1. Introduction

Contemporary consensus within the scientific community highlights the need for a green industrial transition to align with the sustainable development goals delineated by the United Nations (United Nations General Assembly 2015). The concept of circular economy emerges as one of the most promising strategies in this pursuit (Corona et al. Reference Corona, Shen, Reike, Carreón and Worrell2019). The circular economy can be defined as “a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible, (so that) the life cycle of products is extended” (European Parliament 2023, p. 1). The circular economy relies on the concept of decoupling economic growth from resource use through the reduction and recirculation of natural resources. Manufacturing companies are currently investing time and resources to clarify the fundamental criteria for measuring circular economy efficacy and to develop methodologies for the simultaneous development, integration and commercialization of circular and economically viable products and solutions (e.g., EASAC 2016; Linder et al. Reference Linder, Sarasini and van Loon2017; Kalmykova et al. Reference Kalmykova, Sadagopan and Rosado2018; Moraga et al. Reference Moraga, Huysveld, Mathieux, Blengini, Alaerts, Van Acker, de Meester and Dewulf2019). Circularity presents a paradigm shift toward sustainable business models that extend value creation beyond the initial transaction. Understanding the lifecycle value of a product necessitates a holistic approach, from concept to disposal, and a transition from product-centric design to system-centric design, featuring a combination of products and services to be delivered for lifespans that could extend across multiple decades.

In engineering design, various methods have been proposed to offer valuable insights into designing circular products, translating broad circularity principles into specific product requirements from both business and product development perspectives (e.g., MacArthuret al. Reference MacArthur, Zumwinkel and Stuchtey2015; den Hollander et al. Reference Den Hollander, Bakker and Hultink2017). In the work of den Hollander et al. (Reference Den Hollander, Bakker and Hultink2017), circular product design is presented as the combination of design for integrity (i.e., aiming at resisting, postponing and reversing obsolescence at the product and component level) and design for recycling, aiming at preventing and reversing obsolescence at a material level. However, despite the extensive academic literature that presents and discusses various circularity indicators at both the product (e.g., Corona et al. Reference Corona, Shen, Reike, Carreón and Worrell2019) and macro levels (e.g., de Souza et al. Reference de Souza, Fröhling and Pigosso2024), these approaches rarely extend beyond the analysis of specific product features, particularly material flow, neglecting the evolving technological, societal and customer-related landscape. In other words, these methods often focus on specific product features (also highlighted by Corona et al. (Reference Corona, Shen, Reike, Carreón and Worrell2019) in their review of circularity metrics), failing to account for the dynamic nature of the context in which a future circular solution will operate over several years (Mesa Reference Mesa2023), based on a combination of products and services. Consequently, engineers and decision-makers lack tools to guide early-stage design decisions for future circular systems.

Systems engineering offers a potential solution through the research stream of value-driven design (VDD) (Collopy & Hollingsworth Reference Collopy and Hollingsworth2011), which prioritizes maximizing value creation over merely fulfilling requirements. The VDD process proposed by Isaksson et al. (Reference Isaksson, Kossmann, Bertoni, Eres, Monceaux, Bertoni, Wiseall and Zhang2013) for early aircraft design provides some initial guidance on using the value concept to tame complexity when exploring the design space for large systems. Although the VDD process does not explicitly address design for circularity, it introduces system attributes called ilities to capture and assess the desired properties of systems that “manifest themselves after a system has been put to its initial use” (de Weck et al. Reference de Weck, Roos and Magee2011, p. 66). These ilities include system properties like flexibility, scalability, adaptability, and so on (McManus et al. Reference McManus, Richards, Ross and Hastings2007; Hastings Reference Hastings, La Tour and Putbrese2014). Based on such a list of attributes, value robustness was defined as the “ability of a system to continue to deliver stakeholder value in the face of changing contexts and needs” (Ross & Rhodes Reference Ross and Rhodes2008, p. 1). Value robustness can be achieved either by requiring no change in the systems (via over-design) or it can be achieved by active changes within the system in the face of uncertainty, that is, designing a changeable system. Based on such a definition, assessing the value robustness of a system implies a quantification of how changeable a system is, encompassing the evaluation of ilities, for example, flexibility, scalability and adaptability (Ross et al. Reference Ross, Rhodes and Hastings2008; Uday & Marais Reference Uday and Marais2015; Machchhar et al. Reference Machchhar, Melén and Bertoni2024). Nevertheless, current approaches for systems engineering often rely on top-down cascading of requirements that inadequately capture the value robustness of a solution throughout its lifecycle, eventually falling short of capturing the broader design rationale of circular solutions within dynamic contexts. Aligning with the operational principles of the circular economy of maintaining resource value within the system (Suárez-Eiroa et al. Reference Suárez-Eiroa, Fernández, Méndez-Martínez and Soto-Oñate2019), raising awareness of these systems’ ilities during the early stages of design can lead to the selection of solutions that sustain value under diverse customer expectations, operational scenarios and environmental regulations.

To effectively harness the potential of the quantification of such ilities, this article presents the use of computer-based simulations to analyze lifecycle implications and enhance the value robustness of circular solutions. The aim is to present a framework supported by case studies that describe how computer-based simulations can enhance decision-makers’ awareness of the complexity inherent in circular systems. This framework supports the development of circular systems that perform well in dynamic operational environments throughout their entire lifecycle, consequently aiming to maximize long-term value and commercial success, as well as minimize environmental and social impact.

The objective of the article can be defined as follows:

-

• Present a framework for value-robust circular systems design to enhance existing methodology for circular product design. The framework relies on different simulation tools, methods and environments to address the complexities of engineering complex systems by improving the understanding of systems changeability by quantifying “ilities,” ultimately supporting the design of more value-robust circular systems.

The different parts of the framework are demonstrated through their application in four case studies in the field of construction machinery, exploring innovative circular solutions for the future of mining, quarrying and road construction. The different case studies use simulation tools, methods, and environments to tackle the complexities they are mapped to in the framework to design value-robust circular systems.

The paper first describes the research approach adopted based on participatory action research in multiple cases. A deeper explanation of the concepts of complexity, uncertainty and value robustness, and how they are linked to each other, is provided in Section 3. Section 4 presents the proposed framework, describing how the different levels of complexities have been addressed in four case studies. Section 5 discusses the framework, positioning it in relation to the current literature on product and system design, highlighting the impact on engineering practices, and discussing the generalization and limitations of the different case studies. Section 6 draws the conclusions.

2. Research approach

The research presented in this article is the result of an approach combining multiple case studies (Yin Reference Yin2009) and participatory action research (PAR) (Whyte et al. Reference Whyte, Greenwood and Lazes1989) in collaboration with companies operating in the construction machinery industry and development of electric and autonomous solutions for transportation. PAR entails the active involvement of both researchers and practitioners in the design and execution of research projects. This approach aims to resolve practical issues while also contributing to theoretical advancements (Whyte et al. Reference Whyte, Greenwood and Lazes1989). Analogous to action research, PAR utilizes Look-Think-Act cycles, wherein researchers collaborate with practitioners to test theories in real-world contexts, obtain feedback from these implementations, and subsequently refine the theories based on the gathered feedback (Avison et al. Reference Avison, Lau, Myers and Nielsen1999). PAR was applied to four case studies within the construction machinery industry (Cases A, B, C and D). The same group of academic researchers took part in the development of simulation support tools for the specific design challenges defined in each case study. From the industrial side, each case featured a dedicated team of industrial practitioners collaborating in the development with the academic group. An industrial project coordinator also participated in the PAR activities by coordinating the work of the industrial teams in different cases.

The case studies were selected with the intent to approximate the literal replication of the cases, that is, repeating the study with the same methods, conditional and procedures. PAR being a qualitative approach, literal replication could only be approximated in the cases due to the intrinsic context-specific nature of the studies. Nevertheless, data collection methods were reproduced in the four cases, and similar theoretical themes were shared. In detail, the four case studies shared the following similar traits:

-

• They were all focusing on the construction machinery industry.

-

• They were all sparked by the business transition toward the electrification of vehicles and autonomous driving.

-

• They were all guided by the vision to reach zero emissions and zero accidents in a working site.

-

• They all involved cross-functional design teams investigating the use of computer-based simulations, often referred to as digital twins (DTs), to examine future system configurations.

-

• They all shared the same approach to data collection and communication between the industrial practitioners and the academic research group.

-

• They were all supervised by the same industrial coordinator of the cases.

Concurrently, the four cases featured the following differences:

-

• Case A and B focused on mining applications, Case C focused on a large road construction project and Case D focused on both contexts.

-

• Different external stakeholders were involved. This means that different companies besides the one represented by the industrial project coordinator were involved in the data collection process, with Case C also featuring the presence of an IT software provider.

