1. Introduction

Wall-bounded turbulent flows over rough surfaces are among the most common examples of turbulent flows found in nature and engineering. Examples include pipe flows (e.g. Langelandsvik, Kunkel & Smits Reference Langelandsvik, Kunkel and Smits2008), geophysical flows (e.g. Lin et al. Reference Lin, Moeng, Sullivan and McWilliams1997), flows around ships (e.g. Schultz Reference Schultz2007), aircraft (e.g. Kundu, Raghunathan & Cooper Reference Kundu, Raghunathan and Cooper2000) and re-entry vehicles (e.g. Finson & Clarke Reference Finson and Clarke1980), flows within turbomachinery (e.g. Bons et al. Reference Bons, Taylor, McClain and Rivir2001), etc. The characteristics of turbulent flows over hydraulically rough surfaces are significantly different than for flows over surfaces that are considered hydraulically smooth, with the mechanisms responsible for these characteristics exhibiting strong dependence on the roughness geometry. Observed effects of surface roughness on wall-bounded turbulent flows include increased wall shear stress (Cardillo et al. Reference Cardillo, Chen, Araya, Newman, Jansen and Castillo2013), modification of the energy spectrum (Hong, Katz & Schultz Reference Hong, Katz and Schultz2011) and length scales (Cardillo et al. Reference Cardillo, Chen, Araya, Newman, Jansen and Castillo2013) of turbulence, creation of additional vortical structures (Ikeda & Durbin Reference Ikeda and Durbin2007), modification of velocity and Reynolds stress profiles (Krogstad, Antonia & Browne Reference Krogstad, Antonia and Browne1992; Krogstadt & Antonia Reference Krogstadt and Antonia1999; Keirsbulck et al. Reference Keirsbulck, Labraga, Mazouz and Tournier2002; Lee & Sung Reference Lee and Sung2007; Burattini et al. Reference Burattini, Leonardi, Orlandi and Antonia2008; Cardillo et al. Reference Cardillo, Chen, Araya, Newman, Jansen and Castillo2013) and changes to turbulent kinetic energy production (Ikeda & Durbin Reference Ikeda and Durbin2007; Burattini et al. Reference Burattini, Leonardi, Orlandi and Antonia2008).

The earliest effort to understand the effects of surface roughness can be traced back to the pipe flow measurements of Nikuradse (Reference Nikuradse1933). These experiments were used to characterise the dependence of wall shear stress, ![]() $\tau _w$, based on a uniform sand grain roughness height. To make the effects of wall roughness widely available to the scientific and engineering community, Moody (Reference Moody1944), continuing the work of Colebrook (Reference Colebrook1939), developed the Moody chart to predict pressure losses in smooth and rough pipe flows. The ensuing years saw a significant effort aimed at characterising and understanding the effects of arbitrary surface roughness on the scaling of the profile for the mean streamwise velocity component,

$\tau _w$, based on a uniform sand grain roughness height. To make the effects of wall roughness widely available to the scientific and engineering community, Moody (Reference Moody1944), continuing the work of Colebrook (Reference Colebrook1939), developed the Moody chart to predict pressure losses in smooth and rough pipe flows. The ensuing years saw a significant effort aimed at characterising and understanding the effects of arbitrary surface roughness on the scaling of the profile for the mean streamwise velocity component, ![]() $\bar {u}$, as a function of distance from the wall,

$\bar {u}$, as a function of distance from the wall, ![]() $y$. Here the overline is used to indicate a time-averaged quantity. As with smooth-walled flows, the mean velocity profile is commonly expressed using inner scaling, which reflects dependence on the wall shear stress,

$y$. Here the overline is used to indicate a time-averaged quantity. As with smooth-walled flows, the mean velocity profile is commonly expressed using inner scaling, which reflects dependence on the wall shear stress, ![]() $\tau _w$, and kinematic viscosity,

$\tau _w$, and kinematic viscosity, ![]() $\nu$. The velocity scale for inner scaling is therefore

$\nu$. The velocity scale for inner scaling is therefore ![]() $u_\tau =(\tau _w/\rho )^{1/2}$, and the length scale is

$u_\tau =(\tau _w/\rho )^{1/2}$, and the length scale is ![]() $\nu /u_\tau$, with

$\nu /u_\tau$, with ![]() $\rho$ being the density of the fluid. Throughout this article quantities scaled using these inner variables will be expressed using a superscripted

$\rho$ being the density of the fluid. Throughout this article quantities scaled using these inner variables will be expressed using a superscripted ![]() $+$, for example

$+$, for example ![]() $\bar {u}^{+}=\bar {u}/u_\tau$ and

$\bar {u}^{+}=\bar {u}/u_\tau$ and ![]() $y^{+}=yu_\tau /\nu$.

