ratios ![]() $G/d = 10^{-3}$ and

$G/d = 10^{-3}$ and ![]() $10^{-4}$, at flow time

$10^{-4}$, at flow time ![]() $t = 195$, which corresponds approximately to the maximum drag coefficient. A transient animation is provided in supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.296. The wake features the periodic shedding of vortices from the upper shear layer, which interact with secondary vorticity from the wall to form counter-rotating vortex pairs (Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017). Importantly, there is almost no perceptible difference in the wake between

$t = 195$, which corresponds approximately to the maximum drag coefficient. A transient animation is provided in supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.296. The wake features the periodic shedding of vortices from the upper shear layer, which interact with secondary vorticity from the wall to form counter-rotating vortex pairs (Houdroge et al. Reference Houdroge, Leweke, Hourigan and Thompson2017). Importantly, there is almost no perceptible difference in the wake between ![]() $G/d = 10^{-3}$ and

$G/d = 10^{-3}$ and ![]() $G/d = 10^{-4}$, confirming that the assumption of a

$G/d = 10^{-4}$, confirming that the assumption of a ![]() $G/d$-independent outer flow is reasonable for inertial flows.

$G/d$-independent outer flow is reasonable for inertial flows.

Figure 5. Vorticity contours for the rolling cylinder at ![]() $Re = 100$,

$Re = 100$, ![]() $k = 1$ and

$k = 1$ and ![]() $t = 195$, for gap ratios (a)

$t = 195$, for gap ratios (a) ![]() $G/d = 10^{-3}$ and (b)

$G/d = 10^{-3}$ and (b) ![]() $G/d = 10^{-4}$, obtained using the single-domain, finite gap ratio method.

$G/d = 10^{-4}$, obtained using the single-domain, finite gap ratio method.

While the flow far from the interstice is independent of ![]() $G/d$, the interstitial flow depends strongly on gap ratio. Figure 6 presents streamlines (contours of the streamfunction) in the interstice for

$G/d$, the interstitial flow depends strongly on gap ratio. Figure 6 presents streamlines (contours of the streamfunction) in the interstice for ![]() $G/d = 10^{-3}$ and

$G/d = 10^{-3}$ and ![]() $10^{-4}$, and significant differences between the streamfunctions are observed between the two plots. In particular, the upstream and downstream saddle points (labelled

$10^{-4}$, and significant differences between the streamfunctions are observed between the two plots. In particular, the upstream and downstream saddle points (labelled ![]() $S_u$ and

$S_u$ and ![]() $S_d$ in figure 6) move closer to the contact point (

$S_d$ in figure 6) move closer to the contact point (![]() $x = 0$) as

$x = 0$) as ![]() $G/d$ is decreased, and the total mass flow rate through the interstice also decreases with the gap ratio.

$G/d$ is decreased, and the total mass flow rate through the interstice also decreases with the gap ratio.

Figure 6. Contours of the streamfunction ![]() $\varPsi$ near the interstice for the rolling cylinder at

$\varPsi$ near the interstice for the rolling cylinder at ![]() $Re = 100$,

$Re = 100$, ![]() $k = 1$ and

$k = 1$ and ![]() $t = 195$, for gap ratios (a)

$t = 195$, for gap ratios (a) ![]() $G/d = 10^{-3}$ and (b)

$G/d = 10^{-3}$ and (b) ![]() $G/d = 10^{-4}$, obtained using the single-domain, finite gap ratio method outlined in § 3.1. The contour increment is

$G/d = 10^{-4}$, obtained using the single-domain, finite gap ratio method outlined in § 3.1. The contour increment is ![]() $\Delta \varPsi = 10^{-4}$, and axes are stretched vertically for clarity.

$\Delta \varPsi = 10^{-4}$, and axes are stretched vertically for clarity.