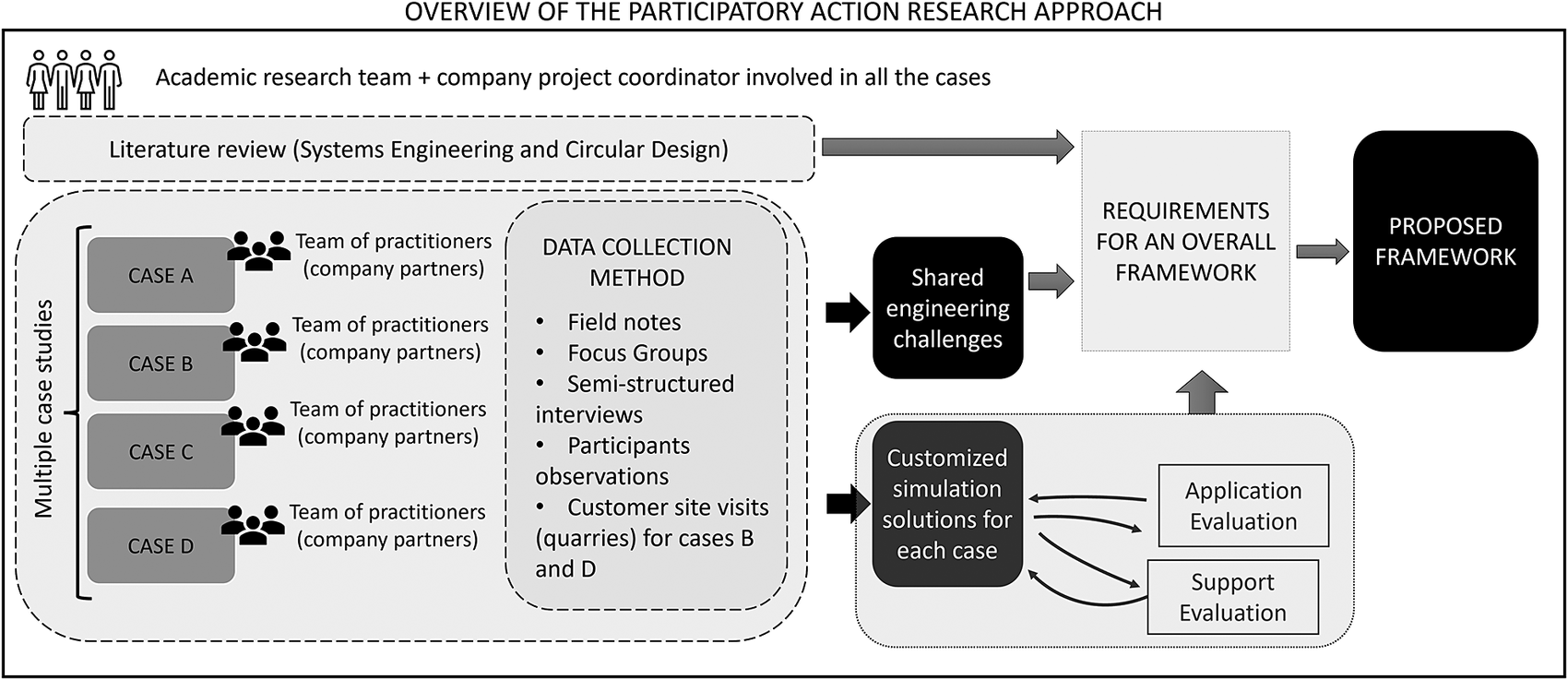

Figure 1 provides an overview of how the research was structured around a PAR approach.

Figure 1. Overview of how the research presented in this article was structured around a participatory action research approach. The figures show the contribution of dedicated teams of practitioners in the four case studies, while the academic research team and the company project coordinator were involved in all the case studies.

2.1. Introduction to the four case studies

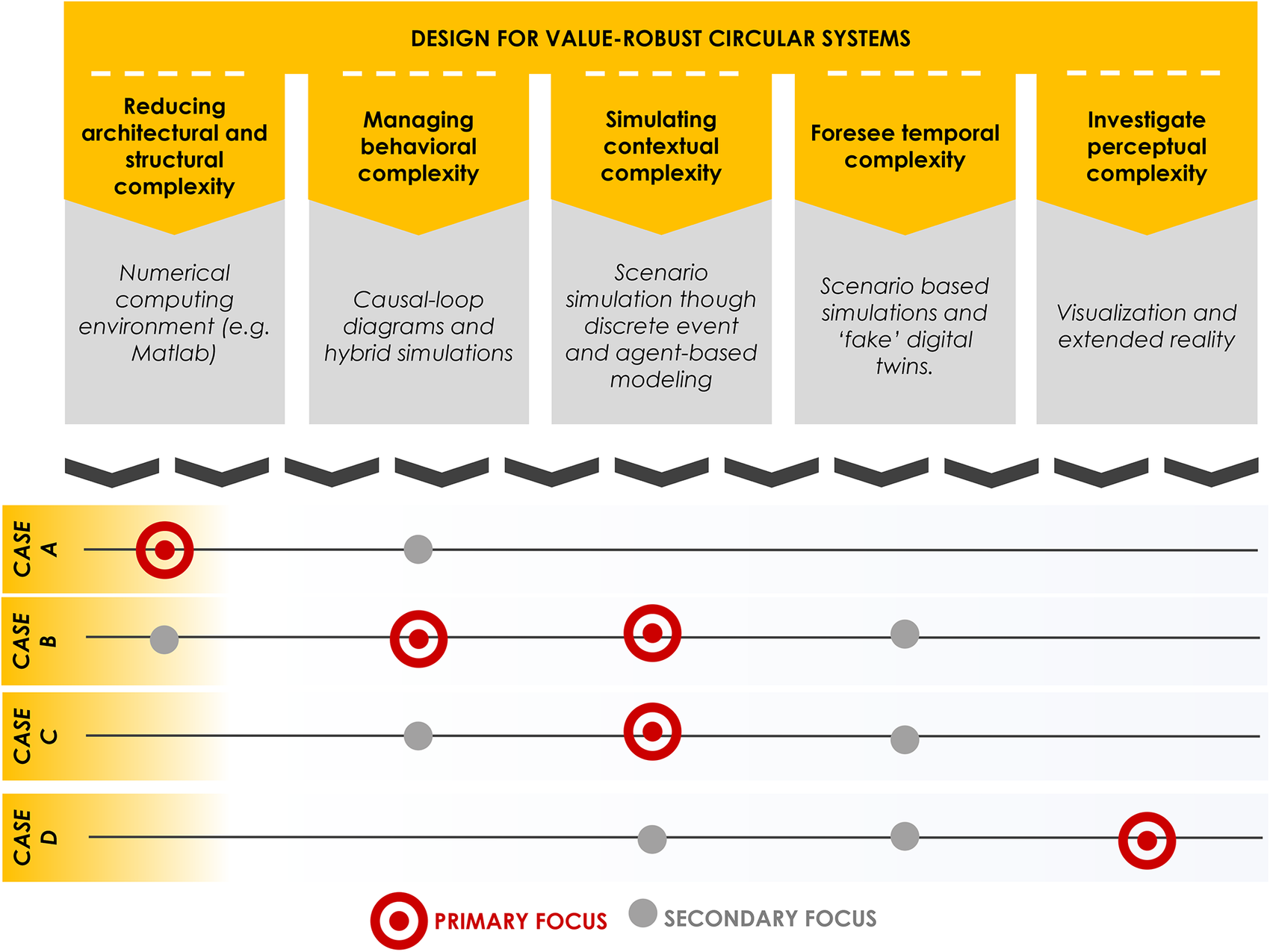

The four case studies shared the overall high-level vision to support the transition to a safer, more sustainable, and more efficient mining, quarry, and road construction industry, thanks to the introduction of autonomy and electromobility. The four cases addressed the complexity challenge with different strategies, each focusing on one or more aspects of system complexity. The four cases shall be regarded as examples of how the dimensions described in the framework in Figure 3 have been addressed with respect to different industrial projects. The case studies, as presented in Figure 3, focused on:

Case A: Tradeoff systems configurations comparing diesel and electrical haulers design in a mining site (detailed description is available in Bertoni et al. Reference Bertoni, Machchhar, Larsson and Frank2022).

Case B: Simulate the behavior of fleets of electrical haulers with varying dimensions while fulfilling requirements on productivity and total cost of ownership (detailed description is available in Melén et al. Reference Melén, Machchhar and Bertoni2024 and Machchar et al. Reference Machchhar, Bertoni, Wall and Larsson2024).

Case C: Explore the conditions required for executing major infrastructure projects with zero emissions and free from fossil fuels, including machinery, infrastructure, and site management systems, and visualize such information to stakeholders.

Case D: Investigate through XR technologies the dynamics of expectations of customers and stakeholders for incremental and radical system innovation in the case of autonomous vehicles collaborating with humans for road construction and ore extraction (a detailed description is available in Scurati et al. Reference Scurati, Bertoni and Bertoni2022 and Machchhar et al. Reference Machchhar, Scurati and Bertoni2023b).

2.2. Data collection and analysis

Data collection and analysis followed the same protocol in the four case studies. The formulation of the overall framework was driven by the convergence of the analysis results combined with the observation emerging from the literature review in System Engineering and Circular Design.

