Introduction

At the end of the productive phase (typically between 65 and 100 weeks of age depending on the hybrid and production system), end-of-lay hens are caught, crated, loaded, and transported to the slaughterhouse (pre-slaughter) (Molnár et al. Reference Molnár, Maertens, Ampe, Buyse, Kempen, Zoons and Delezie2016; Gerpe et al. Reference Gerpe, Stratmann, Bruckmaier and Toscano2021; Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022). The catching process usually entails grasping the hens by either or both leg(s) and carrying them upside down to a crate or container and depositing them within the crate or container drawer (Gerpe et al. Reference Gerpe, Stratmann, Bruckmaier and Toscano2021). Catching and loading can be associated with severe infringements of animal welfare (e.g. stress, fear, and pain resulting from injuries such as fractures and bruises) (Gregory & Wilkins Reference Gregory and Wilkins1989; Nicol & Scott Reference Nicol and Scott1990; Jacobs et al. Reference Jacobs, Delezie, Duchateau, Goethals and Tuyttens2017). Furthermore, hens dead-on-arrival (DOA) can comprise up to 0.2%, including death in the lairage (Food Standards Agency 2021) which may be considered as an indicator of welfare since DOA prevalence has been associated with catching, loading, or transport (Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022). End-of-lay hens are also prone to osteoporosis, which increases the risk of fractures during catching and loading (Whitehead & Fleming Reference Whitehead and Fleming2000). The limited economic value of end-of-lay hens in comparison to broilers, for example, has resulted in scant attention from science and industry as regards improvements to pre-slaughter welfare (Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Depner, Drewe, Garin-Bastuji, Gonzales Rojas and Gortázar Schmidt2019). While automated catching equipment is used in broilers (Delanglez et al. Reference Delanglez, Watteyn, Ampe, Segers, Garmyn, Delezie, Sleeckx, Kempen, Demaître, Van, Antonissen and Tuyttens2025), to our knowledge this technology is yet to extend to being commercially available for hens (Jacobs & Tuyttens Reference Jacobs and Tuyttens2020).

Poultry handling is generally considered to be stressful, both for both animals and catchers (Ljungberg et al. Reference Ljungberg, Gebresenbet and Aradom2007; Delanglez et al. Reference Delanglez, Watteyn, Ampe, Garmyn, Delezie, Antonissen, Sleeckx, Kempen, Demaître, Van Meirhaeghe and Tuyttens2024a,b). This stress may be exacerbated in non-cage housing systems such as floor housing and aviary systems where hens are able to move freely and avoid being caught (Knowles & Wilkins Reference Knowles and Wilkins1998; Mitchell & Kettlewell Reference Mitchell and Kettlewell2004; Gerpe et al. Reference Gerpe, Stratmann, Bruckmaier and Toscano2021). This can lead to hens being handled roughly and further negative effects for them, including elevated levels of stress as measured by higher plasma corticosterone levels, fear, and injuries (Cockrem et al. Reference Cockrem, Candy, Castille and Satterlee2010). Furthermore, poultry catchers are compelled to endure extended periods adopting an uncomfortable posture and must repeatedly lift several kilograms, resulting in physical strain, injuries, and long-term disability (GAO 2005; Arcury & Quandt Reference Arcury and Quandt2007; Delanglez et al. Reference Delanglez, Watteyn, Ampe, Segers, Garmyn, Delezie, Sleeckx, Kempen, Demaître, Van Meirhaeghe, Antonissen and Tuyttens2024b).

Once caught hens are placed into different types of crating or container systems, i.e. (A) loose crates, (B) fixed containers that remain on the truck when the hens are being loaded, and (C) modular systems consisting of a metal frame with drawers (Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022) (Figure 1). For loose crates (Figure 1A), entry is via an opening on the top (controlled via sliding hatches or hinged lids). In fixed containers (Figure 1B), hens are carried outside the establishment and placed directly onto the transport lorry via an opening in front of the container. Finally, the modular system (Figure 1C) has several drawers that slide open. Containers have a higher density per drawer (24–27 hens) than a crate (16–18 hens).

Figure 1. Different crating or container systems for end-of-lay hens with (A) loose crates (e.g. 85 cm × 66 cm × 30 cm [length × width × height] with an opening of 30 cm × 35 cm [length × width]; Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022), (B) fixed containers with front and side access (Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022), and (C) modular systems with sliding plastic drawers (e.g. 110 cm × 69 cm × 20 cm) (Pluimveehandel Samyn 2024).

Unlike the fixed containers, the crates and the modular systems can be brought inside the building itself thereby minimising the carrying distance, although this is not always possible in practice due to overly narrow or cluttered corridors (Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022). In Belgium, end-of-lay hens are commonly caught and crated in either loose crates (60%) or a modular system (40%) (Pluimveehandel Samyn 2024).

The design, shape, and size of the openings of these crating or container systems affect the ease of placing the hens inside them as well as the likelihood of caught hens escaping. The risk of injuries (e.g. broken wings, injuries to the back and thigh, and bruises) tends to be lower in fixed containers or the modular systems compared to loose crates. The opening of container drawers to add more hens increases the risk of escape while closure sees the risk of body parts (e.g. head, wing, leg, or toe) becoming entrapped increase (Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022).

The goal of this study was to develop two add-on prototypes that could be easily attached to a container drawer prior to loading and quickly removed after filling. The aim being to reduce the risks associated with opening (escape) and closing (body part entrapment) modular container system drawers. The design process began with a market study to capture all requirements; the prototypes were then designed and built to address those needs (see Table 1). Both prototypes underwent testing for their effect on hen welfare, ease of use, and catcher opinion during depopulation of end-of-lay hens from commercial aviaries.