Figures 5 and 6 validate our assumption that the flow far from the interstice (the outer flow) is relatively independent of ![]() $G/d$, while the interstitial (inner) flow depends strongly on the gap ratio. This can be demonstrated further by considering the pressure distribution on the surface of the cylinder. Since the wake is periodic, we compute the mean pressure

$G/d$, while the interstitial (inner) flow depends strongly on the gap ratio. This can be demonstrated further by considering the pressure distribution on the surface of the cylinder. Since the wake is periodic, we compute the mean pressure ![]() $\bar {p}$, which is the pressure averaged over a single vortex-shedding cycle. We stress once again that since the single-domain method is used, a single pressure distribution, valid in both the inner and outer domains, is obtained for each gap ratio. This pressure distribution may be non-dimensionalised according to either outer variables (as

$\bar {p}$, which is the pressure averaged over a single vortex-shedding cycle. We stress once again that since the single-domain method is used, a single pressure distribution, valid in both the inner and outer domains, is obtained for each gap ratio. This pressure distribution may be non-dimensionalised according to either outer variables (as ![]() $\bar {p}$) or inner variables (as

$\bar {p}$) or inner variables (as ![]() $\hat {\bar {p}} = \bar {p}\,Re\,(G/d)^{3/2}/(2(1+k))$).

$\hat {\bar {p}} = \bar {p}\,Re\,(G/d)^{3/2}/(2(1+k))$).

Figure 7(a) presents the mean pressure on the cylinder surface for ![]() $Re = 100$,

$Re = 100$, ![]() $k = 1$ and for a range of gap ratios, normalised by inner variables. The theoretical prediction from lubrication theory (2.22) is also shown. The profiles for

$k = 1$ and for a range of gap ratios, normalised by inner variables. The theoretical prediction from lubrication theory (2.22) is also shown. The profiles for ![]() $G/d = 10^{-3}$ and

$G/d = 10^{-3}$ and ![]() $10^{-4}$ are visually indistinguishable from the lubrication solution, confirming that the lubrication solution is valid in the inner region when

$10^{-4}$ are visually indistinguishable from the lubrication solution, confirming that the lubrication solution is valid in the inner region when ![]() $G/d \leq 10^{-3}$.

$G/d \leq 10^{-3}$.

Figure 7. Mean pressure distribution on the cylinder surface normalised using (a) inner and (b,c) outer variables for ![]() $Re = 100$ and

$Re = 100$ and ![]() $k=1$. Solid black lines indicate the analytical solutions for (a) lubrication theory (2.23) and (b) Stokes flow (2.10). A logarithmic

$k=1$. Solid black lines indicate the analytical solutions for (a) lubrication theory (2.23) and (b) Stokes flow (2.10). A logarithmic ![]() $y$-axis is used in (c) to show that the outer solution approaches the Stokes flow solution in the region where the inner and outer solutions are asymptotically matched. The r.m.s. pressure is indicated by dashed lines in (a).

$y$-axis is used in (c) to show that the outer solution approaches the Stokes flow solution in the region where the inner and outer solutions are asymptotically matched. The r.m.s. pressure is indicated by dashed lines in (a).

The lubrication solution for the inner region is obtained under the assumption of steady flow. To check this, we have also plotted profiles of the r.m.s. pressure, normalised by inner variables, in figure 7(a). The r.m.s. pressures are negligible when compared to the mean pressure profiles, therefore the assumption of steady flow is valid in the inner region.

Figure 7(b) shows the mean pressure on the cylinder surface normalised by outer variables, at ![]() $Re = 100$,

$Re = 100$, ![]() $k = 1$ and for a range of gap ratios. Far from the interstice (which is located at

$k = 1$ and for a range of gap ratios. Far from the interstice (which is located at ![]() $\theta = 0,2{\rm \pi}$), the pressure distributions follow a single curve, confirming that the outer flow is independent of the gap ratio. The analytical solution for Stokes flow (2.10) is also presented in figure 7(b). While the inertial solutions for various

$\theta = 0,2{\rm \pi}$), the pressure distributions follow a single curve, confirming that the outer flow is independent of the gap ratio. The analytical solution for Stokes flow (2.10) is also presented in figure 7(b). While the inertial solutions for various ![]() $G/d$ follow a single curve, this curve differs substantially from the Stokes flow solution. Therefore, for inertial flows, there is a

$G/d$ follow a single curve, this curve differs substantially from the Stokes flow solution. Therefore, for inertial flows, there is a ![]() $G/d$-independent outer solution that differs from the Stokes flow solution.

