1. Introduction

Natural convective flows take place when density differences within a fluid domain drive the fluid motion. Natural convection is the dominant heat and mass transport mechanism for many flows of practical interest, both in nature (Cardin & Olson Reference Cardin and Olson1994; Marshall & Schott Reference Marshall and Schott1999; Hartmann, Moy & Fu Reference Hartmann, Moy and Fu2001) and in industrial applications (Krepper, Hicken & Jaegers Reference Krepper, Hicken and Jaegers2002; Bejan Reference Bejan2013). One of the particularly relevant ones in geophysics is the case of convection in porous media (De Paoli Reference De Paoli2023), in which the fluid occupies the interstitial space of a solid porous matrix. This configuration is typical of subsurface transport phenomena, and is relevant for petroleum migration (Simmons, Fenstemaker & Sharp Reference Simmons, Fenstemaker and Sharp2001), water contamination (LeBlanc Reference LeBlanc1984; Van Der Molen & Van Ommen Reference Van Der Molen and Van Ommen1988), underground hydrogen storage (Zivar, Kumar & Foroozesh Reference Zivar, Kumar and Foroozesh2021; Krevor et al. Reference Krevor, de Coninck, Gasda, Ghaleigh, de Gooyert, Hajibeygi, Juanes, Neufeld, Roberts and Swennenhuis2023), superficial formations in dry salty lakes (Lasser, Ernst & Goehring Reference Lasser, Ernst and Goehring2021; Lasser et al. Reference Lasser, Nield, Ernst, Karius, Wiggs, Threadgold, Beaume and Goehring2023) and sea ice growth (Wettlaufer, Worster & Huppert Reference Wettlaufer, Worster and Huppert1997; Feltham et al. Reference Feltham, Untersteiner, Wettlaufer and Worster2006; Middleton et al. Reference Middleton, Thomas, de Wit and Tison2016), to name a few.

Recently, this problem has been the subject of extended investigations due to the implications it can bear for geological carbon sequestration (Huppert & Neufeld Reference Huppert and Neufeld2014; Emami-Meybodi et al. Reference Emami-Meybodi, Hassanzadeh, Green and Ennis-King2015). In this process, carbon dioxide (CO![]() $_{2}$) is injected into underground formations located 1–3 km beneath the Earth's surface, with the aim of permanent storage. After injection, carbon dioxide remains in a supercritical state due to the high pressure at the injections depths, but its density is lower compared with that of the resident fluid (brine), and the injected volume of carbon dioxide migrates on top of the brine layer (MacMinn et al. Reference MacMinn, Neufeld, Hesse and Huppert2012). This situation is undesired, because it may cause a further migration of carbon dioxide to the upper layers, eventually leading to a return of CO

$_{2}$) is injected into underground formations located 1–3 km beneath the Earth's surface, with the aim of permanent storage. After injection, carbon dioxide remains in a supercritical state due to the high pressure at the injections depths, but its density is lower compared with that of the resident fluid (brine), and the injected volume of carbon dioxide migrates on top of the brine layer (MacMinn et al. Reference MacMinn, Neufeld, Hesse and Huppert2012). This situation is undesired, because it may cause a further migration of carbon dioxide to the upper layers, eventually leading to a return of CO![]() $_{2}$ into the atmosphere. However, carbon dioxide is partially soluble in brine, and when these fluids mix a heavier solution (CO

$_{2}$ into the atmosphere. However, carbon dioxide is partially soluble in brine, and when these fluids mix a heavier solution (CO![]() $_{2}$ + brine) forms. When a sufficiently thick layer of this denser mixture builds up, it may become unstable and form convective instabilities (De Paoli Reference De Paoli2021). These flow structures have a favourable effect on the efficiency of the CO

$_{2}$ + brine) forms. When a sufficiently thick layer of this denser mixture builds up, it may become unstable and form convective instabilities (De Paoli Reference De Paoli2021). These flow structures have a favourable effect on the efficiency of the CO![]() $_{2}$ dissolution mechanism, since they contribute to fluid mixing (i.e. CO

$_{2}$ dissolution mechanism, since they contribute to fluid mixing (i.e. CO![]() $_{2}$ permanently stored in brine) in a much more effective manner compared with pure diffusion (Ennis-King, Preston & Paterson Reference Ennis-King, Preston and Paterson2005; Xu, Chen & Zhang Reference Xu, Chen and Zhang2006). On the other hand, the process is made complex by the presence of these nonlinear instabilities, and making reliable predictions of the dissolution dynamics is a non-trivial task.

$_{2}$ permanently stored in brine) in a much more effective manner compared with pure diffusion (Ennis-King, Preston & Paterson Reference Ennis-King, Preston and Paterson2005; Xu, Chen & Zhang Reference Xu, Chen and Zhang2006). On the other hand, the process is made complex by the presence of these nonlinear instabilities, and making reliable predictions of the dissolution dynamics is a non-trivial task.

The dissolution of CO![]() $_{2}$ in brine is a problem characterised by an integral length scale corresponding to the height of the reservoir, which may be of the order of tens or hundreds of meters in geological formations of practical interest (Huppert & Neufeld Reference Huppert and Neufeld2014). Therefore, resolving all the flow scales, from the pores to the reservoir scale, is not an option with the present computational and experimental capabilities. A possible approach commonly employed to revolve the large scales of the flow consists of analysing the flow at the Darcy scale, i.e. the flow is not resolved within the pores, but the quantities of interest (pressure, velocity, concentration and temperature) are obtained as the average over a representative volume containing many pores (Nield & Bejan Reference Nield and Bejan2017). The majority of the works on convective flows in porous media currently available in the literature refer to this case.

$_{2}$ in brine is a problem characterised by an integral length scale corresponding to the height of the reservoir, which may be of the order of tens or hundreds of meters in geological formations of practical interest (Huppert & Neufeld Reference Huppert and Neufeld2014). Therefore, resolving all the flow scales, from the pores to the reservoir scale, is not an option with the present computational and experimental capabilities. A possible approach commonly employed to revolve the large scales of the flow consists of analysing the flow at the Darcy scale, i.e. the flow is not resolved within the pores, but the quantities of interest (pressure, velocity, concentration and temperature) are obtained as the average over a representative volume containing many pores (Nield & Bejan Reference Nield and Bejan2017). The majority of the works on convective flows in porous media currently available in the literature refer to this case.

The mixing process of CO![]() $_{2}$ and brine is idealised considering an homogeneous porous slab with a constant concentration difference applied at the horizontal boundaries (Rayleigh–Bénard), or as a semi-infinite (one-sided) domain where the concentration is fixed at top and no flux is applied at bottom boundary (Hewitt Reference Hewitt2020). In the Rayleigh–Bénard–Darcy case, the system attains a statistically steady state, which has been predicted theoretically (Horton & Rogers Reference Horton and Rogers1945; Lapwood Reference Lapwood1948) and recently accurately described numerically in two (Hewitt, Neufeld & Lister Reference Hewitt, Neufeld and Lister2012; De Paoli, Zonta & Soldati Reference De Paoli, Zonta and Soldati2016; Wen et al. Reference Wen, Akhbari, Zhang and Hesse2018; Ulloa & Letelier Reference Ulloa and Letelier2022) and three dimensions (Hewitt, Neufeld & Lister Reference Hewitt, Neufeld and Lister2014; De Paoli et al. Reference De Paoli, Pirozzoli, Zonta and Soldati2022a; Dhar et al. Reference Dhar, Meunier, Nadal and Méheust2022), also at high Rayleigh–Darcy numbers,

$_{2}$ and brine is idealised considering an homogeneous porous slab with a constant concentration difference applied at the horizontal boundaries (Rayleigh–Bénard), or as a semi-infinite (one-sided) domain where the concentration is fixed at top and no flux is applied at bottom boundary (Hewitt Reference Hewitt2020). In the Rayleigh–Bénard–Darcy case, the system attains a statistically steady state, which has been predicted theoretically (Horton & Rogers Reference Horton and Rogers1945; Lapwood Reference Lapwood1948) and recently accurately described numerically in two (Hewitt, Neufeld & Lister Reference Hewitt, Neufeld and Lister2012; De Paoli, Zonta & Soldati Reference De Paoli, Zonta and Soldati2016; Wen et al. Reference Wen, Akhbari, Zhang and Hesse2018; Ulloa & Letelier Reference Ulloa and Letelier2022) and three dimensions (Hewitt, Neufeld & Lister Reference Hewitt, Neufeld and Lister2014; De Paoli et al. Reference De Paoli, Pirozzoli, Zonta and Soldati2022a; Dhar et al. Reference Dhar, Meunier, Nadal and Méheust2022), also at high Rayleigh–Darcy numbers, ![]() $\operatorname {\mathit {Ra}}^*$ (the Rayleigh–Darcy number indicates the relative importance of convective and diffusive contributions in a flow through a porous medium). The one-sided-Darcy configuration is characterised by a transient behaviour (Riaz et al. Reference Riaz, Hesse, Tchelepi and Orr2006; Fu, Cueto-Felgueroso & Juanes Reference Fu, Cueto-Felgueroso and Juanes2013) consisting of three main phases: (i) an initial diffusive regime in which the mixing layer grows and becomes eventually unstable (De Paoli, Zonta & Soldati Reference De Paoli, Zonta and Soldati2017), (ii) a convective phase characterised by a constant dissolution rate (Hidalgo et al. Reference Hidalgo, Fe, Cueto-Felgueroso and Juanes2012) and (iii) a finite-size regime when the strength of convection reduces gradually (Slim et al. Reference Slim, Bandi, Miller and Mahadevan2013).

$\operatorname {\mathit {Ra}}^*$ (the Rayleigh–Darcy number indicates the relative importance of convective and diffusive contributions in a flow through a porous medium). The one-sided-Darcy configuration is characterised by a transient behaviour (Riaz et al. Reference Riaz, Hesse, Tchelepi and Orr2006; Fu, Cueto-Felgueroso & Juanes Reference Fu, Cueto-Felgueroso and Juanes2013) consisting of three main phases: (i) an initial diffusive regime in which the mixing layer grows and becomes eventually unstable (De Paoli, Zonta & Soldati Reference De Paoli, Zonta and Soldati2017), (ii) a convective phase characterised by a constant dissolution rate (Hidalgo et al. Reference Hidalgo, Fe, Cueto-Felgueroso and Juanes2012) and (iii) a finite-size regime when the strength of convection reduces gradually (Slim et al. Reference Slim, Bandi, Miller and Mahadevan2013).