Table 1. Specific design requirements of the add-on prototypes for end-of-lay hen transport containers per category (animal welfare, catcher well-being/working efficiency, material and hygiene, and construction/cost)

Materials and methods

Development of add-on prototypes

Requirements and specifications for the add-on prototypes were established by conducting a market analysis (interviews with five laying hen farmers, five end-of-lay hen catchers, and one end-of-lay hen transporter) that compared the advantages and disadvantages of different types of crates and containers currently in use for end-of-lay hens in Belgium. The materials commonly used in container construction were also assessed to determine the most suitable options for the add-on components (Table 1).

At four farms the poultry-catching process was observed to determine common elements. With additional input from the key stakeholders (poultry farmers, transporter, and slaughterhouse staff), two prototypes were developed and tested in the field during poultry-catching processes. Both prototypes are add-ons designed to be attached to the open (empty) drawer and removed again once the drawer has been filled. The add-on is then attached to the next empty drawer as the container is filled from top to bottom.

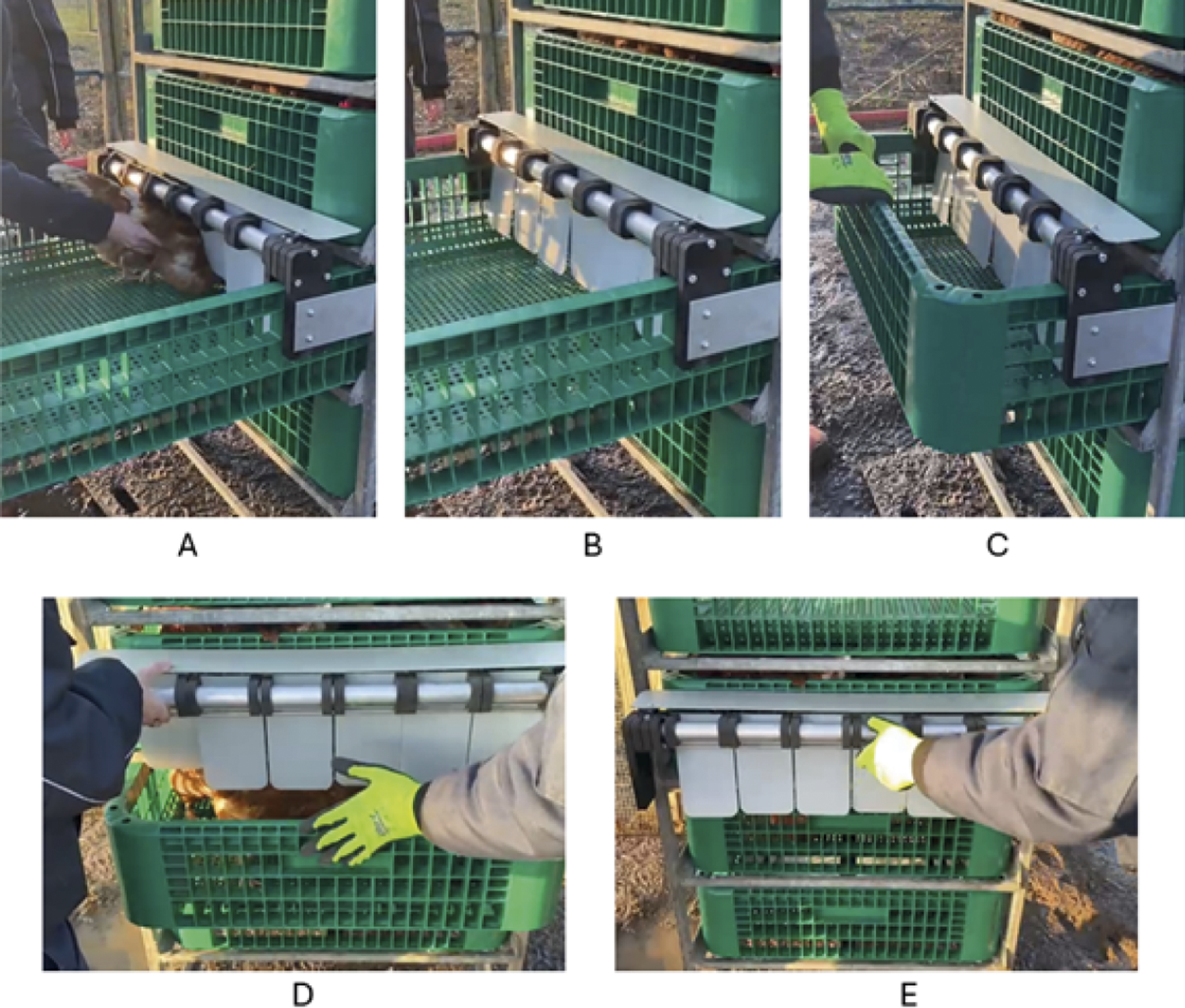

Add-on prototype 1

The first add-on design (Prototype 1; Figure 2) (weight: 3.4 kg) consists of six polyethylene flaps (Figure 2[D]) attached to an aluminium tube (Figure 2[B]). The flaps (Figure 3[A] and [B]) open inwards but are prevented from opening outwards by a small metal tube (Figure 2[C]). This prevents the loaded hens from pushing the flaps outwards to escape (one-way locking mechanism). In addition, the prototype is fitted with aluminium plates at the top to prevent hens escaping and the side (to fix the prototype onto the drawer) (Figure 2[A]). The long sides of the drawer slide under prototype 1 during filling, allowing the catcher to fill back to front (Figure 3[C]). Prototype 1 is attached via magnets (on the sides of the prototype) onto the metal frame of the container (Figure 2[E]); the magnets can hold 62 kg (Flat neodymium strip magnet: 100 mm × 20 × 5 mm; length × width × depth). This allows for easy attachment and removal from the open drawer (Figure 3[D] and [E]).