$y^{+}=yu_\tau /\nu$.

For flows over rough walls where the roughness height exceeds the depth of the corresponding smooth-walled viscous sublayer thickness, there exists a ‘roughness sublayer’ containing the dynamics of the roughness elements. Outside the roughness sublayer, the effect of the roughness is contained within the enhancement of ![]() $\tau _w$ and the mean profile follows the inner-scaled mean velocity scaling of Clauser (Reference Clauser1954) and Hama (Reference Hama1954). They found independently, and almost simultaneously, that the mean velocity profile could be described using a modification to the log law in the form of

$\tau _w$ and the mean profile follows the inner-scaled mean velocity scaling of Clauser (Reference Clauser1954) and Hama (Reference Hama1954). They found independently, and almost simultaneously, that the mean velocity profile could be described using a modification to the log law in the form of

In (1.1), ![]() $\kappa$ is the Kármán constant and

$\kappa$ is the Kármán constant and ![]() $B$ is an additive constant. The outer-layer contribution to the mean flow is represented through profile parameter

$B$ is an additive constant. The outer-layer contribution to the mean flow is represented through profile parameter ![]() $\varPi$ and wake function

$\varPi$ and wake function ![]() $W(y/\delta )$ (Coles Reference Coles1956). Here

$W(y/\delta )$ (Coles Reference Coles1956). Here ![]() $\delta$ indicates the thickness of the wall-bounded flow. The impact of surface roughness to the mean flow is introduced through the roughness function

$\delta$ indicates the thickness of the wall-bounded flow. The impact of surface roughness to the mean flow is introduced through the roughness function ![]() $\Delta U^{+}$ and

$\Delta U^{+}$ and ![]() $y_0^{+}$, the roughness offset which preserves the logarithmic scaling. For fully rough flows, i.e. for flows where the skin-friction coefficient plateaus (becomes essentially constant), the roughness function for uniform sand-grain roughness was found to be

$y_0^{+}$, the roughness offset which preserves the logarithmic scaling. For fully rough flows, i.e. for flows where the skin-friction coefficient plateaus (becomes essentially constant), the roughness function for uniform sand-grain roughness was found to be

where ![]() $k$ is the roughness height and

$k$ is the roughness height and ![]() $B'$ is a constant for fully rough flow. Arising from Nikuradse (Reference Nikuradse1933), the behaviour of the mean streamwise velocity in the log layer for sand-grain roughness,

$B'$ is a constant for fully rough flow. Arising from Nikuradse (Reference Nikuradse1933), the behaviour of the mean streamwise velocity in the log layer for sand-grain roughness, ![]() $k_s$, was found to be

$k_s$, was found to be

leading to ![]() $B'= 8.5$. An in-depth discussion of the various factors affecting

$B'= 8.5$. An in-depth discussion of the various factors affecting ![]() $\Delta U^{+}$ can be found in the recent review article by Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021).

$\Delta U^{+}$ can be found in the recent review article by Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021).

Despite the roughness function providing some characterisation of the rough surface, it fails to be universally valid across different roughness types (Schultz & Flack Reference Schultz and Flack2009; Flack & Schultz Reference Flack and Schultz2014). Schultz & Flack (Reference Schultz and Flack2009) have characterised this non-universality based on a functional relation given by

where ![]() $f$ depends on both the nature of the roughness and the Reynolds number and can vary among different roughness types especially when studying flows in the transitionally rough regime. Hence, it is common to characterise a surface using its ‘equivalent sand grain roughness’,

$f$ depends on both the nature of the roughness and the Reynolds number and can vary among different roughness types especially when studying flows in the transitionally rough regime. Hence, it is common to characterise a surface using its ‘equivalent sand grain roughness’, ![]() $k_s$, which is the value of

$k_s$, which is the value of ![]() $k$ that results in the mean velocity profile following (1.1), (1.2) and (1.3). For transitionally rough flow, the dependence of mean properties on the roughness geometry is particularly exacerbated, as the transition between viscous and pressure drag on the roughness elements is highly dependent on the element geometry.