The Rayleigh–Bénard–Darcy and the one-sided-Darcy systems have been well characterised numerically and theoretically in case of thermal convection at the Darcy scale, i.e. when the flow structures are large compared with the scale of the pores (Hewitt Reference Hewitt2020). Numerical results suggest that a linear relationship exists between the dimensionless mass transfer coefficient (Sherwood number, ![]() $\operatorname {\mathit {Sh}}$) and the Rayleigh–Darcy number (

$\operatorname {\mathit {Sh}}$) and the Rayleigh–Darcy number (![]() $\operatorname {\mathit {Ra}}^*$), in both the Rayleigh–Bénard–Darcy case (Hewitt et al. Reference Hewitt, Neufeld and Lister2012; Pirozzoli et al. Reference Pirozzoli, De Paoli, Zonta and Soldati2021) and during the convective regime of the one-sided-Darcy system (Slim Reference Slim2014; De Paoli et al. Reference De Paoli, Zonta and Soldati2017). Experimental measurements in these configurations (Neufeld et al. Reference Neufeld, Hesse, Riaz, Hallworth, Tchelepi and Huppert2010; Backhaus, Turitsyn & Ecke Reference Backhaus, Turitsyn and Ecke2011; De Paoli, Alipour & Soldati Reference De Paoli, Alipour and Soldati2020; Brouzet, Méheust & Meunier Reference Brouzet, Méheust and Meunier2022), however, suggest a different qualitative and also quantitative behaviour compared with the corresponding Darcy simulations, with a nonlinear scaling of

$\operatorname {\mathit {Ra}}^*$), in both the Rayleigh–Bénard–Darcy case (Hewitt et al. Reference Hewitt, Neufeld and Lister2012; Pirozzoli et al. Reference Pirozzoli, De Paoli, Zonta and Soldati2021) and during the convective regime of the one-sided-Darcy system (Slim Reference Slim2014; De Paoli et al. Reference De Paoli, Zonta and Soldati2017). Experimental measurements in these configurations (Neufeld et al. Reference Neufeld, Hesse, Riaz, Hallworth, Tchelepi and Huppert2010; Backhaus, Turitsyn & Ecke Reference Backhaus, Turitsyn and Ecke2011; De Paoli, Alipour & Soldati Reference De Paoli, Alipour and Soldati2020; Brouzet, Méheust & Meunier Reference Brouzet, Méheust and Meunier2022), however, suggest a different qualitative and also quantitative behaviour compared with the corresponding Darcy simulations, with a nonlinear scaling of ![]() $\operatorname {\mathit {Sh}}$ with

$\operatorname {\mathit {Sh}}$ with ![]() $\operatorname {\mathit {Ra}}^*$. This discrepancy is likely due to non-Darcy effects (Liang et al. Reference Liang, Wen, Hesse and DiCarlo2018), i.e. to the pore-induced flow dynamics not captured by Darcy simulations. Therefore, resolving the flow and the solute transport at the pore scale is crucial to make reliable models to incorporate in large-scale simulations and to predict the underground fluids migration and mixing, and it represents the main motivation for this work.

$\operatorname {\mathit {Ra}}^*$. This discrepancy is likely due to non-Darcy effects (Liang et al. Reference Liang, Wen, Hesse and DiCarlo2018), i.e. to the pore-induced flow dynamics not captured by Darcy simulations. Therefore, resolving the flow and the solute transport at the pore scale is crucial to make reliable models to incorporate in large-scale simulations and to predict the underground fluids migration and mixing, and it represents the main motivation for this work.

When a fluid flows through a matrix of solid obstacles, the fluid follows a random-walk-type path (Woods Reference Woods2015). If the fluid is carrying a solute, in addition to molecular diffusion, solute spreading may occur due to pore-scale change of flow direction (mechanical dispersion), heterogeneities in the aquifer (large-scale dispersion) or other mechanisms, such as dead-end pores (anomalous dispersion). In this work, we only refer to mechanical dispersion, i.e. we assume that the medium is homogeneous and without dead-end spaces. On the one hand, mechanical dispersion produces additional spreading of solute and can be several orders of magnitude more effective than molecular diffusion (Delgado Reference Delgado2007). It has been also observed (Eckel et al. Reference Eckel, Liyanage, Kurotori and Pini2022) that the presence of the finger pattern and the counter-current flow structure enhance the longitudinal spreading of the solute compared with unidirectional dispersion of a single-solute plume. This additional spreading is responsible for the reduction of the local density gradients, diminishing the strength of convective motions and coupling convection and diffusion as mechanisms controlling the mixing process. To quantify the relative importance of pore structure, material properties and driving force on the overall heat or mass transport process, pore-resolved convective flows have been recently employed in the framework of thermal Rayleigh–Bénard convection, in both experiments and simulations. Chakkingal et al. (Reference Chakkingal, Kenjereš, Ataei-Dadavi, Tummers and Kleijn2019) observe that the flow structure and the heat transfer coefficient are determined by the relative size of thermal length scale (boundary layer thickness) and porous length scale (average pore space). These properties determine the penetration of the plumes in the boundary layer region, which is responsible for the heat or mass transfer rate. In a complementary work, Ataei-Dadavi et al. (Reference Ataei-Dadavi, Rounaghi, Chakkingal, Kenjeres, Kleijn and Tummers2019) observed that while at low Rayleigh numbers the transport mechanism is less efficient than in free-fluid Rayleigh–Bénard convection, at larger Rayleigh numbers the classical ![]() $\operatorname {\mathit {Nu}}$ vs

$\operatorname {\mathit {Nu}}$ vs ![]() $\operatorname {\mathit {Ra}}$ scaling (Grossmann & Lohse Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001) is recovered. The nature of this transition has been investigated by Liu et al. (Reference Liu, Jiang, Chong, Zhu, Wan, Verzicco, Stevens, Lohse and Sun2020). They used two-dimensional direct numerical simulations to examine in detail the microscale flow field through a bead pack. They observed that the transition between these two regimes is controlled by two physical mechanisms induced by the porous matrix: (i) the presence of obstacles makes the flow more coherent, with the correlation between temperature fluctuation and vertical velocity enhanced and the counter-gradient convective heat transfer suppressed, leading to heat transfer enhancement; and (ii) the convection strength is reduced due the impedance of the obstacle array, corresponding to heat transfer reduction. They observed that the scaling crossover occurs when the thickness of the thermal boundary layer is comparable to the averaged pore length scale. In addition to the porous structure and the Rayleigh number, in case of thermal convection, the boundary layer thickness and the heat transfer coefficient are determined also by the value of thermal conductivity of the solid and liquid phases (Korba & Li Reference Korba and Li2022; Zhong, Liu & Sun Reference Zhong, Liu and Sun2023).

$\operatorname {\mathit {Ra}}$ scaling (Grossmann & Lohse Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001) is recovered. The nature of this transition has been investigated by Liu et al. (Reference Liu, Jiang, Chong, Zhu, Wan, Verzicco, Stevens, Lohse and Sun2020). They used two-dimensional direct numerical simulations to examine in detail the microscale flow field through a bead pack. They observed that the transition between these two regimes is controlled by two physical mechanisms induced by the porous matrix: (i) the presence of obstacles makes the flow more coherent, with the correlation between temperature fluctuation and vertical velocity enhanced and the counter-gradient convective heat transfer suppressed, leading to heat transfer enhancement; and (ii) the convection strength is reduced due the impedance of the obstacle array, corresponding to heat transfer reduction. They observed that the scaling crossover occurs when the thickness of the thermal boundary layer is comparable to the averaged pore length scale. In addition to the porous structure and the Rayleigh number, in case of thermal convection, the boundary layer thickness and the heat transfer coefficient are determined also by the value of thermal conductivity of the solid and liquid phases (Korba & Li Reference Korba and Li2022; Zhong, Liu & Sun Reference Zhong, Liu and Sun2023).

The discussed findings refer to systems in which the medium is permeable to the scalar (heat or solute) transported. In the frame of solute dispersion, two major differences arise compared to thermal convection, namely the solid is usually impenetrable (over the flow time scales) to the solute, and the ratio between momentum and solute diffusivity (Schmidt number, ![]() $\operatorname {\mathit {Sc}}$) is typically about two orders of magnitude larger than the ratio between momentum and heat diffusivity (Prandtl number,

$\operatorname {\mathit {Sc}}$) is typically about two orders of magnitude larger than the ratio between momentum and heat diffusivity (Prandtl number, ![]() $\operatorname {\mathit {Pr}}$). Gasow et al. (Reference Gasow, Lin, Zhang, Kuznetsov, Avila and Jin2020, Reference Gasow, Kuznetsov, Avila and Jin2021) focused on solute convection investigating solute transport at the pore scale in Rayleigh–Bénard configuration, with the aim of deriving corrections to be included in Darcy models to account for the obstacle-induced solute dispersion. They observed that the pore-induced dispersion, which may be as strong as buoyancy, also affects the momentum transport and it is determined by two length scales (the pore length scale and the domain height). Moreover, the dissolution coefficient (

$\operatorname {\mathit {Pr}}$). Gasow et al. (Reference Gasow, Lin, Zhang, Kuznetsov, Avila and Jin2020, Reference Gasow, Kuznetsov, Avila and Jin2021) focused on solute convection investigating solute transport at the pore scale in Rayleigh–Bénard configuration, with the aim of deriving corrections to be included in Darcy models to account for the obstacle-induced solute dispersion. They observed that the pore-induced dispersion, which may be as strong as buoyancy, also affects the momentum transport and it is determined by two length scales (the pore length scale and the domain height). Moreover, the dissolution coefficient (![]() $\operatorname {\mathit {Sh}}$) is observed to depend also on the Schmidt number (Gasow, Kuznetsov & Jin Reference Gasow, Kuznetsov and Jin2022), in addition to the Rayleigh number and the pore structure (Liu et al. Reference Liu, Jiang, Chong, Zhu, Wan, Verzicco, Stevens, Lohse and Sun2020). These numerical studies, which represent a fundamental step to make large-scale predictions of dissolution in porous media, are still computationally limited to two dimensions, moderate Rayleigh numbers and large porosity values. In comparison, experiments can achieve larger Rayleigh numbers and values of porosity that are more representative of geological formations. In contrast, in the instance of solutal convection, the Rayleigh–Bénard and the semi-infinite configurations are hard to tackle experimentally because of the limitations associated with keeping the solute concentration constant at the boundaries. The porous Rayleigh–Taylor instability, relatively less studied compared with the corresponding Rayleigh–Bénard and one-sided configurations, is an excellent candidate to overcome this obstacle, and it is the object of this work.

