Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Jayaraman, T.V.

Rathi, A.

and

Thotakura, G.V.

2019.

Phase evolution, structure, and magnetic characterization of mechanosynthesized Co40Fe30Ni30 medium-entropy alloy.

Intermetallics,

Vol. 113,

Issue. ,

p.

106583.

Jayaraman, T.V.

Thotakura, G.V.

and

Rathi, A.

2019.

Phase evolution, structure, and magnetic characterization of mechanosynthesized Ni40Fe30Co30 medium-entropy alloy.

Journal of Magnetism and Magnetic Materials,

Vol. 489,

Issue. ,

p.

165466.

Mishra, Rajesh K.

and

Shahi, Rohit R.

2020.

A novel low-density semi-hard magnetic Al20Fe20Mg20Ni20Ti20 high entropy alloy.

Journal of Magnetism and Magnetic Materials,

Vol. 516,

Issue. ,

p.

167342.

Sahu, Priyanka

Bagri, Atul Singh

Anoop, M. D.

Kumar, Manoj

and

Kumar, Vinod

2020.

Impact of Si and Mg on Microstructural and Magnetic Behavior of Fe-Co-Ni (Mg-Si)x (x = 0.00,0.1,0.2) Multicomponent Alloys.

Silicon,

Vol. 12,

Issue. 4,

p.

893.

Jayaraman, T.V.

Rathi, A.

and

Thotakura, G.V.

2020.

Evaluation of the suitability of Fe40Co30Ni30 as a precursor for Fe-rich FeCoNi-based high-entropy semi-hard magnets.

Intermetallics,

Vol. 119,

Issue. ,

p.

106715.

Mishra, Rajesh K.

and

Shahi, Rohit

2020.

A systematic approach for enhancing magnetic properties of CoCrFeNiTi-based high entropy alloys via stoichiometric variation and annealing.

Journal of Alloys and Compounds,

Vol. 821,

Issue. ,

p.

153534.

Zhang, Yingzhe

Li, Xiaopeng

Qin, Qingdong

Li, Juan

Zhao, Honglong

Gao, Xingyong

Su, Xiangdong

and

Chen, Ding

2021.

Influence of Cr and Al to FeCoNiCrxAl2-x alloys synthesised by mechanochemistry.

Materials Science and Technology,

Vol. 37,

Issue. 5,

p.

545.

Chaudhary, Varun

Chaudhary, Richa

Banerjee, Rajarshi

and

Ramanujan, R.V.

2021.

Accelerated and conventional development of magnetic high entropy alloys.

Materials Today,

Vol. 49,

Issue. ,

p.

231.

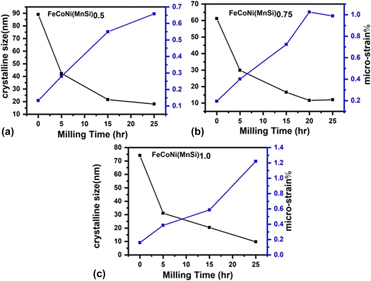

Sahu, Priyanka

Samal, Sumanta

and

Kumar, Vinod

2021.

Microstructural, magnetic, and geometrical thermodynamic investigation of FeCoNi(MnSi)x (0.0, 0.1, 0.25, 0.5, 0.75, 1.0) high entropy alloys.

Materialia,

Vol. 18,

Issue. ,

p.

101133.

Mishra, Rajesh K.

Kumari, Priyanka

Gupta, Amit K.

and

Shahi, Rohit R.

2021.

Design and development of Co35Cr5Fe20−xNi20+xTi20 High Entropy Alloy with excellent magnetic softness.

Journal of Alloys and Compounds,

Vol. 889,

Issue. ,

p.

161773.

Yakın, Alican

Şimşek, Telem

Avar, Barış

Chattopadhyay, Arun K.

Özcan, Sadan

and

Şimşek, Tuncay

2022.

The effect of Cr and Nb addition on the structural, morphological, and magnetic properties of the mechanically alloyed high entropy FeCoNi alloys.

Applied Physics A,

Vol. 128,

Issue. 8,

Khitouni, Nawel

Hammami, Béchir

Llorca-Isern, Núria

Mbarek, Wael Ben

Suñol, Joan-Josep

and

Khitouni, Mohamed

2022.

Microstructure and Magnetic Properties of Nanocrystalline Fe60−xCo25Ni15Six Alloy Elaborated by High-Energy Mechanical Milling.

Materials,

Vol. 15,

Issue. 18,

p.

6483.

Kumari, Priyanka

Gupta, Amit K.

Mishra, Rajesh K.

Ahmad, M.S.

and

Shahi, Rohit R.

2022.

A Comprehensive Review: Recent Progress on Magnetic High Entropy Alloys and Oxides.

Journal of Magnetism and Magnetic Materials,

Vol. 554,

Issue. ,

p.

169142.

Adaan-Nyiak, Moses A.

Alam, Intekhab

and

Tiamiyu, Ahmed A.

2023.

Ball milling process variables optimization for high-entropy alloy development using design of experiment and genetic algorithm.

Powder Technology,

Vol. 427,

Issue. ,

p.

118766.

Milyutin, V.A.

Bureš, R.

Fáberová, M.

Birčáková, Z.

Shishkin, D.A.

Roupcová, P.

Hadraba, H.

Kollár, P.

Füzer, J.

and

Phuong, D.D.

2023.

Multi-component soft magnetic alloy FeNiCoAl0.4Mo0.1Si0.4B0.1 with high frequency stability of permeability.

Materials Science and Engineering: B,

Vol. 293,

Issue. ,

p.

116485.

Sahu, Priyanka

Samal, Sumanta

and

Kumar, Vinod

2023.

Influence of Si and Mn on the Phase Formation, Crystallization Kinetics, and Enhanced Magnetic Properties of Mechanically Alloyed NiCoFe(SiMn)x High Entropy Amorphous Alloys.

Silicon,

Vol. 15,

Issue. 12,

p.

5367.

Mishra, Rajesh K.

Kumari, Priyanka

Gupta, Amit K.

and

Shahi, Rohit R.

2023.

Comparison on structural andmagnetic properties of FeCoNi medium entropy alloy, FeCoNiAl and FeCoNiAlTi high entropy alloys.

Proceedings of the Indian National Science Academy,

Vol. 89,

Issue. 2,

p.

347.

Sahu, Priyanka

Samal, Sumanta

and

Kumar, Vinod

2023.

Microstructure, Non-isothermal Crystallization Kinetics and Magnetic Behaviour Study of [FeCoNi100-x(SiMn)x] High Entropy Amorphous Alloys Synthesized by Mechanical Alloying.

Metals and Materials International,

Vol. 29,

Issue. 9,

p.

2684.

Javdan, M.

Gheisari, Kh.

and

Reihanian, M.

2023.

Mechanically alloyed (FeCoNi)75Cu25−xSix high entropy alloys: Phase evaluation and magnetic properties.

Journal of Alloys and Compounds,

Vol. 952,

Issue. ,

p.

170030.

Sahu, Priyanka

Samal, Sumanta

and

Kumar, Vinod

2023.

Phase Evolution and Soft Magnetic Behavior of Mechanically Alloyed Fe–Co–Ni Medium Entropy Alloy at Different Disk Angular Velocity.

Transactions of the Indian Institute of Metals,

Vol. 76,

Issue. 11,

p.

3065.