$k$ that results in the mean velocity profile following (1.1), (1.2) and (1.3). For transitionally rough flow, the dependence of mean properties on the roughness geometry is particularly exacerbated, as the transition between viscous and pressure drag on the roughness elements is highly dependent on the element geometry.

For turbulence statistics, Townsend (Reference Townsend1976) hypothesised that for sufficiently high Reynolds numbers, the roughness-geometry-dependent behaviour is confined to within a few roughness heights of the wall and the flow in the outer region scales following smooth-wall scaling. Raupach, Antonia & Rjagopalan (Reference Raupach, Antonia and Rjagopalan1991) and Jiménez (Reference Jiménez2004) provide good reviews of the effects of surface roughness on turbulent flows while providing support for Townsend's outer-layer similarity hypothesis. Several experimental (e.g. Perry, Lim & Henbest Reference Perry, Lim and Henbest1987; Schultz & Flack Reference Schultz and Flack2003; Bakken et al. Reference Bakken, Krogstad, Ashrafian and Andersson2005; Connelly, Schultz & Flack Reference Connelly, Schultz and Flack2006; Kunkel & Marusic Reference Kunkel and Marusic2006; Schultz & Flack Reference Schultz and Flack2007) as well as numerical studies (e.g. Lee Reference Lee2002; Ashrafian, Andersson & Manhart Reference Ashrafian, Andersson and Manhart2004; Ashrafian & Andersson Reference Ashrafian and Andersson2006a, Reference Ashrafian and Anderssonb; Ikeda & Durbin Reference Ikeda and Durbin2007; Burattini et al. Reference Burattini, Leonardi, Orlandi and Antonia2008) have shown agreement with Townsend's outer-layer similarity hypothesis for boundary layer, pipe and channel flows. However, several studies have also shown that the effects of wall roughness can be found in the outer layer (e.g. Brzek et al. Reference Brzek, Cal, Johansson and Castillo2008; Cal et al. Reference Cal, Brzek, Johansson and Castillo2009; Hong et al. Reference Hong, Katz and Schultz2011; Cardillo et al. Reference Cardillo, Chen, Araya, Newman, Jansen and Castillo2013), particularly within the behaviour of the turbulence itself, providing evidence that roughness does indeed affect the flow in the outer layer. In some cases (e.g. Krogstad et al. Reference Krogstad, Antonia and Browne1992; Krogstadt & Antonia Reference Krogstadt and Antonia1999; Keirsbulck et al. Reference Keirsbulck, Labraga, Mazouz and Tournier2002; Smalley et al. Reference Smalley, Leonardi, Antonia, Djenidi and Orlandi2002; Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003; Lee & Sung Reference Lee and Sung2007) evidence has been presented showing the non-universality of Townsend's outer-layer similarity hypothesis.

Amongst the observations contradicting Townsend's outer-layer similarity hypothesis are those of Hong et al. (Reference Hong, Katz and Schultz2011) who found that traces of roughness effects in the outer layer can be found through propagation of roughness-length scaled eddies from the inner layer. Cardillo et al. (Reference Cardillo, Chen, Araya, Newman, Jansen and Castillo2013) also comment on the influence of the roughness extending well beyond the inner region of boundary layer flow. Effects of roughness were visible in the outer layer for the turbulent stress tensor as found by Lee & Sung (Reference Lee and Sung2007). However, there was a smaller effect on the anisotropic stress tensor in the outer layer with the same trend observed for third-order moments of the velocity fluctuations as well. In contrast, experimental studies from Krogstadt & Antonia (Reference Krogstadt and Antonia1999) and Keirsbulck et al. (Reference Keirsbulck, Labraga, Mazouz and Tournier2002) show significant changes in the Reynolds stress tensor within turbulent boundary layer flows over rough walls.

