Introduction

The aim of this paper is to develop a more nuanced account of ferrous arms production in the tenth century Byzantine Empire, particularly the labour investments of manufacturing and transporting large quantities of armaments. The Byzantine administrative document dated to the mid-tenth century, known as De Ceremoniis, forms a foundational pillar of this examination. This document provides a unique opportunity to examine military logistics through a lens not otherwise possible. Chapters 44 and 45 of De Ceremoniis provide detailed information regarding the military equipment required for two Byzantine naval expeditions, the first in AD 911, and the second in AD 949. With regard to military equipment, the records for the expedition to Crete in 949 are slightly more detailed.Footnote 1

One of the primary roadblocks that distances us from understanding the labour and production requirements for armament manufacture is our lack of information about the middle Byzantine blacksmith, namely the technology available, the organization of workshop production, and the labour and skill required in the production of complex iron objects. Within Byzantine scholarship, the production of weapons and armour within an individual workshop has garnered little attention.Footnote 2 Elucidating operating conditions in an individual workshop, both imperial and thematic, is an important factor in understanding overall military logistics in the tenth century.

To build a basis for this examination and address questions of production time and labour investment, a series of interviews was conducted with experienced modern blacksmiths. The intention was to gather information regarding the time required – in hours, minutes, and seconds – for manufacturing various pieces of military equipment, the majority of which are explicitly mentioned in De Ceremoniis. In addition, arising somewhat organically from the interviews and my own experimentation, was a deeper inquiry into workshop arrangement and production organization.

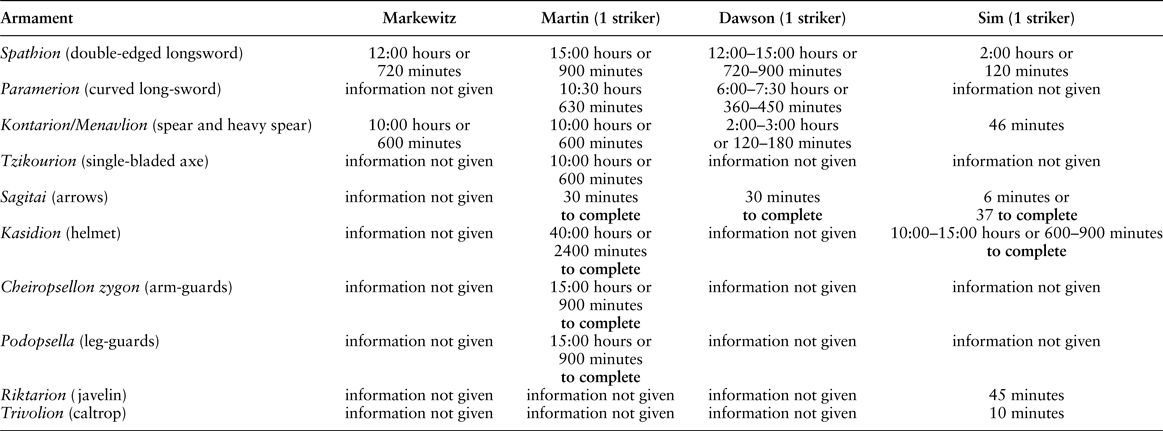

The values provided by the interviewees were expressed in ranges from conservative to liberal estimates. Each artisan had different expertise, methods, and was variably familiar with the specific Byzantine equipment. This variability was reflected in their answers to similar questions and demonstrated a number of factors that determined a smith's ability to produce armaments. Although the specific Byzantine terminology associated with the collection of armaments selected for inquiry may not have been entirely familiar to each individual artisan, they were familiar with their morphology and construction techniques (as best we can currently understand them). For example, Darrell Markewitz, a professional blacksmith and specialist in Norse metallurgy with over 30 years of experience, was familiar with double-edged long-swords similar in size and shape to our current understanding of a Byzantine spathion. This sentiment carried over to other equipment such as spear-heads, as well as splinted arm- and leg-guards.

Robb Martin has been a professional blacksmith for 30 years and has forged an incredible array of arms and armour in the style of various periods. Many of these weapons and armour closely resemble those used by the tenth century Byzantine military, including helmets of the spangenhelm variety, socketed spear-heads, crescent axe-heads, arrowheads, and splinted and tubular arm- and leg-guards. In addition to his range of experience in forging armaments, he has also kept detailed records of the labour involved in each project.

Timothy Dawson has published extensively on the military equipment of the middle Byzantine period contributing to a modern understanding of the technical terminology used in Byzantine sources associated with armaments, their dimensions, and production techniques. In addition, he is an avid recreationist and hobby blacksmith. His combination of practical forging experience and knowledge of Byzantine military equipment made him an excellent candidate for the exploration of labour investments.

David Sim is a Roman experimental archaeologist with over 25 years of experience. Sim has published extensively on the production of Roman military equipment. He is an experienced scholar on the types and construction techniques of Roman armaments as well as a skilled blacksmith and recreationist. His experimentation has been conducted within rigorous parameters in order to produce a set of standardized results.

The ranges produced through the interviews were averaged, and then multiplied by the equipment requirements preserved within the De Ceremoniis, producing simple estimates on the overall time needed to manufacture the listed equipment. These estimates provide a starting point for exploring thematic and imperial production capabilities. It also provides a basis upon which to compare the labour requirements involved in manufacturing and transporting equipment, which ultimately helps to inform our understanding of campaign preparation, and logistical considerations.

Before conducting the interviews, it was first necessary to develop a comprehensive grasp of the technical and sometimes generalized terminology used to describe equipment in the middle Byzantine sources. Part of this process was associating specific construction techniques with sometimes-ambiguous terminology. For example, the terms kasidion (helmet) and cheiropsellon zygon (a pair of arm-guards) used in the De Ceremoniis are sufficiently generalized so as to make it difficult to associate them with historical, archaeological, or artistic examples.Footnote 3 To address this, the armaments chosen for the interviews were based on the frequency at which they appeared in the sources from the early to mid-tenth century, as well as their candidacy for what I refer to as initial production. The designation of initial production is based upon the likelihood that the equipment listed in the De Ceremoniis was being produced specifically for the 911 and 949 expeditions, or simply released from storage. It may have been a more effective use of resources to produce certain items of the Byzantine panoply year-round, rather than in preparation for a campaign. Of the equipment listed in De Ceremoniis, it is doubtful that either mail or lamellar armour was produced solely in preparation for an expedition. As Sim demonstrated, the inordinate amount of time required to produce a full coat of mail would have made it difficult to manufacture in anticipation of a campaign.Footnote 4 Lamellar armour was also extremely labour intensive to manufacture (although much less so than mail), and would have been carried out year round.Footnote 5 Once preparations for a campaign had begun, mail and lamellar coats could simply be released from storage, having been pre-produced throughout the year. It seems rather likely that the production of mail and lamellar was carried out in the imperial workshops rather than by thematic craftsmen due to the complexity of the process (especially regarding mail) and the specialized metallurgical tools required.

