1. Introduction

Low-Reynolds-number motion of objects near surfaces is found across a wide range of engineering, microfluidic and biomedical applications. In particular, when surfaces are in close proximity, considerable research has focused on the study of the fluid and structure interactions that occur within the lubrication layer (Hamrock, Schmid & Jacobson Reference Hamrock, Schmid and Jacobson2004). The dynamics can be quite varied, and include hydrodynamic forces and velocities for spherical particles moving near planar walls (Goldman, Cox & Brenner Reference Goldman, Cox and Brenner1967a,Reference Goldman, Cox and Brennerb), spheroidal particles in shear flows near a solid wall, as studied using a variant of the boundary integral equation method (Gavze & Shapiro Reference Gavze and Shapiro1997), and particle sedimentation near a plane wall accounting for weak non-Newtonian and inertial effects (Becker, McKinley & Stone Reference Becker, McKinley and Stone1996). Dynamics frequently involve cylindrical geometries, such as in the determination of the drag forces on a microcantilever oscillating near a wall (Clarke et al. Reference Clarke, Cox, Williams and Jensen2005), the design and optimization of viscous micropumps (Sen, Wajerski & Gad-el Hak Reference Sen, Wajerski and Gad-el Hak1996; Day & Stone Reference Day and Stone2000; Choi et al. Reference Choi, Lee, Choi and Maeng2010), motion of air bearings, including effects of fluid compressibility (Witelski Reference Witelski1998), and the circular swimming motion of Escherichia coli bacteria near a solid boundary (Lauga et al. Reference Lauga, DiLuzio, Whitesides and Stone2006) and the motor torque of such bacteria (Das & Lauga Reference Das and Lauga2018), among many others. In almost all, if not all, such cases, the cylinder is modelled as infinite. The present paper focuses on the dynamics of three-dimensional (3-D) finite cylindrical rods translating and rotating near a rigid planar wall.

The classic solution for the rotation of a cylinder in a viscously dominated flow was calculated by Jeffery (Reference Jeffery1922) using bipolar coordinates to solve the two-dimensional (2-D) Stokes flow problem. Jeffrey & Onishi (Reference Jeffrey and Onishi1981) extended this work to consider the 2-D flows associated with rotation and translation of an infinite cylinder both parallel and perpendicular to a nearby plane wall, which they solved analytically using a stream function formulation of the Stokes equations, along with the bipolar coordinate representation. Variations on this problem have been studied, including theoretical prediction of the drag force on a zero-thickness disk translating towards a plane wall (Davis Reference Davis1993) and the consequences of slip conditions due to superhydrophobic surfaces (Kaynan & Yariv Reference Kaynan and Yariv2017; Schnitzer & Yariv Reference Schnitzer and Yariv2019). Also, Crowdy (Reference Crowdy2011) rederived the results of Jeffrey & Onishi (Reference Jeffrey and Onishi1981) without approximation and developed an explicit nonlinear dynamical system for treadmilling swimmers. The effect of non-zero Reynolds number for the motion of a cylinder rolling along a wall, both with and without a gap, has also been reported (Merlen & Frankiewicz Reference Merlen and Frankiewicz2011). More recently, studies have expanded on the theories of Jeffrey & Onishi (Reference Jeffrey and Onishi1981) to include additional coupled physics, such as the effects of soft interfaces on the fluid dynamics in the lubrication layer and the forces that originate due to non-conforming contacts (Skotheim & Mahadevan Reference Skotheim and Mahadevan2004, Reference Skotheim and Mahadevan2005; Salez & Mahadevan Reference Salez and Mahadevan2015; Rallabandi et al. Reference Rallabandi, Saintyves, Jules, Salez, Schönecker, Mahadevan and Stone2017; Saintyves et al. Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020).

One, perhaps surprising, result from the original analysis of Jeffrey & Onishi (Reference Jeffrey and Onishi1981) is that the hydrodynamic force on an infinite cylinder moving near a wall is independent of its rotation rate and, by symmetry, the hydrodynamic torque on the cylinder is independent of its translational velocity. A consequence of this fact is that there is no coupling between rotation and translation for an infinite cylinder translating near a planar wall in the absence of an externally applied torque. However, finite objects such as a sphere moving near a planar wall will, in fact, respond by both rotating and translating when either experiencing an external force, to remain torque free, or an external torque to remain force free. For the case of a finite-length cylinder then, these facts suggest that external forces or torques, for the cases of lateral translation and rotation, respectively, lead to a coupling between translation and rotation and originate due to end effects. In a recent experimental study of a finite-length cylinder sliding down a soft incline while free to rotate, the 2-D solution for an infinite cylinder, derived by Rallabandi et al. (Reference Rallabandi, Saintyves, Jules, Salez, Schönecker, Mahadevan and Stone2017) using the Lorentz reciprocal theorem, showed quantitative discrepancies with the experimental results (Saintyves et al. Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). This discrepancy led to the development of a new theory that considers elastohydrodynamic torque as well as the viscous friction induced by the ends of the cylinders. Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020) experimentally and theoretically showed that the cylinder's end-effects play a non-negligible role in the case of motion of a finite-length cylinder and motivate this work.

Finally, several other important works have explored various aspects of particle motion near boundaries using slender-body theory and other asymptotic methods, some of which examined similar configurations to that of the present study. For example, Russel et al. (Reference Russel, Hinch, Leal and Tieffenbruck1977) used slender-body theory to model the glancing and reversing tumbling of inclined rods settling close to a plane wall. A more recent work by Barta & Liron (Reference Barta and Liron1988) built on this work using a singularity method in two regimes, where the body–wall distance was the same order as either the body length or the body width. Youngren & Acrivos (Reference Youngren and Acrivos1975) presented a general numerical approach to calculate the Stokes flow past general shaped bodies such as cylinders which can take into account the end effects. They applied this method to a cylinder translating parallel to its axis. Katz, Blake & Paveri-Fontana (Reference Katz, Blake and Paveri-Fontana1975) also considered the translational motion of rigid slender bodies near a boundary in the limit where the radius of the body is much less than the separation to the wall, which in turn is small compared with the radius of the body. The slender body motion has also been considered near a flat fluid–fluid interface in contrast to a solid plane wall (Yang & Leal Reference Yang and Leal1983). De Mestre & Russel (Reference De Mestre and Russel1975) used slender-body theory to calculate the total drag on rotating and translating rods near a plane wall for body–wall separations which are large relative to the rod radius. Two of the classic theoretical works on slender-body theory are by Batchelor (Reference Batchelor1970) and Cox (Reference Cox1970), who used the slender body theory to calculate the Stokes flow past slender bodies of arbitrary cross-section.

Another closely related work to the present study is that of De Mestre (Reference De Mestre1973), which calculated the drag on a cylinder travelling parallel to a plane wall using slender-body theory. The distinction from the present work is that those results are valid for cases where the distance to the wall is large relative to the cylinder length. One of the relatively fewer experimental studies is by Ui, Hussey & Roger (Reference Ui, Hussey and Roger1984), who measured the drag on cylinders travelling along their axis within a cylindrical container to quantify the wall effects. Mitchell & Spagnolie (Reference Mitchell and Spagnolie2015) used the method of images to model the sedimentation of prolate and oblate spheroids near an inclined wall and suggested the possibility of incorporating lubrication effects along the lines of those introduced in this paper. Lisicki, Cichocki & Wajnryb (Reference Lisicki, Cichocki and Wajnryb2016) derived an explicit relation for the correction to the bulk diffusion tensor of an axially symmetric colloidal particle due to a nearby plane wall. Finally, Koens & Montenegro-Johnson (Reference Koens and Montenegro-Johnson2021) determined the drag per unit length on a slender rod translating parallel to a wall which is valid for all separation distances. This was achieved through asymptotic matching to the results of both De Mestre & Russel (Reference De Mestre and Russel1975) and Jeffrey & Onishi (Reference Jeffrey and Onishi1981).

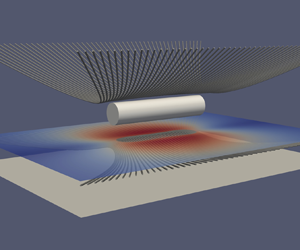

Here, we build on the work of Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020) and generalize their theory to consider rotation and translation, both parallel and perpendicular to a nearby solid planar boundary, of a finite-length cylinder (see figure 1). We use 3-D numerical simulations of the Navier–Stokes equations to calculate the viscous and pressure forces and torques exerted by the fluid on a cylinder for a range of cylinder lengths and cylinder-plane gap heights. We identify conditions where the end effects dominate and drive a qualitative deviation from the case of a 2-D infinite cylinder. In particular, in § 2, we develop theory based on the lubrication approximation within the gap region to calculate the resistance matrices for the cylinder motion in order to describe the relationships between the translational and angular velocities and the forces and torques, and we develop analytical expressions for the resistance components. Next, in § 3, we present the numerical methods used for the 3-D simulations, and we introduce representative results and flow behaviours. Then, we present a comparison between the theory and the numerical simulations in § 4, and show that the numerical results collapse to the theoretical predictions in the long- and short-cylinder limits. Finally, in § 5, we provide discussion and conclusions. Further validation of the numerical methods including the results of convergence tests can be found in the Appendix (A).

Figure 1. The geometrical configuration and coordinate system for a finite-length cylinder moving near a plane wall. We consider the parallel translation (![]() $U\neq 0$), rotation (

$U\neq 0$), rotation (![]() $\varOmega \neq 0$) and perpendicular translation (

$\varOmega \neq 0$) and perpendicular translation (![]() $V\neq 0$) of a finite-length cylinder near a solid plane wall. The cylinder radius and length are

$V\neq 0$) of a finite-length cylinder near a solid plane wall. The cylinder radius and length are ![]() $a$ and

$a$ and ![]() $L$, respectively, and the minimum gap height between the cylinder and the wall is

$L$, respectively, and the minimum gap height between the cylinder and the wall is ![]() $h_0$.

$h_0$.