$G/d$-independent outer solution that differs from the Stokes flow solution.

Figure 7(c) shows the mean pressure on the cylinder surface in the region near the interstice, on a logarithmic ![]() $y$-axis. For small

$y$-axis. For small ![]() $\theta$, the pressure profiles no longer follow a single

$\theta$, the pressure profiles no longer follow a single ![]() $G/d$-independent solution, confirming that gap ratio effects are significant in the inner region. As

$G/d$-independent solution, confirming that gap ratio effects are significant in the inner region. As ![]() $\theta$ is decreased, but still sufficiently large for gap ratio effects to be negligible, the inertial pressure distributions approach the Stokes flow solution. Therefore, the inertial outer-flow solution approaches the Stokes flow solution as

$\theta$ is decreased, but still sufficiently large for gap ratio effects to be negligible, the inertial pressure distributions approach the Stokes flow solution. Therefore, the inertial outer-flow solution approaches the Stokes flow solution as ![]() $\theta$ approaches zero.

$\theta$ approaches zero.

In this subsection, we have examined the flow over a rolling cylinder at a finite gap ratio, using a single-domain numerical computation. By interpreting this solution using the decomposition into inner and outer solutions, we have shown that for a sufficiently small gap ratio (![]() $G/d \leq 10^{-3}$):

$G/d \leq 10^{-3}$):

(i) the inner flow is given by the analytic solution to lubrication theory;

(ii) the outer flow is independent of the gap ratio, but differs from the Stokes flow solution;

(iii) as the interstice is approached, the inertial outer-flow solution approaches the Stokes flow solution.

3.3. Obtaining the outer-flow solution for  $G/d = 0$

$G/d = 0$

The results of § 3.2 show that the outer flow does not depend on ![]() $G/d$, while the inner flow matches the analytic solution obtained using lubrication theory. Therefore, the single-domain approach is inefficient: numerical simulations are performed for each value of

$G/d$, while the inner flow matches the analytic solution obtained using lubrication theory. Therefore, the single-domain approach is inefficient: numerical simulations are performed for each value of ![]() $G/d$, despite the fact that this affects only the inner flow, for which we already have an analytic solution. Therefore, we propose a new approach, where numerical simulations are performed only to obtain the

$G/d$, despite the fact that this affects only the inner flow, for which we already have an analytic solution. Therefore, we propose a new approach, where numerical simulations are performed only to obtain the ![]() $G/d$-independent outer solution. This solution can then be matched with the analytic solution to the inner flow to obtain a complete solution, valid for small gap ratios.

$G/d$-independent outer solution. This solution can then be matched with the analytic solution to the inner flow to obtain a complete solution, valid for small gap ratios.

To obtain the ![]() $G/d$-independent outer flow, we assume

$G/d$-independent outer flow, we assume ![]() $G/d = 0$, thereby avoiding any finite-gap effects. Under this condition, the pressure approaches infinity at the contact point. The infinite pressures are avoided by removing the contact point from the computational domain, as shown in figure 8. New inlet/outlet boundaries are introduced at

$G/d = 0$, thereby avoiding any finite-gap effects. Under this condition, the pressure approaches infinity at the contact point. The infinite pressures are avoided by removing the contact point from the computational domain, as shown in figure 8. New inlet/outlet boundaries are introduced at ![]() $\theta = \pm \theta _c$, and the velocity at these boundaries is set to the Stokes flow velocity profiles (2.7) and (2.8). Since the inertial outer flow solution is approximately equal to the Stokes flow solution for small

$\theta = \pm \theta _c$, and the velocity at these boundaries is set to the Stokes flow velocity profiles (2.7) and (2.8). Since the inertial outer flow solution is approximately equal to the Stokes flow solution for small ![]() $\theta$, this approximation is reasonable when

$\theta$, this approximation is reasonable when ![]() $\theta _c$ is small. All other aspects of the numerical method, including the discretisation methods, boundary conditions and mesh scheme, are identical to the finite-gap simulations described in § 3.1.