At the initial stages of each case study, a primary data collection method comprised semistructured interviews to elicit specific information from individuals occupying various roles within the company. When feasible, interviews were audio-recorded and transcribed, subsequently validated by the respondents. Detailed notes were taken during the interviews when audio recording was not permissible. To complement the data collection process, focus groups were conducted to “capitalize on communication between the research participants to generate data” (Kitzinger Reference Kitzinger1995, p. 299). Participant observations were undertaken at the partner company’s facilities during project meetings and documented through field notes and pictures when allowed. This approach enabled researchers to capture the contextual and environmental nuances in which discussions occurred, along with recording behaviors and reactions. Furthermore, internal company documents and publicly available information detailing existing engineering processes were analyzed to facilitate triangulation.

The initial interviews and focus groups primarily allowed the collection of needs and expectations. Such data allowed the first articulation of the “intended support” requirements. This phase was followed by an iterative process incorporating a series of Look-Think-Act loops (Avison et al. Reference Avison, Lau, Myers and Nielsen1999) between researchers and practitioners. This loop consisted of creating a first solution prototype that was further improved iteratively and incrementally through feedback and joint collaboration in recurrent physical or virtual working sessions between the practitioners and researchers. Such joint iterative activity took the form of weekly or bi-weekly meetings between the project teams of the different cases. It has to be noted that while the industrial participants of such meetings varied to a large extent from one case to another, the same academic research team was involved in all four cases. Such a process facilitated the incremental improvement of the proposed solutions through cross-case verification and validation activities while granting coordination among the different cases in terms of the methods applied and the focus of the work.

For each case study, the verification and evaluation of the actual support adhered to the guidelines of Descriptive Study II of the Design Research Methodology (Blessing & Chakrabarti Reference Blessing and Chakrabarti2009). Focusing on the “Support Evaluation” activity initially ran internally to the research group to verify the functionality of the solutions, later followed by the “Application Evaluation” activity to verify its applicability with the industrial practitioners. Support evaluation involved the empirical testing of the computational capabilities of the computer-based simulations, ensuring the availability of all desired functionalities. Application Evaluation, on the other hand, aimed to verify the applicability and usability of the support in relation to the desired performance and user requirements. This evaluation necessitated the involvement of industrial practitioners in testing and assessing the support, thereby providing iterative feedback for ongoing refinement. In alignment with the Look-Think-Act loops, both evaluation activities were iterative and integral to the continuous improvement process during support development. The iterative validation activities involved customers, suppliers, subcontractors, and IT providers.

Concerning the definition of the proposed framework, the collaborative process of the case studies facilitated the identification of the challenges to be addressed in the design and the subsequent definition of the requirements for the proposed framework. Such inputs were clustered by the research team based on the categories of complexity and “ilities” emerging by the literature review. This brought to the definition of the framework presented in this article, which originates from the findings obtained and the lessons learned during the cases (some of which are described more in detail in related publications by Bertoni et al. Reference Bertoni, Machchhar, Larsson and Frank2022; Scurati et al. Reference Scurati, Bertoni and Bertoni2022; Machchhar et al. Reference Machchhar, Aeddula, Bertoni, Wall and Larsson2023a, Reference Machchhar, Scurati and Bertoni2023b). A complete validation of the framework presented in the paper has not been performed yet. This means that support evaluation and the application evaluation, such as defined by Blessing and Chakrabarti (Reference Blessing and Chakrabarti2009), have been performed at the individual case study level (bottom right corner of Figure 1), while the successful evaluation of the complete framework will require extensive data collection, most likely leading to several iterations in future research. Noticeably, some data concerning the case studies presented in the following section have been artificially modified due to confidentiality issues.

3. Complexity, uncertainty and value robustness in system design

In the realm of systems engineering, (Magee & de Weck Reference Magee and de Weck2004, p. 2) defined a complex system as “a system with numerous components and interconnections, interactions or interdependencies that are difficult to describe, understand, predict, manage, design, and/or change.” These systems require substantial information to define, understand interdependencies, and predict future behaviors (Gaspar et al. Reference Gaspar, Rhodes, Ross and Erikstad2012). Operating within dynamic and uncertain environments, these systems pose significant design challenges. Addressing these complexities requires a multidisciplinary approach, encompassing fields such as psychology, economics, and engineering. In such a context, Rhodes and Ross (Reference Rhodes and Ross2010) identified five key complexity aspects for engineering complex systems, namely:

-

• Structural complexity: concerning the physical manifestation of the components, their relationships, and their interaction in a system.

-

• Behavioral complexity: concerning the operation of the system to deliver the intended value.

-

• Contextual complexity: concerning the influence of external factors on the expected value of the system.

-

• Temporal complexity: concerning the long-term effect of contextual factors on the system’s capability to deliver the expected value.

-

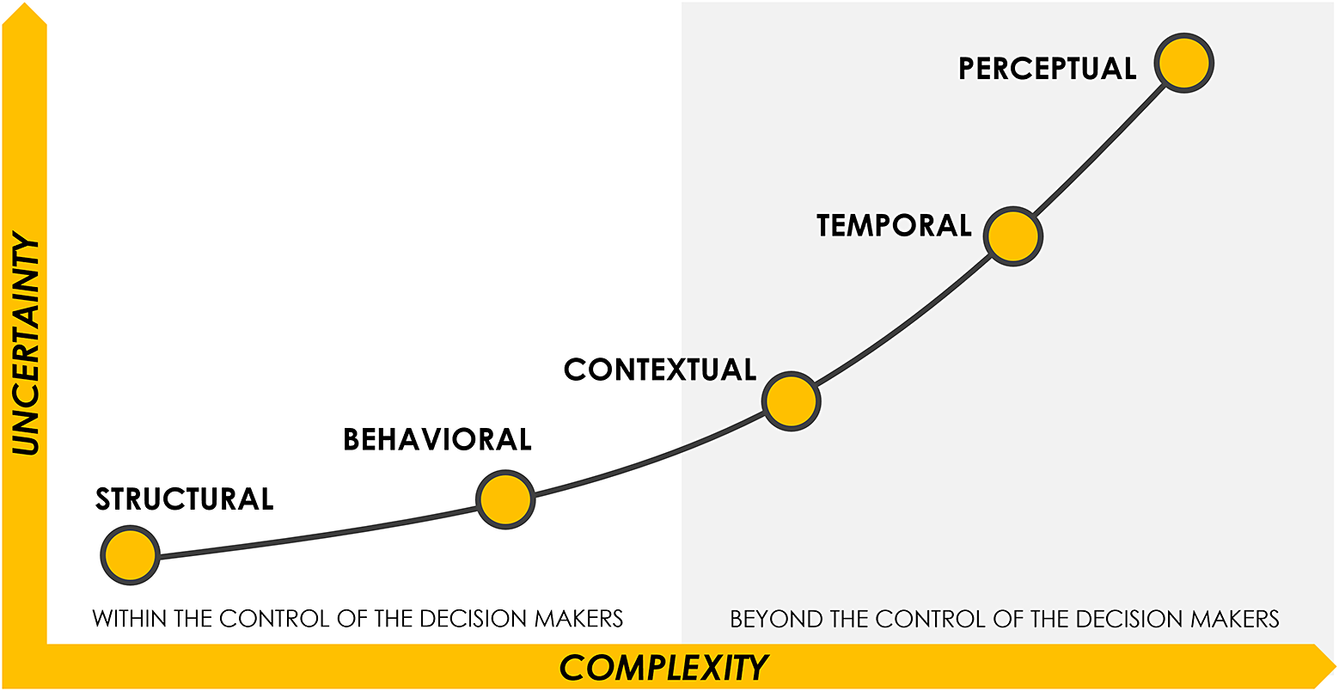

• Perceptual complexity: concerning the value of a system as perceived by different stakeholders along with their cognitive biases.

Addressing these complexity aspects is defined as an indication of the rigor of the development team to develop a value-robust solution. However, the possibility of encountering unforeseen events, especially during the operational phase, introduces many uncertainties in the design decision-making process (Allaverdi & Browning Reference Allaverdi and Browning2020; Gaspar et al. Reference Gaspar, Rhodes, Ross and Erikstad2012; Madni et al. Reference Madni, Sievers, Madni, Ordoukhanian and Pouya2018). To this end, uncertainty can be defined as “the inability to determine the true state of affairs of a system.” (Haimes Reference Haimes2015, p. 185), given by the presence of “things that are not known, or not known precisely” (McManus & Hastings Reference McManus and Hastings2005, p. 2). Gaspar et al. (Reference Gaspar, Hagen and Erikstad2016) linked the complexity aspects to escalating uncertainty levels, representing the relationship between uncertainty and complexity as an exponentially increasing function touching all the uncertainty types and spanning from structural complexity (low complexity and low uncertainty) to perceptual complexity (high complexity and high uncertainty). Figure 2, adapted from the work by Gaspar et al. (Reference Gaspar, Hagen and Erikstad2016), shows this relationship between complexity (x-axis) and uncertainty (y-axis) in the design decision-making process. Furthermore, structural and behavioral aspects are described in the literature to be within the control of the decision-makers, while contextual, temporal and perceptual aspects are considered to be beyond such control.

Figure 2. Complexity vs uncertainty relationship, adapted from Gaspar et al. (Reference Gaspar, Hagen and Erikstad2016).