Jiménez (Reference Jiménez2004) noted that in many cases, the non-conformity of these flows with Taylor's hypothesis was dependent on the ratio of the roughness height to that of the boundary layer thickness, specifically dependent on whether or not ![]() $k$ protruded into the outer-scaled region, suggesting that

$k$ protruded into the outer-scaled region, suggesting that ![]() $k/\delta$ should be less than

$k/\delta$ should be less than ![]() $1/50$. Brzek et al. (Reference Brzek, Cal, Johansson and Castillo2008) postulated that in the case that the scale separation is not large, a mesolayer can be found between the inner and outer layers. This mesolayer diminishes with increasing Reynolds number but at lower Reynolds numbers can lead to the propagation of the viscous stresses from the inner layer to the outer layer. It was also hypothesised that in addition to having a small roughness height when compared with the boundary layer height, the momentum thickness Reynolds number must be greater than

$1/50$. Brzek et al. (Reference Brzek, Cal, Johansson and Castillo2008) postulated that in the case that the scale separation is not large, a mesolayer can be found between the inner and outer layers. This mesolayer diminishes with increasing Reynolds number but at lower Reynolds numbers can lead to the propagation of the viscous stresses from the inner layer to the outer layer. It was also hypothesised that in addition to having a small roughness height when compared with the boundary layer height, the momentum thickness Reynolds number must be greater than ![]() $10\,000$ for Townsend's outer-layer similarity hypothesis to be valid.

$10\,000$ for Townsend's outer-layer similarity hypothesis to be valid.

Another topic of debate is the choice of the appropriate length scale associated with the wall roughness. While Jiménez (Reference Jiménez2004) proposed the use of the ratio of roughness height to that of the boundary layer thickness, ![]() $k/\delta$, Flack, Schultz & Shapiro (Reference Flack, Schultz and Shapiro2005) and Schultz & Flack (Reference Schultz and Flack2005) suggest using the ratio of the effective sand grain roughness to that of the boundary layer thickness,

$k/\delta$, Flack, Schultz & Shapiro (Reference Flack, Schultz and Shapiro2005) and Schultz & Flack (Reference Schultz and Flack2005) suggest using the ratio of the effective sand grain roughness to that of the boundary layer thickness, ![]() $k_s/\delta$. More recently, efforts are being made to quantify the effects of three-dimensional (e.g. MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016; Wu, Christensen & Pantano Reference Wu, Christensen and Pantano2020) and increasingly irregular roughness on turbulent flows (e.g. Busse, Lützner & Sandham Reference Busse, Lützner and Sandham2015; Busse, Thakkar & Sandham Reference Busse, Thakkar and Sandham2017; Forooghi et al. Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017; Pathikonda & Christensen Reference Pathikonda and Christensen2017; Thakkar, Busse & Sandham Reference Thakkar, Busse and Sandham2017, Reference Thakkar, Busse and Sandham2018) aimed at analysing roughness characteristics which resemble naturally occurring roughness. However, the uncertainty and opposing observations associated with the behaviour of turbulent flows over even relatively simple roughness shapes requires further study to provide a better understanding of these flows.

$k_s/\delta$. More recently, efforts are being made to quantify the effects of three-dimensional (e.g. MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016; Wu, Christensen & Pantano Reference Wu, Christensen and Pantano2020) and increasingly irregular roughness on turbulent flows (e.g. Busse, Lützner & Sandham Reference Busse, Lützner and Sandham2015; Busse, Thakkar & Sandham Reference Busse, Thakkar and Sandham2017; Forooghi et al. Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017; Pathikonda & Christensen Reference Pathikonda and Christensen2017; Thakkar, Busse & Sandham Reference Thakkar, Busse and Sandham2017, Reference Thakkar, Busse and Sandham2018) aimed at analysing roughness characteristics which resemble naturally occurring roughness. However, the uncertainty and opposing observations associated with the behaviour of turbulent flows over even relatively simple roughness shapes requires further study to provide a better understanding of these flows.