2. Theory

The classic solution for the low-Reynolds-number motion of an infinite circular cylinder near a plane wall is given by Jeffrey & Onishi (Reference Jeffrey and Onishi1981). This work introduced solutions for three cases: translation parallel to the plane; translation perpendicular to the plane; and rotation about the cylinder's axis. In each case the axis of the cylinder is oriented parallel to the plane. A key result of this work is that a force-free infinite cylinder rotating next to a plane wall does not translate, and a torque-free infinite cylinder translating next to a plane wall does not rotate. Here, we define the dimensionless gap height between the cylinder and the plane wall as ![]() $\epsilon =h_0/a$, where

$\epsilon =h_0/a$, where ![]() $h_0$ is the minimum gap height and

$h_0$ is the minimum gap height and ![]() $a$ is the cylinder radius. The shear viscosity of the fluid is

$a$ is the cylinder radius. The shear viscosity of the fluid is ![]() $\mu$, and the translational velocities parallel and perpendicular to the wall and rotational velocity of the cylinder are

$\mu$, and the translational velocities parallel and perpendicular to the wall and rotational velocity of the cylinder are ![]() $U$,

$U$, ![]() $V$ and

$V$ and ![]() $\varOmega$, respectively (see figure 1). Jeffrey & Onishi (Reference Jeffrey and Onishi1981) showed that the dimensionless torque per unit length (non-dimensionalized by

$\varOmega$, respectively (see figure 1). Jeffrey & Onishi (Reference Jeffrey and Onishi1981) showed that the dimensionless torque per unit length (non-dimensionalized by ![]() $\mu \varOmega a^2$) resisting motion of an infinite-length cylinder rotating next to a plane wall is given by

$\mu \varOmega a^2$) resisting motion of an infinite-length cylinder rotating next to a plane wall is given by

Furthermore, they also showed that an infinite cylinder translating at speed ![]() $U$ parallel to a plane wall experiences zero hydrodynamic torque and a total drag force per unit length (non-dimensionalized by

$U$ parallel to a plane wall experiences zero hydrodynamic torque and a total drag force per unit length (non-dimensionalized by ![]() $\mu U$) that is given by

$\mu U$) that is given by

In these cases, the cylinder either rotates due to the external torque per unit length but does not translate, or it translates due to the external force per unit length but does not rotate. Finally, Jeffrey & Onishi (Reference Jeffrey and Onishi1981) showed that the vertical force per unit length (non-dimensionalized by ![]() $\mu V$) on an infinite cylinder translating at speed

$\mu V$) on an infinite cylinder translating at speed ![]() $V$ perpendicular to a plane wall is given by

$V$ perpendicular to a plane wall is given by

\begin{equation} f_\perp{=}{-}4{\rm \pi}\left[\log(1+\epsilon+\sqrt{2\epsilon + \epsilon^2}) - \frac{\sqrt{2\epsilon+\epsilon^2}}{1+\epsilon}\right]^{{-}1}. \end{equation}

\begin{equation} f_\perp{=}{-}4{\rm \pi}\left[\log(1+\epsilon+\sqrt{2\epsilon + \epsilon^2}) - \frac{\sqrt{2\epsilon+\epsilon^2}}{1+\epsilon}\right]^{{-}1}. \end{equation}

Below, we will also need the relation of force and velocity experienced by a disk of radius ![]() $a$ and zero thickness translating edgewise. Ray (Reference Ray1936) determined an analytical solution for the resistance force experienced by such a disk, and Davis (Reference Davis1993) generalized and expanded this result and presented the theoretical force as

$a$ and zero thickness translating edgewise. Ray (Reference Ray1936) determined an analytical solution for the resistance force experienced by such a disk, and Davis (Reference Davis1993) generalized and expanded this result and presented the theoretical force as

where ![]() $F_\perp$ is non-dimensionalized by

$F_\perp$ is non-dimensionalized by ![]() $\mu V a$, and

$\mu V a$, and ![]() $F_D$ is a higher-order dimensionless force coefficient that has been derived by Davis (Reference Davis1993),

$F_D$ is a higher-order dimensionless force coefficient that has been derived by Davis (Reference Davis1993),

The above-mentioned works focus solely on the cases of infinite- or zero-length cylinders. Here, we focus our attention on the case of finite-length cylinders, as the importance of this geometric feature for cylinder motion near a wall was recently highlighted by Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). Here, we generalize the work of Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020) and develop an analytical description for the motion of finite-length cylinders moving near solid planar walls (![]() $\epsilon \ll 1$) via a lubrication theory including the effects of the ends of the cylinder. In this way, translation and rotation are coupled.

$\epsilon \ll 1$) via a lubrication theory including the effects of the ends of the cylinder. In this way, translation and rotation are coupled.

2.1. Lubrication theory for a finite-length cylinder: wall-parallel translation and rotation

Here, we use lubrication theory to analyse the forces and torques on a finite-length cylinder rotating or translating close to a rigid wall, including end effects (see figure 1). The length of the cylinder is denoted by ![]() $L$. The minimum separation distance between the cylinder and the wall is assumed small relative to the cylinder radius and the cylinder length, so

$L$. The minimum separation distance between the cylinder and the wall is assumed small relative to the cylinder radius and the cylinder length, so ![]() $h_0/a = \epsilon \ll 1$ and

$h_0/a = \epsilon \ll 1$ and ![]() $h_0/L \ll 1$, so that lubrication theory is applicable. The characteristic length scale along the gap, perpendicular to the axis of the cylinder

$h_0/L \ll 1$, so that lubrication theory is applicable. The characteristic length scale along the gap, perpendicular to the axis of the cylinder ![]() $(x)$, is

$(x)$, is ![]() $\ell = \sqrt {2 a h_0}$, and the axial

$\ell = \sqrt {2 a h_0}$, and the axial ![]() $(y)$ length scale is

$(y)$ length scale is ![]() $L$. The ratio of these two quantities is

$L$. The ratio of these two quantities is ![]() $\mathcal {L} =L/\ell = L/(a \sqrt {2 \epsilon })$, which may be either large or small depending on the relative magnitudes of

$\mathcal {L} =L/\ell = L/(a \sqrt {2 \epsilon })$, which may be either large or small depending on the relative magnitudes of ![]() $L/a$ and

$L/a$ and ![]() $\epsilon$. Observe that

$\epsilon$. Observe that ![]() $\mathcal {L}$ characterizes the aspect ratio of the lubricated region, and differs from the aspect ratio

$\mathcal {L}$ characterizes the aspect ratio of the lubricated region, and differs from the aspect ratio ![]() $L/a$ of the cylinder.

$L/a$ of the cylinder.

With these definitions, the gap between the cylinder and the fluid is approximated by the parabolic function ![]() $h(x) \sim h_0(1 + x^2/\ell ^2)$, which is valid inside the lubricated region where

$h(x) \sim h_0(1 + x^2/\ell ^2)$, which is valid inside the lubricated region where ![]() $x = O(\ell )$. Then, the dimensional pressure

$x = O(\ell )$. Then, the dimensional pressure ![]() $p(x,y)$ under a translating and rotating cylinder is governed by the Reynolds equation

$p(x,y)$ under a translating and rotating cylinder is governed by the Reynolds equation

where ![]() $\boldsymbol {\nabla } = \boldsymbol {e}_x\partial _x + \boldsymbol {e}_y\partial _y$ is the gradient in the

$\boldsymbol {\nabla } = \boldsymbol {e}_x\partial _x + \boldsymbol {e}_y\partial _y$ is the gradient in the ![]() $xy$ plane. As is standard in lubrication theory, the pressure is nearly constant across the gap and is much greater than the pressure outside the gap, and so

$xy$ plane. As is standard in lubrication theory, the pressure is nearly constant across the gap and is much greater than the pressure outside the gap, and so ![]() $p(x,y)$ must vanish outside the lubrication region. Along

$p(x,y)$ must vanish outside the lubrication region. Along ![]() $x$, the outer edge of the gap is at

$x$, the outer edge of the gap is at ![]() $x = O(a) \gg \ell$, so

$x = O(a) \gg \ell$, so ![]() $p$ decays smoothly as

$p$ decays smoothly as ![]() $x/\ell \to \pm \infty$. Along

$x/\ell \to \pm \infty$. Along ![]() $y$ the gap width

$y$ the gap width ![]() $h(x)$ diverges abruptly past the two end faces at

$h(x)$ diverges abruptly past the two end faces at ![]() $y= \pm L/2$ and so the pressure must vanish at these planes. Note that, in fact, there is a finite region outside of the edge of the gap where the pressure adjusts to the outer condition. We will later show that this region shrinks with the gap height, and so in the lubrication limit this leads to the boundary conditions

$y= \pm L/2$ and so the pressure must vanish at these planes. Note that, in fact, there is a finite region outside of the edge of the gap where the pressure adjusts to the outer condition. We will later show that this region shrinks with the gap height, and so in the lubrication limit this leads to the boundary conditions

Note that this condition is analogous to other geometries with sharply sloped faces such as slider blocks (Leal Reference Leal2007).

In principle, a solution of (2.6) subject to (2.7) can be used to infer both tangential and normal stresses, whose integrals over the cylinder surface lead to the hydrodynamic force and torque on the cylinder. Rather than evaluate these surface integrals, we will develop an alternative formulation using the Lorentz reciprocal theorem. We will see that this reduces the computation of forces and torques to a single line integral that offers computational and analytical advantages.