Figure 2. The size of the parts of prototype 1 for end-of-lay hen transport containers are shown with (A) aluminium plates, (B) the aluminum tube, (C) the small metal tube, (D) the plastic flaps and (E) a magnet placed on the container drawer.

Figure 3. Use of prototype 1 for end-of-lay hen transport containers while (A) loading the hens into the container drawer, (B) the position of the flaps after the hens are placed in the drawer, (C) gradually closing the container drawer during filling and (D, E) lifting of prototype 1 to remove it from the drawer.

Add-on prototype 2

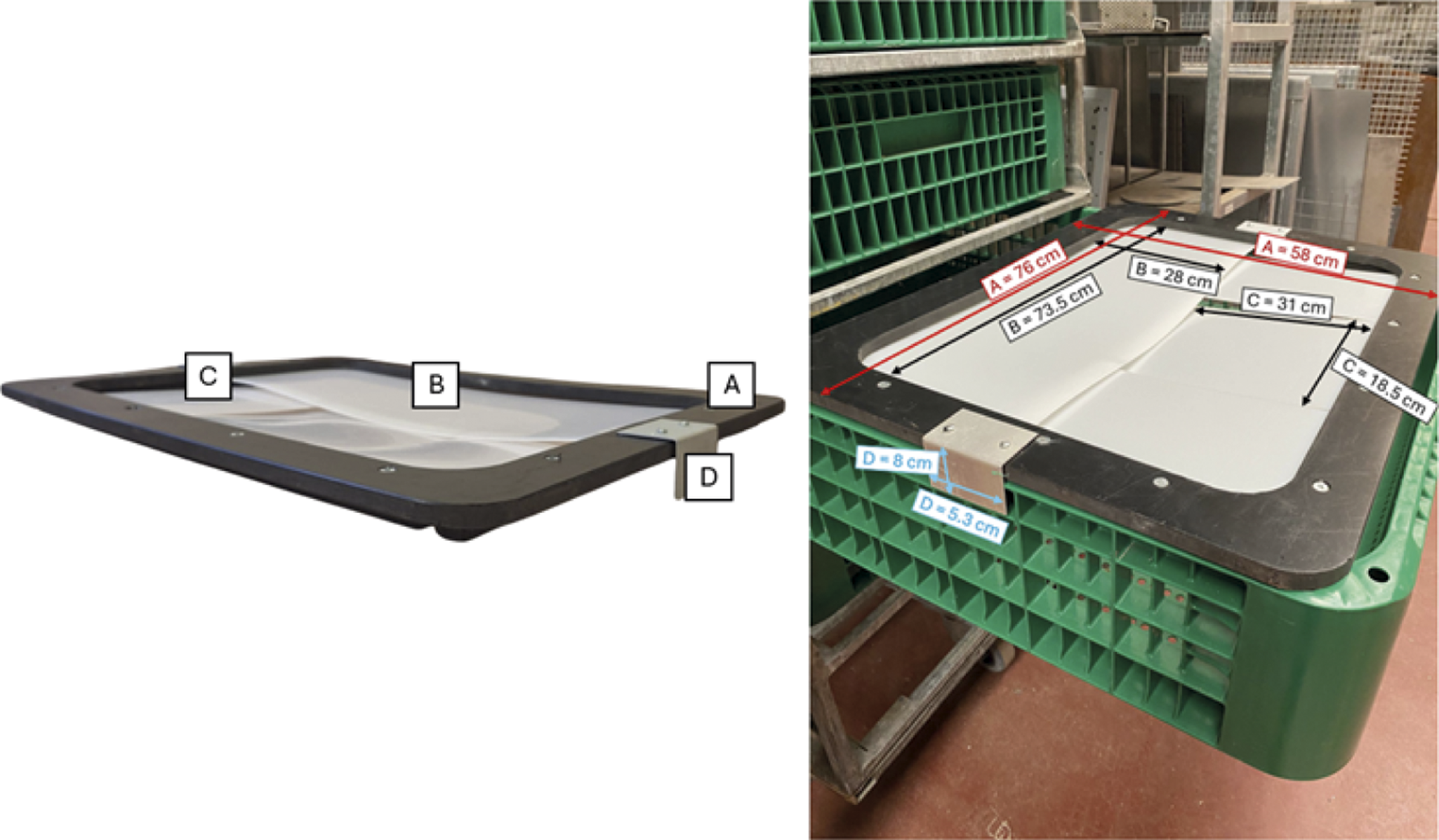

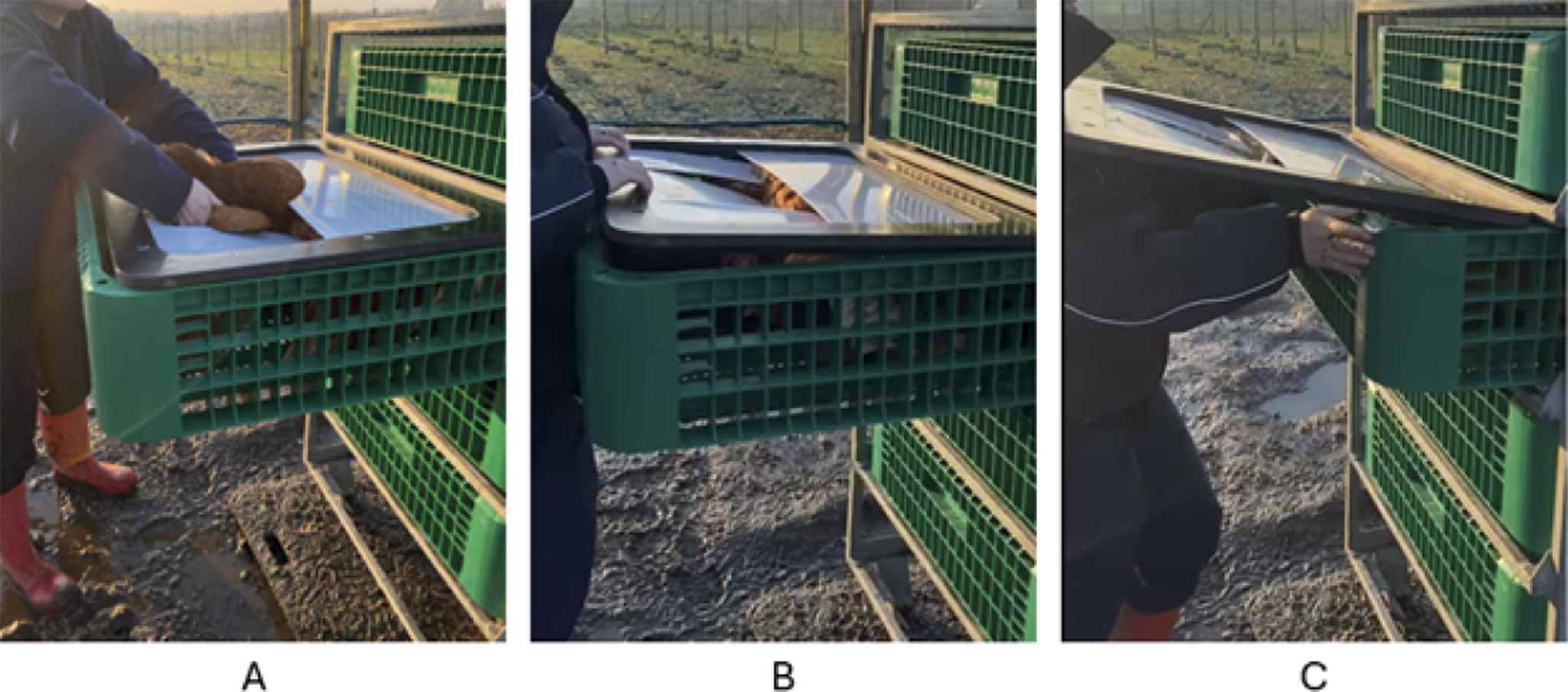

The second add-on design (Prototype 2; Figure 4) (weight: 3.7 kg) consists of four polyethylene flaps (Figure 4[B] and [C]) attached horizontally to a 15-mm thick, high-density polyethylene (HDPE) frame (Figure 4[A]). HDPE is a strong plastic with high impact resistance. One of the flaps is fixed in position to prevent hens from escaping out of the drawer (Figure 4[B]) (a one-way locking mechanism). The three other flaps are flexible enough to allow the placement of the hens into the drawer and only bend in one direction (Figure 4[C]) to prevent escape (a one-way locking mechanism; Figure 5[A]). The add-on is attached to the empty drawer using aluminium hooks (Figure 4[D]). Prototype 2 is placed on the fully open container drawer (Figure5[A]). After filling the drawer, the add-on is removed while the drawer is closing and then attached to the next open drawer (Figure 5[B] and [C]).

Figure 4. The size of the parts of prototype 2 for end-of-lay hen transport containers showing (A) a high-density polyethylene frame, (B) a fixed polyethylene flap, (C) flexible polyethylene flaps and (D) aluminium hooks to fix the prototype onto the container drawer.

Figure 5. Placing (A) a hen into a drawer fitted with prototype 2 for end-of-lay hen transport containers and (B and C) removal of prototype 2 after filling.