$\operatorname {\mathit {Sh}}$) is observed to depend also on the Schmidt number (Gasow, Kuznetsov & Jin Reference Gasow, Kuznetsov and Jin2022), in addition to the Rayleigh number and the pore structure (Liu et al. Reference Liu, Jiang, Chong, Zhu, Wan, Verzicco, Stevens, Lohse and Sun2020). These numerical studies, which represent a fundamental step to make large-scale predictions of dissolution in porous media, are still computationally limited to two dimensions, moderate Rayleigh numbers and large porosity values. In comparison, experiments can achieve larger Rayleigh numbers and values of porosity that are more representative of geological formations. In contrast, in the instance of solutal convection, the Rayleigh–Bénard and the semi-infinite configurations are hard to tackle experimentally because of the limitations associated with keeping the solute concentration constant at the boundaries. The porous Rayleigh–Taylor instability, relatively less studied compared with the corresponding Rayleigh–Bénard and one-sided configurations, is an excellent candidate to overcome this obstacle, and it is the object of this work.

A porous Rayleigh–Taylor system consists of two miscible fluids of different density initially arranged in an unstable configuration and immersed in a porous matrix. After an initial diffusive phase (Wang et al. Reference Wang, Nakanishi, Hyodo and Suekane2016, Reference Wang, Nakanishi, Teston and Suekane2018), the flow is driven by convection, and due to the transient nature of this system, the mixing rate of the two fluids varies in time. In geophysical applications, it is crucial to determine the mixing rate of the involved fluids, to be able to make reliable predictions on the evolution of the volume of subsurface flow. The porous Rayleigh–Taylor system has been studied at the Darcy scale with the aid of Hele-Shaw cells and Darcy simulations (De Wit Reference De Wit2020). The flow behaviour is quantified by the mixing length, i.e. the vertical extension of the mixing region. The growth rate of the mixing length is controlled by the combined action of buoyancy (density difference) and drag (viscous dissipation through the medium) (Boffetta & Musacchio Reference Boffetta and Musacchio2022; De Paoli et al. Reference De Paoli, Perissutti, Marchioli and Soldati2022b). In the case of miscible fluids, the role of diffusion across the fluid–fluid interface is also crucial (Gopalakrishnan et al. Reference Gopalakrishnan, Carballido-Landeira, De Wit and Knaepen2017), as it weakens convection by reducing local density gradients.

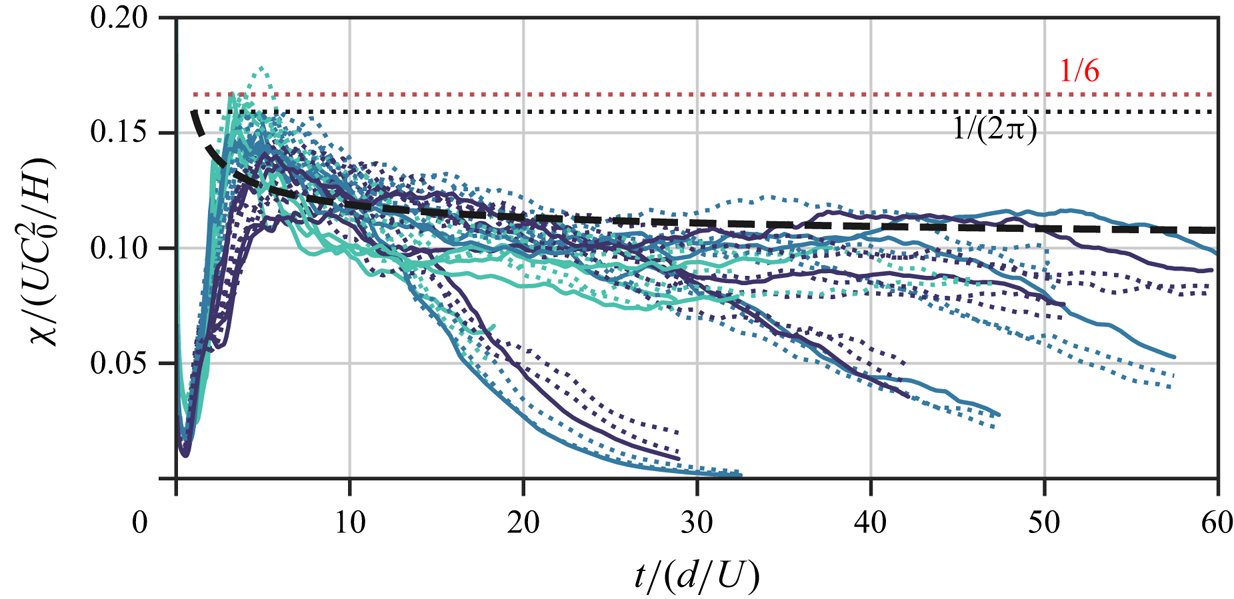

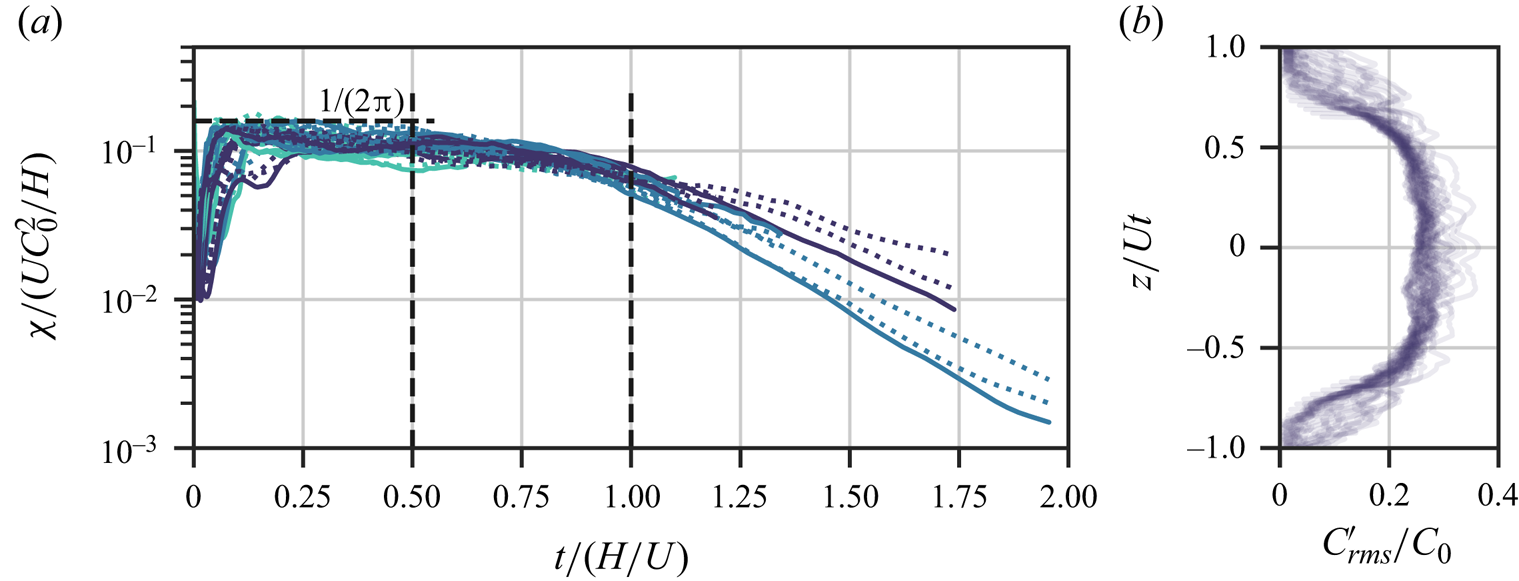

As a result of this time-dependent finger growth process, the mixing dynamics is also transient, and it may be quantified via the mean scalar dissipation rate (Hidalgo et al. Reference Hidalgo, Fe, Cueto-Felgueroso and Juanes2012). The mean scalar dissipation is particularly convenient because it can be exactly related to other flow quantities, e.g. the averaged concentration fluctuations, and it has been already described numerically at the Darcy scale (De Paoli et al. Reference De Paoli, Giurgiu, Zonta and Soldati2019a; De Paoli Reference De Paoli2023). However, in the Rayleigh–Taylor case, the behaviour of dispersion cannot be captured by Darcy simulations despite its crucial role, as it can influence dramatically the onset of the gravitational instabilities (Menand & Woods Reference Menand and Woods2005) and the mixing dynamics. In this flow configuration, the full flow dynamics has been studied with the aid of three-dimensional simulations by Sardina et al. (Reference Sardina, Brandt, Boffetta and Mazzino2018), where the authors consider a thermal convection at relatively large values of porosity (![]() $0.6\unicode{x2013}1$). They proposed a model to incorporate the effect of the medium within a friction coefficient to be included in the Navier–Stokes equations. The case of solutal convection in geological formations may be markedly different, since the porosity is low (0.2–0.4) and the Schmidt numbers about two orders of magnitude larger than in the thermal case, and we aim precisely at this gap.

$0.6\unicode{x2013}1$). They proposed a model to incorporate the effect of the medium within a friction coefficient to be included in the Navier–Stokes equations. The case of solutal convection in geological formations may be markedly different, since the porosity is low (0.2–0.4) and the Schmidt numbers about two orders of magnitude larger than in the thermal case, and we aim precisely at this gap.

We investigate a Rayleigh–Taylor instability in a saturated, homogeneous and isotropic porous medium. We present the results from Hele-Shaw type experiments with bead packs and two-dimensional numerical simulations, where we resolve the flow at the pore scale at high Rayleigh–Darcy numbers, high Schmidt numbers and low values of porosity. Experiments and simulations are specifically designed to reproduce the same fluid and medium properties, namely linear density–concentration dependency, matching porosities and porous medium impermeable to the transported scalar (solutal convection). In the experiments, porous media and fluid properties are varied, and different flow regimes are observed, namely a Darcy-type flow (with the flow structures larger than the pore length scale) and a diffusion–dispersion regime, with the strength of mechanical dispersion being equivalent or dominant with respect to molecular diffusion. Simulations are first validated against the experimental measurements in terms of evolution of the mixing length, and then used to quantify the evolution of the mixing rate, measured by the mean scalar dissipation. Several dissolution regimes have been identified. Initially, the flow is controlled by diffusion. This regime is followed by a convection-dominated phase. The average concentration profiles follow a self-similar behaviour, which we describe theoretically throughout the flow dynamics. In the final regime finite-size effects reduce the solute transport. Our experimental and numerical results are used to explain the evolution of the flow with the aid of physically grounded models.