We introduce as an auxiliary problem the 2-D flow due to a infinite cylinder that translates and rotates with a combination of velocity ![]() $\hat {\boldsymbol {U}}$ and angular velocity

$\hat {\boldsymbol {U}}$ and angular velocity ![]() $\hat {\boldsymbol {\varOmega }}$, associated with the velocity field

$\hat {\boldsymbol {\varOmega }}$, associated with the velocity field ![]() $\hat {\boldsymbol {u}}(\boldsymbol {x})$ and stress

$\hat {\boldsymbol {u}}(\boldsymbol {x})$ and stress ![]() $\hat {\boldsymbol {\sigma }}(\boldsymbol {x})$. This 2-D flow is well known (Jeffrey & Onishi Reference Jeffrey and Onishi1981): its pressure

$\hat {\boldsymbol {\sigma }}(\boldsymbol {x})$. This 2-D flow is well known (Jeffrey & Onishi Reference Jeffrey and Onishi1981): its pressure ![]() $\hat {p}(x)$ is independent of

$\hat {p}(x)$ is independent of ![]() $y$ and satisfies (2.6), but with the boundary conditions (2.7) at

$y$ and satisfies (2.6), but with the boundary conditions (2.7) at ![]() $y = \pm L/2$ relaxed. We apply the reciprocal theorem (Happel & Brenner Reference Happel and Brenner1965; Masoud & Stone Reference Masoud and Stone2019) in the fluid volume

$y = \pm L/2$ relaxed. We apply the reciprocal theorem (Happel & Brenner Reference Happel and Brenner1965; Masoud & Stone Reference Masoud and Stone2019) in the fluid volume ![]() $\mathcal {V}_{lub}$ under the finite-length cylinder, bounded by the curved cylinder surface

$\mathcal {V}_{lub}$ under the finite-length cylinder, bounded by the curved cylinder surface ![]() $S_c$, the wall

$S_c$, the wall ![]() $S_w$ and the two bounding faces at the ends

$S_w$ and the two bounding faces at the ends ![]() $S_{ends}$ defined by

$S_{ends}$ defined by ![]() $(y = \pm L/2,\ 0 \leq z \leq h(x)$). The geometry of the fluid volume being considered in both the main and auxiliary (model) problem is shown in figure 2. Using

$(y = \pm L/2,\ 0 \leq z \leq h(x)$). The geometry of the fluid volume being considered in both the main and auxiliary (model) problem is shown in figure 2. Using ![]() $\boldsymbol {n}$ to denote the normal to these surfaces into

$\boldsymbol {n}$ to denote the normal to these surfaces into ![]() $\mathcal {V}_{\rm lub}$, and

$\mathcal {V}_{\rm lub}$, and ![]() $\boldsymbol {u}(\boldsymbol {x})$ and

$\boldsymbol {u}(\boldsymbol {x})$ and ![]() $\boldsymbol {\sigma }(\boldsymbol {x})$ to represent the velocity and stress, respectively, around the finite (3-D) cylinder, we obtain

$\boldsymbol {\sigma }(\boldsymbol {x})$ to represent the velocity and stress, respectively, around the finite (3-D) cylinder, we obtain

The above expression simplifies to

\begin{align} \boldsymbol{F} \boldsymbol{\cdot} \hat{\boldsymbol{U}} + \boldsymbol{T}\boldsymbol{\cdot}\hat{\boldsymbol{\varOmega}} - \hat{\boldsymbol{F}}\boldsymbol{\cdot}\boldsymbol{U} - \hat{\boldsymbol{T}}\boldsymbol{\cdot} \boldsymbol{\varOmega} &= \int_{S_{ends}}(\boldsymbol{n}\boldsymbol{\cdot}\hat{\boldsymbol{\sigma}}\boldsymbol{\cdot} \boldsymbol{{u}} - \boldsymbol{n}\boldsymbol{\cdot}\boldsymbol{\sigma}\boldsymbol{\cdot} \hat{\boldsymbol{{u}}})\,\mathrm{d}S \nonumber\\ &\simeq \int_{S_{ends}}-\hat{p}u_y\boldsymbol{n}\boldsymbol{\cdot} \boldsymbol{e}_y\,\mathrm{d}S, \end{align}

\begin{align} \boldsymbol{F} \boldsymbol{\cdot} \hat{\boldsymbol{U}} + \boldsymbol{T}\boldsymbol{\cdot}\hat{\boldsymbol{\varOmega}} - \hat{\boldsymbol{F}}\boldsymbol{\cdot}\boldsymbol{U} - \hat{\boldsymbol{T}}\boldsymbol{\cdot} \boldsymbol{\varOmega} &= \int_{S_{ends}}(\boldsymbol{n}\boldsymbol{\cdot}\hat{\boldsymbol{\sigma}}\boldsymbol{\cdot} \boldsymbol{{u}} - \boldsymbol{n}\boldsymbol{\cdot}\boldsymbol{\sigma}\boldsymbol{\cdot} \hat{\boldsymbol{{u}}})\,\mathrm{d}S \nonumber\\ &\simeq \int_{S_{ends}}-\hat{p}u_y\boldsymbol{n}\boldsymbol{\cdot} \boldsymbol{e}_y\,\mathrm{d}S, \end{align}

where the approximation is valid in the lubrication limit; note that ![]() $\boldsymbol {n} = \mp \boldsymbol {e}_y$ at the ends at

$\boldsymbol {n} = \mp \boldsymbol {e}_y$ at the ends at ![]() $y = \pm L/2$. We then substitute

$y = \pm L/2$. We then substitute ![]() $u_y = ({1}/{2\mu })({\partial p}/{\partial y})z(z-h)$, consistent with lubrication, into (2.9). We write

$u_y = ({1}/{2\mu })({\partial p}/{\partial y})z(z-h)$, consistent with lubrication, into (2.9). We write ![]() $\mathrm {d}S = \mathrm {d}x\,\mathrm {d}z$ and evaluate the

$\mathrm {d}S = \mathrm {d}x\,\mathrm {d}z$ and evaluate the ![]() $z$ part of the surface integrals on

$z$ part of the surface integrals on ![]() $S_\text {ends}$ (with limits between

$S_\text {ends}$ (with limits between ![]() $0$ and

$0$ and ![]() $h(x)$), and utilize symmetry about

$h(x)$), and utilize symmetry about ![]() $y=0$ to obtain

$y=0$ to obtain

\begin{equation} \boldsymbol{F} \boldsymbol{\cdot} \hat{\boldsymbol{U}} + \boldsymbol{T}\boldsymbol{\cdot}\hat{\boldsymbol{\varOmega}} - \hat{\boldsymbol{F}}\boldsymbol{\cdot}\boldsymbol{U} - \hat{\boldsymbol{T}}\boldsymbol{\cdot} \boldsymbol{\varOmega} \simeq \frac{1}{6 \mu} \left.\int_{{-}x_{\infty}}^{x_{\infty}} h^3 \hat{p} \frac{\partial^{}p}{\partial y^{}}\right|_{y ={-}L/2}\,\mathrm{d}x. \end{equation}

\begin{equation} \boldsymbol{F} \boldsymbol{\cdot} \hat{\boldsymbol{U}} + \boldsymbol{T}\boldsymbol{\cdot}\hat{\boldsymbol{\varOmega}} - \hat{\boldsymbol{F}}\boldsymbol{\cdot}\boldsymbol{U} - \hat{\boldsymbol{T}}\boldsymbol{\cdot} \boldsymbol{\varOmega} \simeq \frac{1}{6 \mu} \left.\int_{{-}x_{\infty}}^{x_{\infty}} h^3 \hat{p} \frac{\partial^{}p}{\partial y^{}}\right|_{y ={-}L/2}\,\mathrm{d}x. \end{equation}

As previously noted, the quantity ![]() $x_{\infty } = O(a)$ represents the outer ‘edge’ of the lubricated film. Later, we will simply define

$x_{\infty } = O(a)$ represents the outer ‘edge’ of the lubricated film. Later, we will simply define ![]() $x_{\infty } = a$ and consider the limit

$x_{\infty } = a$ and consider the limit ![]() $a/\ell \to \infty$. Observe that the present approach still involves solving (2.6), (2.7) for

$a/\ell \to \infty$. Observe that the present approach still involves solving (2.6), (2.7) for ![]() $p(x,y)$, but now the forces and torques can be determined by evaluating a line integral in (2.10) rather than a surface integral.

$p(x,y)$, but now the forces and torques can be determined by evaluating a line integral in (2.10) rather than a surface integral.

Figure 2. The geometry of the fluid volume being considered for the application of the reciprocal theorem. In the main problem, we consider the fluid volume directly under a finite-length cylinder, which is indicated by the grey shaded volume bounded by the areas ![]() $S_c$,

$S_c$, ![]() $S_w$ and

$S_w$ and ![]() $S_{ends}$. As an auxiliary (model) problem, we consider the same volume, but under an infinite cylinder. Thus, for the two cases, the fluid geometry being considered is identical, but the boundary conditions on the pressure are different, as shown. In the main problem,

$S_{ends}$. As an auxiliary (model) problem, we consider the same volume, but under an infinite cylinder. Thus, for the two cases, the fluid geometry being considered is identical, but the boundary conditions on the pressure are different, as shown. In the main problem, ![]() $p=0$ at the ends of the volume, and in the model problem

$p=0$ at the ends of the volume, and in the model problem ![]() ${\partial \hat p}/{\partial y}=0$ at the ends.

${\partial \hat p}/{\partial y}=0$ at the ends.

In the analysis below, it will be useful to define the dimensionless coordinates

so that the two ends of the cylinder are at ![]() $Y = \pm \mathcal {L}/2$. The pressure in the auxiliary problem involving translation and rotation is then

$Y = \pm \mathcal {L}/2$. The pressure in the auxiliary problem involving translation and rotation is then

The corresponding force and torque are

which scale with the length of the cylinder ![]() $L$. We note that these forces and torques are the leading terms of the 2-D results of Jeffrey & Onishi (Reference Jeffrey and Onishi1981) for small

$L$. We note that these forces and torques are the leading terms of the 2-D results of Jeffrey & Onishi (Reference Jeffrey and Onishi1981) for small ![]() $\epsilon$ and are equivalent to (2.1)–(2.3) in this limit. The linearity of the flows in the main problem (3-D cylinder) and the auxiliary problem (2-D cylinder) lets us analyse rotation and the two components of translation separately. A linear superposition of these results will yield the hydrodynamic force and torque on a cylinder undergoing combined rotation and translation.

$\epsilon$ and are equivalent to (2.1)–(2.3) in this limit. The linearity of the flows in the main problem (3-D cylinder) and the auxiliary problem (2-D cylinder) lets us analyse rotation and the two components of translation separately. A linear superposition of these results will yield the hydrodynamic force and torque on a cylinder undergoing combined rotation and translation.