Experiment on commercial farms

This study was conducted on five commercial aviary farms (four in Belgium, one in France) from March 2024 to June 2024 (Table 2). Per farm, one flock of end-of-lay hens was assessed during depopulation (average age: 86 weeks, range: 75–92 weeks, breed: Isa Brown). One professional catching company and two non-professional catching teams participated in the study. They were instructed to manually catch and crate the hens as per standard procedure, i.e. by grasping one leg per hen and holding three hens upside down in each hand. The aim was to sample 800 hens with each treatment, but this differed per flock (see Table 2). For the last two flocks only two experimental treatments were used, i.e. control and prototype 1 as catchers reported extensive difficulties when using prototype 2. No ethical approval was required. For each treatment, a relatively small sample size of approximately 800 animals was monitored to investigate the possible differences between the treatments. The animals were required to be caught and transported to the slaughterhouse as part of standard procedures. Therefore, the impact on the animals taking part was minimised. No adjustments were made to the standard procedures, aside from the implementation of the two developed prototypes. The guidelines from European (EU Directive 2010/63) and Belgian (RD 29 May 2013) legislation regarding the definition of an animal experiment were adhered to. Just before starting the catching process the catching teams (all of whom lacked experience with the add-on prototypes) were given a brief demonstration and instruction on how to use the prototypes. All teams could briefly practice loading hens into 2–3 drawers with both prototypes. Measurements and observations were conducted for each flock during loading in the container and at the evisceration zone of the slaughterhouse on the day after depopulation.