$\theta _c$ is small. All other aspects of the numerical method, including the discretisation methods, boundary conditions and mesh scheme, are identical to the finite-gap simulations described in § 3.1.

Figure 8. For zero gap ratio simulations, the contact point is removed from the mesh and replaced with prescribed velocity boundaries, thereby avoiding the infinite pressure at the contact point. The parameters ![]() $\Delta x$ and

$\Delta x$ and ![]() $N_y$ are the minimum cell spacing in the

$N_y$ are the minimum cell spacing in the ![]() $x$-direction, and the number of cells across the film thickness, respectively.

$x$-direction, and the number of cells across the film thickness, respectively.

Figure 9 presents vorticity contours obtained using the zero-gap method, for ![]() $k = 1$,

$k = 1$, ![]() $Re = 100$ and

$Re = 100$ and ![]() $\theta _c = 0.01$. A transient animation is also provided in supplementary movie 1. The observed wake is nearly identical to that obtained using the single-domain simulations at

$\theta _c = 0.01$. A transient animation is also provided in supplementary movie 1. The observed wake is nearly identical to that obtained using the single-domain simulations at ![]() $G/d = 10^{-3}$ and

$G/d = 10^{-3}$ and ![]() $10^{-4}$ (figures 5a,b), confirming that the proposed numerical approach is capable of predicting correctly the

$10^{-4}$ (figures 5a,b), confirming that the proposed numerical approach is capable of predicting correctly the ![]() $G/d$-independent outer flow.

$G/d$-independent outer flow.

Figure 9. Vorticity contours for the rolling cylinder at ![]() $Re = 100$,

$Re = 100$, ![]() $k = 1$ and

$k = 1$ and ![]() $t = 195$, obtained using the

$t = 195$, obtained using the ![]() $G/d = 0$ method outlined in this subsection.

$G/d = 0$ method outlined in this subsection.

Figure 10(a) presents streamfunction contours near the contact point for ![]() $G/d = 0$,

$G/d = 0$, ![]() $k = 1$ and

$k = 1$ and ![]() $Re = 100$ obtained numerically with

$Re = 100$ obtained numerically with ![]() $\theta _c = 0.01$, while figure 10(b) presents streamfunction contours for Stokes flow (2.7) and (2.8). The predicted streamlines are nearly identical, confirming that the proposed method produces a velocity field that is approximately equal to the Stokes flow solution near the contact point. Moreover, the streamfunctions for the finite-gap cases, shown in figures 6(a,b), appear to converge towards the zero-gap solution as

$\theta _c = 0.01$, while figure 10(b) presents streamfunction contours for Stokes flow (2.7) and (2.8). The predicted streamlines are nearly identical, confirming that the proposed method produces a velocity field that is approximately equal to the Stokes flow solution near the contact point. Moreover, the streamfunctions for the finite-gap cases, shown in figures 6(a,b), appear to converge towards the zero-gap solution as ![]() $G/d$ approaches zero.

$G/d$ approaches zero.

Note that the outer solution obtained under the assumption ![]() $G/d = 0$ is valid for

$G/d = 0$ is valid for ![]() $|\theta | \gg 2\sqrt {G/d}$ (see (2.27)), and the inner lubrication solution must be used when

$|\theta | \gg 2\sqrt {G/d}$ (see (2.27)), and the inner lubrication solution must be used when ![]() $|\theta |$ is below this value. To illustrate this point, figure 11(a) presents the mean pressure along the cylinder surface for

$|\theta |$ is below this value. To illustrate this point, figure 11(a) presents the mean pressure along the cylinder surface for ![]() $Re = 100$ and

$Re = 100$ and ![]() $k = 1$ obtained using the

$k = 1$ obtained using the ![]() $G/d = 0$ approach outlined in this subsection, with