Our findings are relevant to the convection of miscible fluids in porous media. However, we note that some differences occur when CO![]() $_2$ sequestration is considered, including the non-monotonic relationship between the fluid density and the solute concentration (Hidalgo et al. Reference Hidalgo, Dentz, Cabeza and Carrera2015), and the partial miscibility of the phases involved (Huppert & Neufeld Reference Huppert and Neufeld2014). These effects, as well as additional limitations (dimensionality of the systems and idealised structure of the media) later discussed in detail, prevent a direct application of the present findings to CO

$_2$ sequestration is considered, including the non-monotonic relationship between the fluid density and the solute concentration (Hidalgo et al. Reference Hidalgo, Dentz, Cabeza and Carrera2015), and the partial miscibility of the phases involved (Huppert & Neufeld Reference Huppert and Neufeld2014). These effects, as well as additional limitations (dimensionality of the systems and idealised structure of the media) later discussed in detail, prevent a direct application of the present findings to CO![]() $_2$ dissolution in geological formations. Nonetheless, these results represent a fundamental ingredient required to build a modelling framework for large-scale simulations, as they are obtained in a well-defined and controlled physical system.

$_2$ dissolution in geological formations. Nonetheless, these results represent a fundamental ingredient required to build a modelling framework for large-scale simulations, as they are obtained in a well-defined and controlled physical system.

The paper is organised as follows. In § 2 the problem is formulated. We describe the experimental and the numerical set-ups in § 3. We present our results in terms of qualitative flow dynamics (§ 4), mixing length and concentration profiles (§ 5), flow structure and wavenumber (§ 6). In § 7 we quantify the dissolution rate, which we describe by physical models in each of the regimes identified. Finally, in § 8 we summarise our findings and provide a brief perspective on future research directions.

2. Problem formulation

The process of convective dissolution is studied here in the frame of the Rayleigh–Taylor instability. It can be modelled as two layers of miscible fluids having different density, initially separated by a flat interface and located in an accelerated reference frame (Boffetta & Mazzino Reference Boffetta and Mazzino2017). The process is simulated in the context of porous media flows, mimicked with the aid of a porous layer (height ![]() $H$, width

$H$, width ![]() $L$) made of spheres (diameter

$L$) made of spheres (diameter ![]() $d$). The fluids fully saturate the medium, have the same viscosity (

$d$). The fluids fully saturate the medium, have the same viscosity (![]() $\mu$) but different density and are arranged in an unstable configuration, with the heavy fluid (density

$\mu$) but different density and are arranged in an unstable configuration, with the heavy fluid (density ![]() $\rho _0$) lying on top of the lighter fluid (density

$\rho _0$) lying on top of the lighter fluid (density ![]() $\rho _w$). Therefore, the maximum density difference within the system is

$\rho _w$). Therefore, the maximum density difference within the system is ![]() $\Delta \rho =\rho _0-\rho _w$. The system, consisting of a porous slab saturated with two fluids in an accelerated field (gravity acceleration,

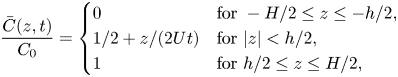

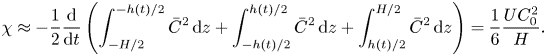

$\Delta \rho =\rho _0-\rho _w$. The system, consisting of a porous slab saturated with two fluids in an accelerated field (gravity acceleration, ![]() $g$), is sketched in figure 1(a). The density difference is induced by the presence of a solute, which is quantified by the solute concentration

$g$), is sketched in figure 1(a). The density difference is induced by the presence of a solute, which is quantified by the solute concentration ![]() $C$, taking its maximum at the upper layer (

$C$, taking its maximum at the upper layer (![]() $C=C_0$) and minimum at the lower layer (

$C=C_0$) and minimum at the lower layer (![]() $C=0$). The reference frame (

$C=0$). The reference frame (![]() $x,z$) is defined as in figure 1(a) such that it is centred at the mid height of the domain and

$x,z$) is defined as in figure 1(a) such that it is centred at the mid height of the domain and ![]() $z$ is aligned with

$z$ is aligned with ![]() $g$ but in opposite direction. We aim at mimicking a system with horizontal boundaries (

$g$ but in opposite direction. We aim at mimicking a system with horizontal boundaries (![]() $z=\pm H/2$) that are impermeable to both fluid and solute, and we consider

$z=\pm H/2$) that are impermeable to both fluid and solute, and we consider

with ![]() $\boldsymbol {n}$ the unit vector perpendicular to the boundary.

$\boldsymbol {n}$ the unit vector perpendicular to the boundary.

Figure 1. Sketch illustrating the system considered. (a) Domain with explicit indication of the boundary conditions (no flux of mass or solute through the horizontal walls) and domain dimensions in horizontal (![]() $L$) and vertical (

$L$) and vertical (![]() $H$) directions. The reference frame (

$H$) directions. The reference frame (![]() $x,z$) as well as the initial position of the interface (red dashed line) are indicated, with the heavy fluid (density

$x,z$) as well as the initial position of the interface (red dashed line) are indicated, with the heavy fluid (density ![]() $\rho _0$, concentration

$\rho _0$, concentration ![]() $C=C_0$) initially lying on top of the lighter fluid (

$C=C_0$) initially lying on top of the lighter fluid (![]() $\rho _w$,

$\rho _w$, ![]() $C=0$). (b) In the experiments, a transparent medium consisting of monodisperse beads and fluids of different colours are used. (c) In the simulations, the geometry consists of an array of spheres (diameter

$C=0$). (b) In the experiments, a transparent medium consisting of monodisperse beads and fluids of different colours are used. (c) In the simulations, the geometry consists of an array of spheres (diameter ![]() $d$) fully saturated with fluid. The fluid carrying the solute moves thought the spheres.

$d$) fully saturated with fluid. The fluid carrying the solute moves thought the spheres.

In the present flow configuration, the dimensionless parameters controlling the system can be grouped into three main categories: medium parameters (Darcy number, porosity), fluid parameters (Schmidt number) and flow parameters (Rayleigh, Rayleigh–Darcy, Péclet and Reynolds numbers).

We consider a simplified configuration in which the medium is homogeneous and isotropic. Assuming the structure obtained from the sphere packing as an isotropic and homogeneous medium, it can be fully described by two global quantities, namely porosity and permeability. The porosity, ![]() $\phi$, represents the ratio between the volume of fluid and the total volume (fluid and solid) of the domain considered, and therefore it varies between

$\phi$, represents the ratio between the volume of fluid and the total volume (fluid and solid) of the domain considered, and therefore it varies between ![]() $\phi =0$ (pure solid) and

$\phi =0$ (pure solid) and ![]() $\phi =1$ (pure fluid). The permeability,

$\phi =1$ (pure fluid). The permeability, ![]() $k$, quantifies the ability of the porous matrix to allow a fluid to flow through it. For a given geometry of the medium, the Darcy number

$k$, quantifies the ability of the porous matrix to allow a fluid to flow through it. For a given geometry of the medium, the Darcy number

quantifies the relative dimension of the microscopic pore scale (![]() $\sqrt {k}$) and the macroscopic length scale (

$\sqrt {k}$) and the macroscopic length scale (![]() $H$) (Hewitt Reference Hewitt2020).

$H$) (Hewitt Reference Hewitt2020).

The dimensionless parameter that quantifies the fluid properties is the Schmidt number, which is the ratio of momentum diffusivity (kinematic viscosity, ![]() $\mu /\rho _o$) to mass diffusivity

$\mu /\rho _o$) to mass diffusivity ![]() $D$,

$D$,

The dimensionless flow parameters and the relevant flow scales are obtained by combining domain, medium and fluid properties. A possible velocity scale of the flow is the buoyancy velocity

which is obtained at the equilibrium between driving forces (![]() $gk\Delta \rho$) and viscous dissipation through the medium (

$gk\Delta \rho$) and viscous dissipation through the medium (![]() $\mu$).

$\mu$).

Multiple length scales are effective in this problem. One can consider as a reference length scale the distance ![]() $\ell$ over which advection and diffusion balance (Slim Reference Slim2014)

$\ell$ over which advection and diffusion balance (Slim Reference Slim2014)

Possible alternatives include the characteristic bead size (sphere diameter, ![]() $d$) or the domain height (

$d$) or the domain height (![]() $H$). We show that each of these scales is relevant in different phases of the dissolution process. Solutal convection in pure fluids is characterised by the competing effect of convection (solute-induced density differences) and dissipation or diffusion, respectively. The relative importance of these contributions is measured by the concentration Rayleigh number based on the domain size (

$H$). We show that each of these scales is relevant in different phases of the dissolution process. Solutal convection in pure fluids is characterised by the competing effect of convection (solute-induced density differences) and dissipation or diffusion, respectively. The relative importance of these contributions is measured by the concentration Rayleigh number based on the domain size (![]() $\operatorname {\mathit {Ra}}$) or on the diameter of the spheres (

$\operatorname {\mathit {Ra}}$) or on the diameter of the spheres (![]() $\operatorname {\mathit {Ra}}_d$),

$\operatorname {\mathit {Ra}}_d$),

respectively. These parameters include convection and dissipation, but do not consider the presence of the medium, which has a stabilising effect on convection due to the additional friction on the surface of the pores. The ratio of the strength of these contributions is estimated by the Rayleigh–Darcy number

We remark that the concentration Rayleigh number (2.6a,b) and the Rayleigh–Darcy number (2.7) are linked to the porous medium properties via the Darcy number (2.2) and the porosity. Finally, two more flow parameters are used to determine whether the flow can be modelled as a Darcy flow or not. Following Hewitt (Reference Hewitt2020), the flow can be considered as a Darcy-type flow, if the length scale of the flow structures is much larger than the representative volume over which the quantities are averaged. It is obtained for (i) viscous forces dominating over inertia at the pore scale and (ii) length scale of the convective flow large compared with the pore size. These conditions are fulfilled if

with ![]() $Re$ and

$Re$ and ![]() $\operatorname {\mathit {Pe}}$ the pore-scale Reynolds number and the Péclet number, respectively. In this study, only a few experiments (and no simulations) fall in the Darcy case, and the relative flow dynamics is discussed later in § 4. Note that in this definition of

$\operatorname {\mathit {Pe}}$ the pore-scale Reynolds number and the Péclet number, respectively. In this study, only a few experiments (and no simulations) fall in the Darcy case, and the relative flow dynamics is discussed later in § 4. Note that in this definition of ![]() $\operatorname {\mathit {Pe}}$ it is assumed that the pore-scale length used as a length scale for

$\operatorname {\mathit {Pe}}$ it is assumed that the pore-scale length used as a length scale for ![]() $\operatorname {\mathit {Pe}}$ is

$\operatorname {\mathit {Pe}}$ is ![]() $\sqrt {k}$. An alternative choice consists of using

$\sqrt {k}$. An alternative choice consists of using ![]() $d$, which would produce larger values of

$d$, which would produce larger values of ![]() $\operatorname {\mathit {Pe}}$ (by a factor of approximately 7.5 in this configuration).