Table 2. General information about the aviary flocks included in the study such as the flock size of the end-of-lay hens, the number of hens per container drawer, the order of the treatments, the number of hens loaded with the standard container (S), with prototype 1 (P1), and with prototype 2 (P2), with the number of containers between brackets, the number of catchers per treatment, the type of catching team (P = Professional of N-P= Non-professional), the number of catchers who filled out the survey, and the number of hens scored for the different treatments (S, P1, P2) in the slaughterhouse

On-farm measurements

A team of trained researchers conducted on-farm observations and measurements of the experimental groups using either the standard container or prototypes 1 or 2. Two researchers monitored the loading of hens into the containers. They timed the duration of filling each drawer (from opening until closing), counted the number of escaped hens per drawer, and counted the number of times a hen’s body part became trapped in the drawer. After an entire experimental group of each flock had been loaded in the containers, the total process was scored by one researcher (always the same one) on a 1–7 point Likert scale for noisiness, hen restlessness, and loading inefficiency into the container (Table 3). The number of hens loaded in the containers per treatment and the number of catchers were recorded for each flock.

Table 3. Explanation of the different scores on the 7-point Likert scale for (1) noise during the catching process, (2) restlessness of the hen during the catching process, and (3) the loading inefficiency in container during the catching process

After loading all experimental groups per flock, the catchers were surveyed to gather their opinions regarding the standard container versus prototype 1 versus prototype 2 (first three flocks only). A hard copy of the survey was presented in Dutch, English, or French and catchers were asked to rank the different treatments from 1 (best) to 3 (worst) and to indicate the ease of use and calmness of the hens on a scale from 0 (worst) to 100% (best). Furthermore, an open question enabled specific comments to be made. In total, 18 of 20 (non)-professional catchers completed (90%) the survey (Table 2). No ethical approval was required since all participants had provided informed consent prior to participation and had been informed of their right to withdraw from the survey at any time. Participant anonymity was ensured, and briefings regarding data usage and storage were provided.

Measurements at the slaughterhouse

During depopulation, the research team marked the transport containers with different coloured straps to indicate the treatment (standard container, prototype 1, prototype 2) to enable data collection per experimental group at the slaughterhouse (Table 2). End-of-lay hens from all five farms were slaughtered at the same slaughterhouse in Flanders using CO2 stunning and the same researcher noted the number of DOA hens per treatment per flock. In the evisceration zone, two observers counted the number of injuries per hen, including bruises on and fractures of the wings (observer 1) and legs (observer 2), and bruises on the breast (observer 1). Only fresh bruises (≥ 1 cm without yellow or green discolouration and with red discolouration) and fresh fractures (with or without protruding bone, accompanied by redness/blueness) were registered, in order to exclude injuries sustained prior to depopulation or during defeathering. Multiple injuries of the same type (bruises or fractures) per body part (legs, breasts, and wings) were counted as one injury. A bruise combined with a fracture was only counted as a fracture.

To calculate and compare the prevalence of these injuries per body region, the number of end-of-lay hens assessed per experimental group (per treatment) were estimated per flock slaughtered. Estimation was based on timing the observations per treatment group per flock and the slaughter line speed, which averaged 140 hens per minute (range 108–160 hens per minute). The prevalence of different types of injuries was calculated using the following formula (Jacobs et al. Reference Jacobs, Delezie, Duchateau, Goethals and Tuyttens2017):

Statistical analysis

R (version 4.2.1) was used for data processing. On-farm measurements and slaughterhouse measurements were analysed using linear mixed models with treatment (standard container, prototype 1, or prototype 2) as a fixed effect and the flock as a random effect. The responses are presented as means (± SE) or percentages (± SE). Subsequently, a type III ANOVA analysis was performed to determine P-values for the differences between treatments. A P-value < 0.05 was considered statistically significant. A post hoc test (pairwise comparisons) with a Tukey correction was applied if there was a significant difference. The different assumptions for a linear model were checked before applying the ANOVA tests: the models’ residuals had to be normally distributed and homoscedastic (based on a graphical assessment using a histogram, QQ plot of the residuals, and a residual versus fitted plot). For the survey of the catchers, prototype 1 was compared to the standard type. A binomial test with a probability of 0.5 was used to analyse the ranking. For the indication of preference with percentages, the normality was checked for the difference between the percentages of the standard type and prototype 1 with a QQ plot. All data were normally distributed. This was all performed on the total data and the subdivision between professional and non-professional catchers. The catchers also ranked prototype 2 but always indicated it as the worst; the standard type and prototype 1 were never scored worst. In addition, prototype 2 was eliminated from the study because it did not improve the loading of end-of-lay hens in the container. However, the data from prototype 2 were incorporated into the statistical analysis.

Results

The scores assigned by researchers during depopulation on commercial farms showed a significant treatment effect (Table 4). The score given for hen restlessness was lower for prototype 1 (4.20) compared to prototype 2 (5.67) (P = 0.02), however, no difference was found in comparison with the standard container (4.80) (Table 4). Furthermore, the score given for loading inefficiency in container was better for the standard container (3.20) than for prototype 2 (5.33) (P = 0.05), while prototype 1 was in-between (3.60). The timed duration of filling the drawers numerically confirmed a tendency toward efficiency score differences but these differences were not statistically significant. No significant differences were found in the prevalence of body part entrapments or escapes among the three treatments (Table 4).

Table 4. Mean (± SE) summary of the on-farm assessment after catching with the standard container (Standard), prototype 1 (P1), and prototype 2 (P2) of end-of-lay hens at five farms

Superscripts (a, b) indicate pairwise significant differences between the columns. Significant P-values (P < 0.05) are indicated in bold.

