Using Solid and Liquid Digestate as Fertilizer for a Sustainable Processing Tomato Cultivation

The paper “Solid and liquid digestate generated from biogas production as a fertilizer source in processing tomato yield, quality and some health-related compounds“, published in The Journal of Agricultural Science, has been chosen as the latest Editorial Highlight.

As the global energy crisis intensifies and non-renewable resources, particularly fossil fuels, approach depletion, sustainable alternatives are gaining global prominence. Biogas plants offer numerous advantages, making them a sustainable and eco-friendly solution for energy generation and highlighting the importance of waste management.

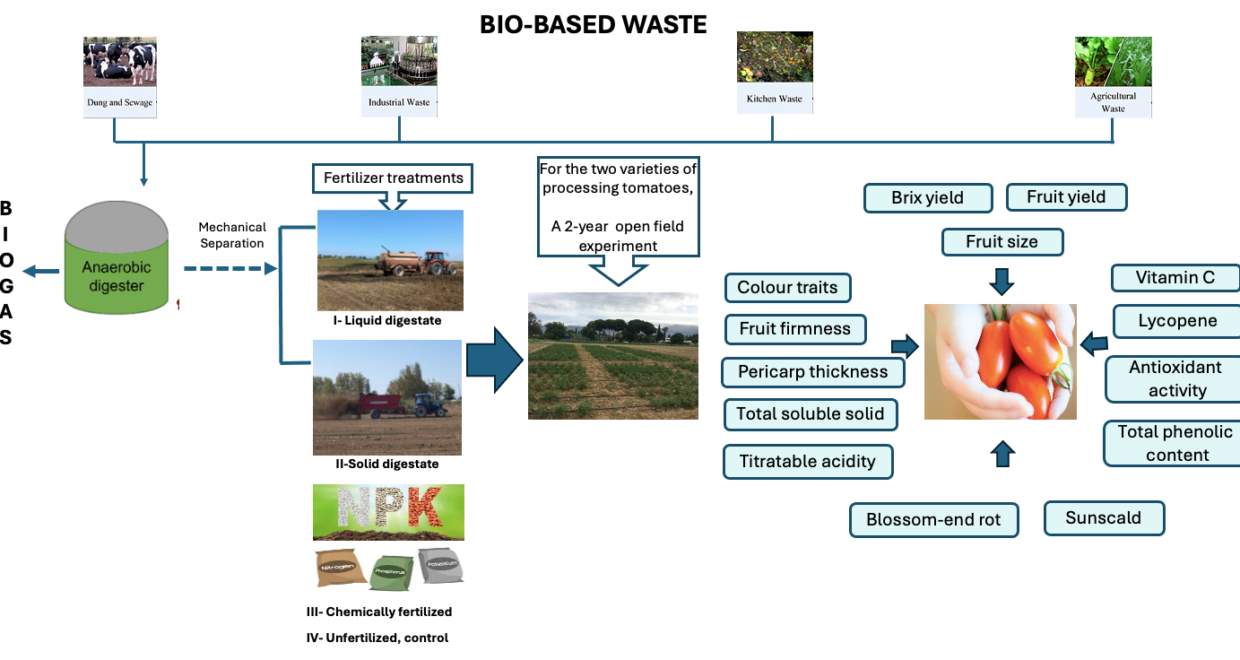

While sustainable sources are getting high interest, amounts of biogas plants have visible increases. Biogas production, a low-carbon energy source, has led to heightened focus on sustainable management of its by-product, anaerobic digestate. Digestates are the residual material left after the anaerobic digestion of organic matter-such as food waste, manure, or crop residues. This process not only generates biogas for energy production but also leaves behind material packed with nutrients like nitrogen, phosphorus, and potassium-key components for plant growth. The unprocessed digestate poses environmental and safety risks, including greenhouse gas emissions and potential soil contamination. Therefore, the development of a comprehensive and globally applicable utilization for the sustainable management of digestate is of crucial importance.

On the other hand, in recent years, the agricultural sector has been increasingly looking for sustainable alternatives to chemical fertilizers. One of these alternatives could be digestate, a by-product of the anaerobic digestion process. Digestates come in two main forms: solid and liquid. Solid digestate has a thicker, compost-like texture, while liquid digestate is more water-based. Both types contain valuable nutrients that can significantly benefit plant growth, making them a promising alternative to chemical fertilizers.

Digestate production is also closely linked to the principles of the circular economy, where organic waste is transformed into valuable resources. Instead of being discarded in landfills or incinerated, organic waste is converted into digestate, which can then be returned to the soil, enriching it with essential nutrients.

Given the growing interest in sustainable agriculture and waste management solutions, digestates are emerging as an environmentally friendly and cost-effective fertilizer option. However, the use of digestates is not without challenges, including variability in nutrient content. Understanding these aspects is crucial for maximizing the benefits of digestates while ensuring their safe and effective use in agriculture.

The economic importance of processing tomatoes is significant, as they represent a major crop within the global agricultural economy, particularly in regions with favorable growing conditions. Processing tomatoes—those grown specifically for use in products such as sauces, pastes, juices, and canned goods—hold a vital place in both agricultural and industrial sectors. Processing tomatoes, must have high yield without compromising the overall quality of obtained product.

As we face the challenges of excessive and long-term use of chemical fertilizers, digestate stands out as an organic fertilizer with immense environmental, agronomic and nutritional potential. Its ability to support sustainable agriculture, being an environmentally friendly and cost-effective option, could make it an important position in the future of agriculture.

The Journal of Agricultural Science Editorial Highlights are selected by the Editor-in-Chief and are freely available for one month. View the recent selections here.