$G/d = 0$ approach outlined in this subsection, with ![]() $\theta _c = 0.01$, and a solution obtained using the conventional single-domain approach outlined in § 3.1, for finite gap ratio

$\theta _c = 0.01$, and a solution obtained using the conventional single-domain approach outlined in § 3.1, for finite gap ratio ![]() $G/d = 10^{-4}$. The Stokes flow solution for the outer flow (2.10) is also shown. All solutions are in good agreement between

$G/d = 10^{-4}$. The Stokes flow solution for the outer flow (2.10) is also shown. All solutions are in good agreement between ![]() $\theta = 0.1$ and

$\theta = 0.1$ and ![]() $\theta = 0.3$. However, finite-gap effects become significant for

$\theta = 0.3$. However, finite-gap effects become significant for ![]() $\theta < 0.1$, and the

$\theta < 0.1$, and the ![]() $G/d = 0$ solution does not match the

$G/d = 0$ solution does not match the ![]() $G/d = 10^{-4}$ solution in this region.

$G/d = 10^{-4}$ solution in this region.

Figure 11. (a) Mean pressure distribution on the cylinder surface for ![]() $G/d = 0$ and

$G/d = 0$ and ![]() $10^{-4}$ at

$10^{-4}$ at ![]() $Re = 100$ and

$Re = 100$ and ![]() $k = 1$. (b) Difference between the mean pressure distributions for inertial flow and Stokes flow (

$k = 1$. (b) Difference between the mean pressure distributions for inertial flow and Stokes flow (![]() $\bar {p}-p_{Stokes}$) at

$\bar {p}-p_{Stokes}$) at ![]() $Re = 100$ and

$Re = 100$ and ![]() $k =1$.

$k =1$.

Therefore, we introduce a transition angle ![]() $\theta _0$ that separates the inner and outer solutions. By using the numerically obtained

$\theta _0$ that separates the inner and outer solutions. By using the numerically obtained ![]() $G/d = 0$ outer solution for

$G/d = 0$ outer solution for ![]() $|\theta | \geq \theta _0$, and the inner lubrication solution for

$|\theta | \geq \theta _0$, and the inner lubrication solution for ![]() $|\theta | < \theta _0$, we obtain a complete solution to the flow over a rolling cylinder at small, but finite, gap ratios. Importantly,

$|\theta | < \theta _0$, we obtain a complete solution to the flow over a rolling cylinder at small, but finite, gap ratios. Importantly, ![]() $\theta _0$ must lie in the asymptotic matching region given by (2.27), therefore we require

$\theta _0$ must lie in the asymptotic matching region given by (2.27), therefore we require ![]() $2\sqrt {G/d} \leq \theta _0 \leq 2$. However, an additional constraint is that

$2\sqrt {G/d} \leq \theta _0 \leq 2$. However, an additional constraint is that ![]() $\theta _0$ must be sufficiently small for inertial effects to be negligible. For this, we assume a film thickness Reynolds number

$\theta _0$ must be sufficiently small for inertial effects to be negligible. For this, we assume a film thickness Reynolds number ![]() $Re_h \lessapprox 1$, which by (2.14) requires

$Re_h \lessapprox 1$, which by (2.14) requires ![]() $\theta _0 \lessapprox 2/\sqrt {Re}$. The range

$\theta _0 \lessapprox 2/\sqrt {Re}$. The range ![]() $0.1 \leq \theta \leq 0.3$ satisfies these conditions approximately for

$0.1 \leq \theta \leq 0.3$ satisfies these conditions approximately for ![]() $G/d = 10^{-4}$ and

$G/d = 10^{-4}$ and ![]() $Re = 100$, therefore

$Re = 100$, therefore ![]() $\theta _0$ may take any value within this range. This is confirmed by the agreement between the inner and outer solutions over this range as observed in figure 11(a).

$\theta _0$ may take any value within this range. This is confirmed by the agreement between the inner and outer solutions over this range as observed in figure 11(a).