Although the setting for this examination is the tenth century Byzantine Empire, the information developed through an investigation into labour investments may help to better understand pre-modern economy on a broader scale. The value of this study is that the methods, and to some extent the results, can be used to assess arms manufacturing in any culture which utilized similar production techniques. For example, using the detailed technical treatises on arms manufacture that exist in the Arab world, in conjunction with the results presented here, a more holistic picture of the Arab arms production industry might be produced. The experimental methodology presented here, though nothing new, is quite adaptable, and might be used in other situations where historic documents provide such fine-grained details as De Ceremoniis.

The cargo of the 949 expedition

The cargo listed in chapter 45 of De Ceremoniis presents two problems for the exploration of labour investments. The first, mentioned above, is that specific styles and construction techniques from tenth century equipment cannot always be reliably associated with the terminology used in De Ceremoniis. The second is that the compilation process that saw the creation of chapter 45 of the De Ceremoniis meant that the lists of equipment are muddled, and the same items appear repeatedly through several sections. Haldon designates the sections of the text, I through VIII: (I) The required personal and artillery equipment, (II) the equipment required from the department of the eidikon, (III) the equipment required from the department of the vestarion, (IV) equipment related to ships and naval tackle, as well as specific numbers of artillery equipment (repeated from I), (V) the costs associated with the required equipment (though incomplete), (VI) various extra hardware required for the expedition – bolts, tar, pitch, and cables – given to the drouggarios of the fleet (admiral), (VII) valuable clothing used as gifts for foreign leaders and deserters given to the drouggarios, and (VIII) another list of items for similar purposes also given to the drouggarios.Footnote 6

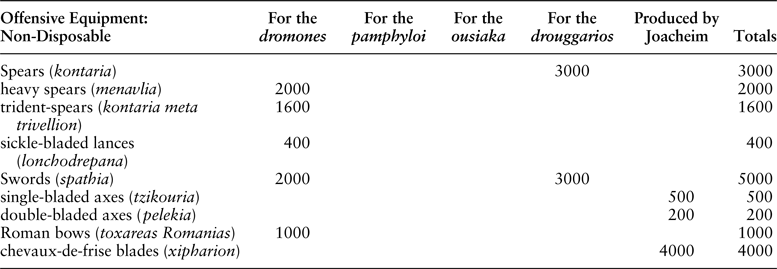

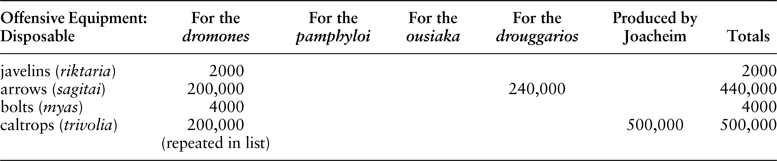

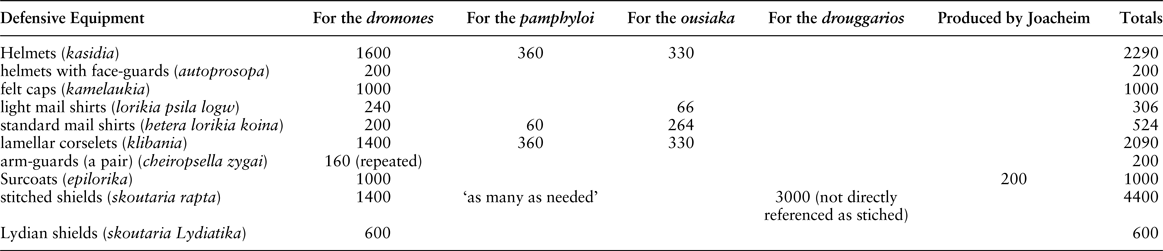

It seems likely that the redactor(s) of these chapters were working with multiple sources of information and copied the lists out several times. Four sections in particular provide the most comprehensive information. The sections are introduced as follows: (1) For the fitting out of 1 dromon (20 sailed to Crete), (2) For the 6 pamphyloi (although 7 sailed to Crete, the equipment for 6 is given), (3) For the ousiaka chelandia (33 sailed to Crete), and (4) What was dispersed from the department of the Eidikon for the Cretan campaign.Footnote 7 One particular section of (4), regarding the equipment given to the drouggarios by the lower armoury, seems to indicate a different set of armaments from those required for the fitting of the dromones. The use of the term menavlia in section (1)Footnote 8 and kontaria in (4)Footnote 9 seems to indicate that these are different lists. Although the majority of this equipment was likely already in storage and was simply released for the expedition, there is a clear indication of initial fabrication specifically for the 949 expedition. Under heading (4), the archon and spatharios Joacheim is tasked with the purchase of charcoal and the production of 500,000 caltrops, 500 single-bladed battle-axes, 200 double-bladed battle-axes, and 4000 blades for the so-called chevaux-de-frise.Footnote 10 After examining the lists in detail and removing the overlapping information, the final tally of required equipment was identified, displayed in Tables 1, 2 and 3.

Table 1. Non-disposable offensive equipment listed in chapter 45 of the De Ceremoniis.

Table 2. Disposable offensive equipment listed in chapter 45 of the De Ceremoniis.

Table 3. Defensive equipment listed in chapter 45 of the De Ceremoniis.