2.1.1. Rotation and wall-parallel translation

The case of a finite-length cylinder translating parallel to a wall and that of a rotating cylinder will turn out to be closely related, so we consider them together. Due to symmetry, the force is along ![]() $x$ so we can set

$x$ so we can set ![]() $\hat {V} = 0$ in the auxiliary problem without consequence. A cylinder that translates parallel to a wall without rotation has a pressure

$\hat {V} = 0$ in the auxiliary problem without consequence. A cylinder that translates parallel to a wall without rotation has a pressure ![]() $p(x,y) = (\mu U \ell /h_0^2) P_{\parallel }(X,Y)$, where

$p(x,y) = (\mu U \ell /h_0^2) P_{\parallel }(X,Y)$, where ![]() $P_{\parallel }(X,Y)$ satisfies the rescaled form of (2.6),

$P_{\parallel }(X,Y)$ satisfies the rescaled form of (2.6),

To isolate the force and the torque on this cylinder, we use (2.10) and set ![]() $\hat {\varOmega } = 0$ and

$\hat {\varOmega } = 0$ and ![]() $\hat {U} = 0$, respectively. Utilizing the results in (2.12) and (2.13a,b), then from (2.10) we obtain the force and torque on a translating finite-length cylinder as

$\hat {U} = 0$, respectively. Utilizing the results in (2.12) and (2.13a,b), then from (2.10) we obtain the force and torque on a translating finite-length cylinder as

$$\begin{gather} F_{{\parallel}} ={-}\frac{2 {\rm \pi}\mu U \ell L}{h_0} + \frac{2\mu U \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X \end{gather}$$

$$\begin{gather} F_{{\parallel}} ={-}\frac{2 {\rm \pi}\mu U \ell L}{h_0} + \frac{2\mu U \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X \end{gather}$$ $$\begin{gather}T_{{\parallel}} = \frac{2\mu U a \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X, \end{gather}$$

$$\begin{gather}T_{{\parallel}} = \frac{2\mu U a \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X, \end{gather}$$

where the terms involving the integrals are due to the cylinder's ends. A cylinder that rotates without translating has a pressure ![]() $p_{\rm rot}(x,y) = (\mu a \varOmega \ell /h_0^2) P_{\parallel }(X,Y)$ where

$p_{\rm rot}(x,y) = (\mu a \varOmega \ell /h_0^2) P_{\parallel }(X,Y)$ where ![]() $P_{\parallel }(X,Y)$ is the solution to (2.14); note that it is identical to

$P_{\parallel }(X,Y)$ is the solution to (2.14); note that it is identical to ![]() $p_{\parallel }(x,y)$ with the substitution

$p_{\parallel }(x,y)$ with the substitution ![]() $U \mapsto a \varOmega$ due to the structure of (2.6). As before, we isolate the force and torque on the purely rotating finite-length cylinder by setting

$U \mapsto a \varOmega$ due to the structure of (2.6). As before, we isolate the force and torque on the purely rotating finite-length cylinder by setting ![]() $\hat {\varOmega } = 0$ and

$\hat {\varOmega } = 0$ and ![]() $\hat {U} = 0$, respectively, and use the results in (2.12) and (2.13a,b) in (2.10) to obtain

$\hat {U} = 0$, respectively, and use the results in (2.12) and (2.13a,b) in (2.10) to obtain

$$\begin{gather} F_{rot} = \frac{2\mu \varOmega a \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X \end{gather}$$

$$\begin{gather} F_{rot} = \frac{2\mu \varOmega a \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X \end{gather}$$ $$\begin{gather}T_{rot} ={-}\frac{2 {\rm \pi}\mu \varOmega a^2 \ell L}{h_0} + \frac{2\mu \varOmega a^2 \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}} \right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X. \end{gather}$$

$$\begin{gather}T_{rot} ={-}\frac{2 {\rm \pi}\mu \varOmega a^2 \ell L}{h_0} + \frac{2\mu \varOmega a^2 \ell^2}{3 h_0} \left.\int_0^{X_{\infty}} X H \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}} \right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X. \end{gather}$$ Since ![]() $\ell = \sqrt {2 a h_0}$, the prefactors of the end-correction terms in (2.15) and (2.16) are independent of the dimensionless gap

$\ell = \sqrt {2 a h_0}$, the prefactors of the end-correction terms in (2.15) and (2.16) are independent of the dimensionless gap ![]() $\epsilon$. This suggests a logarithmic divergence of the integral, which is a common feature of lubrication problems involving curved surfaces (Claeys & Brady Reference Claeys and Brady1989). To evaluate the integrals, we consider the limit

$\epsilon$. This suggests a logarithmic divergence of the integral, which is a common feature of lubrication problems involving curved surfaces (Claeys & Brady Reference Claeys and Brady1989). To evaluate the integrals, we consider the limit ![]() $X_{\infty } \!= O(a/\ell ) \gg 1$. For long cylinders (

$X_{\infty } \!= O(a/\ell ) \gg 1$. For long cylinders (![]() $L \gg a$), the integrals are expected to scale as

$L \gg a$), the integrals are expected to scale as ![]() $\log \epsilon$ as suggested by Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). We will see that the dependence is more complex for a finite aspect ratio

$\log \epsilon$ as suggested by Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). We will see that the dependence is more complex for a finite aspect ratio ![]() $L/a$. To obtain insight into this dependence, we require a precise

$L/a$. To obtain insight into this dependence, we require a precise ![]() $X_{\infty }$ beyond orders of magnitude and define

$X_{\infty }$ beyond orders of magnitude and define ![]() $X_{\infty } \equiv a/\ell = (2 \epsilon )^{-1/2}$ as the outer edge of the lubrication region. The arbitrary choice of prefactor in this definition will be absorbed into the contribution of the flow ‘outside’ the lubricated layer and will be later addressed by comparison with direct numerical simulations.

$X_{\infty } \equiv a/\ell = (2 \epsilon )^{-1/2}$ as the outer edge of the lubrication region. The arbitrary choice of prefactor in this definition will be absorbed into the contribution of the flow ‘outside’ the lubricated layer and will be later addressed by comparison with direct numerical simulations.

Including the contribution of the flow outside the lubrication layer, the force and torque on a cylinder undergoing a combination of wall-parallel translation and rotation can be written compactly in terms of a resistance matrix

where

\begin{equation} \mathcal{I}(\epsilon, L/a) = \int_0^{1/\sqrt{2\epsilon}} \left.\frac{4 X H}{3} \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}} \right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X, \end{equation}

\begin{equation} \mathcal{I}(\epsilon, L/a) = \int_0^{1/\sqrt{2\epsilon}} \left.\frac{4 X H}{3} \frac{\partial^{}P_{{\parallel}}}{\partial Y^{}} \right|_{Y ={-}\mathcal{L}/2} \mathrm{d} X, \end{equation}

which depends on both ![]() $\epsilon$ and

$\epsilon$ and ![]() $L/a$ (equivalently

$L/a$ (equivalently ![]() $X_{\infty }$ and

$X_{\infty }$ and ![]() $\mathcal {L}$). The constants

$\mathcal {L}$). The constants ![]() $c^{F \varOmega }$,

$c^{F \varOmega }$, ![]() $c^{F U}$ and

$c^{F U}$ and ![]() $c^{T \varOmega }$ are contributions from the flow outside the lubrication region and depend only on

$c^{T \varOmega }$ are contributions from the flow outside the lubrication region and depend only on ![]() $L/a$ in the limit

$L/a$ in the limit ![]() $\epsilon \to 0$. The cross-coupling terms

$\epsilon \to 0$. The cross-coupling terms ![]() $R^{F\varOmega } = R^{TU}$ are identical due to the symmetry of Stokes flows (Hinch Reference Hinch1972) and are absent for infinite cylinders without end effects (Jeffery Reference Jeffery1922). The other two resistance coefficients

$R^{F\varOmega } = R^{TU}$ are identical due to the symmetry of Stokes flows (Hinch Reference Hinch1972) and are absent for infinite cylinders without end effects (Jeffery Reference Jeffery1922). The other two resistance coefficients ![]() $R^{FU}$ and

$R^{FU}$ and ![]() $R^{T \varOmega }$ involve corrections relative to their infinite-cylinder limits due to end effects. All of the end-effect resistance terms depend on the single integral

$R^{T \varOmega }$ involve corrections relative to their infinite-cylinder limits due to end effects. All of the end-effect resistance terms depend on the single integral ![]() $\mathcal {I}$, which requires the solution to (2.14). Note that (2.17) does not require that the end effects are small corrections, and are therefore applicable to arbitrary

$\mathcal {I}$, which requires the solution to (2.14). Note that (2.17) does not require that the end effects are small corrections, and are therefore applicable to arbitrary ![]() $L/a$.

$L/a$.

We solve the problem (2.14) by replacing the right-hand side with ![]() $\partial p / \partial t$ and use numerical integration until we achieve a steady solution for different values of

$\partial p / \partial t$ and use numerical integration until we achieve a steady solution for different values of ![]() $\mathcal {L}$. We then evaluate (2.18) for different

$\mathcal {L}$. We then evaluate (2.18) for different ![]() $X_{\infty } = (2 \epsilon )^{-1/2}$, ensuring that the solution domain is much wider than

$X_{\infty } = (2 \epsilon )^{-1/2}$, ensuring that the solution domain is much wider than ![]() $X_{\infty }$. This procedure produces numerical estimates for

$X_{\infty }$. This procedure produces numerical estimates for ![]() $\mathcal {I}$ within lubrication theory that depend on both

$\mathcal {I}$ within lubrication theory that depend on both ![]() $\epsilon$ and

$\epsilon$ and ![]() $L/a$. Below, we analyse the solutions of (2.14) asymptotically in the limit of small

$L/a$. Below, we analyse the solutions of (2.14) asymptotically in the limit of small ![]() $\epsilon$, assuming finite

$\epsilon$, assuming finite ![]() $L/a$, and estimate the integral

$L/a$, and estimate the integral ![]() $\mathcal {I}$. We separately analyse two limits

$\mathcal {I}$. We separately analyse two limits ![]() $\mathcal {L} \gg 1$ and

$\mathcal {L} \gg 1$ and ![]() $\mathcal {L} \ll 1$ and then construct an approximation valid for all

$\mathcal {L} \ll 1$ and then construct an approximation valid for all ![]() $\mathcal {L}$.