$\operatorname {\mathit {Pe}}$ (by a factor of approximately 7.5 in this configuration).

The flow scales of the experiments are listed in table 1, whereas the dimensionless parameters corresponding to present experiments and simulations are reported in table 2.

Table 1. Dimensional parameters of the performed experiments. The domain size is constant (![]() $L=H=200$ mm,

$L=H=200$ mm, ![]() $B=28.5$ mm). Fluid temperature (

$B=28.5$ mm). Fluid temperature (![]() $\vartheta$), solute mass fraction (

$\vartheta$), solute mass fraction (![]() $\omega _M$) and density contrast (

$\omega _M$) and density contrast (![]() $\Delta \rho$) are reported. Fluid viscosity and diffusivity are

$\Delta \rho$) are reported. Fluid viscosity and diffusivity are ![]() $\mu =9.2\times 10^{-4}\ {\rm Pa}\ {\rm s}^{-1}$ and

$\mu =9.2\times 10^{-4}\ {\rm Pa}\ {\rm s}^{-1}$ and ![]() $D=1.65\times 10^{-9}\ {\rm m}^2\ {\rm s}^{-1}$, respectively. Water density is assumed to be

$D=1.65\times 10^{-9}\ {\rm m}^2\ {\rm s}^{-1}$, respectively. Water density is assumed to be ![]() $\rho _0=10^3\ {\rm kg}\ {\rm m}^{-3}$. Bead diameter (

$\rho _0=10^3\ {\rm kg}\ {\rm m}^{-3}$. Bead diameter (![]() $d$), medium porosity (

$d$), medium porosity (![]() $\phi$) and permeability (

$\phi$) and permeability (![]() $k$) are indicated. Flow length scale

$k$) are indicated. Flow length scale ![]() $\ell$ and velocity scale

$\ell$ and velocity scale ![]() $U$, defined as in (2.5) and (2.4), respectively, are also reported.

$U$, defined as in (2.5) and (2.4), respectively, are also reported.

Table 2. Dimensionless parameters of the performed experiments (E#) and the simulations (S#). The domain aspect ratio of the experiments and the simulations is 1 and ![]() $\sqrt {3}$, respectively.

$\sqrt {3}$, respectively.

3. Methodology

We investigate convective mixing in confined porous media. The flow driving force consists of the density differences induced by the presence of a solute. We consider two miscible fluids characterised by a linear dependency of density with concentration. The fluids are immersed in a fully saturated, homogeneous and isotropic porous medium. Laboratory experiments and numerical simulations are used to investigate the problem. In § 3.1 we present the experimental set-up, consisting of a bead pack and an optical measurement system. Pore-resolved two-dimensional simulations, where circular impermeable obstacles are employed to mimic the solid matrix of the porous medium, are discussed in § 3.2.

3.1. Laboratory experiments

The laboratory experiments are performed with the aid of a thick Hele-Shaw cell filled with monodisperse beads and saturated with two fluids of different densities in an unstable configuration. The parameters that can be varied are the density difference ![]() $\Delta \rho$ between the fluids, and the diameter

$\Delta \rho$ between the fluids, and the diameter ![]() $d$ of the beads. Combining these parameters one can determine the flow reference scales, namely

$d$ of the beads. Combining these parameters one can determine the flow reference scales, namely ![]() $\ell$ and

$\ell$ and ![]() $U$. The experiments performed are listed in table 1.

$U$. The experiments performed are listed in table 1.

In the following, we discuss the experimental set-up, the measurement procedure, the fluid properties and the porous medium properties. The employed Hele-Shaw cell used is sketched in figure 2(a). It consists of a hexagonal container with uniform thickness. The shape is designed to simplify the fluid extraction/injection phases. The hexagonal walls (made of PMMA layers, thickness 8 mm) are transparent to allow optical access to the flow, and are kept in place by a thick frame (25 mm) and bolts. A gasket (2 mm thick) is placed between the frame and the walls to prevent fluid leakage. The cell is initially filled with monodisperse glass spheres, then it is vibrated to consolidate the medium, and finally the two fluids of different density are injected via the upper and lower valves. Note that a gate (thickness 1 mm, material polyethylene terephthalate, PET), as indicated in the side view in figure 2b), initially divides the upper and the lower sides of the cells to prevent fluids from mixing. A 1-mm-high housing, equipped with a rubber seal all along its length, is obtained on the front wall, and the gate fits in. The gate can slide through an opening located on the back side of the cell, which has additional seals held in place by a plastic frame.

Figure 2. (a) Schematic representation of the Hele-Shaw cell. The cell is filled with beads and different fluids from the upper and lower valves. The gate keeps the fluids initially separated. The reference frame of the lab (![]() $x,y,z$) is shown. The area of the gate (highlighted in green) and the measurement region (highlighted in red) are discussed in detail in the panels (b) and (c). (b) Side view of the gate mechanism. The gate is removed and the fluids can mix. A system of seals is used to prevent mixing of the fluids before the gate is open. After the gate is extracted, the cell is rotated about the

$x,y,z$) is shown. The area of the gate (highlighted in green) and the measurement region (highlighted in red) are discussed in detail in the panels (b) and (c). (b) Side view of the gate mechanism. The gate is removed and the fluids can mix. A system of seals is used to prevent mixing of the fluids before the gate is open. After the gate is extracted, the cell is rotated about the ![]() $x$-axis (i.e. upside down) as indicated by the red arrow. (c) Front view of the measurement region. After the cell is rotated, the fluids are in an unstable configuration (heavy solution on top of the lighter fluid) and the recording starts.

$x$-axis (i.e. upside down) as indicated by the red arrow. (c) Front view of the measurement region. After the cell is rotated, the fluids are in an unstable configuration (heavy solution on top of the lighter fluid) and the recording starts.

When the medium is consolidated and the fluids are injected, the cell is placed in a stable configuration (with light fluid on top of the heavy one). The gate is later removed and the cell rotates about the ![]() $x$-axis (red arrow in figure 2b) to turn in the initial unstable condition (heavy fluid on top of the light one) chosen to initialise the experiment. The measurements are performed only in the central portion of the domain, indicated in red in figure 2(a) and discussed in figure 2(c), which has size

$x$-axis (red arrow in figure 2b) to turn in the initial unstable condition (heavy fluid on top of the light one) chosen to initialise the experiment. The measurements are performed only in the central portion of the domain, indicated in red in figure 2(a) and discussed in figure 2(c), which has size ![]() $H\times L \times B=200\times 200\times 28.5$ mm

$H\times L \times B=200\times 200\times 28.5$ mm![]() $^3$. The cell is illuminated on one side by a LED light (Phlox LEDW-BL

$^3$. The cell is illuminated on one side by a LED light (Phlox LEDW-BL ![]() $300\times 300$ mm

$300\times 300$ mm![]() $^{2}$) and on the opposite side a high-resolution camera (Nikon D850 with lenses AF Nikkor, 50 mm, 1 : 1.8D) records the evolution of the flow at an acquisition rate that varies between 0.05 and 2 frames per second.

$^{2}$) and on the opposite side a high-resolution camera (Nikon D850 with lenses AF Nikkor, 50 mm, 1 : 1.8D) records the evolution of the flow at an acquisition rate that varies between 0.05 and 2 frames per second.

To allow here a reliable comparison of experimental results against the direct numerical simulations, the fluids employed in the experiments have been specifically selected because of the linear dependency of the density of the solution with respect to the solute concentration (Slim et al. Reference Slim, Bandi, Miller and Mahadevan2013; De Paoli et al. Reference De Paoli, Perissutti, Marchioli and Soldati2022b). This condition is indeed met not only in the simulations presented here, but also in most of the numerical works available in the literature.

The employed fluids are water and an aqueous solution of KMnO![]() $_4$ (Potassium Permanganate, Thermo Scientific, ACS reagent). We consider that the dynamic viscosity,

$_4$ (Potassium Permanganate, Thermo Scientific, ACS reagent). We consider that the dynamic viscosity, ![]() $\mu =9.2\times 10^{-4}\ {\rm Pa}\ {\rm s}$, is constant and independent of the solute concentration (Slim et al. Reference Slim, Bandi, Miller and Mahadevan2013). Similarly, we assume that the diffusion coefficient is not sensibly affected by solute concentration, and corresponds to

$\mu =9.2\times 10^{-4}\ {\rm Pa}\ {\rm s}$, is constant and independent of the solute concentration (Slim et al. Reference Slim, Bandi, Miller and Mahadevan2013). Similarly, we assume that the diffusion coefficient is not sensibly affected by solute concentration, and corresponds to ![]() $D=1.65\times 10^{-9}\ {\rm m}^{2}\ {\rm s}^{-1}$. While water density (

$D=1.65\times 10^{-9}\ {\rm m}^{2}\ {\rm s}^{-1}$. While water density (![]() $\rho _w$) is nearly constant among the experiments (it is only dependent on temperature,

$\rho _w$) is nearly constant among the experiments (it is only dependent on temperature, ![]() $\vartheta$), the density of the aqueous solution of KMnO

$\vartheta$), the density of the aqueous solution of KMnO![]() $_4$ can be varied by changing the solute concentration in the aqueous solution,

$_4$ can be varied by changing the solute concentration in the aqueous solution, ![]() $C$, which is used to control the density difference between the heavy and the light fluid. The mass fraction of the solution is defined as

$C$, which is used to control the density difference between the heavy and the light fluid. The mass fraction of the solution is defined as

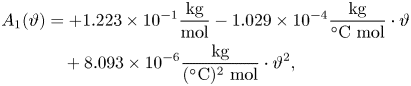

The respective dependency of density, mass fraction and concentration can easily be determined. The density of the mixture, ![]() $\rho (C)$, can be well approximated by a linear function of the solute concentration, i.e. it meets the desired condition:

$\rho (C)$, can be well approximated by a linear function of the solute concentration, i.e. it meets the desired condition:

The concentration–density profiles as well as additional details are reported in Appendix A.1.