Considerations for arms production

Division of labour

Throughout this paper, production time is measured in both labour hours and elapsed time. Labour hours can be explained as the total number of hours that have been invested into the production of an object; this does not necessarily mirror the elapsed time. Elapsed time represents the amount of chronological time that has run its course from the beginning of production to the end. It is the metric of elapsed time that is most useful in determining how quickly a batch of equipment might be produced. Without understanding and accounting for concurrent activity, it is difficult to arrive at an elapsed time for the overall process. Without detailed technical treatises from the middle Byzantine period, we can only make logical assumptions on how and when concurrent labour was used.

Sim suggests that the optimal workshop organization, or production team, requires five individuals, depending on the size of the forged object.Footnote 11 The first individual was the skilled blacksmith who both participates in and directs the work. The next three were strikers with large sledgehammers whose main purpose was to accelerate the forging process. The final individual, the fire-tender, was tasked with maintaining the forge, powering the bellows, and adding fuel when required. It is certainly also possible that when a commission was received by a workshop, that additional labourers were brought in to complete tasks that required relatively little experience.

Many of these factors change when discussing the imperial workshops, particularly that in Constantinople, which likely drew on a much larger and more highly skilled workforce, due to its centralized location.

Ninth century Arab polymath Amr ibn Bahr al-Jāhiz describes the arms production industry as such,

Before a sword is put on by its wearer or wielded by its bearer, it has passed through many hands and various classes of craftsmen, none of whom can do an other's work or excel in it, and indeed would not claim or undertake to do so. For the man who smelts and refines the metal of a sword is other than the one who draws it out into shape; the latter is other than the one who forges it, smoothes the broadside, and adjusts its blade; the latter again other than the one who quenches and sharpens it. Yet another man fits its pommel and rivets the tang in; the one who makes the studs for the tang, the pommel, and the blade is different from the one who carves the wood of the scabbard, and he from the one who tans the leather for it, and the latter from the one who decorates it; and the one who decorates it and fits its tip is different from the one who pierces the holes in its carrying-straps.Footnote 12

In the case of a sword, while the wood, leather, and rivets for assembling handles may have been produced in a separate workshop, it is likely that the final assembly was carried out in the same workshop responsible for the primary forging (referred to here as the primary workshop). The time required to manufacture the handle components would have been significantly less than that required for producing a sword. It would thus make logical sense for the handle components to be manufactured and transported to the primary workshop. The difficulty in transporting iron objects in contrast to wood and leather would have also made it more effective to bring the component pieces to the primary workshop.

This formula is certainly not concrete, and there are several examples of equipment where a different method of production may have been used. In cases where the component pieces required a similar or greater labour investment to the iron elements, it may have been a more effective use of resources to transport the iron components. For example, it is possible that the production of fletched arrow-shafts would have been a greater labour investment than the production of arrowheads. Similarly, the time required to produce a spear shaft might have been longer than that required to produce a head. The orders recorded in the De Ceremoniis do not explicitly reference the use of multiple workshops for the production of separate equipment components, although it does not seem likely that individual thematic workshops would have the resources to carry out each individual trade – leather tanning, wood sculpting, forging – simultaneously. What we have preserved in the De Ceremoniis might thus be the initial commission, which would have been taken by the strategos or another thematic official and broken down amongst a number of workshops on a more localized scale. These are details that are highly speculative and based simply upon logical assumptions rather than any specific evidence. It seems most likely in the context of the tenth-century Byzantine Empire, especially in the themes, that the process of arms manufacture was carried out within a single workshop, with some components being produced elsewhere.

Use of strikers

The use of strikers was one method utilized in the ancient world to increase the efficiency of forging, a very physically demanding discipline. The role of a striker was not one that required extensive experience or skill, but physical fitness and the ability to follow directions. The hammer blows of the striker(s) were directed by the skilled smith who struck the metal in the area he wished to be manipulated. The striker(s) would swing in time with the skilled smith's blows as well as those of their fellow strikers. Since strikers were only needed for the portions of the project that required large quantities of iron to be moved, they could fulfill other roles while the smith was completing tasks of greater expertise. These could include cutting and forging billets into more manageable bars, producing the accoutrements for arms (quillons, pommels, handle components, and pins or rivets), as well as assembling and finishing equipment.

The use of strikers is an important consideration when assessing forging time. The general consensus when discussing the topic of strikers with modern blacksmiths was that each striker had the capability to increase the speed of production by approximately 30%. It is difficult to evaluate how and when strikers were used, especially when considering the diversity in skill and resources of craftspeople across the empire from which the state was extracting labour. If any standardization was maintained it was more likely to have been in the imperial armouries, where control over manufacture could be more closely regulated. The biggest limiting factor in the use of strikers was the size of the project. Larger armaments, such as swords, might afford the use of up to three strikers. In contrast, the use of multiple strikers would be ineffective with objects as small as arrowheads or caltrops. The figures provided in the following tables by Dawson, Martin, and Sim were contingent upon the use of a striker, while those of Markewitz were not.

The three-stage process

The basic model of weapon production can be segregated into three primary stages. The three-stage process is a general outline, and the individual experience and forging techniques of each smith interviewed did not necessarily reflect this style of manufacture; there is no single correct way to produce an armament. The variability that arose when assessing modern interpretations of manufacturing processes is further exacerbated when examining ancient metallurgical traditions. Without fully understanding the morphology of equipment and the techniques used in their manufacture, we cannot be sure that their production followed the three stages identified below. For example, a sword of composite construction, i.e. one that has been forge-welded, is manufactured differently than a sword produced from a single bar. With this variable nature in mind, the three stages that I have chosen to use as a rough outline are as follows:

The first step in this process, referred to here as barsmithing, is to forge a suitable bar for the current project. Depending on the dimensions of the final product, this can be an onerous process that requires large quantities of iron to be manipulated. Although it may be laborious, forging blanks does not require extensive smithing experience, and can be done effectively by newcomers to the trade. It is this stage in the process that would likely have had the least effect on the overall elapsed time of the project. This is due to the low relative skill involved in barsmithing, and the ability for a workshop to pre-produce many suitable bars concurrent to other activities.

The second step is to forge the object itself from the bar, whether that is a sword, spear, or axe. The techniques involved in forging complex iron objects (i.e. forge-welding, pattern-welding, beveling, fullering, quenching, possibly tempering, and straightening) require proficiency as a smith, and thus are only effectively carried out by an experienced blacksmith.