$\mathcal {L}$.

2.1.2. Rods and thick disks:  $\mathcal {L} \gg 1$

$\mathcal {L} \gg 1$

The limit ![]() $\mathcal {L} \gg 1$, which is equivalent to

$\mathcal {L} \gg 1$, which is equivalent to ![]() $L \gg a (2 \epsilon )^{1/2}$, corresponds both to rods and thick disks. We first consider

$L \gg a (2 \epsilon )^{1/2}$, corresponds both to rods and thick disks. We first consider ![]() $\mathcal {L} \rightarrow \infty$, where the 3-D flow due to one end is isolated from that of the other, and focus on the flow around the end at

$\mathcal {L} \rightarrow \infty$, where the 3-D flow due to one end is isolated from that of the other, and focus on the flow around the end at ![]() $Y = -\mathcal {L}/2$. Observing that the solution depends on

$Y = -\mathcal {L}/2$. Observing that the solution depends on ![]() $X$ only through

$X$ only through ![]() $H(X)$, we change the independent variable from

$H(X)$, we change the independent variable from ![]() $X$ to

$X$ to ![]() $H$. Next, we note that the only length scale in the limit

$H$. Next, we note that the only length scale in the limit ![]() $\mathcal {L} \to \infty$ is

$\mathcal {L} \to \infty$ is ![]() $\ell$, which motivates the similarity variable

$\ell$, which motivates the similarity variable ![]() $\eta = (Y + \mathcal {L}/2)/\sqrt {H}$, which behaves as

$\eta = (Y + \mathcal {L}/2)/\sqrt {H}$, which behaves as ![]() $(Y + \mathcal {L}/2)/X$ for large

$(Y + \mathcal {L}/2)/X$ for large ![]() $X$.

$X$.

We seek a solution of the form ![]() $P_{\parallel } = 2X/H^2 (1 - q(H, \eta ) )$ and recall that

$P_{\parallel } = 2X/H^2 (1 - q(H, \eta ) )$ and recall that ![]() $2X/H^2$ corresponds to the 2-D limit (see (2.12)), so

$2X/H^2$ corresponds to the 2-D limit (see (2.12)), so ![]() $-2X/H^2 q(H,\eta )$ is the contribution from end effects. Substituting this ansatz into (2.6),

$-2X/H^2 q(H,\eta )$ is the contribution from end effects. Substituting this ansatz into (2.6), ![]() $q(H, \eta )$ is found to satisfy

$q(H, \eta )$ is found to satisfy

\begin{align} & 4(H-1)\left(H \frac{\partial^{2}q}{\partial H^{2}}-\eta\frac{\partial}{\partial H}\frac{\partial q}{\partial \eta}\right) + \left(1+\eta^2-\frac{\eta^2}{H}\right)\frac{\partial^{2}q}{\partial \eta^{2}} \nonumber\\ &\quad + 2(H+2)\frac{\partial q}{\partial H} + \left(2-\frac{5}{H}\right)\eta\frac{\partial q}{\partial \eta} - 6q = 0 \end{align}

\begin{align} & 4(H-1)\left(H \frac{\partial^{2}q}{\partial H^{2}}-\eta\frac{\partial}{\partial H}\frac{\partial q}{\partial \eta}\right) + \left(1+\eta^2-\frac{\eta^2}{H}\right)\frac{\partial^{2}q}{\partial \eta^{2}} \nonumber\\ &\quad + 2(H+2)\frac{\partial q}{\partial H} + \left(2-\frac{5}{H}\right)\eta\frac{\partial q}{\partial \eta} - 6q = 0 \end{align}which is an exact transformation of (2.6) and (2.7).

Rather than solve (2.19) exactly, we develop an approximation valid for large ![]() $H$ (equivalently, large

$H$ (equivalently, large ![]() $X$). The structure of the equation and the boundary conditions suggest a power series

$X$). The structure of the equation and the boundary conditions suggest a power series

Inserting this expansion into (2.19) we find at leading order,

which admits the solution

The pressure due to the end at ![]() $Y = -\mathcal {L}/2$ is therefore approximately

$Y = -\mathcal {L}/2$ is therefore approximately

valid for large ![]() $H$ (or large

$H$ (or large ![]() $X$).

$X$).

To construct a solution accounting for both ends for finite ![]() $\mathcal {L} \gg 1$, it is necessary to evaluate the pressure produced by (2.23) at the opposite end

$\mathcal {L} \gg 1$, it is necessary to evaluate the pressure produced by (2.23) at the opposite end ![]() $Y = \mathcal {L}/2$. This can then be corrected to accommodate the zero pressure condition, for example by a series of successive reflections. Relative to the 2-D pressure

$Y = \mathcal {L}/2$. This can then be corrected to accommodate the zero pressure condition, for example by a series of successive reflections. Relative to the 2-D pressure ![]() $2X/H^2$, this pressure perturbation is

$2X/H^2$, this pressure perturbation is ![]() $q_0(\mathcal {L}/\sqrt {H})$, which behaves as

$q_0(\mathcal {L}/\sqrt {H})$, which behaves as

\begin{gather}q_0 \left(\mathcal{L}/\sqrt{H(X)}\right) \sim \left\{\begin{array}{l@{}} \frac{ 8 (1 + X^2)^{3/2}}{15 {\rm \pi}\mathcal{L}^3}, & X \ll \mathcal{L}, \\ 1 + O(\mathcal{L}/X), & X \gg \mathcal{L}, \end{array} \right. \end{gather}

\begin{gather}q_0 \left(\mathcal{L}/\sqrt{H(X)}\right) \sim \left\{\begin{array}{l@{}} \frac{ 8 (1 + X^2)^{3/2}}{15 {\rm \pi}\mathcal{L}^3}, & X \ll \mathcal{L}, \\ 1 + O(\mathcal{L}/X), & X \gg \mathcal{L}, \end{array} \right. \end{gather}

valid for ![]() $\mathcal {L} \gg 1$. Observe that while the similarity solution produces a small

$\mathcal {L} \gg 1$. Observe that while the similarity solution produces a small ![]() $O(\mathcal {L}^{-3}$) error at the opposite end for

$O(\mathcal {L}^{-3}$) error at the opposite end for ![]() $X \lesssim \mathcal {L}$, the error is

$X \lesssim \mathcal {L}$, the error is ![]() $O(1)$ for

$O(1)$ for ![]() $X \gg \mathcal {L}$. Thus, the similarity solution is not uniformly convergent to the exact solution for

$X \gg \mathcal {L}$. Thus, the similarity solution is not uniformly convergent to the exact solution for ![]() $\mathcal {L} \gg 1$ but is rather part of an ‘inner’ solution valid for

$\mathcal {L} \gg 1$ but is rather part of an ‘inner’ solution valid for ![]() $X \lesssim \mathcal {L}$.

$X \lesssim \mathcal {L}$.

From (2.24) we expect that an ‘outer’ solution different to (2.23) must dominate for ![]() $X \gtrsim \mathcal {L} \gg 1$. We identify this outer solution by approximating

$X \gtrsim \mathcal {L} \gg 1$. We identify this outer solution by approximating ![]() $H \sim X^2$ for large

$H \sim X^2$ for large ![]() $X >0$ and seek separable solutions of (2.14) to find

$X >0$ and seek separable solutions of (2.14) to find

$$\begin{gather} p(X \gg \mathcal{L}) \sim \frac{3}{2X^5} \left( \mathcal{L}^2 - 4Y^2\right) + \sum_{n = 1, 3, 5, \ldots} c_n \varphi_n(x)\cos \left(n {\rm \pi}Y/\mathcal{L} \right), \end{gather}$$

$$\begin{gather} p(X \gg \mathcal{L}) \sim \frac{3}{2X^5} \left( \mathcal{L}^2 - 4Y^2\right) + \sum_{n = 1, 3, 5, \ldots} c_n \varphi_n(x)\cos \left(n {\rm \pi}Y/\mathcal{L} \right), \end{gather}$$ The coefficients ![]() $c_n$ are obtained by matching to the inner solution. For long cylinders

$c_n$ are obtained by matching to the inner solution. For long cylinders ![]() $\mathcal {L} \gg 1$, the ‘inner solution’ throughout most of the domain apart from regions close to each end is the 2-D pressure

$\mathcal {L} \gg 1$, the ‘inner solution’ throughout most of the domain apart from regions close to each end is the 2-D pressure ![]() $2X/H^2$, which decays as

$2X/H^2$, which decays as ![]() $X^{-3}$. Thus, the dominant

$X^{-3}$. Thus, the dominant ![]() $X^{-5}$ behaviour of the first term of the outer solution (2.25) must be suppressed for small

$X^{-5}$ behaviour of the first term of the outer solution (2.25) must be suppressed for small ![]() $X/\mathcal {L}$ to match with the inner solution. Projecting the first term in (2.25a) onto a basis of

$X/\mathcal {L}$ to match with the inner solution. Projecting the first term in (2.25a) onto a basis of ![]() $\cos (n {\rm \pi}Y/\mathcal {L})$, this matching condition yields the coefficients

$\cos (n {\rm \pi}Y/\mathcal {L})$, this matching condition yields the coefficients ![]() $c_n = -16 \mathcal {L}^2 \sin (n {\rm \pi}/2)/(n {\rm \pi})^3$.

$c_n = -16 \mathcal {L}^2 \sin (n {\rm \pi}/2)/(n {\rm \pi})^3$.

