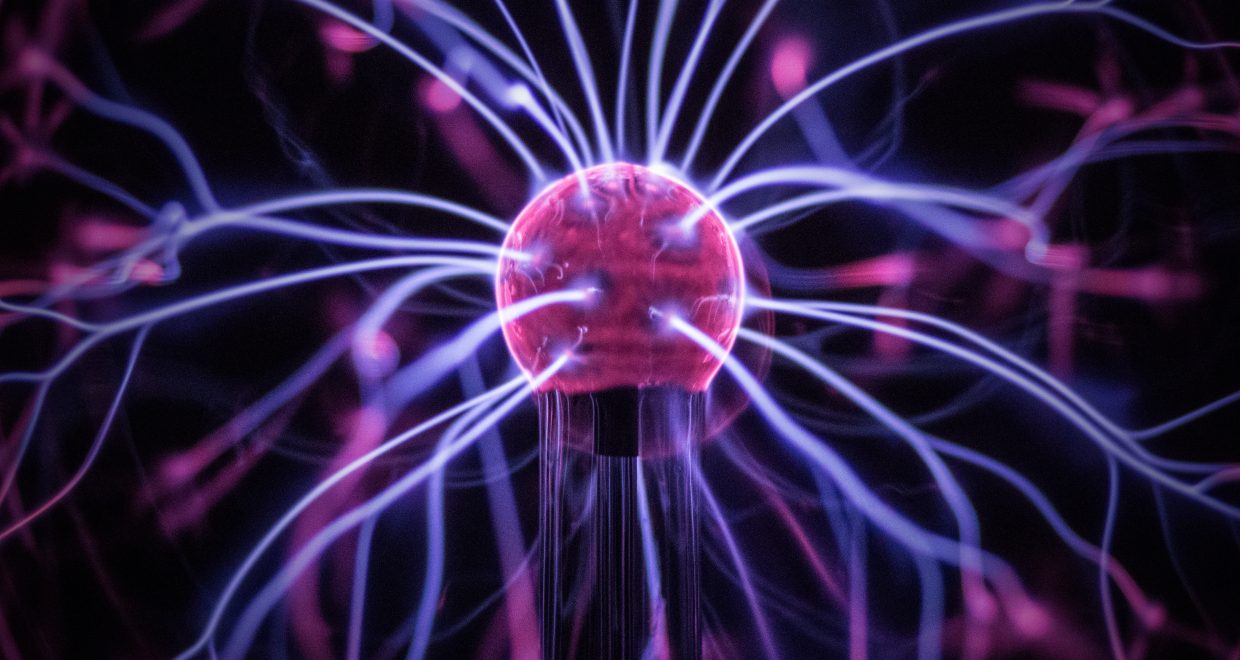

Frontiers of plasma-enabled materials processing and devices

Plasma-based synthesis and processing is an important technique for fabricating and functionalizing novel and technologically-useful materials at different length scales. Plasmas enable reactions and interactions that are otherwise impossible to achieve with conventional methods (e.g. thermal) because of unique energy coupling via charged particles.

However, with the diverse chemistries and materials accessible by plasma-enabled processes comes complexity. There are many different plasma sources, ranging from those operated at low pressures (vacuum) to high pressures (atmospheric), degrees of equilibrium, from non-thermal and non-equilibrium to thermal equilibrium, and many types of plasma-material interactions, from dry to wet interfaces, and from top-down to bottom-up nano-approaches, as well as atomic-scale deposition/etching, enabling future device fabrication using desired materials.

Despite such vast differences from one plasma-based process to another and the complexity of sciences that are encompassed, there are basic fundamentals underlying the plasma physics and chemistry and the synthesis of materials. The symposium covers topics related to new frontiers in materials design to device fabrication, and attempt to identify and address current challenges, as well as advanced understanding on plasma phenomena via different plasma simulation modeling techniques.

A collection of papers published in MRS Advances focuses on plasma-driven atomic scale manipulation of microfabrication and inorganic materials processing. Several papers highlight the fabrication of transparent conductive oxide (TCO) using dry plasma processing towards next-generation electronic devices (Sputter Epitaxy of ZnOx(InN)1-x films on Lattice-mismatched Sapphire Substrate; Effects of nitrogen impurity on ZnO crystal growth on Si substrates; VHF Plasma CVD Synthesis of Photochromic ZnO Nanoparticle).

Others explore new frontiers in materials design to device fabrication (Impact of CMOS TiN Metal Gate Process on Microstructure and its Correlation with Electrical Properties; Material Characterization of Plasma Treated Aluminum Particles via Different Gases), and advancing understanding of plasma phenomena via different plasma simulation modeling techniques (AlN Etching under ICP Cl2/BCl3/Ar Plasma Mixture: Experimental Characterization and Plasma Kinetic Model).

MRS Advances is co-published by the Materials Research Society and Cambridge University Press.