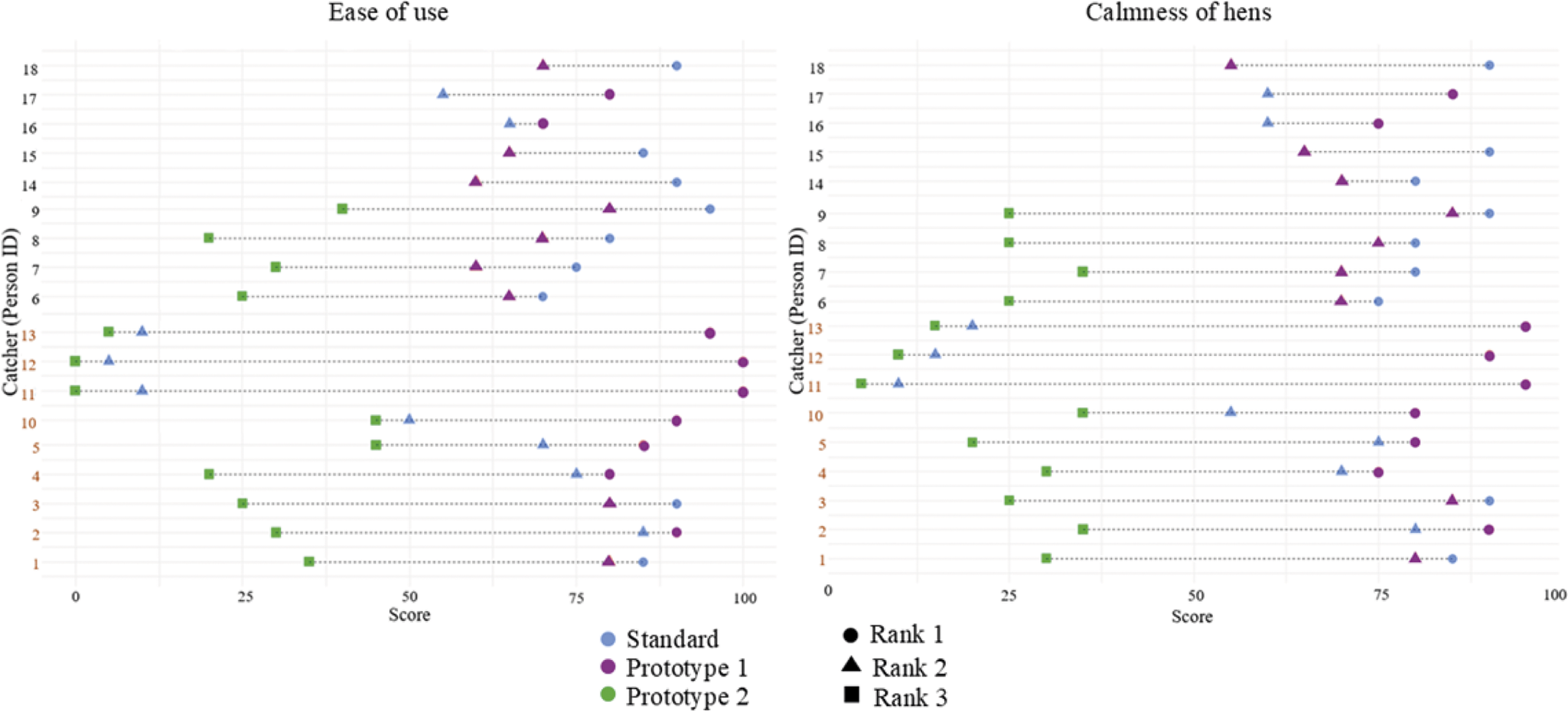

The survey of the catchers revealed that all catchers that used all three types (standard, P1, and P2) (i.e. catcher 1–13) gave the lowest (worst) score to prototype 2 for ease of use and hen calmness; none of these scores were higher than 50% (out of 100) (Figure 6). The best score was given to prototype 1 and the standard container, but no significant difference was found between the rankings of these (an equal number of catchers preferred both types) (P = 1) (Figure 6). Prototype 1 never received a score < 50%, whereas three catchers gave a very low score (< 25%) to the standard container for both criteria (Figure 6).

Figure 6. Ease of use (left) and calmness of the hens (right) as scored by the surveyed catchers (professional = orange on the y-axis; n = 9; and non-professional = black on the y-axis; n = 9, with n the number of catchers surveyed) for the standard type (blue; n = 18), prototype 1 (purple; n = 18), and prototype 2 (green; n = 13).

Regarding the ease of use and calmness of the hens, professional catchers tended to prefer prototype 1 to the standard container (mean: 91 [± 7]% vs 88 [± 4]%; P = 0.10 and mean: 88 [± 4]% vs 86 [± 8]%; P = 0.09). No significant difference was found in the preference between the standard container and prototype 1 for the ease of use (84 [± 9]% vs 75 [± 7]%, respectively; P = 0.12) and calmness of the hens (mean: 84 [± 6]% vs 80 [± 7]%, respectively; P = 0.34) according to non-professional catchers.

Specific comments by the catchers for prototype 1 were that the hens could be pushed to the back of the drawer and that the flaps prevented them from coming forward again or escaping out of the container drawer. For prototype 2, the catchers mentioned the difficulty of placing the last hens in the drawer due to the limited space beneath the flexible flaps.