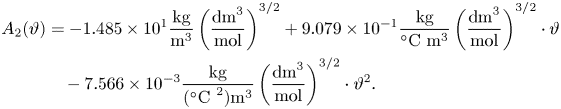

With the aim of mimicking a homogeneous and isotropic porous medium, we fill the cell with monodisperse spheres having diameter ![]() $d$, with

$d$, with ![]() $1~{\rm mm} \le d \le 4$ mm. Provided that the spheres are monodisperse, the diameter of the beads and the porosity of the medium are the two parameters that determine the medium property, i.e. the permeability. In the following, we discuss bead size, medium porosity and permeability. Again, a summary of all the experimental parameters considered is reported in table 1.

$1~{\rm mm} \le d \le 4$ mm. Provided that the spheres are monodisperse, the diameter of the beads and the porosity of the medium are the two parameters that determine the medium property, i.e. the permeability. In the following, we discuss bead size, medium porosity and permeability. Again, a summary of all the experimental parameters considered is reported in table 1.

The porosity of the medium indicates the ratio between the volume of fluid used to fill the cell and the total cell volume (fluid and beads). We measure the porosity by comparing the volume of water required to fill the cell with and without the beads. The preparation of the medium is crucial in determining the cell porosity and permeability. In this work, the cell is vibrated before injecting the fluid so that the medium consolidates. Following this procedure, the beads form a close random packing and the expected value of porosity in case of monodisperse spheres is ![]() $\phi = 0.359\unicode{x2013}0.375$ (Haughey & Beveridge Reference Haughey and Beveridge1969; Dullien Reference Dullien1991). The values of porosity measured experimentally are

$\phi = 0.359\unicode{x2013}0.375$ (Haughey & Beveridge Reference Haughey and Beveridge1969; Dullien Reference Dullien1991). The values of porosity measured experimentally are ![]() $\phi =0.37$ for all nominal diameters considered, except

$\phi =0.37$ for all nominal diameters considered, except ![]() $d=3.00$ mm, in which the value of porosity measured is slightly lower (

$d=3.00$ mm, in which the value of porosity measured is slightly lower (![]() $\phi =0.35$). This difference can be possibly attributed to the lower quality of the beads with

$\phi =0.35$). This difference can be possibly attributed to the lower quality of the beads with ![]() $d=3.00$ mm, which have a wide distribution of diameters (see Appendix A.2). Indeed, the more dispersed the diameters, the lower the value of porosity that can be achieved.

$d=3.00$ mm, which have a wide distribution of diameters (see Appendix A.2). Indeed, the more dispersed the diameters, the lower the value of porosity that can be achieved.

The permeability is inferred from the Kozeny–Carman correlation, i.e.

where ![]() $k_C$ is the Carman constant. This phenomenological correlation is obtained for creeping flow, and it is found to be independent of the particle shape (Dullien Reference Dullien1991) (for non-spherical particles,

$k_C$ is the Carman constant. This phenomenological correlation is obtained for creeping flow, and it is found to be independent of the particle shape (Dullien Reference Dullien1991) (for non-spherical particles, ![]() $d$ is the equivalent diameter). The Carman constant originally proposed within the Kozeny–Carman formulation (monodisperse spheres) is

$d$ is the equivalent diameter). The Carman constant originally proposed within the Kozeny–Carman formulation (monodisperse spheres) is ![]() $k_C = 4.8\pm 0.3$, usually approximated to 5, which gives

$k_C = 4.8\pm 0.3$, usually approximated to 5, which gives ![]() $36k_C=180$. At a later time, Ergun proposed the Blake–Kozeny formulation, in which the coefficient is

$36k_C=180$. At a later time, Ergun proposed the Blake–Kozeny formulation, in which the coefficient is ![]() $36k_C=150$. Both formulations are based on fitting of experimental data for flow through granular beds. Other formulations have been proposed to improve the predictions at low or high values of porosity, as well as to include the effect of the Reynolds number. A detailed review on the possible values of

$36k_C=150$. Both formulations are based on fitting of experimental data for flow through granular beds. Other formulations have been proposed to improve the predictions at low or high values of porosity, as well as to include the effect of the Reynolds number. A detailed review on the possible values of ![]() $k_C$ is provided by Xu & Yu (Reference Xu and Yu2008), where a more general phenomenological formulation is also proposed. For the specific case of monodisperse spheres packed randomly, Zaman & Jalali (Reference Zaman and Jalali2010) have shown that the Kozeny–Carman formulation (3.3) with

$k_C$ is provided by Xu & Yu (Reference Xu and Yu2008), where a more general phenomenological formulation is also proposed. For the specific case of monodisperse spheres packed randomly, Zaman & Jalali (Reference Zaman and Jalali2010) have shown that the Kozeny–Carman formulation (3.3) with ![]() $k_C=5$ provides good results, and this is the correlation we employ.

$k_C=5$ provides good results, and this is the correlation we employ.

The flow is recorded by the camera. The raw images of the measurement region are analysed to quantify the flow evolution. An example is shown in figure 3, where an instantaneous intensity field obtained from experiment E12 is discussed. The measurement region (see figure 2c) consists of the central squared portion of the cell, having size ![]() $H\times H = (200\ {\rm mm})^{2}$. The denser solution, initially on top, is much darker than the lighter one (transparent). The thickness of the cell is large, and the light intensity detected at the upper layer is weakly evolving during the experiment. Therefore, for better accuracy and due to symmetry of the system, we consider only the lower portion of the cell for the experimental measurements (

$H\times H = (200\ {\rm mm})^{2}$. The denser solution, initially on top, is much darker than the lighter one (transparent). The thickness of the cell is large, and the light intensity detected at the upper layer is weakly evolving during the experiment. Therefore, for better accuracy and due to symmetry of the system, we consider only the lower portion of the cell for the experimental measurements (![]() $z/H\le 0$).

$z/H\le 0$).

Figure 3. Processing of images. (a) Normalised intensity profile ![]() $I_1$, defined in (3.4), shown over the entire measurement region for the experiment E12. The initial position of the interface (

$I_1$, defined in (3.4), shown over the entire measurement region for the experiment E12. The initial position of the interface (![]() $z/H=0$, red solid line) is reported. The instantaneous position of the interface, defined as an isocontour of

$z/H=0$, red solid line) is reported. The instantaneous position of the interface, defined as an isocontour of ![]() $I_{1}$, is also shown (blue line). (b) Corrected intensity profile

$I_{1}$, is also shown (blue line). (b) Corrected intensity profile ![]() $I_2$, defined as in (3.5). The corrected intensity

$I_2$, defined as in (3.5). The corrected intensity ![]() $I_{2}$ is lower than 1 within the mixing region. (c) Horizontally averaged intensity profiles. The lower edge of the mixing region, determined by the position where

$I_{2}$ is lower than 1 within the mixing region. (c) Horizontally averaged intensity profiles. The lower edge of the mixing region, determined by the position where ![]() $\bar {I}_{2}$ is lower than a given threshold value, is reported (dashed red line). This is related to the mixing length

$\bar {I}_{2}$ is lower than a given threshold value, is reported (dashed red line). This is related to the mixing length ![]() $h$, discussed in detail in § 5. See also supplementary movie 1 available at https://doi.org/10.1017/jfm.2024.328.

$h$, discussed in detail in § 5. See also supplementary movie 1 available at https://doi.org/10.1017/jfm.2024.328.

The preprocessed fields are analysed to produce intensity profiles and infer the time-dependent evolution of the interface. The preprocessing consists of several steps, illustrated in figure 3. The initial light intensity distribution ![]() $I(x,z,t=0)$, obtained from the raw images, is used to compute and store the initial mean light intensity values of the high (

$I(x,z,t=0)$, obtained from the raw images, is used to compute and store the initial mean light intensity values of the high (![]() $I_H$,

$I_H$, ![]() $z/H>0$) and low (

$z/H>0$) and low (![]() $I_L$,

$I_L$, ![]() $z/H<0$) fluid density layers. The normalised light intensity field

$z/H<0$) fluid density layers. The normalised light intensity field

is suitable to visualise the instantaneous flow configuration. It is used, for instance, to identify the instantaneous position of the interface of the mixing region (figure 3a). However, we observe in figure 3(c) that the horizontally averaged intensity profile ![]() $\bar {I}_1$ varies smoothly within the mixing region, and therefore it is not a good indicator to determine the edge of the interface. We introduce the corrected intensity (figure 3b),

$\bar {I}_1$ varies smoothly within the mixing region, and therefore it is not a good indicator to determine the edge of the interface. We introduce the corrected intensity (figure 3b), ![]() $I_2$, defined as

$I_2$, defined as

with ![]() $\hat {I}_1(x,z,0)$ the initial intensity field

$\hat {I}_1(x,z,0)$ the initial intensity field ![]() $I_1(x,z,t=0)$ computed with a moving average (squared window of size 10 pixels). We observe that

$I_1(x,z,t=0)$ computed with a moving average (squared window of size 10 pixels). We observe that ![]() $I_{2}$ is lower than 1 only within the mixing region and this property, which is also clear from the horizontally averaged profiles in figure 3(c), makes

$I_{2}$ is lower than 1 only within the mixing region and this property, which is also clear from the horizontally averaged profiles in figure 3(c), makes ![]() $I_2$ a more reliable observable to quantify the extension of the mixing region (red dashed line).

$I_2$ a more reliable observable to quantify the extension of the mixing region (red dashed line).

3.2. Numerical simulations

In the numerical part of this study, we solve the Navier–Stokes equations for momentum, subject to the Oberbeck–Boussinesq approximation. This means that variations in the density are only significant in the buoyancy term. We assume the flow to be incompressible and impose ![]() $\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {u} = 0$ on the velocity field

$\boldsymbol {\nabla } \boldsymbol {\cdot } \boldsymbol {u} = 0$ on the velocity field ![]() $\boldsymbol {u}$. We consider variations in density to be linearly related to the concentration field

$\boldsymbol {u}$. We consider variations in density to be linearly related to the concentration field ![]() $C$, which itself satisfies an advection–diffusion equation. We therefore consider the following governing equations

$C$, which itself satisfies an advection–diffusion equation. We therefore consider the following governing equations

where ![]() $\rho _0$ is a reference density,

$\rho _0$ is a reference density, ![]() $\nu =\mu /\rho _0$ is the kinematic viscosity,

$\nu =\mu /\rho _0$ is the kinematic viscosity, ![]() $D$ the solutal diffusivity,

$D$ the solutal diffusivity, ![]() $g$ gravitational acceleration and

$g$ gravitational acceleration and ![]() $\beta$ the solutal contraction coefficient describing the linear relationship between density and concentration. The pressure

$\beta$ the solutal contraction coefficient describing the linear relationship between density and concentration. The pressure ![]() $p$ satisfies a Poisson equation such that a divergence-free velocity field is ensured.