Given the challenges of making design decisions in such a highly complex and uncertain context by using a requirements cascading process, VDD emerges in the field of systems engineering as one of the methodologies to enable tradeoffs in complex systems from a multidisciplinary perspective (Bertoni et al. Reference Bertoni, Bertoni, Panarotto, Johansson and Larsson2016). Unlike traditional systems engineering practices that often focus on incremental improvements, VDD seeks to avoid local optima by exploring a more comprehensive design space (Collopy & Hollingsworth Reference Collopy and Hollingsworth2011), ultimately guiding the concept selection by the potential value generation rather than on requirement fulfillment. The definition of value, and how to quantify it, is therefore central in a VDD approach requiring a quantifiable metric to be used for trading off different design concepts. Despite the early application proposing the use of Surplus Value as a metric (Collopy & Hollingsworth Reference Collopy and Hollingsworth2011), several authors have discussed the use of different quantifiable value criteria (also defined as value drivers or dimensions) to reflect the concept of value in different contexts better (Isaksson et al. Reference Isaksson, Kossmann, Bertoni, Eres, Monceaux, Bertoni, Wiseall and Zhang2013; Monceaux et al. Reference Monceaux, Kossman, Wiseall, Bertoni, Isaksson, Eres, Bertoni and Rianantsoa2014).

To this concern, McManus and Hastings (Reference McManus and Hastings2005) and Ross et al. (Reference Ross, Rhodes and Hastings2008) have highlighted how, when exploring the potential value of complex systems, changes are inevitable in reality and perception in a long lifecycle. On this rationale, McManus and Hastings (Reference McManus and Hastings2005) formulated the concept of “ilities,” introducing criteria such as flexibility, scalability, sustainability, reusability, upgradeability and so forth These are acknowledged to be overarching properties of a system that is able to either change the form or function to bring about a change in the operation as a response to changes in the requirements and context (Mekdeci et al. Reference Mekdeci, Ross, Rhodes and Hastings2015). Robustness was defined as one of the core system’s attributes to be understood and assessed. Similarly, a robust system was defined by Ross et al. (Reference Ross, Rhodes and Hastings2008) as one that (1) is capable of adapting to changes in missions and requirements, (2) is expandable and scalable, being designed to accommodate growth in capability, (3) is able to function given threats in the environment reliably, (4) is effectively and affordably sustainable over its lifecycle, (5) is developed using products designed for use in various systems and (6) is easily modified to leverage new technologies. Reflecting such a list of attributes, value robustness was defined as the “ability of a system to continue to deliver stakeholder value in the face of changing contexts and needs” (Ross & Rhodes Reference Ross and Rhodes2008, p. 1). In practice, value robustness can be achieved either by requiring no change in the systems (via over-design), and these systems are called passively value-robust, or it can be achieved by active changes within the system in the face of uncertainty.

In systems engineering, several case studies have assessed the application of passive versus active value robustness strategies to guide the engineering design decision of new systems. For instance, Allaverdi et al. (Reference Allaverdi, Herberg and Lindemann2013) analyzed both active and passive changeability as a means to sustain value delivery across the lifecycle of a shore drilling system, while Gaspar et al. (Reference Gaspar, Hagen and Erikstad2016) investigated value-robustness perception in the design of ships.

3.1. Value robustness and circular systems design

Within the fields of circular economy and product-service systems (PSSs), the concept of value is predominantly perceived as a dynamic concept, characterized by a through-life creation perspective (Isaksson et al. Reference Isaksson, Larsson and Rönnbäck2009), encompassing maintenance, exchange services, updates, and more (Matschewsky et al. Reference Matschewsky, Lindahl and Sakao2020; Sassanelli et al. Reference Sassanelli, Urbinati, Rosa, Chiaroni and Terzi2020). In such context, Machchhar et al. (Reference Machchhar, Aeddula, Bertoni, Wall and Larsson2023a) argued that the measure of value robustness for a PSS should go beyond sustaining the value to an acceptable level along the lifecycle, rather designing for a potential increase in value along the lifecycle (e.g., designing a system that could generate higher value in the context of more restrictive future environmental regulations). This perspective aligns with the broader systems engineering understanding that value extends beyond traditional cost–benefit analyses. Although, the value discussion in PSS is firmly grounded on the broader notions of “benefit” (Rondini et al. Reference Rondini, Bertoni and Pezzotta2020), “customer experience” (Schallehn et al. Reference Schallehn, Seuring, Strähle and Freise2019) and “need fulfillment” (Bertoni & Bertoni Reference Bertoni and Bertoni2019), systems engineering research makes it clear that (e.g., in Ross et al. Reference Ross, Rhodes and Hastings2008) to maintain value delivery over a system lifecycle, either the system or its perception, must change over time.

Despite not directly referring to the concept of value robustness, various approaches to promote circular product and system design have been proposed under the umbrella of eco-design (Pigosso et al. Reference Pigosso, Rozenfeld and McAloone2013), design for sustainability (Bhamra & Lofthouse Reference Bhamra and Lofthouse2016), design for environment (Sroufe et al. Reference Sroufe, Curkovic, Montabon and Melnyk2000), sustainable product development (Byggeth et al. Reference Byggeth, Broman and Robèrt2007) and design for circularity (den Hollander et al. Reference Den Hollander, Bakker and Hultink2017). The work by den Hollander et al. (Reference Den Hollander, Bakker and Hultink2017) has often been cited as providing precise and generalizable principles for designing a circular product from a lifecycle perspective. Den Hollander et al. (Reference Den Hollander, Bakker and Hultink2017) argued that circular product design is guided by the Inertia Principle, identifying product integrity as the primary design objective to be pursued. Product integrity shall also be preferred to the second principle of circular product design, identified in recyclability. In synthesis, den Hollander et al. (Reference Den Hollander, Bakker and Hultink2017) defined circular product design as the combination of design for integrity (i.e., aiming at resisting, postponing, and reversing obsolescence at the product and component levels) and design for recycling. Focusing on preventing and reversing obsolescence, such a definition can be seen as a proxy, at a product level, for the concept of value-robustness for complex systems, under the assumption that a product keeps creating value as far as it does not become obsolete.

Incorporating a more systematic perspective on the product lifecycle, but still not considering the idea of changeability to achieve value robustness, Wiprächtiger et al. (Reference Wiprächtiger, Haupt, Heeren, Waser and Hellweg2020) proposed a sustainable and circular system design method, primarily based on the mass of material circulating in the system and eventually retained, recycled, or ending up in waste management. Similarly, in a literature review about design for X methods for circularity, Sassanelli et al. (Reference Sassanelli, Urbinati, Rosa, Chiaroni and Terzi2020) categorized the approaches into five macro areas essential for enhancing circularity in products and services. In such a review, the focus lies mainly on the extension of product lifecycles by improving sustainability and reliability.

The importance of design for changeability to achieve circularity is highlighted more recently by Askar et al. (Reference Askar, Bragança and Gervásio2022) to address the dynamic challenges of product lifecycles in the design of buildings. However, despite the recognition of the significance of changeability, there remains a significant research gap in developing and implementing design methods and frameworks that explicitly incorporate changeability (Sullivan et al. Reference Sullivan, Arias Nava, Rossi and Terzi2023). This is especially true when designing for a system capable of delivering the expected value performance throughout its life and, eventually, grabbing the opportunity to increase value in the face of uncertainty, and at the same time capable of withstanding the adverse effects of all the internal and external changes that might occur along the lifecycle.

4. A framework for value-robust circular systems design through computer-based simulations

Traditionally, in an engineering design process, the formalization of the information about needs and expectations collected in the early design stages drives the idea-generation phase, leading to concept generation and early concept specifications. This phase is typically the moment in which design for X strategies has the fundamental role of supporting engineers in making critical decisions about the future performances of the yet-to-be-developed product. This is also the phase when engineers dealing with circularity consideration must link circularity with stakeholder needs and potential business implications that may change over time. In such a phase, approaches based on design for integrity and design for recycling are limited in providing circularity assessment support for complex systems.

The framework presented in this section is intended to support this design phase and leverages the findings from four case studies performed in the context of construction equipment. The framework covers the gap in the current approaches for circular design when making design decisions, considering dynamic systems that could change over time and last for several decades. To do so, the framework goes beyond the results of the single case studies, providing the structure for a simulation architecture to combine results obtained with heterogeneous approaches into a system simulation. Such a structure of the framework is the result of addressing the engineering challenges collected through empirical studies in the field of construction machinery, which have highlighted three significant challenges defined as follows:

-

1- Understanding the best combination of system components and subsystems to deliver the desired functions during the whole lifecycle. This challenge was driven by the need to simplify the systems architecture and quantify the contribution of individual subsystems to different operational strategies, thereby supporting modularity decisions (primarily emerging from Cases A and B).

-

2- Managing the uncertainty created by the transition toward electromobility, understanding what design would best mitigate the risk in front of a highly unpredictable future operational context in terms of technology, governmental regulations, and customer acceptance (primarily emerging from Cases B and C).