We now have two approximations for the pressure: (2.23) for ![]() $1 \ll X \lesssim \mathcal {L}$ and (2.25) for

$1 \ll X \lesssim \mathcal {L}$ and (2.25) for ![]() $X \gtrsim \mathcal {L}$, which are smoothly matched around

$X \gtrsim \mathcal {L}$, which are smoothly matched around ![]() $X = O(\mathcal {L})$. The integrand of (2.18) is therefore

$X = O(\mathcal {L})$. The integrand of (2.18) is therefore

\begin{gather}\displaystyle \frac{4}{3} X H \left. \frac{\partial P_{\parallel}}{\partial Y}\right|_{Y=-\mathcal {L}/2} \sim \left\{\begin{array}{l@{}} \frac{64 X^2}{3{\rm \pi}(1 + X^2)^{3/2}}, & X \lesssim \mathcal {L} ,\\ \frac{8\mathcal {L}}{X^2} - \sum_{n = 1,3,5,\ldots} \frac{64 \mathcal {L}}{3 n^2 {\rm \pi}^2} X^3 \varphi_n(X), & X \gtrsim \mathcal {L}. \end{array}\right. \end{gather}

\begin{gather}\displaystyle \frac{4}{3} X H \left. \frac{\partial P_{\parallel}}{\partial Y}\right|_{Y=-\mathcal {L}/2} \sim \left\{\begin{array}{l@{}} \frac{64 X^2}{3{\rm \pi}(1 + X^2)^{3/2}}, & X \lesssim \mathcal {L} ,\\ \frac{8\mathcal {L}}{X^2} - \sum_{n = 1,3,5,\ldots} \frac{64 \mathcal {L}}{3 n^2 {\rm \pi}^2} X^3 \varphi_n(X), & X \gtrsim \mathcal {L}. \end{array}\right. \end{gather}

With this formulation, (2.26b) matches smoothly onto (2.26a) as shown in figure 3. We note that (2.26a) is formally only valid for ![]() $1 \ll X \lesssim \mathcal {L}$ since (2.22) only approximately solves (2.19), although it provides a good approximation to numerical solutions even for

$1 \ll X \lesssim \mathcal {L}$ since (2.22) only approximately solves (2.19), although it provides a good approximation to numerical solutions even for ![]() $X = O(1)$, as seen in figure 3. Comparing the leading terms of the two estimates in (2.26) confirms the crossover at

$X = O(1)$, as seen in figure 3. Comparing the leading terms of the two estimates in (2.26) confirms the crossover at ![]() $X = O(\mathcal {L})$ that we anticipated earlier.

$X = O(\mathcal {L})$ that we anticipated earlier.

Figure 3. (a) Kernel ![]() $\frac {4}{3}X H ({\partial P_\parallel }/{\partial Y})|_{Y = -\mathcal {L}/2}$ of

$\frac {4}{3}X H ({\partial P_\parallel }/{\partial Y})|_{Y = -\mathcal {L}/2}$ of ![]() $\mathcal {I}$ (2.18) for

$\mathcal {I}$ (2.18) for ![]() $\mathcal {L} = 10$, showing the numerical solution of the lubrication problem (solid black curve), the approximate inner solution (2.26a) (dot–dashed red curve) and the outer solution (dashed green curve). Asymptotes of the inner and outer solutions are indicated showing smooth matching between the two at

$\mathcal {L} = 10$, showing the numerical solution of the lubrication problem (solid black curve), the approximate inner solution (2.26a) (dot–dashed red curve) and the outer solution (dashed green curve). Asymptotes of the inner and outer solutions are indicated showing smooth matching between the two at ![]() $X = O(\mathcal {L})$. (b) The integral

$X = O(\mathcal {L})$. (b) The integral ![]() $\mathcal {I}(\epsilon, L/a)$ for different combinations of

$\mathcal {I}(\epsilon, L/a)$ for different combinations of ![]() $\epsilon$ and

$\epsilon$ and ![]() $L/a$ showing numerical results (symbols) and the analytic approximation (2.29).

$L/a$ showing numerical results (symbols) and the analytic approximation (2.29).

Integrating the asymptotic solution (2.26) between ![]() $0 < X < X_{\infty }$ (recall that

$0 < X < X_{\infty }$ (recall that ![]() $X_{\infty } = (2 \epsilon )^{-1/2}$) yields the resistances defined in (2.17). Due to the slow

$X_{\infty } = (2 \epsilon )^{-1/2}$) yields the resistances defined in (2.17). Due to the slow ![]() $X^{-1}$ decay of the inner integrand (2.26a), the integral depends on the relative magnitudes of

$X^{-1}$ decay of the inner integrand (2.26a), the integral depends on the relative magnitudes of ![]() $X_{\infty }$ and

$X_{\infty }$ and ![]() $\mathcal {L}$. For long rods with

$\mathcal {L}$. For long rods with ![]() $a \ll L$ (or

$a \ll L$ (or ![]() $X_{\infty } \ll \mathcal {L}$) only the inner solution is relevant to the integral, so

$X_{\infty } \ll \mathcal {L}$) only the inner solution is relevant to the integral, so ![]() $\mathcal {I}$ scales as

$\mathcal {I}$ scales as ![]() $\log (\epsilon ^{-1})$, as shown in Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). Conversely, for thin disks with

$\log (\epsilon ^{-1})$, as shown in Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). Conversely, for thin disks with ![]() $a \gg L$ (or

$a \gg L$ (or ![]() $X_{\infty } \gg \mathcal {L} \gg 1$), the inner part of the solution is cut off by the crossover at

$X_{\infty } \gg \mathcal {L} \gg 1$), the inner part of the solution is cut off by the crossover at ![]() $X = O(\mathcal {L})$, giving rise to a result that behaves as

$X = O(\mathcal {L})$, giving rise to a result that behaves as ![]() $\log (\mathcal {L})$. For intermediate

$\log (\mathcal {L})$. For intermediate ![]() $a/L$ we integrate (2.26) using standard asymptotic techniques, adding its inner and outer parts and subtracting off the common part

$a/L$ we integrate (2.26) using standard asymptotic techniques, adding its inner and outer parts and subtracting off the common part ![]() $8 \mathcal {L}/X^2$. This result will be presented shortly after a brief discussion of the disk limit.

$8 \mathcal {L}/X^2$. This result will be presented shortly after a brief discussion of the disk limit.

2.1.3. Disks:  $\mathcal {L} \ll 1$

$\mathcal {L} \ll 1$

For very thin disks (![]() $L \ll \ell$ or

$L \ll \ell$ or ![]() $\mathscr {L} \ll 1$), pressure gradients along

$\mathscr {L} \ll 1$), pressure gradients along ![]() $Y$ are more important than those along

$Y$ are more important than those along ![]() $X$. Then (2.6) reduces to

$X$. Then (2.6) reduces to ![]() $H^3\partial _Y^2 P_{\parallel } \approx -6 \partial _X H$, with the boundary conditions (2.7), which yields

$H^3\partial _Y^2 P_{\parallel } \approx -6 \partial _X H$, with the boundary conditions (2.7), which yields

Now, the relevant integral in (2.17) is

\begin{equation} \mathcal{I} = \int_{0}^{1/\sqrt{2\epsilon}} \frac{4}{3} X (1 + X^2) \left.\frac{\partial P_{{\parallel}}}{\partial Y}\right|_{Y={-}\mathscr{L}/2}\mathrm{d}x = 2 {\rm \pi}\mathcal{L} - \frac{8L}{a} \quad (\mathcal{L} \ll 1), \end{equation}

\begin{equation} \mathcal{I} = \int_{0}^{1/\sqrt{2\epsilon}} \frac{4}{3} X (1 + X^2) \left.\frac{\partial P_{{\parallel}}}{\partial Y}\right|_{Y={-}\mathscr{L}/2}\mathrm{d}x = 2 {\rm \pi}\mathcal{L} - \frac{8L}{a} \quad (\mathcal{L} \ll 1), \end{equation}

up to corrections of ![]() $O(\epsilon )$.

$O(\epsilon )$.

Synthesizing the results for large and small ![]() $\mathcal {L}$, we construct a uniform approximation for all

$\mathcal {L}$, we construct a uniform approximation for all ![]() $\mathcal {L}$ in terms of a rapidly converging series

$\mathcal {L}$ in terms of a rapidly converging series

\begin{equation} \mathcal{I}(\epsilon, L/a) \simeq \frac{64}{3{\rm \pi}} \sinh^{{-}1} \left(\frac{L}{a \sqrt{2 \epsilon}} \right) - \frac{8 L}{a} + \sum_{n = 1, 3, 5, \ldots} 64 \,{\rm e}^{{-}n {\rm \pi}a/L} \left(\frac{1}{3 n {\rm \pi}} + \frac{L}{a n^2 {\rm \pi}^2}\right), \end{equation}

\begin{equation} \mathcal{I}(\epsilon, L/a) \simeq \frac{64}{3{\rm \pi}} \sinh^{{-}1} \left(\frac{L}{a \sqrt{2 \epsilon}} \right) - \frac{8 L}{a} + \sum_{n = 1, 3, 5, \ldots} 64 \,{\rm e}^{{-}n {\rm \pi}a/L} \left(\frac{1}{3 n {\rm \pi}} + \frac{L}{a n^2 {\rm \pi}^2}\right), \end{equation}

which is valid for ![]() $\epsilon \ll 1$, and we recall that

$\epsilon \ll 1$, and we recall that ![]() $\mathcal {L} = L/(a \sqrt {2 \epsilon })$. This approximation is obtained from the asymptotic integration of (2.26) at large

$\mathcal {L} = L/(a \sqrt {2 \epsilon })$. This approximation is obtained from the asymptotic integration of (2.26) at large ![]() $\mathcal {L}$, with the modification

$\mathcal {L}$, with the modification ![]() $\log (2\mathcal {L}) \mapsto \log (\mathcal {L} + \sqrt {1 + \mathcal {L}^2}) = \sinh ^{-1} \mathcal {L}$ to accommodate the linear dependence (2.28) for small