The simplest parameterisation of surface roughness would be through the previously discussed roughness height, ![]() $k$, and a wavelength,

$k$, and a wavelength, ![]() $\lambda$, describing the distance between roughness peaks. Thus, here we examine the scaling behaviour of the roughness sublayer using turbulent channel flow with two-dimensional sinusoidal roughness – the simplest geometry containing both

$\lambda$, describing the distance between roughness peaks. Thus, here we examine the scaling behaviour of the roughness sublayer using turbulent channel flow with two-dimensional sinusoidal roughness – the simplest geometry containing both ![]() $k$ and

$k$ and ![]() $\lambda$. We also restrict our examination to channel flows, as performing numerical simulations for channel flows is relatively simple compared with that of boundary layer flows due to the convenience of using periodic boundary conditions without rescaling the flow or using any turbulence generation mechanisms (e.g. Lund, Wu & Squires Reference Lund, Wu and Squires1998; Klein, Sadiki & Janicka Reference Klein, Sadiki and Janicka2003; Xie & Castro Reference Xie and Castro2008; Wu Reference Wu2017; Dhamankar, Blaisdell & Lyrintzis Reference Dhamankar, Blaisdell and Lyrintzis2018).

$\lambda$. We also restrict our examination to channel flows, as performing numerical simulations for channel flows is relatively simple compared with that of boundary layer flows due to the convenience of using periodic boundary conditions without rescaling the flow or using any turbulence generation mechanisms (e.g. Lund, Wu & Squires Reference Lund, Wu and Squires1998; Klein, Sadiki & Janicka Reference Klein, Sadiki and Janicka2003; Xie & Castro Reference Xie and Castro2008; Wu Reference Wu2017; Dhamankar, Blaisdell & Lyrintzis Reference Dhamankar, Blaisdell and Lyrintzis2018).

Direct numerical simulations (DNS) by Ikeda & Durbin (Reference Ikeda and Durbin2007) observed that the rough wall serves as an energy source or sink for the turbulent kinetic energy flux through irregular spanwise vortex shedding. This observation was in agreement with what had been previously observed in experiments by Hanjalić & Launder (Reference Hanjalić and Launder1972) and Hudson, Dykhno & Hanratty (Reference Hudson, Dykhno and Hanratty1996) on the effect of two-dimensional roughness elements on turbulent channel flows. Additional DNS of sinusoidal turbulent channel flows by De Angelis, Lombardi & Banerjee (Reference De Angelis, Lombardi and Banerjee1997) provided support for Townsend's outer-layer similarity hypothesis and showed redistribution of turbulent kinetic energy in the spanwise direction in close proximity to the wave troughs. Direct numerical simulations conducted by Orlandi, Leonardi & Antonia (Reference Orlandi, Leonardi and Antonia2006) showed a weak dependence of the roughness function on the geometry of the roughness element unless the statistics were normalised by the wall normal Reynolds stress component, particularly for three-dimensional geometries (Orlandi & Leonardi Reference Orlandi and Leonardi2006).

The primary objective of this work is to quantitatively examine the roughness sublayer within sinusoidal roughness distributions on wall-bounded flows by comparing DNS of turbulent channel flows over smooth walls and walls with sinusoidal roughness shapes at matched friction Reynolds number. By analysing these simulations we intend to build on the previous work in this field and also try to find answers to the questions posed in Flack (Reference Flack2018). Comparisons of different roughness geometries are accomplished by varying the amplitude and wavelength of the sinusoidal wall to quantify the individual effects of varying one of these parameters independent of the other. We begin by analysing the first-order mean flow quantities to study the effects of wavelength and amplitude modification. A new set of reference scales based on the strength and diffusion characteristics of the shear layer are introduced to better capture the flow physics in the vicinity of the roughness elements. This scaling is used to extend the analysis of the first-order mean flow quantities to include higher-order quantities such as the components of the Reynolds stress tensor as well as the terms of the turbulent kinetic energy budget equation. We end this article by providing a heuristic model to estimate the pressure and skin drag acting on the roughness elements.