Figure 11(b) presents a comparison between the pressure distribution obtained under the zero-gap assumption, and the pressure obtained using the single-domain, finite-gap method. Here, we have subtracted the pressure from the Stokes flow solution (2.10) to show more clearly the inertial contribution. Away from the contact point, the single-domain and zero-gap solutions are nearly indistinguishable, therefore the zero-gap method proposed in this subsection is capable of determining the outer solution for finite-gap inertial flows, in the domain where this solution is applicable.

To summarise, we have shown that the inertial outer-flow solution obtained under the assumption ![]() $G/d = 0$ correctly describes the flow in the outer region (

$G/d = 0$ correctly describes the flow in the outer region (![]() $|\theta | \gg 2/\sqrt {G/d}$) for small, but finite, gap ratios. We can then construct a complete solution by taking the numerically obtained outer solution for

$|\theta | \gg 2/\sqrt {G/d}$) for small, but finite, gap ratios. We can then construct a complete solution by taking the numerically obtained outer solution for ![]() $|\theta | \geq \theta _0$, and using the inner lubrication solution for

$|\theta | \geq \theta _0$, and using the inner lubrication solution for ![]() $|\theta | < \theta _0$, where

$|\theta | < \theta _0$, where ![]() $\theta _0$ is in the range

$\theta _0$ is in the range ![]() $2\sqrt {G/d} \ll \theta _0 \ll 2$ and

$2\sqrt {G/d} \ll \theta _0 \ll 2$ and ![]() $\theta _0 \lessapprox 2/\sqrt {Re}$.

$\theta _0 \lessapprox 2/\sqrt {Re}$.

A grid resolution study is performed to confirm that a grid-independent outer-flow solutions is obtained. Table 3 lists four meshes used for this resolution study, including the number of cells in each mesh (![]() $N_c$), the representative cell sizes

$N_c$), the representative cell sizes ![]() $\Delta x$ and

$\Delta x$ and ![]() $N_y$ (which are illustrated in figure 8), and the cut-out angle

$N_y$ (which are illustrated in figure 8), and the cut-out angle ![]() $\theta _c$. The time-mean and r.m.s. wake force and moment coefficients are also provided, and changes to these quantities between meshes 2 and 3 are below 1 %. Therefore, mesh 2 is considered sufficient to resolve the force and moment coefficients.

$\theta _c$. The time-mean and r.m.s. wake force and moment coefficients are also provided, and changes to these quantities between meshes 2 and 3 are below 1 %. Therefore, mesh 2 is considered sufficient to resolve the force and moment coefficients.

Table 3. Comparison in the predicted mean and r.m.s. wake force and moment coefficients for ![]() $Re = 200$ and

$Re = 200$ and ![]() $k = 1$, evaluated using different grid resolutions. The relative differences between the predictions from meshes 2 and 3, and meshes 2 and 4, are given in parentheses.

$k = 1$, evaluated using different grid resolutions. The relative differences between the predictions from meshes 2 and 3, and meshes 2 and 4, are given in parentheses.

Mesh 4 has the same resolution as mesh 2, but with ![]() $\theta _c = 0.02$. Changes to the mean and r.m.s. wake force and moment coefficients between meshes 2 and 4 are below 0.02 %, confirming that

$\theta _c = 0.02$. Changes to the mean and r.m.s. wake force and moment coefficients between meshes 2 and 4 are below 0.02 %, confirming that ![]() $\theta _c = 0.01$ is sufficiently small to not introduce any significant errors.

$\theta _c = 0.01$ is sufficiently small to not introduce any significant errors.

Note that the minimum spacing in the ![]() $x$-direction for mesh 2 is

$x$-direction for mesh 2 is ![]() $\Delta x = 10^{-5}$, an order of magnitude smaller than the minimum spacing used for the finite

$\Delta x = 10^{-5}$, an order of magnitude smaller than the minimum spacing used for the finite ![]() $G/d$ computations (table 1). This was to reduce numerical errors associated with taking the difference of large numbers, which occurs in some of our analysis (see Appendix A). However, in Appendix A, we demonstrate that taking a larger value of

$G/d$ computations (table 1). This was to reduce numerical errors associated with taking the difference of large numbers, which occurs in some of our analysis (see Appendix A). However, in Appendix A, we demonstrate that taking a larger value of ![]() $\Delta x = 5 \times 10^{-4}$ does not significantly affect the predicted force and moment coefficients.