$\log (2\mathcal {L}) \mapsto \log (\mathcal {L} + \sqrt {1 + \mathcal {L}^2}) = \sinh ^{-1} \mathcal {L}$ to accommodate the linear dependence (2.28) for small ![]() $\mathcal {L}$. Comparing (2.29) with the numerical solution of the Reynolds equation shows excellent agreement for

$\mathcal {L}$. Comparing (2.29) with the numerical solution of the Reynolds equation shows excellent agreement for ![]() $\epsilon \lesssim 0.02$ (or

$\epsilon \lesssim 0.02$ (or ![]() $X_{\infty } \gtrsim 5$) for all

$X_{\infty } \gtrsim 5$) for all ![]() $L/a$ as shown in figure 3(b). In the limit of long and short cylinders, the approximation of this integral representing the end effects converges to

$L/a$ as shown in figure 3(b). In the limit of long and short cylinders, the approximation of this integral representing the end effects converges to

\begin{gather} \displaystyle \mathcal{I}\sim \left\{\begin{array}{l@{}} \frac{32}{3 {\rm \pi}} \log \frac{8L^2}{a^2 \epsilon}, & \quad a \gg L, \\ \frac{32}{3 {\rm \pi}} \left(\log \frac{{\rm \pi}^2}{2 \epsilon} - 3 \right), & \quad a \ll L. \end{array}\right. \end{gather}

\begin{gather} \displaystyle \mathcal{I}\sim \left\{\begin{array}{l@{}} \frac{32}{3 {\rm \pi}} \log \frac{8L^2}{a^2 \epsilon}, & \quad a \gg L, \\ \frac{32}{3 {\rm \pi}} \left(\log \frac{{\rm \pi}^2}{2 \epsilon} - 3 \right), & \quad a \ll L. \end{array}\right. \end{gather}

Observe that the integral behaves as ![]() $\mathcal {I} \sim 32/(3 {\rm \pi}) \log (1/\epsilon )$ up to additive constants involving

$\mathcal {I} \sim 32/(3 {\rm \pi}) \log (1/\epsilon )$ up to additive constants involving ![]() $L/a$. This logarithmic dependence on

$L/a$. This logarithmic dependence on ![]() $\epsilon$ was identified in Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). While the present theory also quantifies the role of

$\epsilon$ was identified in Saintyves et al. (Reference Saintyves, Rallabandi, Jules, Ault, Salez, Schönecker, Stone and Mahadevan2020). While the present theory also quantifies the role of ![]() $L/a$, the resistances (2.17) involve further additive constants

$L/a$, the resistances (2.17) involve further additive constants ![]() $(c^{F\varOmega },\ c^{FU},\ c^{T \varOmega })$ due to the flow outside the lubrication layer that may also depend on

$(c^{F\varOmega },\ c^{FU},\ c^{T \varOmega })$ due to the flow outside the lubrication layer that may also depend on ![]() $L/a$. Later, we will show that (2.29) captures much of the

$L/a$. Later, we will show that (2.29) captures much of the ![]() $L/a$ dependence of the full numerical simulations for small

$L/a$ dependence of the full numerical simulations for small ![]() $\epsilon$.

$\epsilon$.

2.2. Lubrication theory for motion normal to the wall

When the cylinder translates normal to the wall, there is no torque by symmetry and the hydrodynamic force opposes motion. Now, the pressure in the lubrication region is ![]() $p(x, y) = (\mu V \ell ^2/h_0^3) P_{\perp }(X,Y)$, where

$p(x, y) = (\mu V \ell ^2/h_0^3) P_{\perp }(X,Y)$, where ![]() $P_{\perp }(X,Y)$ satisfies the rescaled version of (2.6) given by

$P_{\perp }(X,Y)$ satisfies the rescaled version of (2.6) given by

Utilizing the reciprocal formulation (2.10) with the 2-D results (2.12) and (2.13a,b), we find the wall-normal force on the finite-length cylinder to be

\begin{equation} F_{{\perp}} ={-}\frac{3 \sqrt{2} {\rm \pi}\mu V L}{\epsilon^{3/2}} \left( 1- \frac{\mathcal{J}(\mathcal{L})}{6 {\rm \pi}\mathcal{L}}\right), \quad \text{where} \quad \mathcal{J}(\mathcal{L}) = \left.\int_{0}^{\infty} 4 H \frac{\mathrm{d}^{}P_{{\perp}}}{\mathrm{d} Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d}X, \end{equation}

\begin{equation} F_{{\perp}} ={-}\frac{3 \sqrt{2} {\rm \pi}\mu V L}{\epsilon^{3/2}} \left( 1- \frac{\mathcal{J}(\mathcal{L})}{6 {\rm \pi}\mathcal{L}}\right), \quad \text{where} \quad \mathcal{J}(\mathcal{L}) = \left.\int_{0}^{\infty} 4 H \frac{\mathrm{d}^{}P_{{\perp}}}{\mathrm{d} Y^{}}\right|_{Y ={-}\mathcal{L}/2} \mathrm{d}X, \end{equation}

where the first term is the 2-D result (Jeffrey & Onishi Reference Jeffrey and Onishi1981) and the second is due to end effects. Here, we have pre-emptively taken the limit ![]() $X_{\infty } \to \infty$ since the integrals will turn out to converge rapidly. Observe that

$X_{\infty } \to \infty$ since the integrals will turn out to converge rapidly. Observe that ![]() $\mathcal {J}$ depends solely on

$\mathcal {J}$ depends solely on ![]() $\mathcal {L} = L/\sqrt {2 a \epsilon }$ for small

$\mathcal {L} = L/\sqrt {2 a \epsilon }$ for small ![]() $\epsilon$, in contrast to

$\epsilon$, in contrast to ![]() $\mathcal {I}$, which depended separately on

$\mathcal {I}$, which depended separately on ![]() $\epsilon$ and

$\epsilon$ and ![]() $L/a$.

$L/a$.

For disks with ![]() $\mathcal {L} \ll 1$, we approximate

$\mathcal {L} \ll 1$, we approximate ![]() $\partial _Y^2 P_{\perp } \gg \partial ^2_X P_{\perp }$ as before and find

$\partial _Y^2 P_{\perp } \gg \partial ^2_X P_{\perp }$ as before and find

For large ![]() $\mathcal {L}$, the same type of solution structure holds as before: an inner (isolated-ends) solution dominates for

$\mathcal {L}$, the same type of solution structure holds as before: an inner (isolated-ends) solution dominates for ![]() $X \ll \mathcal {L}$ and gives way at

$X \ll \mathcal {L}$ and gives way at ![]() $x \gtrsim O(L)$ to a more rapidly decaying outer solution. This time, we find the inner solution itself decays more rapidly than before, such that

$x \gtrsim O(L)$ to a more rapidly decaying outer solution. This time, we find the inner solution itself decays more rapidly than before, such that ![]() $4 H \partial {P_{\perp }}/\partial Y|_{Y = - \mathcal {L}/2} \sim 9 {\rm \pi}X^{-3}$ for

$4 H \partial {P_{\perp }}/\partial Y|_{Y = - \mathcal {L}/2} \sim 9 {\rm \pi}X^{-3}$ for ![]() $1 \ll X \ll \mathcal {L}$. This means that the inner solution dominates the integral

$1 \ll X \ll \mathcal {L}$. This means that the inner solution dominates the integral ![]() $\mathcal {J}$ for large

$\mathcal {J}$ for large ![]() $\mathcal {L}$ and converges to a finite constant, and the outer solution contributes an amount

$\mathcal {L}$ and converges to a finite constant, and the outer solution contributes an amount ![]() $O(\mathcal {L}^{-2})$, which is negligible.

$O(\mathcal {L}^{-2})$, which is negligible.

For arbitrary ![]() $\mathcal {L}$ we calculate

$\mathcal {L}$ we calculate ![]() $\mathcal {J}(\mathcal {L})$ from a numerical solution of (2.31). The result is shown in figure 4, which demonstrates the predicted asymptotic behaviour

$\mathcal {J}(\mathcal {L})$ from a numerical solution of (2.31). The result is shown in figure 4, which demonstrates the predicted asymptotic behaviour ![]() $\mathcal {J} \sim 6 {\rm \pi}\mathcal {L}$ at small

$\mathcal {J} \sim 6 {\rm \pi}\mathcal {L}$ at small ![]() $\mathcal {L}$. From the numerics, we infer

$\mathcal {L}$. From the numerics, we infer ![]() $\mathcal {J}(\mathcal {L} \to \infty ) \approx 24.25$. Later, we will compare the lubrication result (2.32) for the hydrodynamic force for wall-normal translation, as well as the ones for rotation and wall-parallel translation, with direct numerical simulations of the 3-D flow. These simulations are described in the next section.

$\mathcal {J}(\mathcal {L} \to \infty ) \approx 24.25$. Later, we will compare the lubrication result (2.32) for the hydrodynamic force for wall-normal translation, as well as the ones for rotation and wall-parallel translation, with direct numerical simulations of the 3-D flow. These simulations are described in the next section.

Figure 4. Numerical results for ![]() $\mathcal {J}(\mathcal {L})$ from (2.32) predicted by lubrication theory for the problem of motion normal to the wall, showing the analytical result

$\mathcal {J}(\mathcal {L})$ from (2.32) predicted by lubrication theory for the problem of motion normal to the wall, showing the analytical result ![]() $\mathcal {J} \sim 6 {\rm \pi}\mathcal {L}$ for small

$\mathcal {J} \sim 6 {\rm \pi}\mathcal {L}$ for small ![]() $\mathcal {L}$. The horizontal dashed line at

$\mathcal {L}$. The horizontal dashed line at ![]() $\mathcal {J} = 24.25$ is the asymptote at large

$\mathcal {J} = 24.25$ is the asymptote at large ![]() $\mathcal {L}$ inferred from the numerical results.

$\mathcal {L}$ inferred from the numerical results.

