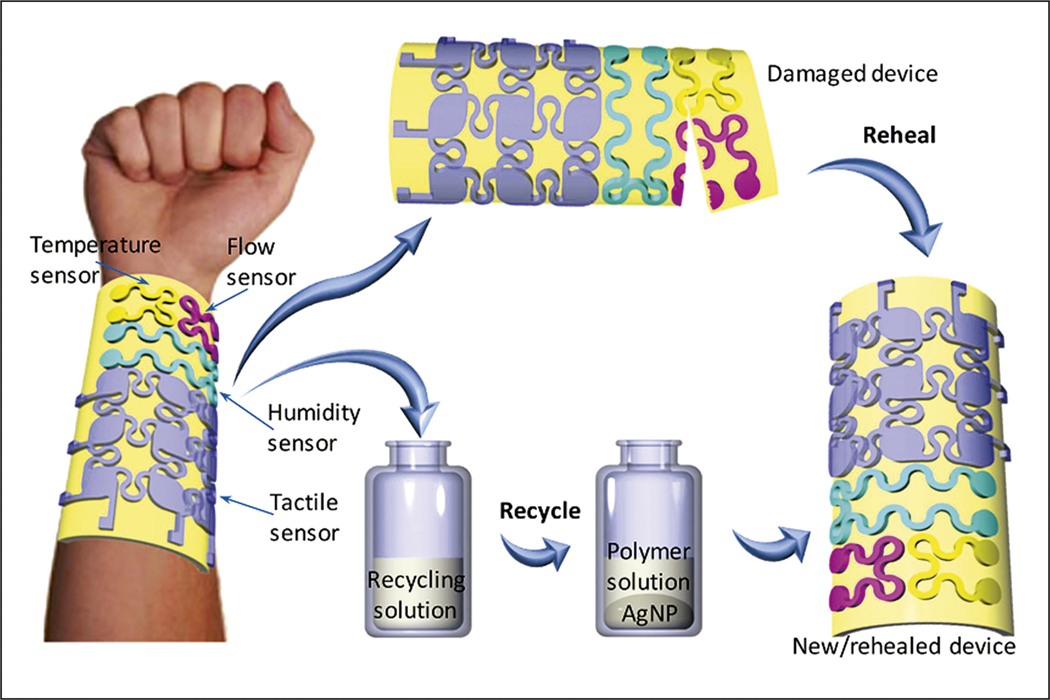

From communications to health care to entertainment, materials research is rapidly advancing to improve the interface between humans and machines, with the aim of shrinking down wearable technology and adapting them to the contours of our bodies. In the process, researchers want to make devices as efficient and inexpensive as possible. Now a research team from the Mechanical Engineering and Chemistry Departments of the University of Colorado Boulder has designed an electronic skin (“e-skin”) nanocomposite that senses haptics (force), temperature, liquid and airflow rates, and environmental humidity. The team leaders—Professors Wei Zhang and Jianliang Xiao—along with co-authors—Zhanan Zou, Chengpu Zhu, Yan Li, and Xingfeng Lei—published their design in a recent issue of Science Advances (doi:10.1126/sciadv.aaq0508).

The researchers used a polyimine polymer as the basis for their bioinspired flexible device and relied on commercially available monomers to produce it. Zhang, Xiao, and colleagues added silver nanoparticles during the synthesis stage to make the polymer electronically conductive, and imprinted specific patterns into the polymer melt to develop functional sensors. The team implemented serpentine-style sensor arrays to minimize any effects of device bending on the received signals. The final production step compressed the material at 80°C under 8.5 kPa applied pressure to fully cross-link the thermoset matrix. The device is flexible and comfortably lays on a human arm or on any rugged surface.

“Polyimine represents a novel type of ‘smart,’ malleable thermoset material,” Zhang says. “It doesn’t require any catalyst to achieve reversible bond formation, and such a unique feature enables the device’s easy processing, self-healing, and recyclability.”

The research team relied on capacitance changes between two arrays to measure haptics (tactile/force impacts) and recorded pressure sensitivity as small as 0.007 kPa–1. Electrical resistance changes were used to measure differences in water currents (up to 10 m/s flow rate) and temperature (0.17%/°C sensitivity). Finally, since humidity from the air diffuses into the sensor and swells its polymer network, relative resistance changes can also track that parameter with a high accuracy (0.22 %/% RH). The researchers tested these sensors in dynamic environments and successfully deconvoluted specific properties from constantly changing surrounding conditions.

A conceptual illustration of the flexible, self-healing, and recyclable electronic skin sensor. Credit: Science Advances.

“This e-skin is sensitive and flexible, so that it can be mounted onto prosthetic hands to provide sensation,” Xiao says. “Another example is to integrate e-skin on robotic arms and fingers, then robots can do many fine tasks like humans, such as holding a baby comfortably.”

The most exciting feature of this device is its ability to repair and regenerate. These sensors may often encounter cuts and abrasions that erode their functionality. The team led by Zhang and Xiao discovered that, once they applied a rehealing solution (a dispersion of the original chemical precursors in ethanol) and heat-pressed the device, polymers regrew across cuts in the device and sealed all broken surfaces. The resulting chemical “stitches” are much stronger than traditional noncovalent bonds that repair fractures, and the performance of the repaired device returned to its full capacity. Multiple cuts and multiple reheals did not degrade performance in any way.

Going even further, the researchers designed a recycling solution that deconstructs the thermoset into short oligomers/precursors and silver nanoparticles. These, in turn, can be used to make new devices with different shapes and functionalities. From start to finish, less than 6 hours are needed to break down an old device and make a new one. This unique capability reduces cost and electronic waste and makes this approach even more attractive.