-

3- Effectively communicating and gathering early feedback on radical innovations enabled by autonomous driving technology within the traditionally conservative construction machinery industry. This involves showcasing technological advancements, proving increased customer profitability, and, in specific markets, demonstrating the improvement of environmental performance to regulators and institutions throughout the machine’s lifecycle (primarily emerging from Cases C and D).

The proposed framework supports assessing a system’s capacity to maintain value over time while considering structural, behavioral, contextual, temporal, and perceptual complexities. In other words, it supports engineers in designing value-robust solutions, given the changing system structure, environmental conditions, value perceptions, and legislature.

Figure 3 presents the proposed framework for value-robust circular systems design. The framework is complementary to the established strategies for designing circular products. The founding rationale is that the investigation of systems circularity goes beyond assessing product integrity and recyclability (den Hollander et al. Reference Den Hollander, Bakker and Hultink2017). While integrity and recyclability are relevant for the design of products or components of the system, a broader view of the overall system is needed to consider its value robustness under changeable conditions along its lifecycle. Given the added system complexity, the framework highlights what dimensions of value robustness need to be considered. Such dimensions include considering potential design strategies and methods to mitigate the negative impact of five levels of complexity. The definition of the levels of complexity is derived from the existing literature in systems engineering, in particular, work by Rhodes and Ross (Reference Rhodes and Ross2010) (as described in Section 3), further investigated by authors in the field of aerospace and maritime engineering (e.g., Mekdeci et al. Reference Mekdeci, Ross, Rhodes and Hastings2015; Gaspar et al. Reference Gaspar, Hagen and Erikstad2016; Rehn et al. Reference Rehn, Pettersen, Garcia, Brett, Erikstad, Asbjørnslett, Ross and Rhodes2019; Sapol & Szajnfarber Reference Sapol and Szajnfarber2022; Dwyer & Efatmaneshnik Reference Dwyer and Efatmaneshnik2023).

Figure 3. Framework for value-robust circular systems design, expanding the concept of circular product design toward the value-robust changeable systems.

The following subsections describe in detail the framework proposed in Figure 3, describing which role the four case studies had in the different phases of the framework. To this concern, the bottom part of Figure 3 lists the four case studies, highlighting their primary and secondary focus.

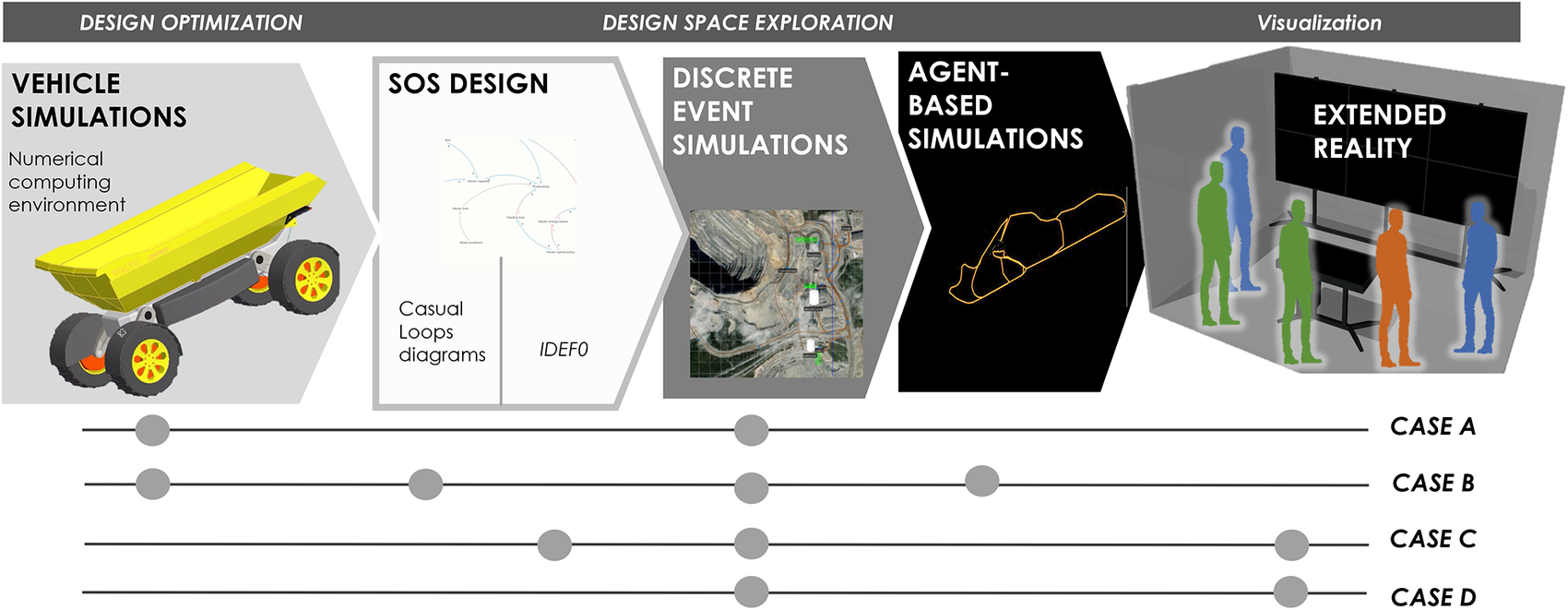

Figure 4 shows instead a high-level summary of the simulation approaches used in the four case studies: each case study is listed at the bottom of the figure with a grey dot symbolizing which types of simulations have been used in the case study results. Discrete event simulations were used in all four cases to support design space exploration. Cases A and B encompassed the use of vehicle simulations and relationship modeling (e.g., Causal loop diagrams), while Cases C and D extended the focus more into the visualization of results and the use of eXtended Reality (XR) solutions.

Figure 4. Summary of the simulation approaches used in the four case studies.

The following subsections describe in detail the five levels of complexity presented in the framework and how those have been addressed in the case studies by computer-based simulations.

4.1. Reducing architectural and structural complexity through a numerical computing environment

Structural and architectural complexity notions are commonly related to the number of subsystems, components, and parts, their dependencies, and how they connect and interact (Sinha & Suh Reference Sinha and Suh2018). The idea of reducing structural complexity consists of delivering the desired functions of a system with the simplest possible combinations of parts, components, and subsystems, that is, with a simple architecture. Decisions about architectural and structural complexity are usually in decision-makers’ control; that is, engineers can proactively design to reduce such complexity. Fined balanced strategies for modular product and service design and approaches based on platform design are typically claimed to reduce architectural and structural complexity and mitigate changes and conflicting requirements (Albers et al. Reference Albers, Bursac, Scherer, Birk, Powelske and Muschik2019; Aziz et al. Reference Aziz, Wahab, Ramli and Azhari2016).

In Case A, several machines operating in the same mining site were simulated to find the best compromise between machine design parameters (e.g., payload, battery size, traveling speed) and the overall site performances (e.g., productivity, energy efficiency, emissions). The structural and behavioral complexity constituted a simultaneous evaluation of effective configuration and control policies for these vehicles, which led to uncertainty in decision-making concerning the most valuable solutions. To address this challenge, a vehicle simulation model was created in MATLAB, combining the system’s design variables, state variables, control policies, and contextual variables into an optimization problem to assist early design decisions. To solve the problem, a global optimizer incorporated Dynamic Programming, and the setup was used to configure a viable machine and evaluate its optimal control policy.