The final step is that of finishing. The finishing stage requires grinding, polishing and assembling the weapon. The skill required to finish a weapon is relatively low and could be carried out by a semi-skilled cutler concurrently with the complex forging carried out by an experienced blacksmith.

The production of armour can be segregated into similar stages, although there is larger variability in manufacturing techniques due to the diversity of armour styles utilized in the tenth century (lamellar, mail, splinted-bronze or wooden greaves).Footnote 13 Since the production of iron helmets of the spangenhelm variety, as well as tubular and splinted iron arm- and leg-guards most closely resemble the stages in production of weaponry, they feature most prominently in the current research.Footnote 14

The first stage in the production of a spangenhelm involves forging suitable bars for the frame and modular panels of the helmet.

The second stage involves forging the frame of the helmet and hammering out a series of thin metal sheets for use as panels. These panels are then shaped to fit within the frame.

The final stage involves riveting the protective iron components of the helmet together, together with leather fittings within the helmet, and finally grinding and polishing. The production of splinted arm- and leg-guards follows similar stages.

The three-stage process was simply a heuristic tool that allowed me to display the interview results in a manner that most logically corresponded to the efficient production of arms. As a result of the individual experience of each interview candidate, some of the answers provided did not incorporate such segregation. For example, the production time of an arrowhead was not often given in a three-stage process, but as a total time to completion. Those instances, where a total time of completion was given, are marked in Table 4 as: to complete. This made it difficult to assess which stages in production may have run concurrently. Such is the downfall of a method that incorporates modern opinions of ancient practice. Nevertheless, it reflects the inherent variability in individual blacksmithing styles, corresponding nicely with the variability that could be expected when extracting labour from thematic artisans throughout a large geographic range.

Table 4. Figures given for the production of equipment by the interviewees. Those labelled to complete, refer to those in which a figure is given for the entire process rather than solely object fabrication.

When considering all of the steps that are involved in the production of equipment, the one that appears to most reliably define the speed at which an order could be completed (the elapsed time), is the second stage of manufacture, the skilled component of forging. Although the process of finishing required the largest investment in time and labour, it required significantly less skill, and could be effectively carried out by strikers or other labourers. Estimates from experimentation and personal communication with the interviewees suggest that finishing time is often two to three times longer than that of initial fabrication (the first two stages of the process). This is corroborated by personal experimentation as well as that carried out by Sim (in Sim's case, it is significantly longer than the first and second stages).Footnote 15

The degree of finishing on any particular weapon largely determines how long this process takes. In the case of mass-produced munitions swords, it is unlikely that equipment was finished to a high degree, and so this figure is likely inflated within the context of the records of the De Ceremoniis. It may have been the case that finishing was exceptionally crude, although without many archaeological examples to draw from, this is entirely speculative. Nevertheless, the finishing time is a significant metric that cannot be ignored when discussing overall elapsed time.

Despite the significant time required to finish a weapon to a high degree, I believe that the skilled manufacturing stage still represents the most reliable metric for the purposes of determining production speed. In the case of each interviewee, it was assumed that a single craftsman carried out the finishing step in a linear process, after the first two stages. When the finishing steps are divided amongst a group of individuals or possibly even workshops (i.e. production of handle components, scabbards, grinding, polishing, and assembly), the time required to finish equipment decreases significantly.

It is also likely that care was taken by the skilled blacksmith during the second stage to remove as much excess material as possible and leave the surfaces as flat as possible, so as to reduce the amount that had to be removed during grinding and polishing. From personal experimentation, a reliable but rough finish can be applied to an object as large as a spathion in several hours, and much quicker with weapons such as axes, spears, caltrops, and arrowheads.

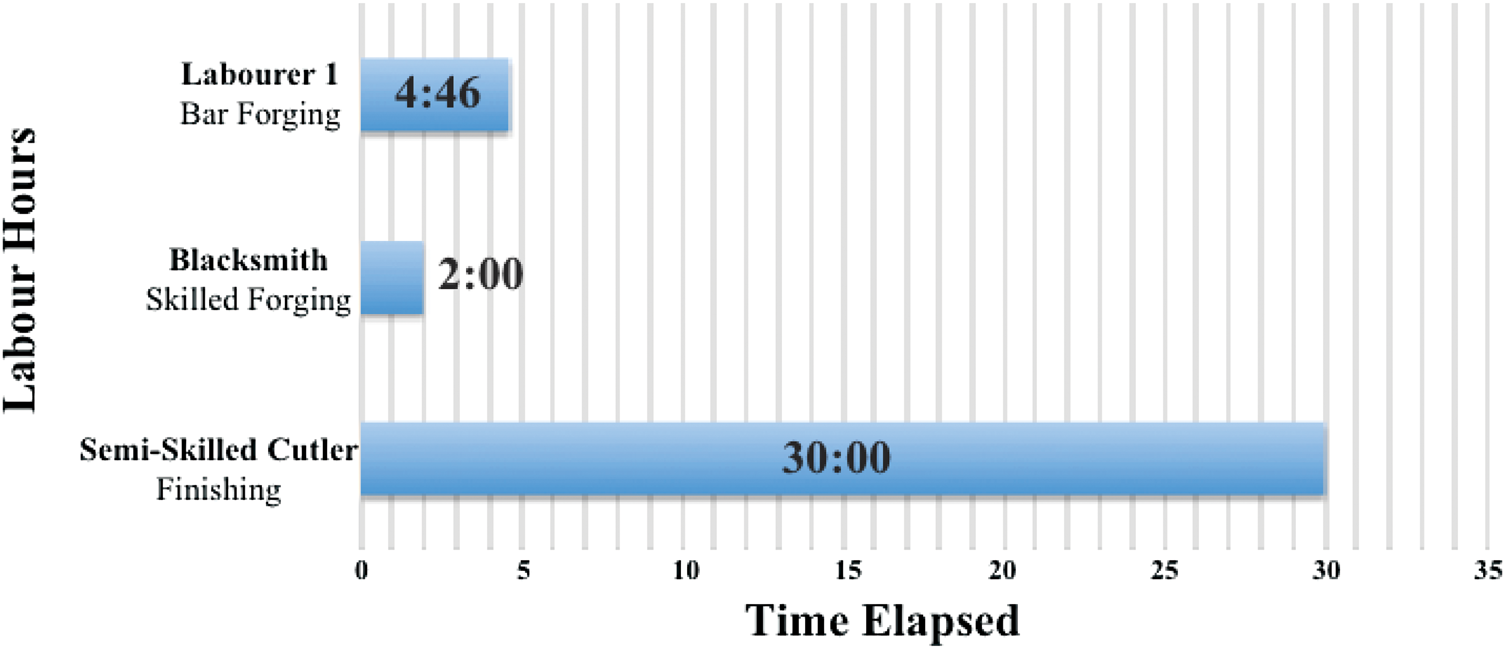

Figure 1 displays how a workshop might have multiple operations running concurrently. This chart assumes that a bar had already been forged for the skilled blacksmith to work with. It also assumes that a forged sword blank was ready for finishing by the cutler.