$\Delta x = 5 \times 10^{-4}$ does not significantly affect the predicted force and moment coefficients.

In this subsection, we have simulated the flow over a cylinder at ![]() $G/d = 0$ by removing the contact point from the computational domain in order to avoid the infinite pressure at the contact point. Pirozzoli, Orlandi & Bernardini (Reference Pirozzoli, Orlandi and Bernardini2012) have also performed numerical simulations of the rolling cylinder at

$G/d = 0$ by removing the contact point from the computational domain in order to avoid the infinite pressure at the contact point. Pirozzoli, Orlandi & Bernardini (Reference Pirozzoli, Orlandi and Bernardini2012) have also performed numerical simulations of the rolling cylinder at ![]() $G/d = 0$, but do not report any difficulties with infinite pressures at the contact point. They report finite values for the drag coefficient at

$G/d = 0$, but do not report any difficulties with infinite pressures at the contact point. They report finite values for the drag coefficient at ![]() $G/d = 0$, in contrast with both the Stokes flow predictions and the present study. This discrepancy is likely a result of insufficient resolution to capture the flow near the contact point. They use a relatively low grid resolution of 40 points per cell radius, which means that near the contact point (specifically, for

$G/d = 0$, in contrast with both the Stokes flow predictions and the present study. This discrepancy is likely a result of insufficient resolution to capture the flow near the contact point. They use a relatively low grid resolution of 40 points per cell radius, which means that near the contact point (specifically, for ![]() $-0.1 < x/d < 0.1$), the cylinder and the wall lie in the same computational cell. It is unlikely that the flow in this region is resolved satisfactorily, and the finite drag coefficients reported in that work are considered unreliable. However, since the outer flow is relatively insensitive to the flow near the contact point, the outer flow may be resolved correctly in their work.

$-0.1 < x/d < 0.1$), the cylinder and the wall lie in the same computational cell. It is unlikely that the flow in this region is resolved satisfactorily, and the finite drag coefficients reported in that work are considered unreliable. However, since the outer flow is relatively insensitive to the flow near the contact point, the outer flow may be resolved correctly in their work.

3.4. Application of the proposed method to other problems

This paper has considered only the two-dimensional flow over a rolling cylinder. However, we anticipate that the approach outlined in this work may be extended to other rolling body problems, such as the flow over a rolling sphere or a finite cylinder (wheel). The method of matched asymptotic expansions has already been applied to the Stokes flow over a rolling sphere (Goldman et al. Reference Goldman, Cox and Brenner1967; O'Neill & Stewartson Reference O'Neill and Stewartson1967; Cooley & O'Neill Reference Cooley and O'Neill1968), to decompose the flow into inner and outer expansions. Therefore, we expect that the same method may be applied to the inertial flow over a rolling sphere.

We remark, however, that there are both qualitative and quantitative differences between the Stokes flows over rolling cylinders and spheres. For example, both the torque applied to a purely translating cylinder and the force applied to a purely rotating cylinder are zero (Jeffrey & Onishi Reference Jeffrey and Onishi1981), which is not the case for the rolling and translating spheres. Moreover, the force and moment applied to a rolling sphere both exhibit a logarithmic dependence on the gap ratio (Goldman et al. Reference Goldman, Cox and Brenner1967; O'Neill & Stewartson Reference O'Neill and Stewartson1967; Cooley & O'Neill Reference Cooley and O'Neill1968), compared to the ![]() $(G/d)^{-1/2}$ dependence for the force and moment applied to the rolling cylinder (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011). Despite these differences, the method of asymptotic expansions has been applied successfully to the Stokes flow over both cylinders and spheres, therefore the same approach should be applicable to the inertial flow over a rolling sphere.