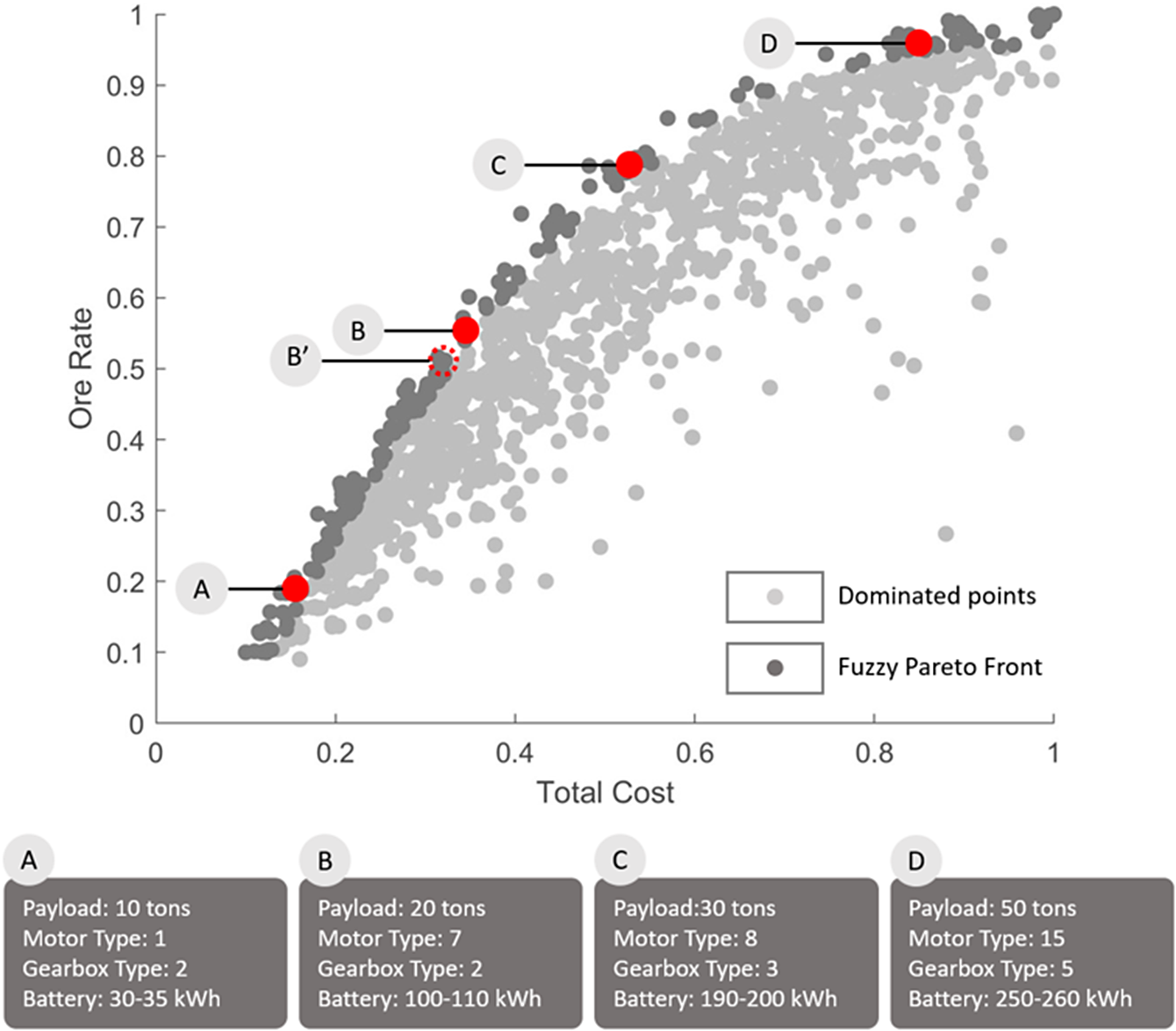

Figure 5 visualizes the results of the simulations showing the Pareto-optimal solutions for the configuration of fully electric machines, where the x-axis represents the total cost of the operation, and the y-axis indicates the rate of ore production. The same visualization was obtained for diesel machines. The red dots indicate some of the configurations of the electric machine along the fuzzy Pareto front. The impact of control policies is visible, for instance, in design points B and B′, which have the same design configuration but a different control policy (i.e., different prioritizations for time and energy). This variation is reflected in the cost function (or the value function) of an optimal control problem (Bertsekas Reference Bertsekas2019), where each unique weighing factor leads to distinct energy consumption rates per cycle, ultimately impacting operational costs and emissions.

Figure 5. Scatter plot showing the Pareto optimal designs for electric machines in case A. Design points B and B′ have the same design configuration but a different control policy.

A similar approach was applied in Case B, where dynamic programming was applied to the vehicle dynamics simulation of electric haulers. As a different case, B focused on the operational level performances of predetermined hauler configurations, with specific motor, gearbox, batteries, etc., representing predetermined electric configurations, having 25- and 35-ton capacity. In both cases, the overall energy efficiency, coupled with the source of energy selected in the scenarios, drove the calculation of the overall environmental performances of the systems.

4.2. Managing behavioral complexity with causal loop diagrams and hybrid simulations

Behavioral complexity is generated by the multiple parts of the designed system that concurrently operate to deliver the intended value. The high interconnection and interaction between subsystems, components, and parts generate potentially unpredictable system dynamics. This makes it difficult to predict the behavior of a system, thus leading to a certain level of uncertainty in decision-making that needs to be managed. Model-based systems engineering (MBSE) is one of the known approaches to model such behavior while systems are still in the design stage, using executable (Rhodes & Ross Reference Rhodes and Ross2010) models (often using SysML or UML language). Additionally, model-driven approaches for product and systems development, combining executable multidisciplinary models communicating through interfaces, have been the subject of demonstration in different industrial fields (Bertoni et al. Reference Bertoni, Larsson, Wall and Askling2021).

Case A addressed behavioral complexity by modeling the operational scenario in a commercial discrete event simulation (DES) tool. Consid ering a whole mining site, each machine configuration with the related control policies (as described in Section 4.2) collectively evolved to characterize a unique behavior in the site. The site layout, its topography, and its infrastructure constituted the boundaries inside which the simulations were run. The Pareto frontier design configurations (as shown in Figure 5) were used to populate the data necessary to run the simulations. Such simulations were enabled by input–output data communication between vehicle simulations and site simulations.

Case B expanded the approach for managing behavioral complexity by using causal loop diagrams and agent-based simulations. In case B, the central questions revolved around designing a system of systems that can scale up while remaining energy-efficient, creating an all-electric facility, optimizing energy usage, and designing the necessary digital infrastructure for communication and information management. Addressing site efficiency rather than only machine efficiency was crucial for achieving significant savings and avoiding unaccounted bottlenecks. In such a context, standardization and interoperability were critical aspects of building systems with machines and processes from different manufacturers. Casual loop diagrams were applied to visualize the intra- and interdependencies that exist in a mining site. Those served as input to combined discrete event and agent-based models developed in Java-based, open-source software. This model enabled quantifying vehicle behavior (primarily haulers), simulation of resource flows, energy consumption, and interactions, and identifying and quantifying key performance indicators for environmental impact.

A similar challenge was faced at the beginning of Case C, focusing on a large road infrastructure project. Here, a series of models representing the current construction process were developed using IDEF0 notation to capture the hierarchy of activities and tasks, input–output relationships, and required mechanisms. The conceptual model for the site was based on the analysis of drone images and data provided by the company partner. These models served as the basis for developing DES models of both site operations and related energy consumption in the different nodes of the network (the latter supporting the simulation of contextual complexity as described in Section 4.4). The necessity of capturing the hierarchy of activity (e.g., using IDEF0) was given by the complexity of the project involving macro-activities (such as earth removal, material removal and deposition, and rock blasting and deposition), involving various pieces of machinery, such as excavators, wheel loaders, dump trucks and stone crushers. The site was also divided into sections in the reference model, influencing the simulation model’s calculations and defining worst-case scenarios regarding energy usage. The number of construction equipment on the site, their power requirements, their task description, their operational schedule, and site topology were considered input variables to construct alternative scenarios to obtain data related to power and energy patterns, as well as productivity, cost, and downtime. Those results also served later as input for the simulation of contextual complexity.

4.3. Simulating contextual complexity through discrete-event and agent-based simulations

The challenge of contextual complexity is that the external uncertainties are beyond the control of the decision-makers, thus making it cumbersome to build a system capable of handling these uncertainties. SE literature purports technology, market, environment, expectations, competitors, regulations, and fashions as some of the external factors that influence the system’s value, leading to contextual complexity (de Weck et al. Reference de Weck, Eckert and Clarkson2007). This viewpoint is preserved in PSS literature, where researchers have acknowledged a changing context and its influence on the value of the PSS (Richter et al. Reference Richter, Sadek and Steven2010). Facing this challenge, the use of scenario simulations based on agent-based and discrete event modeling (Rondini et al. Reference Rondini, Tornese, Gnoni and Pezzotta2017) or the creation of environmental interaction models (Zhang et al. Reference Zhang, Qin, Li, Zou and Ding2020) have been described as beneficial in trying to anticipate the effect that contextual complexity might have on the future system.

