Article contents

A green fabrication strategy for porous Yb3Al5O12 ceramics with high strength and tunable gas permeability

Published online by Cambridge University Press: 13 September 2016

Abstract

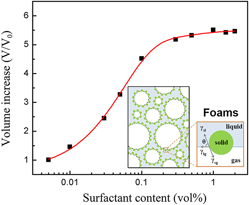

Novel porous Yb3Al5O12 ceramics are successfully fabricated via a green and simple foam-gelcasting approach. Using a nontoxic water-soluble copolymer of isobutylene and maleic anhydride (Isobam), together with a surfactant EMAL TD (Surf-E), 50 vol% solid loading Yb3Al5O12 aqueous ceramic slurries are prepared. Thanks to the small contents of organic additives (0.4 wt% Isobam and 1 vol% Surf-E) added, low linear shrinkage (∼13.9%), and mass loss (∼2.21 wt%) are obtained after pressureless sintering of gelcasted green body at 1600 °C for 4 h under an air atmosphere. Furthermore, porous Yb3Al5O12 ceramics with controlled porosity and spherical-like cells possess excellent structural and shape stability. The flexural strength and compressive strength of the as-prepared porous Yb3Al5O12 ceramics with a relative density of 20% remain as high as 6.3 and 19.7 MPa, respectively, and the gas permeability can be tuned between 4.3 × 10−13 and 7.8 × 10−11 m2 with exponentially increasing porosity from 58% to 84%.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 5

- Cited by