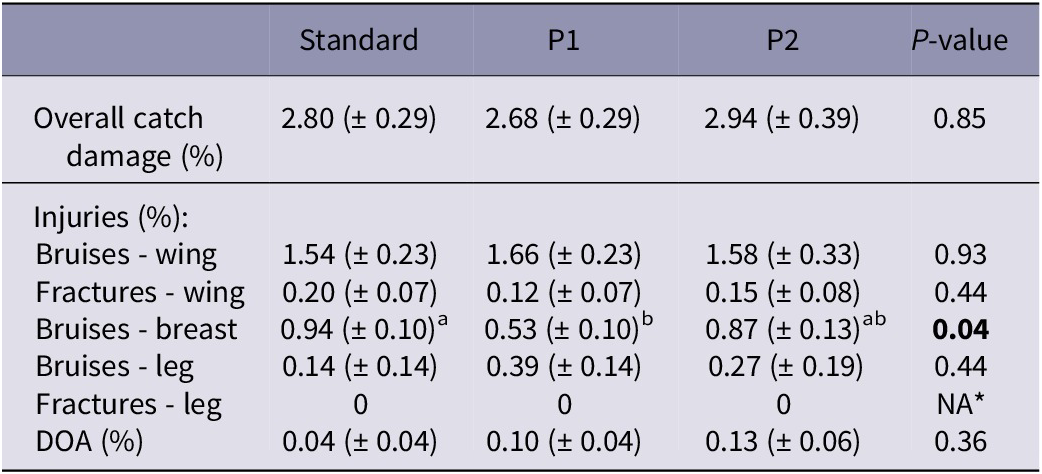

Assessments at the slaughterhouse revealed no significant differences in the overall prevalence of injuries between the standard container, prototype 1, and prototype 2 (Table 5). For the specific injuries scored at the slaughterhouse, there was only a significant treatment difference for bruises on the breast, with 0.41% fewer bruises for prototype 1 (0.53%) compared to the standard container (0.94%) (P = 0.04), and with no difference for prototype 2 (0.87%) (Table 5). No significant difference for DOA was observed among the three treatments (Table 5).

Table 5. Summary of the assessment at the slaughterhouse after catching with the standard container (Standard), prototype 1 (P1), and prototype 2 (P2) of end-of-lay hens at five farms, expressed as mean ± SE

Superscripts (a, b) indicate pairwise significant differences between the columns. Significant P-values (P < 0.05) are indicated in bold.

*Statistical processing of the data was impossible because there was no variation in the data

Discussion

In this study, two new add-on prototypes attached to the drawers of transport containers for end-of-lay hens were compared to the standard transport container (without any add-ons) with the aim of assessing potential effects on the well-being of end-of-lay hens and catchers. Add-on prototype 1 was associated with minor hen welfare advantages (fewer breast bruises compared to the standard type) without indications of a negative effect on loading efficiency in container or catcher opinion. Add-on prototype 2 showed no improvement in loading efficiency in container compared to the standard type and was not favoured by the catchers, and, in fact, was abandoned after trialling on flock 3.

The choice of designing removable add-on prototypes was made in favour of designing an entirely new transport container system. Use of an effective add-on is more cost-effective and easier than conversion to an entirely new system. Moreover, if successful, the add-ons can be quickly manufactured and distributed on a large scale. The focus of the present study was to optimise the loading of end-of-lay hens into containers. Inexperienced (untrained) catchers often struggle to load hens into containers due to them frequently trying to escape from the drawer, thereby increasing the risk of hens’ body parts becoming entrapped. The present study showed no improvement in either the number of escapes from the drawer or prevalence of entrapments of hens’ body parts with either add-on prototype in comparison to the standard container and do not meet important design criteria.

Catching and loading of end-of-lay hens can result in stress, pain and injury. Depopulation of end-of-lay hens can result in 8.1% severe injuries (e.g. bone damage or dislocated joints) (Gerpe et al. Reference Gerpe, Stratmann, Bruckmaier and Toscano2021) and 7.9% injuries (Delanglez et al. Reference Delanglez, Watteyn, Ampe, Segers, Garmyn, Delezie, Sleeckx, Kempen, Demaître, Van Meirhaeghe, Antonissen and Tuyttens2024b). Kristensen et al. (Reference Kristensen, Berry and Tinker2001) mentioned an injury incidence of 2.66%, similar to the outcome of this study (2.7–2.9%). The relatively low incidence of injury in the current study might be linked to the close presence of external observers, which could have influenced the manner of handling (e.g. more gentle handling), although observers were also present in the other studies mentioned.

Moreover, while all hens here were caught by one leg since it is common practice in Belgium, catching by two legs is actually associated with fewer fractures (Gregory et al. Reference Gregory, Wilkins, Austin, Belyavin, Alvey and Tucker1992) and is recommended as best practice (Nielsen et al. Reference Nielsen, Alvarez, Bicout, Calistri, Canali, Drewe, Garin-Bastuji, Gonzales Rojas, Gortázar Schmidt, Herskin, Michel, Miranda Chueca, Padalino, Roberts, Spoolder, Stahl, Viltrop, Winckler, Mitchell, Vinco, Voslarova, Candiani, Mosbach-Schulz, Van der Stede and Velarde2022; Animal Welfare Committee 2023). Therefore, the catching method could affect injuries and ease of loading. Improving catching and carrying methods could influence the study results, but this was not investigated. Only a minor welfare improvement in the present study was observed with prototype 1 (i.e. fewer breast bruises compared to the standard container). For several hen welfare indicators (entrapments, escapes, bruises leg, and DOA) only small numerical differences not reaching significance were observed compared to the standard container. These comparisons have a low power due to the low prevalence and the strong variability in prevalence as the standard error is almost as large as the average. A post hoc power analysis was not performed as more measurements are unlikely to result in significant differences.