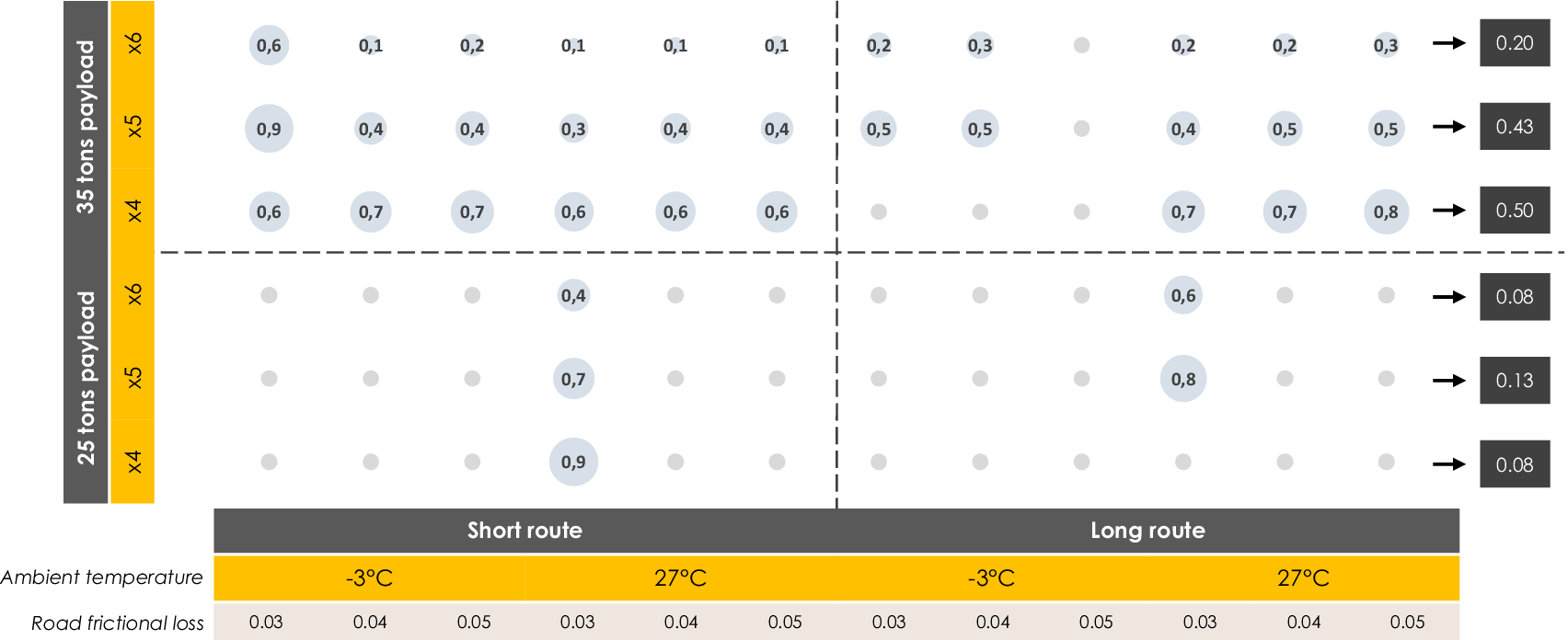

Beyond managing behavioral complexity, Case B also focused on broadening the awareness of uncertainties and secondary effects related to the transition to electromobility and autonomy, focusing on contextual variability. To do so, a reference mining site featuring autonomous and electrical haulers with 25- and 35-ton capacities was modeled. Considering the electrical haulers to be autonomous enabled the execution of an optimal control policy for completing a task (i.e., moving material from A to B) free from user-based deviations. For the sake of the case study, the design space was further limited to a single type of hauler, although, in theory, any hauler could be included. The contextual variables included in the simulation consisted of variations in ambient temperature and road frictional loss. Figure 6 shows the result of running 72 simulations to find the most value-robust solution for the modeled operational scenario. Unfeasible designs are indicated by a grey dot lacking any internal number. The size and numerical annotation in the circles reflects the value of the system for the given context, where the value corresponds to the utilization degree at the specified production rate. The average aggregated value of a system for all contexts combined is denoted in the black rectangle box to the right end of the figure.

Figure 6. Value of a fleet of Haulers (SoS) for contextual changes within a mining site. The numbers in the black boxes on the right represent the aggregated value for the corresponding SoS.

It is worth noting that under the specified conditions of long routes, −3 °C and a road frictional loss of 0.05, none of the options can meet requirements. This underscores the crucial importance of maintaining optimal route conditions for fleet operation in such a case and how the robustness is better tackled by managing the operational context rather than investing in product design. The inherent value of simulation setups like this one lies in their versatility, enabling simulations across various mining sites. Performing these simulations iteratively can reveal the most value-robust configurations of systems, given the contextual changes. This is especially crucial when assessing the implications of transitioning to a circular business model, for instance, deploying a fleet of haulers to different mining sites throughout their lifecycle.

In Case C, the contextual complexity was represented by the energy supply and electrical infrastructure needed to support the project. In this case, computational support was deployed mainly to anticipate contextual complexity in battery-electric operations. Energy provision from the grid was identified early on as a major criticality in developing value-robust electrified solutions, being unevenly distributed in both time and space. The availability of electrical energy varies significantly throughout the day, week, and year due to various factors such as demand fluctuations, grid congestion, and supply constraints. The electrification of the site introduced new constraints to the operational schedule since this variability requires machine/site operators to constantly monitor the available power supply. At the same time, operational restrictions, such as the inability to work at night due to environmental legislation (i.e., noise), contribute to uneven distribution. Another criticality in large infrastructure projects is the distance to a sufficiently powerful connection point in the power grid. Localized generation (e.g., solar power) and storage solutions (e.g., batteries and hydrogen) are suggested to potentially mitigate these imbalances. The output of the simulations concerning behavioral complexity was fed into an energy simulation model that made it possible to explore the design space for the electrified solution in terms of charging strategy, site battery size, location of the charging points, number of batteries needed to operate the site, and more, in general, the design of the grid given the existing constraints. To deal with contextual complexity together with behavioral complexity, Case C explored the use of simulation support to:

-

• Model the energy supply systems, illustrating how a future energy distribution might look to supply a future fossil/emission-free infrastructure project.

-

• Model of site operations considering worst-case scenarios, using DES to simulate the work on the site and model various scenarios.

-

• Model the costs at the complete site/system level, demonstrating that the technical solutions developed can be translated into a commercially viable solution on a real site.

Similar models have been developed in Case D, which also partly focused on the large road construction project. In that case, simulation models addressed contextual changes such as alternative routes for the haulers, ore properties (i.e., the material excavated and carried by the machines), and weather conditions.

4.4. Foreseeing temporal complexity

Temporal complexity escalates the concept of contextual complexity by introducing a time dimension in the system-context interaction. It implies foreseeing the incurrence of external contextual factors as a sequence time. Often, this phenomenon is referred to as a contextual drift, where the order and interplay of these external factors are crucial. A sequential arrangement of these external factors is necessary to understand the implications of the irreversible decisions made at different times. For example, the decision to scale up a system (e.g., a bike-sharing system) to meet a peak in demand may not be easily reversed if the demand fluctuates in the future due to recurring seasonal changes, weather conditions, or economic conjuncture. In such a context, scenario-based simulations might be too limited if only linked to a specific time domain. However, the emergence of digital twins is increasingly recognized as a promising approach to address temporal complexity. Specifically, scholars envision a potential future where virtual beta prototypes (also termed “fake twins” by Bertoni & Bertoni Reference Bertoni and Bertoni2022) could play a crucial role. These virtual entities could simulate significant system design alterations while operating concurrently with their real-world counterpart. This concept hinges on the notion that, as these virtual models accumulate data over time, they will eventually reach a tipping point, indicating when a twin transitions from a mere simulation to a valuable predictive tool. Such tools would offer insights into future products and contextual dynamics for providers and customers, thereby factoring in considerations such as investments, switching costs, and risks into the decision-making equation.

The simulations developed in Cases B, C and D allowed engineering to manually change simulation parameters and test the models’ sensibility to future scenario variations. However, an application primarily addressing temporal complexity was lacking in the case studies. This is because the creation of such a digital twin needed to be coupled with capabilities for continuous data capturing and updating from the operational stages. In this way, a system of interest could be regularly monitored, analyzed and optimized based on changing conditions. However, to reach such a scenario, data needed to be collected during consecutive time periods, and a series of functional Beta prototypes of the systems needed to be available to support continuous improvement and development of the systems for years or potentially decades. Such a dataset spanning several years was not available during the case studies.

4.5. Investigating perceptual complexity through visualization and XR

The differences in the stakeholders’ opinions concerning a system’s value result in perceptual complexity. In such a case, the considerations of decision-maker’s cognitive and subjective biases are fundamental, particularly in multi-stakeholder environments, where efforts are often made to reconcile differing opinions. However, the essence of perceptual complexity is the dynamics of expectations from the system through time (Gaspar et al. Reference Gaspar, Rhodes, Ross and Erikstad2012). Effective decision-making during the design phases requires implementing practical data-gathering and communication strategies. Idrissov et al. (Reference Idrissov, Škec and Maier2020) enlist several visualization techniques intending to support decision-making, including parallel coordinate plots, tree diagrams, network diagrams, scatter plots, heat maps, and so forth. XR is an umbrella term for virtual, augmented and mixed reality technologies, delivering a variety of visual and interactive experiences. The rise in the capabilities of game engines and the availability of simulation tools integrating XR modules has made the use of XR applications increasingly popular among researchers and practitioners to tackle perceptual limitations (Davila Delgado et al. Reference Davila Delgado, Oyedele, Beach and Demian2020). Subjectivity is challenging to model, and research to address the perceptual complexity in system design is still in its infancy. Contributions in the field of PSS have focused on PSS perception by creating shared stakeholders’ experiences and providing a sense of full scalability, although implying the use of large physical prototypes (Bertoni & Ruvald Reference Bertoni and Ruvald2021). Instead, XR applications have been proposed to virtually replicate intangible and subjective customer experiences while testing systems, combining product-related and service-related features (Peruzzini et al. Reference Peruzzini, Mengoni and Raponi2016).

Case D investigated the dynamics of expectations for the new system in the case of autonomous vehicles collaborating with humans for road construction and ore extraction in a mine. In this case, simulation models addressed contextual changes such as alternative hauler routes, ore properties (i.e., the material excavated and carried by the machines), weather conditions, and so forth. In this case, XR was used to import machines in the scene, create fleets, configure the system (e.g., creating and visualizing paths), as well as organize the work (e.g., operators and schedules). The users could set specific requirements or ideal ranges (e.g., costs, emissions, timing) to identify the best possible strategies. 2D and 3D views allowed for viewing different road portions and angles. An example of output and parameters that could be manipulated and visualized in the application can be observed in Figure 7 (an extended description can be found in Scurati et al. Reference Scurati, Bertoni and Bertoni2022 and Machchhar et al. Reference Machchhar, Scurati and Bertoni2023b).