$p$ satisfies a Poisson equation such that a divergence-free velocity field is ensured.

We solve (3.6) and (3.7) in a two-dimensional domain of height ![]() $H$ and of width

$H$ and of width ![]() $\sqrt {3}H$. Periodic boundary conditions are imposed in the horizontal (

$\sqrt {3}H$. Periodic boundary conditions are imposed in the horizontal (![]() $x$) direction for all flow variables. At the top and bottom walls (

$x$) direction for all flow variables. At the top and bottom walls (![]() $z=\pm H/2$), we impose the boundary conditions (2.1a,b), i.e. zero mass flux of solute (

$z=\pm H/2$), we impose the boundary conditions (2.1a,b), i.e. zero mass flux of solute (![]() $\partial _z C = 0$) and no penetration (

$\partial _z C = 0$) and no penetration (![]() $w=0$, where

$w=0$, where ![]() $w$ is the vertical velocity). In addition, since the pore-scale flow is resolved, the no-slip condition applies along these walls (

$w$ is the vertical velocity). In addition, since the pore-scale flow is resolved, the no-slip condition applies along these walls (![]() $\boldsymbol {u}=\boldsymbol {0}$). In the following subsections, we describe the properties of the solid porous matrix that occupies a portion of the simulation domain, as well as details of the numerical implementation for the flow solver and the conditions at the liquid–solid boundaries.

$\boldsymbol {u}=\boldsymbol {0}$). In the following subsections, we describe the properties of the solid porous matrix that occupies a portion of the simulation domain, as well as details of the numerical implementation for the flow solver and the conditions at the liquid–solid boundaries.

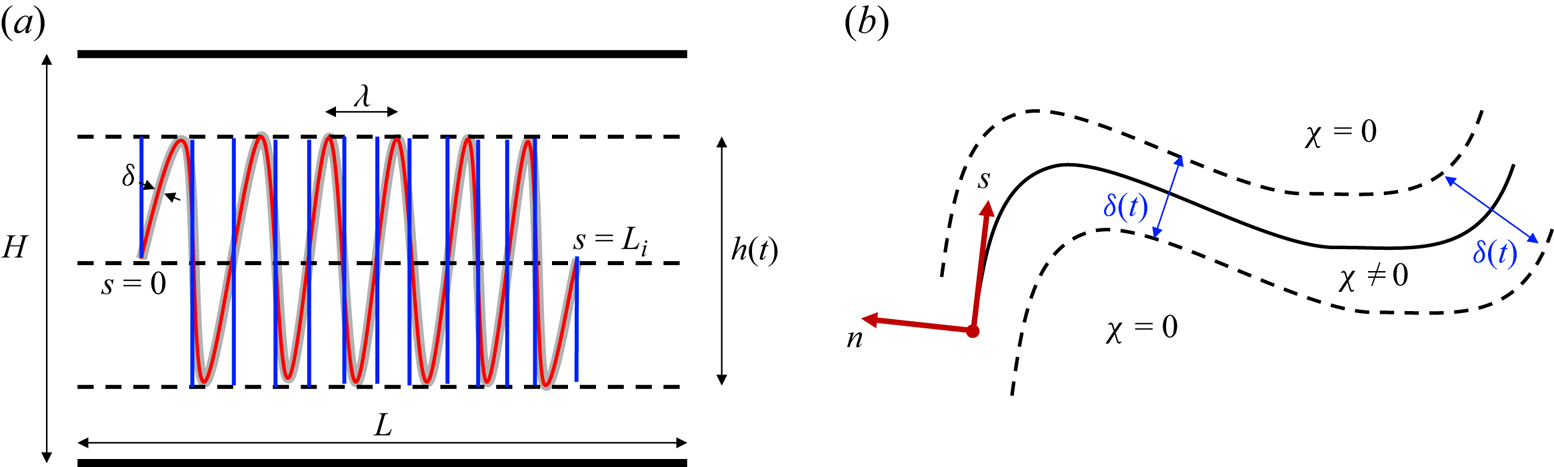

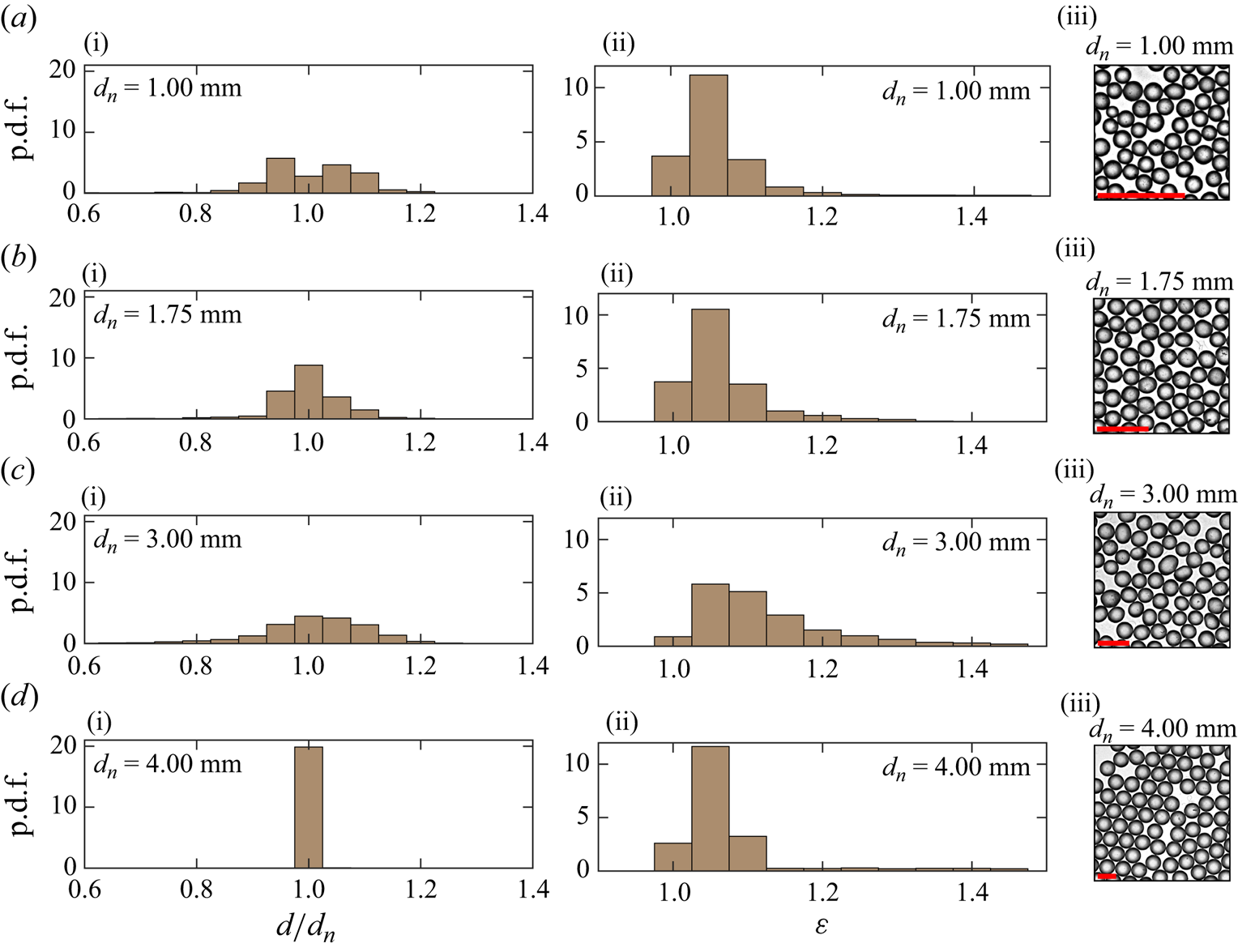

The numerical simulations are designed to match the porosity of the experiments, namely ![]() $\phi =0.37$. To consider a two-dimensional set-up most similar to the monodisperse spherical bead pack of the experiments, we construct the solid phase in the simulations from circles of a given diameter

$\phi =0.37$. To consider a two-dimensional set-up most similar to the monodisperse spherical bead pack of the experiments, we construct the solid phase in the simulations from circles of a given diameter ![]() $d$. Most past studies of a similar configuration (e.g. Sardina et al. Reference Sardina, Brandt, Boffetta and Mazzino2018; Liu et al. Reference Liu, Jiang, Chong, Zhu, Wan, Verzicco, Stevens, Lohse and Sun2020) that explicitly resolve the pore-scale dynamics with a liquid–solid boundary are performed at a higher porosity, allowing for a wide range of configurations for the solid phase. Since we aim to match a low experimental porosity of

$d$. Most past studies of a similar configuration (e.g. Sardina et al. Reference Sardina, Brandt, Boffetta and Mazzino2018; Liu et al. Reference Liu, Jiang, Chong, Zhu, Wan, Verzicco, Stevens, Lohse and Sun2020) that explicitly resolve the pore-scale dynamics with a liquid–solid boundary are performed at a higher porosity, allowing for a wide range of configurations for the solid phase. Since we aim to match a low experimental porosity of ![]() $\phi =0.37$, we prescribe a hexagonal arrangement of the circular beads, as shown in figure 4(a), which allows for free percolation of the fluid in two dimensions at these low porosities. Such perfectly regular arrangements are not representative of the porous matrix in the experiments, so we also repeat our simulations in domains in which random shifts from this hexagonal arrangement are made to the positions of the solid circles. An example of these random shifts is shown in figure 4(b). To prevent regions of trapped fluid, we limit the random perturbations to the grey areas in that schematic, such that the (black) solid regions do not overlap.