Fig. 1. Concurrent labour hours over a 35 hour period for the production of a gladius based on Sim, Roman Iron, 94.

Results and analysis

It is important to note that the results produced through these interviews are estimates. Concrete numbers are very difficult to achieve due to the number of variables that may affect a process as complex as state-wide arms manufacture (i.e. the variable skill and resources of blacksmiths throughout the empire). The purpose of this study is to take a step towards better understanding the Byzantine arms production industry and provide a basis upon which to begin this examination.

The values represented in Table 4 constitute the labour-hour estimates provided by each of the four artisans interviewed on the forging time of the selected equipment (Dawson, Markewitz, Martin, Sim). This represents stage two of the manufacturing process and excludes the hours involved in barsmithing and finishing. Several instances where the values provided represent total time investments, including barsmithing and finishing, are indicated as to complete. The opinions of the participants were built upon an identical set of information provided to each on the morphology and dimensions of the armaments, as well as the technology available to the Byzantines (excluding Sim's figures, which are based on early Imperial equipment). The answers were largely contingent on the familiarity of each smith with the selected equipment, as well as his own experience with forging arms, which predictably produced a range of opinions.

The figures provided by Sim for the skilled portion of forging immediately stand out as being an outlier, significantly lower than those of the other participants. A look at the parameters that guided Sim's experimentation may better explain his results, ‘All items were made as if they were mass-produced. The items had to be produced in the minimum amount of time and with minimum fuel consumption.’Footnote 16 This illustrates his desire to recreate what he believed would be the most efficient and effective way for a workshop to produce armaments. It should also be noted that the blade of a Pompeii type gladius – that which Sim's reproductions were based upon – measures anywhere from 42–50 centimetres.Footnote 17 According to the Sylloge Tacticorum Footnote 18, a spathion should be no less than 4 spans without the handle or approximately 60–76 centimetres (40–45% larger than the blade of a gladius).Footnote 19 This helps to explain why Sim's figure is such a significant outlier. Regarding arrowheads and caltrops, Sim states that only caltrops were work-hardened.Footnote 20 There is some evidence to suggest that Byzantine arrowheads may have been work-hardened.Footnote 21 Although work-hardening does not require a significant amount of time or labour, an incremental increase in the time required to manufacture a single object is amplified when considering the mass quantities of equipment recorded in the De Ceremoniis.

Sim's figure of two hours for the skilled component of gladius forging using a single striker fits well with the limited evidence that exists for fabricae in the late Roman period. One fragmentary papyrus (P. Berlin 6765) dating from the second or third century records the armaments produced in an Egyptian fabrica over the course of two days.Footnote 22 The text records the completion of ten swords on the first day, although it does not indicate whether their fabrication had begun on the same day of their completion.Footnote 23 Applying Sim's value of two hours, and assuming a ten-hour workday, this would allow for a single skilled blacksmith to produce five sword-blanks per day, although this is a liberal estimate and does not account for the human element and the intense physicality of this work.

Since this establishment had a workforce of up to 100 individuals (milites legionari, immunes, cohortales, galliarii, pagani, and custodiae), then a figure of ten swords per day is not unreasonable, although that is contingent upon the assumption that labour was sub-divided and carried out concurrently.Footnote 24 The completion of ten swords in one day also suggests a much lower figure than 30 hours for finishing. It is unlikely that these swords were finished to the degree demonstrated by Sim in his experimentation.

Simon James suggests a mode of production within the fabricae where a single craftsman was responsible for each stage of equipment manufacture.Footnote 25 Based upon personal experimentation, as well as that carried out by Sim, the process for a single craftsman to produce a sword with the use of a single striker – from barsmithing, to weapon manufacture, finishing, and assembly – requires approximately 40 hours of labour.Footnote 26 The production of ten swords in one day, as suggested by P. Berlin 6765, simply would not be possible with the mode of production suggested by James. This, at the very least, demonstrates that concurrent labour may have been an important factor in the operation of fabricae. It is also relevant to note that this particular fabrica was not a small establishment and had significant capabilities for armament production. Although there is no indication as to the size of the workforce or methods of production employed in the imperial armamenta of the tenth century, we might postulate that they had similar capabilities. We might also speculate that a centrally located fabrica such as that in Constantinople, which had appeared by 539,Footnote 27 and continued operations into the tenth century, might have had a larger production capacity than a provincial fabrica.

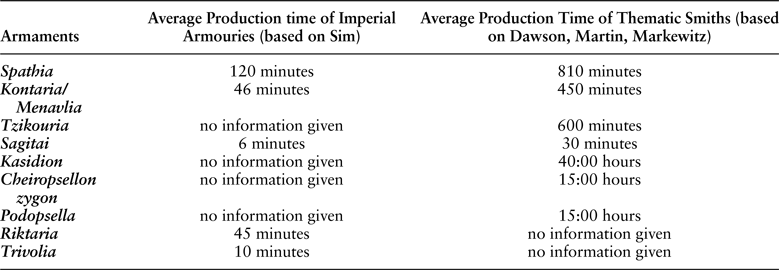

In contrast to the more industrialized production of armaments displayed in Sim's experimentation,Footnote 28 the figures provided by Dawson, Martin, and Markewitz more closely resemble ‘one offs’, where increasing efficiency and reducing labour investments were not necessarily the primary motivation. The figures provided by Dawson, Martin and Markewitz might better adhere to the circumstances of a thematic artisan tasked with producing single batches of armaments at irregular intervals.