Figure 7. Virtual scene displaying haulers’ paths. Users can make choices for products, construction strategies and requirements and impact desired.

The user or team selected scenarios and contexts. Once the scenario was visualized, the navigation interface could be used to render a walkthrough of the scenario, either in a free modality focusing on a specific area or a guided way, navigating through the site and illustrating aspects depending on the user’s settings with the support of a virtual operator. Both drone and operator views could be selected to observe the whole scene or rather interact with specific objects and entities. Figure 8 illustrates a case-related demonstration of a guided walkthrough for a mining site while the other view-switching options are available on the sides. The case seeks to exploit virtual environments and their capabilities to explore and evaluate different aspects and involve different stakeholders while dealing with perceptual complexity. This is achieved by integrating alternative visualization and interaction modalities, allowing users to switch between observing the environment, viewing data and taking actions with a selective focus. This possibility supports a better assessment of problems and solutions and a better mutual understanding of how each actor performs this assessment. In turn, this provides a more transparent overview of perceptual complexity and helps the team investigate how perspectives can be merged.

Figure 8. A virtual guided walk through a mining site. The user can select the objects or locations to visit and the explanation they want to hear from the virtual guide.

5. Discussion

The framework presented in the article can be positioned at the intersection between academic literature focusing on circular product design and the literature concerning ilities identification and quantification in systems engineering. This article builds on the limitation of the current established product-centric approaches for circular design in addressing the full scale of potential circularity implications related to the design of more complex systems. The framework approaches the problem of assessing the value robustness of systems by decomposing the problem into the five levels of complexity introduced by the uncertainties ingrained in the system to be designed. This approach allows engineers to entirely or partially address those aspects individually until they agree that a sufficient level of awareness is reached to make a design decision. The framework for value-robust circular systems design is introduced as a complementary strategy to support product and systems circularity in the early design stages. This approach promotes a holistic perspective in design decision-making, supporting the development of more resilient and sustainable systems. Building on protocols for designing resilient systems, such as Fiskel (Reference Fiksel2003) proposed, this framework strengthens the feedback loop between exploring new technologies, proposing innovative concepts, and evaluating system performance. It provides methodological support to assess potential secondary impacts on system design, ensuring a more comprehensive evaluation process.

At the core of the proposed framework is the use of computer-based simulations (e.g., numerical computations, discrete-event, agent-based simulations) to support the numerical quantification of the value robustness of a system, that, together with the circularity assessment of specific subsystems of product components, creates an increased awareness about the circularity potential of the yet-to-be designed system. The possibility to numerically quantify and visualize the potential circularity implications of the overall system in early design becomes, therefore, a means to proactively design for more circular and eventually sustainable solutions, avoiding the risk of circularity considerations being perceived as a higher-level problem not operationalizable at the design level when systems and product requirements are set. Previous research in the field of value-driven design (Isaksson et al. Reference Isaksson, Kossmann, Bertoni, Eres, Monceaux, Bertoni, Wiseall and Zhang2013; Bertoni et al. Reference Bertoni, Bertoni, Panarotto, Johansson and Larsson2016) has discussed and demonstrated how to impact engineering practices effectively, methods for value assessment need to be integrated into everyday engineering work using tools and methods that practitioners commonly use. Based on the same rationale, the proposed framework suggests using simulation approaches, such as dynamic system simulations, discrete event simulations, and agent-based simulations, along with visualization techniques, such as XR, for enhanced decision-making during the early design stage. These tools have become increasingly accessible to engineers in recent years due to advancements in computational power and enhanced programming interfaces provided by various software vendors. XR environments developed with game engines and XR modules integrated into many DES software platforms can effectively present simulation content to decision-makers. This approach enhances their perception and understanding of simulation results, as demonstrated in case D. XR’s visualization and interaction capabilities allow users to experiment with cause-effects loops, editing the scene and receiving feedback. The implications of different choices, as well as events and changes in the context, could be presented in a user-friendly way for a variety of audiences, including stakeholders with both technical and nontechnical backgrounds and professional roles as engineers, site managers and operators. Moreover, this could enable discussions, knowledge sharing and perspective change.

The case studies showed that the combination of simulations, encompassing two or more aspects of complexity, supported a preliminary overall system of circularity considerations. This was possible at a project management/leadership level, without the necessity of the responsibility of the different simulation activities to be experts of circularity themselves, but instead focusing on a specific simulation approach in a complexity dimension. In fact, many of the engineers involved in the case studies who worked on detailed simulations did not specifically consider value robustness or circularity. The framework was then built bottom-up as a prescriptive solution, aggregating their final outputs of the different cases and contributing to increased system awareness on the multiple aspects central to providing innovative value-robust systems solutions. In a nutshell, the validation of each component of the framework has been run in different cases, while a complete validation of the overall framework as a unique stand-alone approach cannot be claimed.

The presented research can also be framed as a contribution to the academic discussion in the field of DTs, repeatedly stressing the need to use data from physical and virtual representations of products and systems to support decision-making during the design of forthcoming solutions regarding product performance and life cycle impact (e.g., Machchhar & Bertoni, Reference Machchhar and Bertoni2022). Nevertheless, in developing DTs, issues remain concerning dealing with uncertainty generated by lifecycle considerations in terms of assessing the economic impact and providing evidence of a proposed solution’s environmental and sustainability impact (Bertoni & Bertoni Reference Bertoni and Bertoni2022). The framework described in the paper and the connected case studies suggest that the concepts of systems simulations and DTs are central to creating more comprehensive decision support. However, some limitations are acknowledged when applied in real case studies, such as follows.

First, the description of the proposed framework did not address the selection and utilization of metamodeling methods to support the multidisciplinary analysis. Although deeming the representation and capturing of the relationships and interactions between different levels to be critical for successfully deploying the framework, such discussion has been considered outside the paper’s scope. The choice was driven both by the rationale of keeping the discussion revolving around the core contribution of the paper and by the lack of literature on a generic meta-modeling strategy to be applied for ilities modeling and assessment.

Second, while the framework introduces the design for value-robust changeable systems as a complementary strategy for circular product design, it does not specify which simulation approaches align with the design-for-X strategies for circular product design. Additionally, it does not explore the dimensions that should be considered essential for a specific design approach. For instance, the design team might prioritize investigating perceptual complexity concerning a product design typology centered on product attachment and emotional durability. In this case, investing in simulation support that emphasizes XR experiences could take precedence over developing simulation support for addressing architectural and structural complexity.

Third, the article presents cases of application of the proposed framework contextualized in the construction equipment industry. As mentioned in Section 4.5, the cases lack an application primarily addressing temporal complexity due to the absence of a large amount of data to be gathered during consecutive time periods. Such a dataset was not available in the timeframe of the research, leaving the task of foreseeing temporal complexity to future research. In this regard, Bertoni et al. (Reference Bertoni, Machchhar, Larsson and Frank2022) proposed the idea of running “fake twins” simulation, for instance, radical changes in the system that run in parallel with the entity that exists at present. The result would be the availability of both the real and fake instantiations of the twin running simultaneously over several scenarios based on the same dataset as input. However, to benefit from such fake twinning, the authors also highlighted that a considerable accumulation of data would be needed before the virtual models reach a tipping point showing when a fake twin will become value-adding, considering investments, switching costs, risks and so on.

Fourth, concerning visualization in XR, the latest development of game engines and XR platforms, including their integration with other simulation tools (e.g., DES software), has made such simulation and visualization models more accessible. However, many questions about their design have yet to be answered, for instance, concerning the level of detail and fidelity required to maximize the benefits of XR tools, the ideal interaction and navigation modalities, and the optimal level of immersion (i.e., using headsets or screen-based systems).

6. Conclusion

Designing value-robust circular systems introduces significant complexity, especially when making early-stage decisions with limited future knowledge about the product and the system to be designed. Existing methods focus on circular product development but lack comprehensive approaches for designing complex systems over long lifecycles. Identifying this gap, the article has proposed a value-robust circular systems design framework that integrates the use of computer-based simulations to reduce structural complexity, manage behavioral complexity, anticipate contextual complexity, foresee temporal complexity, and investigate perceptual complexity. The framework is introduced as complementary to circular product design approaches, proposing and demonstrating through four case studies the use of different simulation techniques. The case study implementations described in the article operationalize the proposed framework in the field of construction machinery and would need to be further refined and validated in future research in different industrial contexts.

Acknowledgements

The research presented in this paper has received financial support from the Swedish Innovation Agency through the TRUST-SOS and ASPECT research projects, from the Swedish Transport Administration (Trafikverket) through the project Elektrifierad Infrastrukturbyggnation and from Strategic Innovation Program Swedish Mining Innovation, concurrently funded by the Swedish Innovation Agency (VINNOVA), the Swedish Research Council for Sustainable Development (FORMAS) and the Swedish Energy Agency (Energimyndigheten) in the frame of the eTwin project.