$\phi =0.37$, we prescribe a hexagonal arrangement of the circular beads, as shown in figure 4(a), which allows for free percolation of the fluid in two dimensions at these low porosities. Such perfectly regular arrangements are not representative of the porous matrix in the experiments, so we also repeat our simulations in domains in which random shifts from this hexagonal arrangement are made to the positions of the solid circles. An example of these random shifts is shown in figure 4(b). To prevent regions of trapped fluid, we limit the random perturbations to the grey areas in that schematic, such that the (black) solid regions do not overlap.

Figure 4. Schematic of the porous medium layout in the simulations. (a) Regular hexagonal distribution of solid circles used in the simulations. (b) An example of random perturbations to the regular pattern. Grey areas mark the possible area in which each solid circle can move without overlapping another. (c) Schematic of the total domain for ![]() $H/d=70$, with solid particles in grey, and the fluid domain coloured according to the initial concentration.

$H/d=70$, with solid particles in grey, and the fluid domain coloured according to the initial concentration.

As discussed in § 3.1, the permeability ![]() $k$ is key to understanding the effect of the porous medium properties on the flow. For example, the velocity scale

$k$ is key to understanding the effect of the porous medium properties on the flow. For example, the velocity scale ![]() $U$ of (2.4) relies on the balance between buoyancy, permeability and viscosity. While the determination of the permeability for three-dimensional arrays of spheres is well studied, for two-dimensional flows (array of cylinders with infinite length) the situation has been investigated less. By definition, the value of permeability would be determined by measuring the pressure drop across the medium for different flow rates. Happel & Brenner (Reference Happel and Brenner2012) suggest that

$U$ of (2.4) relies on the balance between buoyancy, permeability and viscosity. While the determination of the permeability for three-dimensional arrays of spheres is well studied, for two-dimensional flows (array of cylinders with infinite length) the situation has been investigated less. By definition, the value of permeability would be determined by measuring the pressure drop across the medium for different flow rates. Happel & Brenner (Reference Happel and Brenner2012) suggest that ![]() $k_C=5$ holds also for two-dimensional media. They considered a flow perpendicular to an array of cylinders (indicated as perpendicular flow in Xu & Yu Reference Xu and Yu2008) and observed that for

$k_C=5$ holds also for two-dimensional media. They considered a flow perpendicular to an array of cylinders (indicated as perpendicular flow in Xu & Yu Reference Xu and Yu2008) and observed that for ![]() $0.25<\phi <0.55$, the Carman constant can very well approximated as

$0.25<\phi <0.55$, the Carman constant can very well approximated as ![]() $k_C=5$. Therefore, also in the two-dimensional case, we assume that (3.3) with

$k_C=5$. Therefore, also in the two-dimensional case, we assume that (3.3) with ![]() $k_C=5$ applies.

$k_C=5$ applies.

We use the highly parallelised AFiD (advanced finite-difference) code to perform our simulations. The governing equations (3.6) and (3.7) are solved using second-order central finite differences to compute spatial derivatives, with time-stepping performed using an implicit Crank–Nicolson method for the vertical diffusive terms (![]() $\partial _{zz}$) and a third-order explicit Runge–Kutta scheme for all other terms. A fractional-step method is used to impose the divergence-free condition at each time step, where a Poisson equation is solved for the pressure. Further details of the numerical scheme can be found in Verzicco & Orlandi (Reference Verzicco and Orlandi1996) and van der Poel et al. (Reference van der Poel, Ostilla-Mónico, Donners and Verzicco2015). A multiple-resolution method is applied to the concentration field for accurate simulation at low diffusivities, following Ostilla-Monico et al. (Reference Ostilla-Monico, Yang, van der Poel, Lohse and Verzicco2015). Cubic Hermite interpolation is used to interpolate the concentration field to the velocity grid for the buoyancy forcing, and to interpolate the velocity field to the refined grid for advection of the concentration field.

$\partial _{zz}$) and a third-order explicit Runge–Kutta scheme for all other terms. A fractional-step method is used to impose the divergence-free condition at each time step, where a Poisson equation is solved for the pressure. Further details of the numerical scheme can be found in Verzicco & Orlandi (Reference Verzicco and Orlandi1996) and van der Poel et al. (Reference van der Poel, Ostilla-Mónico, Donners and Verzicco2015). A multiple-resolution method is applied to the concentration field for accurate simulation at low diffusivities, following Ostilla-Monico et al. (Reference Ostilla-Monico, Yang, van der Poel, Lohse and Verzicco2015). Cubic Hermite interpolation is used to interpolate the concentration field to the velocity grid for the buoyancy forcing, and to interpolate the velocity field to the refined grid for advection of the concentration field.

The solid phase is handled using the immersed boundary method (Verzicco Reference Verzicco2023). We follow the direct forcing approach of Fadlun et al. (Reference Fadlun, Verzicco, Orlandi and Mohd-Yusof2000) such that zero velocity is imposed in the solid during the implicit step of the numerical solution. In this approach, linear interpolation is used at the first grid nodes in the fluid from the solid boundary, so that the interface is captured more accurately than the grid resolution. Similarly for the concentration field, we ensure zero normal gradient at the immersed boundary by specially treating these boundary nodes.

The collection of performed simulations are listed in table 2. For each set of parameters, we perform three simulations: one with the regular hexagonal packing defining the centre positions of the solid circles, and two with (distinct) random perturbations to this arrangement. Each simulation is initialised with zero velocity, and an initial concentration field of

where ![]() $\mathcal {H}$ is the Heaviside function, and

$\mathcal {H}$ is the Heaviside function, and ![]() $W$ is a white noise random variable taking values between

$W$ is a white noise random variable taking values between ![]() $-1$ and

$-1$ and ![]() $1$, producing a region of random perturbations of width

$1$, producing a region of random perturbations of width ![]() $H/100$ across the interface. Uniform grid spacing is used in all directions, with a resolution of at least 32 grid points per solid diameter for the velocity grid and a resolution 4 times that for the refined concentration grid. The largest computational grids are used for simulations S10–S12, where

$H/100$ across the interface. Uniform grid spacing is used in all directions, with a resolution of at least 32 grid points per solid diameter for the velocity grid and a resolution 4 times that for the refined concentration grid. The largest computational grids are used for simulations S10–S12, where ![]() $H/d=70$, with the base grid at a resolution of

$H/d=70$, with the base grid at a resolution of ![]() $4096\times 2365$ and the refined grid at a resolution of

$4096\times 2365$ and the refined grid at a resolution of ![]() $16384\times 9459$. This resolution is noticeably higher than in previous studies (e.g. Sardina et al. Reference Sardina, Brandt, Boffetta and Mazzino2018), and allows us to accurately simulate the small-scale structures arising from buoyancy-driven flows at high

$16384\times 9459$. This resolution is noticeably higher than in previous studies (e.g. Sardina et al. Reference Sardina, Brandt, Boffetta and Mazzino2018), and allows us to accurately simulate the small-scale structures arising from buoyancy-driven flows at high ![]() $Sc$.

$Sc$.

4. Flow dynamics

We now present the results of the experiments and simulations. The experiments are performed by changing the bead diameter (![]() $d$) and the density difference (

$d$) and the density difference (![]() $\Delta \rho$). Simulations are performed for different values of diameter-based Rayleigh number

$\Delta \rho$). Simulations are performed for different values of diameter-based Rayleigh number ![]() $(\operatorname {\mathit {Ra}}_d)$ and domain to bead size

$(\operatorname {\mathit {Ra}}_d)$ and domain to bead size ![]() $(H/d)$.

$(H/d)$.

Under certain flow conditions, a fluid flow through a porous medium may be considered as a Darcy flow. In a Darcy flow, the length scale of the flow structures is much greater than the representative volume over which the quantities are averaged (Hewitt Reference Hewitt2020). This representative volume typically includes a number of solid particles and the interstitial fluid. Darcy conditions are met when (i) the flow is controlled by viscous forces at the pore scale ![]() $(Re\ll 1)$, and (ii) the length scale of the convective flow is large compared with the pore size

$(Re\ll 1)$, and (ii) the length scale of the convective flow is large compared with the pore size ![]() $(\operatorname {\mathit {Pe}}\ll 1)$. One can observe from table 2 that only a few experiments (E1–E3 and E5) fall in the Darcy case. A qualitative observation of this result is provided by looking at the raw images in figures 5 and 6.

$(\operatorname {\mathit {Pe}}\ll 1)$. One can observe from table 2 that only a few experiments (E1–E3 and E5) fall in the Darcy case. A qualitative observation of this result is provided by looking at the raw images in figures 5 and 6.

Figure 5. Flow evolution (raw images of laboratory experiments) for different bead size, ![]() $d$, and same density difference,

$d$, and same density difference, ![]() $\Delta \rho \approx 7\ {\rm kg}\ {\rm m}^{-3}$. The permeability is increased while the driving force remains unchanged. The flow structure changes remarkably from (a–d), due to the change in the size of the fingers relative to the beads. For visualisation purposes, only the central lower portion of the domain is shown, approximately corresponding to

$\Delta \rho \approx 7\ {\rm kg}\ {\rm m}^{-3}$. The permeability is increased while the driving force remains unchanged. The flow structure changes remarkably from (a–d), due to the change in the size of the fingers relative to the beads. For visualisation purposes, only the central lower portion of the domain is shown, approximately corresponding to ![]() $1/8\le x/H\le 7/8$ and

$1/8\le x/H\le 7/8$ and ![]() $z/H\le 0$ (length of scale bar is 2 cm).

$z/H\le 0$ (length of scale bar is 2 cm).

Figure 6. Flow evolution (raw images of laboratory experiments) for the same bead size, ![]() ${d=1.75}$ mm, and different density differences,

${d=1.75}$ mm, and different density differences, ![]() $\Delta \rho$. The driving force is increased while the permeability remains unchanged. The flow structure changes remarkably from (a) to (d), due to the change in the size of the fingers relative to the beads. For visualisation purposes, only the central lower portion of the domain is shown, approximately corresponding to

$\Delta \rho$. The driving force is increased while the permeability remains unchanged. The flow structure changes remarkably from (a) to (d), due to the change in the size of the fingers relative to the beads. For visualisation purposes, only the central lower portion of the domain is shown, approximately corresponding to ![]() $1/8\le x/H\le 7/8$ and

$1/8\le x/H\le 7/8$ and ![]() $z/H\le 0$ (length of scale bar is 2 cm).

$z/H\le 0$ (length of scale bar is 2 cm).

In figure 5, we consider the variation of the flow topology for the same driving force (![]() $\Delta \rho \approx 7\ {\rm kg}\ {\rm m}^{-3}$) and different values of permeability (i.e. different