The stress that birds generally experience during the catching and loading process can be linked to catchers’ handling, attitude, experience and efficiency (Cransberg et al. Reference Cransberg, Hemsworth and Coleman2000; Kristensen et al. Reference Kristensen, Berry and Tinker2001; Pilecco et al. Reference Pilecco, Almeida, Tabaldi, Naas, Garcia, Caldara and Francisco2013). For hens’ restlessness no significant differences were found between prototypes 1 and 2 in comparison with the standard type. When comparing prototype 1 to prototype 2, the hens were noticeably calmer as confirmed by the catchers’ statements. Loading efficiency of prototype 1 and the standard container was equivalent, and the standard container showed better loading efficiency in container in comparison to prototype 2. Professional catchers indicated (trend) that they preferred prototype 1 over the standard container for the ease of use, possibly indicating a more efficient catching process. Increased efficiency may lead to less catcher fatigue which could result in fewer injured birds (Nijdam et al. Reference Nijdam, Arens, Lambooij, Decuypere and Stegeman2004; Kittelsen et al. Reference Kittelsen, Granquist, Aunsmo, Moe and Tolo2018). In general, catchers aim to complete the catching process as quickly as possible. Inefficiency can lead to frustration and, in turn, harsher handling of the birds (Millman et al. Reference Millman, Christley, Rigby, Dennis, O’Brien and Williams2017; Kittelsen et al. Reference Kittelsen, Granquist, Aunsmo, Moe and Tolo2018). Gentle handling reduces fear, stress and injuries thus improving general animal welfare (Tinker et al. Reference Tinker, Berry, Rycroft and Sparks2004; Cockrem et al. Reference Cockrem, Candy, Castille and Satterlee2010).

In this study, catchers were given limited time to practice with the prototypes. We cannot rule out the possibility that more experience with the add-ons would have affected how the different techniques compared. Effective training and communication can enhance the identification of risks to animal welfare associated with handling procedures (Grandin Reference Grandin2015, Reference Grandin2018; Ceballos et al. Reference Ceballos, Sant’Anna, Boivin, de Oliveira Costa, de L. Carvalhal M and da Costa MJR2018). Although the present study gathered no information about the level of experience of the professional catchers who participated here, they are likely to have carried out the process of catching hens via the standard containers more often than the non-professional catchers. The heavy and repetitive nature of this work makes professional catchers more likely to experience intense discomfort (GAO 2005) with a greater likelihood of developing upper body (Nowell Reference Nowell2001; Quandt et al. Reference Quandt, Grzywacz, Marín, Carrillo, Coates, Burke and Arcury2006; Lipscomb et al. Reference Lipscomb, Epling, Pompeii and Dement2007, Reference Lipscomb, Kucera, Epling and Dement2008) and musculoskeletal injuries (GAO 2005) compared to non-professionals. Their additional experience may result in a broader perspective and a greater likelihood providing an insight into how best to optimise the process.

Prototype 2 was least preferred by the catchers in comparison to both prototype 1 and the standard container as it required considerable force to push the hens through the flaps and position them far enough into the drawer. An advantage of prototype 2 however is that the drawer can remain open continuously, enabling catchers to continue working without anyone standing by the container. A disadvantage would be that the drawer’s dimensions (height) prevent gentle placement of the hens into the drawer. Prototype 2 is therefore not suitable due to a lack of improvement in hen restlessness and no advantage in loading efficiency in container.

Fieldwork offers realistic insights into the use of the add-on prototypes but comes with challenges such as sector reluctance, while controlled testing in semi-commercial settings could better isolate any impact they may have and provide more information regarding the exact impact of add-on prototypes. This paper focused on optimising the loading of end-of-lay hens by designing new add-on prototypes. However, other aspects can influence animal welfare (injuries and DOAs) such as the catching method (Benincasa et al. Reference Benincasa, Sakamoto, Silva and Lobos2020), manner of handling (Zulkifli et al. Reference Zulkifli, Norma, Chong and Loh2000, Bedanova et al. Reference Bedanova, Voslarova, Chloupek, Pistekova, Suchy, Blahova, Dobsikova and Vecerek2007), and the duration of the process (Chauvin et al. Reference Chauvin, Hillion, Balaine, Michel, Peraste, Petetin, Lupo and Le Bouquin2011).

Animal welfare implications and Conclusion

The design of transport containers is crucial for loading efficiency in container, prevention of hen escape and entrapment of body parts, and decreasing the incidence of injuries and DOA in end-of-lay hens. A great deal of effort is being expended to prevent and remedy these problems as they negatively impact the well-being of both catcher and hen. Two add-on prototypes were designed to solve these problems. These simple and cost-effective designs can be easily adapted to fit different containers. Designing an entirely new container is extremely costly and time-consuming. Therefore, add-on prototype 1 could provide valuable and timely improvements to hen welfare and commercial practices. Prototype 2 did not show the desired effects. Prototype 1 showed only a small improvement for one specific animal welfare indicator (fewer breast bruises). However, it is difficult to link the fewer breast bruises directly to the use of prototype 1 because other aspects in the procedure can have an influence such as the catching method and transportation. Furthermore, a tendency toward professional catcher preference based on ease of use and calmness of the hens in comparison to the standard type. In addition, no significant difference in loading efficiency in container and hen restlessness was observed between the standard container and prototype 1. Catcher frustration levels due to inefficient catching or loading may influence their handling of the hens. Prototype 1 shows promise, as evidenced not only by the numerical differences observed but also the interest expressed by one catching company active in Belgium and The Netherlands in adopting this prototype. More testing on a larger scale (e.g. increased practice and familiarity among the catchers) could provide valuable insights into the effectiveness of this prototype and would reveal whether further design improvements are needed to enhance both animal welfare and the well-being of catchers.

Acknowledgements

The authors would like to thank HSA (Grant Application 04: Designing transport containers for more humane loading and transportation of end-of-lay hens to the slaughterhouse) and Ghent University (COVID - PhD scholarship) for financing this project. Our gratitude goes out to Dana De Wart, Dimitri Van Grembergen, Anja Van Havermaet, Freija De Backer, Yara Degrave, Wouter Luyckx, Marijn De Craecker, Niamh Cleiren, Timo De Waele, the participating laying hen farms, catching teams, transporter, and slaughterhouse for their help with the experiments. We also acknowledge Miriam Levenson (ILVO) for English-language editing.

Competing interests

None.