Fragile Cargo: measuring the mechanical properties of soft capsules

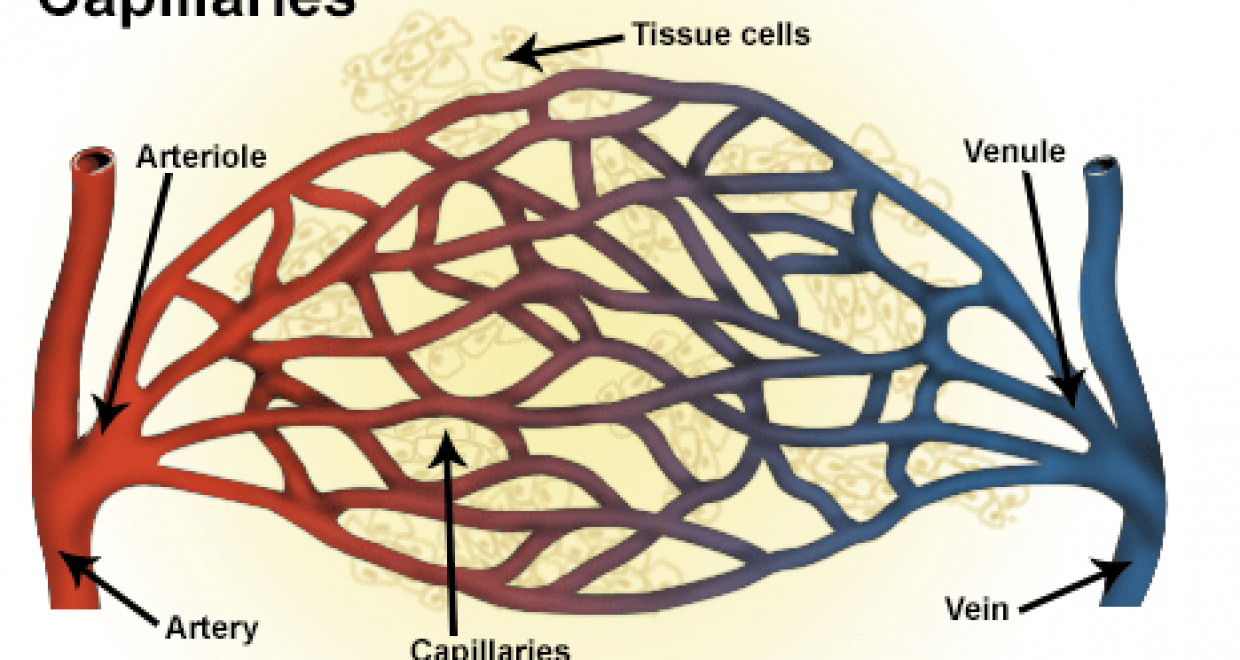

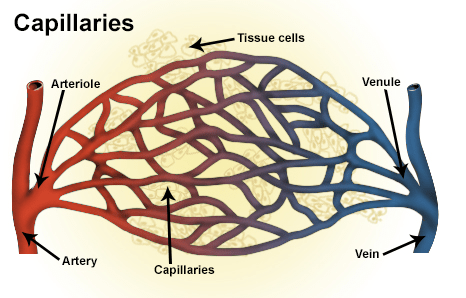

Our bodies are complicated networks. Our vasculature – the veins, arteries, and capillaries that shuttle blood, oxygen, and nutrients to every part of us – is itself a complex series of interconnected tubes that span a wide range of length scales. At their widest, arteries and veins have diameters on the order of millimetres to tens of millimeters[MOU1] , while the narrowest capillaries can be as small as a few micrometers. It may come as a surprise then, that the smallest capillaries are much narrower than our red blood cells (RBCs) – our body’s means for carrying oxygen and carbon dioxide to and from our lungs. This may sound like a recipe for disaster, but the truth is that RBCs are wonderfully deformable and are designed such that they can squish and squeeze themselves into even the smallest capillaries.

Put simply, RBCs are like little packages that deliver resources all over the body. Though we may think of the flow of blood like water flowing through the plumbing of our homes, blood flow becomes complicated when the size of the blood vessels approaches the size of the RBCs. The RBCs presence affects the blood flow through each vessel, which depends on the deformation of the RBCs and blood vessels, which in return is a function of the flow conditions – thus creating a complex feedback system.

