No CrossRef data available.

Article contents

High-performance antistatic acrylic coating by incorporation with modified graphene

Published online by Cambridge University Press: 21 January 2019

Abstract

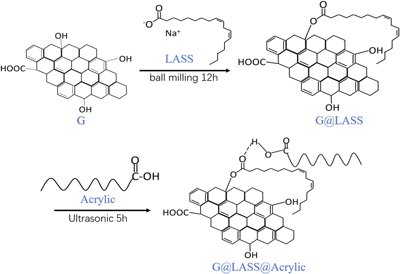

Graphene (G) has attracted great interest because of its excellent chemical and electrical properties. However, the aggregation of graphene restricts its application. Herein, linoleic acid sodium salt (LASS), a low-cost and environmentally friendly material, was used to improve the dispersion of graphene through covalent interaction. Then, the mixture (G@LASS) was integrated with acrylic resin matrix via hydrogen bond between the carboxyl and ester groups. The excellent interfacial compatibility between G@LASS and acrylic matrix, as well as good dispersibility of G@LASS, was demonstrated by Fourier-transform infrared spectroscopy, X-ray photoelectron spectroscopy, Raman, and scanning electron microscopy tests. Compared with acrylic matrix, the surface hydrophobicity of G@LASS@Acrylic increased considerably because of its compact structure. G@LASS@Acrylic composites meet the requirement of antistatic materials when the content of G was only about 0.5 wt%. The results showed that conductive pathways were established successfully through this method.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019