The figures developed through the interviews confirmed some of my speculations and entirely confounded others. It was no surprise to me that a spathion would prove the most difficult and labour intensive to produce. What I did not expect was that a similarly sized paramerion could be produced at a significantly quicker rate. This is due to the beveling process, one of the most labour intensive elements of sword-forging. The technique requires the smith to hammer a bevel along the entire edge of the sword blade. In the case of a spathion, four edges required beveling, while the paramerion only required two. This effectively halves the labour required to forge this style of sword when compared to a double-edged blade. Beveling along only one edge also naturally produces a curve, which may have been a characteristic of the paramerion. If ease of production was the primary focus of sword making, then one might expect single-edged curved swords to appear more prominently throughout history. The prolific use of double-edged swords throughout history suggests that two edges provided a significant benefit for the increased labour implications.

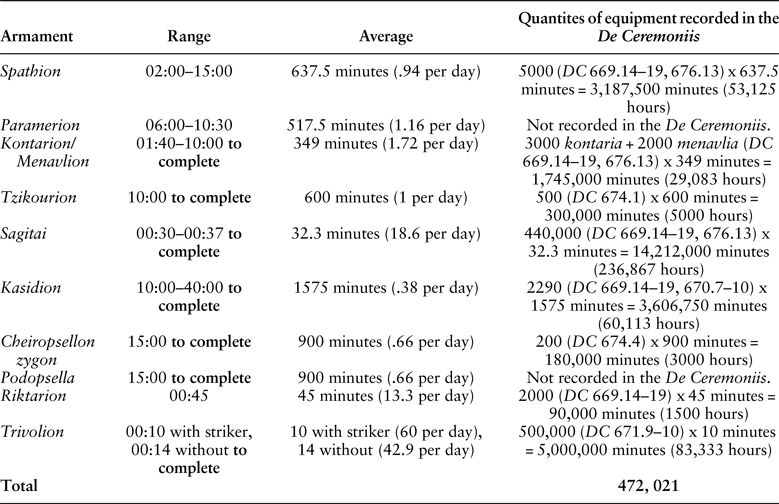

Table 5 displays the range and average production times of the selected equipment based upon the information provided in the interviews. Where ranges (i.e. 12–15 hours, or 720–900 minutes) were given, the average of that range was used (i.e. 13.5 hours, or 810 minutes) to calculate the total average between the participants (for the spathion: 120 + 720 + 810 + 900 = 2550 / 4 = 637.5 minutes). This figure represents the average time required to forge each piece of equipment. In the final column, these values were multiplied by the quantities of equipment listed in the De Ceremoniis. The final value, represented in both minutes and hours, is the total accumulated labour hours for the forging of each piece of equipment (excluding barsmithing and finishing times). These figures allow us to estimate, as accurately as possible, the time elapsed in the production of this particular collection of equipment for the 949 expedition.

Table 5. Range and averages of the figures provided by the interviewees. Column four multiplies these averages by the quantities of respective equipment recorded in the De Ceremoniis. A figure for the total number of hours invested is represented in the final row.

Also displayed in Table 5 is the total value of accumulated elapsed time for the production of the selected portion of equipment. Producing an accurate figure for the overall blacksmithing population in the tenth century is simply impossible without detailed occupational records. Likewise, producing an accurate figure for the population of the empire in the mid-tenth century presents almost insurmountable difficulties. Estimates range from nine to nineteen million from the mid-tenth to early eleventh centuries.Footnote 29 If there was a population anywhere from nine to nineteen million people living within the borders of the Byzantine Empire from 959–1025, then 1, 100, or 1000 blacksmiths represent a diminutive portion of that population. A significantly larger percentage of the overall population must have been involved in smithing practices (although only a portion of this population would be involved in arms production, and through a process that remains unclear, select workshops must have been sanctioned by the state to produce arms), particularly since iron was so closely woven into the fabric of middle Byzantine society, and was present in virtually every industry; the prolific discovery of metal artifacts and production waste at Byzantine sites attests to this fact.Footnote 30 The figures of 1, 100, and 1000 were chosen as arbitrary values as a basis for beginning this examination, because we simply have no indication as to the size of the workforce employed by the state. Instances in the De Ceremoniis that refer to equipment orders given to specific themes provide a measure of information with which to assess production capability. Based upon the figures in Table 5, just over one year was required for 1000 blacksmiths to complete production on this small portion of the cargo recorded in the De Ceremoniis.

Table 6 displays the number of days required – based upon a ten-hour workday and 365-day work year – to produce the selected equipment. For example, a single blacksmith would require 5312.5 days, or approximately 14.5 years, to complete 5000 spathia. One hundred smiths were able to complete this task in 53.1 days. For 1000 blacksmiths, 5.3 days would be required to complete a requisition of this size. The figures represented in Table 6 have interesting implications for the production of arms throughout the empire: if the time-to-completion of an armament commission could be deduced from the sources, then using these figures we may begin to assess the necessary manpower required for completion and begin to guess at the production capability of the themes. The time that had elapsed from the beginning to the end of an order is not clearly stated in the text. This likely fluctuated depending upon the size and type of equipment produced, and so becomes difficult to estimate with reasonable accuracy.

Table 6. Based on the average production times of Table 5, the elapsed time from the beginning of the order to completion. This is based on a 10 hour work day.

The mass quantity of disposable weaponry produced for the expedition appears to have represented the largest labour investment. This seems counter-intuitive as disposable weapons would not often have been recovered and thus had to be re-manufactured once expended. This may have been the case with the 949 expedition, as the De Ceremoniis records that 500,000 caltrops were to be produced specifically for this expedition.Footnote 31 Arrowheads constitute over half of the labour required for the entire cargo (50.2%, 236,867 hours). This may be inflated due to the manner in which the information was presented (i.e. to completion), and with the division of labour and concurrent processes, the overall speed would increase. Using Sim's 5-minute figureFootnote 32 for skilled forging, this reduces the overall time by a significant measure (7.8%, 36,667 hours). There is some evidence to suggest that Byzantine arrowheads may have been work-hardened and, although not a significant labour investment, it still must be considered.Footnote 33 Caltrops also represent a significant labour investment (17.7%, 83,333 hours).

