Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Nagamani Jaya, Balila

Bhowmick, Sanjit

Asif, S.A. Syed

and

Jayaram, Vikram

2015.

In-situ study of microscale fracture of diffusion aluminide bond coats: Effect of platinum.

Journal of Materials Research,

Vol. 30,

Issue. 21,

p.

3343.

Hintsala, E.

Kiener, D.

Jackson, J.

and

Gerberich, W. W.

2015.

In-Situ Measurements of Free-Standing, Ultra-Thin Film Cracking in Bending.

Experimental Mechanics,

Vol. 55,

Issue. 9,

p.

1681.

Bohnert, C.

Schmitt, N.J.

Weygand, S.M.

Kraft, O.

and

Schwaiger, R.

2016.

Fracture toughness characterization of single-crystalline tungsten using notched micro-cantilever specimens.

International Journal of Plasticity,

Vol. 81,

Issue. ,

p.

1.

Costin, Walter L.

Lavigne, Olivier

Kotousov, Andrei

Ghomashchi, Reza

and

Linton, Valerie

2016.

Investigation of hydrogen assisted cracking in acicular ferrite using site-specific micro-fracture tests.

Materials Science and Engineering: A,

Vol. 651,

Issue. ,

p.

859.

Ast, Johannes

Merle, Benoit

Durst, Karsten

and

Göken, Mathias

2016.

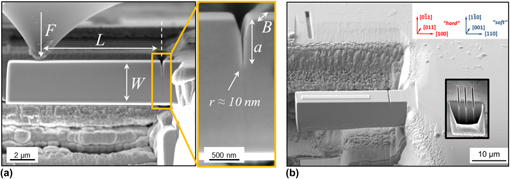

Fracture toughness evaluation of NiAl single crystals by microcantilevers—a new continuous J-integral method.

Journal of Materials Research,

Vol. 31,

Issue. 23,

p.

3786.

Jaya, B. Nagamani

and

Jayaram, Vikram

2016.

Fracture Testing at Small-Length Scales: From Plasticity in Si to Brittleness in Pt.

JOM,

Vol. 68,

Issue. 1,

p.

94.

Costin, Walter L.

Lavigne, Olivier

and

Kotousov, Andrei

2016.

A study on the relationship between microstructure and mechanical properties of acicular ferrite and upper bainite.

Materials Science and Engineering: A,

Vol. 663,

Issue. ,

p.

193.

Treml, R.

Kozic, D.

Schöngrundner, R.

Kolednik, O.

Gänser, H.-P.

Brunner, R.

and

Kiener, D.

2016.

Miniaturized fracture experiments to determine the toughness of individual films in a multilayer system.

Extreme Mechanics Letters,

Vol. 8,

Issue. ,

p.

235.

Gao, Yue

Liu, Zhanli

Zeng, Qinglei

Wang, Tao

Zhuang, Zhuo

and

Hwang, Keh-Chih

2017.

Theoretical and numerical prediction of crack path in the material with anisotropic fracture toughness.

Engineering Fracture Mechanics,

Vol. 180,

Issue. ,

p.

330.

Mueller, Martin Guillermo

Žagar, Goran

and

Mortensen, Andreas

2017.

Stable room-temperature micron-scale crack growth in single-crystalline silicon.

Journal of Materials Research,

Vol. 32,

Issue. 19,

p.

3617.

Eisenhut, Lena

Schaefer, Florian

Gruenewald, Patrick

Weiter, Laura

Marx, Michael

and

Motz, Christian

2017.

Effect of a dislocation pile-up at the neutral axis on trans-crystalline crack growth for micro-bending fatigue.

International Journal of Fatigue,

Vol. 94,

Issue. ,

p.

131.

Ast, Johannes

Göken, Mathias

and

Durst, Karsten

2017.

Size-dependent fracture toughness of tungsten.

Acta Materialia,

Vol. 138,

Issue. ,

p.

198.

Schütze, M.

and

Quadakkers, W. J.

2017.

Future Directions in the Field of High-Temperature Corrosion Research.

Oxidation of Metals,

Vol. 87,

Issue. 5-6,

p.

681.

Snartland, B.D.

Hagen, A.B.

and

Thaulow, C.

2017.

Fracture mechanical testing of single crystal notched α-iron micro-cantilevers.

Engineering Fracture Mechanics,

Vol. 175,

Issue. ,

p.

312.

Ast, Johannes

Mohanty, Gaurav

Guo, Yi

Michler, Johann

and

Maeder, Xavier

2017.

In situ micromechanical testing of tungsten micro-cantilevers using HR-EBSD for the assessment of deformation evolution.

Materials & Design,

Vol. 117,

Issue. ,

p.

265.

Preiß, Eva I.

Merle, Benoit

and

Göken, Mathias

2017.

Understanding the extremely low fracture toughness of freestanding gold thin films by in-situ bulge testing in an AFM.

Materials Science and Engineering: A,

Vol. 691,

Issue. ,

p.

218.

Maňák, Jan

and

Vokoun, David

2018.

Microbending Experiments on Pure Magnesium with Nonbasal Slip Orientation.

Materials,

Vol. 11,

Issue. 8,

p.

1434.

Gruenewald, Patrick

Schaefer, Florian

Thielen, Matthias

Marx, Michael

and

Motz, Christian

2018.

Small scale fracture mechanics of ductile materials: Advantage of fatigue precracks and comparison of J-integral evaluations.

Materialia,

Vol. 4,

Issue. ,

p.

104.

Dehm, G.

Jaya, B.N.

Raghavan, R.

and

Kirchlechner, C.

2018.

Overview on micro- and nanomechanical testing: New insights in interface plasticity and fracture at small length scales.

Acta Materialia,

Vol. 142,

Issue. ,

p.

248.

Snartland, Brage Dahl

Alvaro, Antonio

Osen, Vidar

and

Thaulow, Christian

2018.

Crack arrest testing at the micro-scale.

Engineering Fracture Mechanics,

Vol. 201,

Issue. ,

p.

157.

$\sqrt {\rm{m}}$ for the soft orientation and around 8.5 MPa

$\sqrt {\rm{m}}$ for the soft orientation and around 8.5 MPa $\sqrt {\rm{m}}$ for the hard orientation, that (ii) there is a strong influence of the anisotropic behavior of NiAl on the fracture toughness values, and that (iii) the J-integral technique is the most accurate quantification method.

$\sqrt {\rm{m}}$ for the hard orientation, that (ii) there is a strong influence of the anisotropic behavior of NiAl on the fracture toughness values, and that (iii) the J-integral technique is the most accurate quantification method.