Despite the complexity of such a system, nature appears to have identified soft capsule as a great way to deliver important resources while keeping the contents protected. For example, similar motifs appear in the design of cells, bacteria, and eggs (not so much the hard shell of a chicken egg, but softer ones like fish or human). Likewise, soft capsules are also used extensively in industry for flavour and odour delivery, as well as in medicine, where cell-like encapsulation techniques are being explored as ways to deliver delicate mRNA-based vaccines. Developing products and systems that rely on soft capsules to deliver material through channels depends on our understanding of how the capsules respond to variable and sometimes high-stress flows, as well as the way flow is altered in these channels by the inclusion of capsules.

This November, the Journal of Fluid Mechanics hosted a seminar with Dr. Anne-Virginie Salsac, Director of Research at the CNRS (National Centre for Scientific Research) in the Biomechanics and Bioengineering Laboratory (UMR CNRS 7338), Université de Technologie de Compiègne (France). During the seminar, Dr. Salsac discussed her recent work related to the development of soft microcapsule delivery methods. It is an interesting and potentially fruitful place from which to draw inspiration, but designing and testing the mechanical properties of small, deformable capsules in real flow scenarios is challenging. For this reason, Salsac and her collaborators have worked to develop a way to characterize the material properties of soft microcapsules flowing through channels of different geometries.

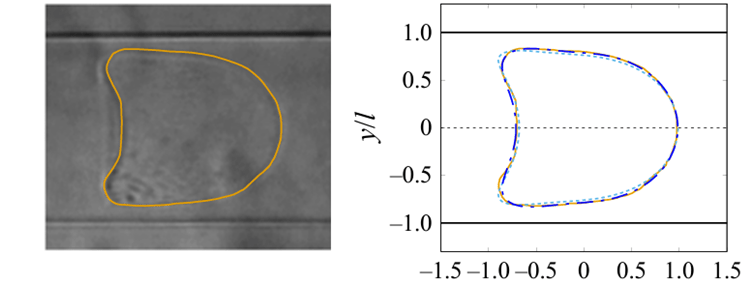

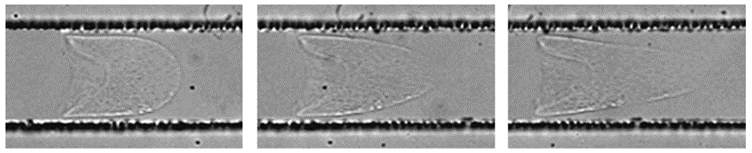

Their work relies on a combination of mathematical modelling and physical experiments, which were used to develop an algorithm that could predict the deformation and material properties of a capsule subjected to specific flow conditions. Using numerical models, one can accurately predict the way a soft capsule will respond to a flow; however, their accuracy depends on how tightly controlled the flow is. Likewise, it is sometimes easy to observe the deformations a soft capsule experiences during flow, but the material properties of the capsule may not be known. By combining numerical calculations and experimental observations of actual capsules during flow, Salsac and her collaborators developed a method to measure the material properties of soft capsules as they pass through microchannels.

Of course, one might expect a softer capsule would experience larger deformations than a stiffer capsule, but even more detailed information can be determined in this way.

For example, a soft capsule can become softer or stiffer as the stresses on the capsule increase and the way this difference manifests itself can range from subtle to dramatic. In a moderate flow, a capsule that softens will not appear all that different from a capsule that stiffens. But, in a strong, high-stress flow, a capsule that softens may in fact stretch and flow like chewing gum being sucked through a straw. It can even experience rupture and breakup, which could be a real problem when a capsule is expected to deliver delicate cargo. Other, more nuanced observations can also be understood with this method, like smaller-scale wrinkling that the membrane making up the capsule can experience when it squishes through a tube.

Alternative methods for determining the mechanical properties of soft capsules do exist, from poking and prodding them with sensitive instruments, to measuring the change in viscosity of a fluid containing many capsules under different flow conditions. However, very few of these approaches are both sensitive enough to characterize very soft capsules, or exact enough to characterize individual capsules without damaging them. In addition, this method can be performed during the fabrication process, so long as the capsules can be imaged optically.

Currently, Dr. Salsac and her collaborators are aiming to use this measurement technique to develop other useful and interesting processes, e.g. in the fabrication of soft capsules in microfluidic environments. Some of these directions were discussed during November’s seminar, which can be accessed here. For a text-based experience, live-tweeted notes from the seminar can be found here. Finally, for those interested in implementing this technique into their own work, details of the method have recently been published in FLOW and can be found here.

In addition to publishing interdisciplinary and widely interesting research, FLOW is committed to making research accessible through articles like this. Be sure to follow Flow and the Journal of Fluid Mechanics on Twitter to stay up to date with the latest developments in the field and see what is featured next on the blog.