A second-century passage preserved in Justinian's Digesta Footnote 34 provides some interesting insight into the importance of various trades.Footnote 35 The excerpt discusses a group of immunes who are exempt from regular onerous tasks so that they may focus their time on their specific craft. Among the crafts listed, with specific references to armaments, are arrow-makers, sword-smiths, helmet-makers, and bow-makers. These craftsmen may have been acknowledged for the significant labour implications of their craft or the skill that they possessed.

Table 7 presents an alternative method of organizing the information provided through the interviews. The drastically smaller production time frames offered by Sim through his experimentation might be a better indication of the production capabilities of an imperial armoury. In contrast, the ‘one-off’ circumstances of Martin, Markewitz and Dawson might better reflect the production capabilities of thematic blacksmiths producing military equipment at irregular intervals. Therefore, it might be useful to separate the information provided by Sim as an outlier. If we isolate the equipment produced in the themes and the equipment produced in the imperial workshops and apply the separate data sets to the respective production method, some interesting comparisons can be made. The text clearly demarcates that the production of 200,000 arrowheads and 3000 menavlia was to be carried out in thematic workshops. The average production time of an arrowhead using the ‘thematic averages’ is 30 minutes. To produce 200,000 arrowheads would therefore require 100,000 hours, 100 working days for 100 smiths, or 10 working days for 1000 smiths. To produce 3000 menavlia based on the average of 7.5 hours would have required 22,500 hours, 22.5 working days for 100 smiths and 2.25 working days for 1000 smiths. Undoubtedly, the largest consideration with regards to the accuracy of these estimates is the number of thematic blacksmiths available for the production of these armaments.

Table 7. Average production time of imperial armouries and thematic workshops.

Conversely, since Joachim of the imperial armouries received payment to produce 500,000 caltrops, we might assume that these were produced entirely within the imperial armouries. If this was the case, then this might take 100 craftsmen (the size of the workforce mentioned in P. Berlin 6765) 83.3 working days to complete (83,333 hours).Footnote 36

Thematic production capability

Several examples that may hold some significance in determining the production capabilities of thematic workshops are found in chapter 44 of De Ceremoniis regarding the expedition in 911 to the Syrian coast.Footnote 37 One passage records a requisition given to the krites of the theme of Hellas for the manufacture of 1000 menavlia. The passage goes on to state that the first commission was completed, and another batch was required of the same theme. No time frame is given for the length of time that elapsed from the beginning of the first commission to its completion. However, we can estimate that 1000 menavlia would take approximately 5816.7 hours to complete. If 100 smiths worked 10 hours per day, this might take approximately 5.8 days to complete. Alternatively, it might take 1000 blacksmiths just 5.8 hours. These figures do not include the time required to distribute information to the chosen thematic blacksmiths or transport the finished equipment to a central location or provincial rallying point.

Another passage that may prove significant in determining the production capabilities of the themes comes from the same passage in which several other orders are noted.Footnote 38 Thessaloniki, Nikopolis, and the themes of Hellas and the Peloponnese each undertook the production of 200,000 arrows and 3000 menavlia. As a total sum, this would be 800,000 arrows and 12,000 menavlia, a significant quantity of equipment. To produce 800,000 arrowheads would have required approximately 430,667 labour hours. One thousand blacksmiths would require approximately 43 days to complete this batch. If we assume that each theme was contributing a quarter of the labour required concurrently, then the process would take only 10.75 days. To produce 12,000 menavlia would have taken 69,800 hours. This would take 1000 blacksmiths 6.98 days to complete, or 1.75 days if manufactured concurrently. In the case of arrowheads, I believe this number is once again inflated, a result of the manner in which the information was presented during the interviews. If barsmithing and finishing both occurred concurrently, then a much lower number could be expected. However, this does not account for the production of arrow-shafts and fletching, which may have represented a larger time investment than the arrowhead itself.

Equipment transportation

There are a multitude of reasons why Thessaloniki, Nikopolis, and the themes of Hellas and the Peloponnese may have been chosen as production zones, i.e. pre-existing production infrastructure, reliable transport routes, or access to raw materials. It is likewise possible that equipment was manufactured in areas occupied by larger thematic military populations, able to transport equipment when marching for campaign. Text B of Haldon's Three Treatises dating to the tenth century details a system in which the strategoi were responsible for assembling the equipment required for an expedition (although other officials are sometimes mentioned in this role).Footnote 39 The aplekta, managed by the protonotarioi, were used as storage centres for amassing equipment and supplies along the expeditionary route.Footnote 40 When an army passed through the designated region, the equipment could be picked up and carried by the soldiers and their baggage train. Alternatively, thematic units may have visited local aplekta and gathered supplies and equipment before heading to an expeditionary meeting point that was, in the case of the 949 campaign, probably Constantinople.Footnote 41 It is likely that the preparations for each campaign played out in a slightly different manner, and thematic production zones were chosen at least partially based upon their access to reliable transportation.

It is unclear who was in charge of localized transportation from the producing workshop to the aplekta. It is possible that this was carried out under the jurisdiction of state officials (possibly the krites in the example regarding the Hellas theme). If the transport of equipment was overseen by the workshops producing it, the state was largely relieved of this burden. Was the state then involved in providing the equipment necessary for transport, such as wagons and beasts of burden to pull them? Alternatively, did the state only select those workshops with access to the necessary transportation equipment for the movement of armaments? Many of these factors remain unknown, although one can speculate that the state would have ensured it maintained favourable circumstances.

Some interesting comparisons can be drawn, based on the timeframes presented in Tables 5 and 6, between labour requirements for equipment production and time-spent itinerant. Regarding the expedition to Crete in 949, De Ceremoniis does not explicitly state where the majority of the equipment was produced. To illustrate the difficulties involved in equipment transport, the aforementioned passage from chapter 44 of De Ceremoniis, regarding the 911 expedition, will be used. The text states that a production order of 1000 menavlia was sent to the krites of the Hellas theme. The passage continues, confirming that the initial 1000 had been completed and another 1000 were required.Footnote 42 We will assume that the ultimate destination of the equipment produced in Hellas was Constantinople. We will also assume that the aplekton used to aggregate the equipment was located in or near Larissa – a city somewhat centralized within Hellas (the passage states in regards to its destination, “wherever had been agreed”).Footnote 43 It should be mentioned that there are no aplekta recorded for Hellas in the sources from the tenth century, although unspecified localized distribution centres must also have existed.Footnote 44 Regarding the 911 expedition, it is not definitively stated from where the expedition launched – as is the case with the 949 expedition – and it is certainly possible that the equipment was aggregated not in Constantinople, but elsewhere, or carried by thematic units to a rally-point closer to the theatre of battle. This example then is used only to provide some comparison of production and transportation timeframes.