3. Simulations

Three-dimensional numerical OpenFOAM simulations were used to solve the zero-Reynolds-number flow fields around finite-length cylindrical rods rotating and translating parallel or perpendicular to a nearby planar boundary. In this section, we describe the numerical methods used and give representative results to illustrate the fluid dynamics in such systems. The computational domain and the mesh design are described in Appendix A.1, and the numerical method and boundary conditions applied are described in Appendix A.2. Simulations were performed for a range of ![]() $\epsilon =h_0/a$ and

$\epsilon =h_0/a$ and ![]() $L/a$ for different translation and rotation cases. A visual representation of the computational results is presented in § 3.1, and a detailed comparison between the theoretical and numerical results is given in § 4.

$L/a$ for different translation and rotation cases. A visual representation of the computational results is presented in § 3.1, and a detailed comparison between the theoretical and numerical results is given in § 4.

Note that in typical related experimental systems, the most common scenario would be the case of an object under the action of an external force such as gravity or an external torque such as an applied magnetic torque. In the case of an external force, the object will naturally translate and rotate such that the object is torque free. Likewise, in the case of an external torque, the object will translate and rotate such that it is force free. In the numerical simulations in this work, we directly impose the motion of the finite-length cylinders, either rotation-free translation or translation-free rotation, and then measure the resultant forces and torques. Thus, we occasionally reference, for example, the torque due to translation or the force due to rotation, though we recognize that in most common scenarios the cylinder will be torque free or force free, depending on the situation.

3.1. Simulation results

In order to motivate and give some physical insights into the fluid dynamics of the present system, we first present results of the numerical simulations that are representative of the flow behaviours that we characterize. First, in figure 5, we give a streamline visualization of the flow patterns seen in each of the three cases: rotation next to the wall (figure 5a); translation parallel to the wall (figure 5b); and translation normal to the wall (figure 5c). Here, the cylinder has an aspect ratio of ![]() $L/a = 10.0$. Streamlines were generated inside the gap, and the figure is visualized from below the cylinder (the perspective is looking through the plane wall at the streamlines inside the gap). As can be seen, the streamlines near the cylinder ends are significantly distorted out of plane, leading to the force and torque deviations from the infinite cylinder calculations. For example, fluid near the ends preferentially tries to go around the cylinder rather than through the gap due to the large pressures there. This effectively reduces the total width of the lubrication layer that resembles the 2-D limit. These 3-D effects in the gap account for the majority of the hydrodynamic torque and force on the parallel translation and rotation cases, respectively, as well as the deviation of the hydrodynamic force on the normal translation case from the2-D result. Thus, the theoretical analysis of the lubrication layer can allow us to predict the rotation speed of a freely translating cylinder near a planar boundary, for example. Note that the flat end surfaces themselves also contribute an additional component to the deviation of the forces and torques on such cylinders, but for small

$L/a = 10.0$. Streamlines were generated inside the gap, and the figure is visualized from below the cylinder (the perspective is looking through the plane wall at the streamlines inside the gap). As can be seen, the streamlines near the cylinder ends are significantly distorted out of plane, leading to the force and torque deviations from the infinite cylinder calculations. For example, fluid near the ends preferentially tries to go around the cylinder rather than through the gap due to the large pressures there. This effectively reduces the total width of the lubrication layer that resembles the 2-D limit. These 3-D effects in the gap account for the majority of the hydrodynamic torque and force on the parallel translation and rotation cases, respectively, as well as the deviation of the hydrodynamic force on the normal translation case from the2-D result. Thus, the theoretical analysis of the lubrication layer can allow us to predict the rotation speed of a freely translating cylinder near a planar boundary, for example. Note that the flat end surfaces themselves also contribute an additional component to the deviation of the forces and torques on such cylinders, but for small ![]() $\epsilon$ the dominant contribution comes from the lubrication layer.

$\epsilon$ the dominant contribution comes from the lubrication layer.

Figure 5. Numerically computed streamlines for the flow driven by a finite-length cylinder (a) rotating, (b) translating parallel to and (c) translating perpendicular, and away from, a nearby plane wall. Here, the cylinder has ![]() $L/a = 10$, and the view is from below the cylinder (i.e. looking through the plane wall at streamlines within in the gap). The arrows represent the direction of the streamlines. Far from the ends of the cylinder, we see the approximate 2-D solution expected for an infinite cylinder. Near the end of the cylinder, there is a visible distortion of the streamlines as the flow in the lubrication layer deviates from the 2-D solution and becomes fully 3-D. This deviation of the flow from the 2-D result in the outer extent of the lubrication region results in the end effects experienced by finite-length cylinders. As

$L/a = 10$, and the view is from below the cylinder (i.e. looking through the plane wall at streamlines within in the gap). The arrows represent the direction of the streamlines. Far from the ends of the cylinder, we see the approximate 2-D solution expected for an infinite cylinder. Near the end of the cylinder, there is a visible distortion of the streamlines as the flow in the lubrication layer deviates from the 2-D solution and becomes fully 3-D. This deviation of the flow from the 2-D result in the outer extent of the lubrication region results in the end effects experienced by finite-length cylinders. As ![]() $\epsilon$ decreases, the extent of this deviation region decreases. Note, for the translation parallel to the wall case, the reference frame when generating the streamlines has been shifted so that the cylinder is stationary.

$\epsilon$ decreases, the extent of this deviation region decreases. Note, for the translation parallel to the wall case, the reference frame when generating the streamlines has been shifted so that the cylinder is stationary.

Next, we show representative velocity and pressure profiles within the gap for each of the three cases. Figure 6 shows the dimensionless velocity and pressure profiles located on the plane midway between the wall and the nearest edge of the cylinder, looking from below the cylinder, for the case of translation parallel to the plane wall. Results are presented for a range of dimensionless gap heights ![]() $\epsilon = h_0/a$. Here, the pressure has been non-dimensionalized by

$\epsilon = h_0/a$. Here, the pressure has been non-dimensionalized by ![]() $\mu \ell U/h_0^2$. As the gap height decreases, the lubrication layer becomes narrower, since the characteristic width of this layer is

$\mu \ell U/h_0^2$. As the gap height decreases, the lubrication layer becomes narrower, since the characteristic width of this layer is ![]() $\ell = \sqrt {2ah_0}$. One of the key things to learn from this visualization is the distribution of

$\ell = \sqrt {2ah_0}$. One of the key things to learn from this visualization is the distribution of ![]() $u_y$ near the cylinder ends. Due to the large pressures needed to drive the flow through the lubrication layer, near the ends we see that the flow preferentially is directed around the cylinder, as opposed to through the gap. As mentioned, this leads to an effective shortening of the 2-D portion of the lubrication layer as the region near the ends becomes 3-D, and these 3-D regions are largely responsible for the deviations from the 2-D infinite cylinder predictions as described in the lubrication theory developed in § 2.

$u_y$ near the cylinder ends. Due to the large pressures needed to drive the flow through the lubrication layer, near the ends we see that the flow preferentially is directed around the cylinder, as opposed to through the gap. As mentioned, this leads to an effective shortening of the 2-D portion of the lubrication layer as the region near the ends becomes 3-D, and these 3-D regions are largely responsible for the deviations from the 2-D infinite cylinder predictions as described in the lubrication theory developed in § 2.

Figure 6. Dimensionless velocities and pressures inside the gap for the case of a finite-length cylinder (aspect ratio ![]() $L/a = 10$) translating parallel to the wall. Results are plotted on a slice parallel to the plane boundary through the midpoint of the gap for different dimensionless gap heights

$L/a = 10$) translating parallel to the wall. Results are plotted on a slice parallel to the plane boundary through the midpoint of the gap for different dimensionless gap heights ![]() $\epsilon = h_0/a$. The upper panel (a) illustrates the perspective that is used to generate these panels and those of the following two figures as well, while (b–e) show the non-dimensional velocity and pressure components.

$\epsilon = h_0/a$. The upper panel (a) illustrates the perspective that is used to generate these panels and those of the following two figures as well, while (b–e) show the non-dimensional velocity and pressure components.

Figure 7 shows similar results for the case of a rotating cylinder, and figure 8 shows the results for the case of a cylinder translating normal to the plane wall. Qualitatively, the results for the rotation case are quite similar to the case of translation parallel to the wall except for the velocity component in the ![]() $x$-direction. In the rotation case, the maximum

$x$-direction. In the rotation case, the maximum ![]() $u_x$ is aligned with the cylinder axis in the figure view, whereas the maximum

$u_x$ is aligned with the cylinder axis in the figure view, whereas the maximum ![]() $u_x$ is located at an offset from the cylinder axis for the case of translation parallel to the wall. The case of wall-normal translation shows slightly different behaviour in figure 8. Here, the

$u_x$ is located at an offset from the cylinder axis for the case of translation parallel to the wall. The case of wall-normal translation shows slightly different behaviour in figure 8. Here, the ![]() $u_x$ and

$u_x$ and ![]() $u_y$ profiles generally show the expected behaviour, which is that the fluid is pulled into the lubrication layer along the length of the cylinder and at the ends (note that the figure uses

$u_y$ profiles generally show the expected behaviour, which is that the fluid is pulled into the lubrication layer along the length of the cylinder and at the ends (note that the figure uses ![]() $V > 0$, i.e. translation away from the plane wall). Furthermore, the

$V > 0$, i.e. translation away from the plane wall). Furthermore, the ![]() $u_z$ panel shows that the direction of flow directly under the cylinder is in the direction of the cylinder motion, as expected. Finally the

$u_z$ panel shows that the direction of flow directly under the cylinder is in the direction of the cylinder motion, as expected. Finally the ![]() $p$ panel shows that a strong pressure is developed throughout the entire lubrication layer attempting to restrict the motion of the cylinder.

$p$ panel shows that a strong pressure is developed throughout the entire lubrication layer attempting to restrict the motion of the cylinder.

Figure 7. Dimensionless velocities and pressures inside the gap for the case of a finite-length cylinder (aspect ratio ![]() $L/a = 10$) rotating near a plane wall. Results are plotted on a slice parallel to the plane boundary through the midpoint of the gap for different dimensionless gap heights

$L/a = 10$) rotating near a plane wall. Results are plotted on a slice parallel to the plane boundary through the midpoint of the gap for different dimensionless gap heights ![]() $\epsilon = h_0/a$.