These figures will be compared using two methods. The first, utilizes ORBIS (http://orbis.stanford.edu) to create basic travel timeframes. The ORBIS calculations indicate that the transport time is greater by both ox-cart (752 kilometers at 12 km/day = 62.7 days) and open sea (972 kilometers at 72 km/day = 13.5 days) from Larissa to Constantinople, than the overall production time for 1000 menavlia, produced by 100 blacksmiths (5.8 days). In fact, the values produced through the interviews indicate that 10 blacksmiths could complete the order of 1000 menavlia in a similar amount of time – approximately 58 days – to that spent in transport. There are numerous factors that may affect this interpretation; the speed of completion was determined by the number of blacksmiths available to produce the equipment. The rate at which the animals moved was largely dependent on seasonal pasturage, road conditions, and topography. Travel was favourable by both open sea and road in the spring and summer months, when sailing conditions were more stable and access to pasturage was plentiful. This would reduce the need for pack animals to carry dry fodder, and thus increase the quantity of equipment that could be transported.

The second method uses Haldon's figure of approximately 19–22 kilometres per day for the average travel rate of a unit composed of infantry and cavalry. A similar result is produced using this metric and demonstrates once again that transportation time largely overshadows production time.Footnote 45 The journey from Larissa to Constantinople might take a thematic unit anywhere from approximately 33.6–39.2 days. This is still significantly longer than the 5.8-day production speed of 100 smiths. I believe it is significant that in both of these instances the time spent in transport seems to largely overshadow the time spent in production and provides a lens into the statewide considerations necessary when organizing mass armament production and distribution.

Observations on transportation methods

The significant weight of ferrous arms in the large quantities described in the De Ceremoniis would have posed some logistical challenges for transportation. Although pack animals, such as mules and horses, were able to carry some equipment, they prove slow and inefficient in regard to rate of travel. Packing and unpacking the animals over long journeys would also have required significant effort. It is reasonable to suggest that wagons may have been the most efficient means of terrestrial transport, in terms of speed, quantity of equipment transported, and human exertion (unstrapping the wagon from the animal, as opposed to unpacking the animal's load). Naval transport was undoubtedly the most effective means, although not without its own limitations (i.e. danger of winter travel, access to ports).

Based upon personal experimentation, a figure of 1 kg for a spathion seems a reasonable estimate. With that figure in mind, one pack-mule might be able to carry 85 spathia. If we assume that all 5000 spathia mentioned in the lists of the De Ceremoniis required transportation to some centralized distribution point, then approximately 59 pack-mules would be required to transport this load.

The method of storing equipment while itinerant must also have been a consideration, and the morphology of some equipment would have made it difficult to transport. For instance, spears, swords, and arrows could be bundled and stacked fairly effectively and transported on a pack-mule, horse, or wagon. Caltrops, however, due to their four sharp tines, may have proved more difficult. A leather or textile sack would probably prove ineffective at holding caltrops as the tines were intended to pierce leather and flesh. A crate might be the best option for transporting such weapons. If so, how many caltrops could fit within one crate, and how many crates on a wagon?

It is possible that the state alleviated the burden of transporting some items of equipment by centralizing their production. Those caltrops recorded in the De Ceremoniis represent one of the few instances where the initial production of equipment is explicitly referenced. The text seems to indicate that all 500,000 caltrops were to be produced within the imperial armamenton, probably located in Constantinople, rather than released from storage for the expedition.Footnote 46 It may be that the difficulties of transporting caltrops meant that it was a more effective use of time and labour to produce them in a central location, rather than order their production from thematic artisans. Rust must also have been a consideration over long journeys, and periods of extended storage. Iron objects, and particularly small iron objects such as caltrops or arrowheads, may have fused together with oxide in a matter of days if left exposed and untreated.Footnote 47

Ignoring the issue of morphology and assuming that a pack-mule was able to transport caltrops without problem, then some interesting figures can be produced. Utilizing Sim's figure of 18 g for a reproduction Roman caltrop,Footnote 48 then a pack-mule would have been able to carry a load of up to 4750 caltrops, a total weight of approximately 85 kg (the carrying capacity of a pack-mule minus its saddle, not accounting for dry fodder).Footnote 49 This would mean that just over 100 pack-mules would be needed to transport a load of 500,000 caltrops. These figures should be used only as simple guidelines to help understand the implications of transporting mass quantities of military equipment.

Conclusions

It has been the aim of this paper to begin to take steps towards better understanding arms production in the middle Byzantine period. My aim was to highlight an area of scholarship that has been neglected and create some interest in pursuing the topic further. In addition, some significant information can be drawn from the current research that helps to advance our understanding of military logistics in the tenth-century Byzantine Empire. The first deals with the production time of various pieces of equipment. These figures not only served as the basis for the current examination but can also be used as ballpark estimates for a variety of different historical settings. This includes the contemporary Arabs, Vikings, Avars, and Western European cultures. The second deals with thematic production capabilities. Although there is still much to learn about how the arms manufacturing industry operated and how it was administered, we can now begin to discuss the production capabilities of the themes, and the number of blacksmiths that may have been utilized by the state. Finally, we can begin to compare the time requirements of equipment manufacture to those of equipment transportation and form reasonable conclusions on expeditionary preparations and considerations.

There are certainly limitations to the present methodology. Without fully understanding workshop organization, manufacturing techniques, state administration of arms production, and the size of the imperial and thematic workshops, any conclusions are based upon logical assumptions rather than specific evidence. Regardless, the value of examining these unknowns is not diminished.

Jordan M. Dills holds an M.A. in Anthropology from Trent University. His research interests include, on a broad scale, Byzantine military logistics and the production and distribution of weapons and armour, as well as the use of the sling in Classical warfare. In addition to his research, Jordan is an experienced field archaeologist. He is currently working as an Archaeological Inventory Officer for the Province of British Columbia, Canada.