2. Computational methods

2.1. Computational methods and solver

A higher-order accurate, incompressible, spectral-element-based Navier–Stokes solver, Nek5000 (Fischer et al. Reference Fischer, Lottes, Kerkemeier, Marin, Heisey, Obabko, Merzari and Peet2016), was used to perform the DNS for this study. It uses a spectral-element method for spatial discretisation and the message passing interface for parallelisation making it well-suited for such large-scale turbulence computations (Offermans et al. Reference Offermans, Marin, Schanen, Gong, Fischer and Schlatter2016). The suitability of Nek5000 for performing such scale-resolved simulations has also been recently demonstrated by Rezaeiravesh, Vinuesa & Schlatter (Reference Rezaeiravesh, Vinuesa and Schlatter2021).

2.2. Flow conditions and parameters

The bulk Reynolds number

where ![]() $U_b$ is the volume averaged or ‘bulk’ velocity and

$U_b$ is the volume averaged or ‘bulk’ velocity and ![]() $\delta$ the channel half-height, was adjusted by modifying the kinematic viscosity to achieve a constant effective friction Reynolds number of

$\delta$ the channel half-height, was adjusted by modifying the kinematic viscosity to achieve a constant effective friction Reynolds number of

for all cases. Having a constant ![]() ${Re}_\tau$ ensures that the ratio between the geometric length scale,

${Re}_\tau$ ensures that the ratio between the geometric length scale, ![]() $\delta$, and viscous length scale,

$\delta$, and viscous length scale, ![]() $\nu /u_\tau$, is identical for all cases despite each case having significantly different

$\nu /u_\tau$, is identical for all cases despite each case having significantly different ![]() ${Re}$. Note that here we define

${Re}$. Note that here we define ![]() $u_\tau$ as the effective friction velocity using the total drag acting on the wall, i.e. contributions from both viscous and pressure drag are incorporated into

$u_\tau$ as the effective friction velocity using the total drag acting on the wall, i.e. contributions from both viscous and pressure drag are incorporated into ![]() $u_\tau$ such that

$u_\tau$ such that

\begin{equation} u_\tau = \sqrt{\frac{\tau_\nu + \tau_p}{\rho}} = \sqrt{\frac{\delta (-{\rm d}P/{{\rm d}\kern0.7pt x})}{\rho}}, \end{equation}

\begin{equation} u_\tau = \sqrt{\frac{\tau_\nu + \tau_p}{\rho}} = \sqrt{\frac{\delta (-{\rm d}P/{{\rm d}\kern0.7pt x})}{\rho}}, \end{equation}

where ![]() $\tau _\nu$ is the viscous shear stress at the wall,

$\tau _\nu$ is the viscous shear stress at the wall, ![]() $\tau _p$ is the component of pressure stress acting on the roughness elements parallel to the mean flow direction and

$\tau _p$ is the component of pressure stress acting on the roughness elements parallel to the mean flow direction and ![]() ${\rm d}P/{{\rm d}\kern0.7pt x}$ is the mean-pressure gradient along the channel. It should also be noted that this definition of

${\rm d}P/{{\rm d}\kern0.7pt x}$ is the mean-pressure gradient along the channel. It should also be noted that this definition of ![]() $u_\tau$ was used to follow the implementation in experimental studies where it is not possible to discriminate between viscous and pressure contributions to the wall shear stress.

$u_\tau$ was used to follow the implementation in experimental studies where it is not possible to discriminate between viscous and pressure contributions to the wall shear stress.

The different roughness cases considered, including their ![]() ${Re}$,

${Re}$, ![]() ${Re}_\tau$,

${Re}_\tau$, ![]() $u_\tau$ and wall steepness,

$u_\tau$ and wall steepness, ![]() $\sigma = 2a/\lambda$, have been provided in table 1. Note that the use of approximately constant

$\sigma = 2a/\lambda$, have been provided in table 1. Note that the use of approximately constant ![]() ${Re}_\tau$ means that comparison of cases using inner scaling will also act as a comparison in outer scaling. Topographical parameters such as the frontal solidity,

${Re}_\tau$ means that comparison of cases using inner scaling will also act as a comparison in outer scaling. Topographical parameters such as the frontal solidity, ![]() $\varLambda$, and streamwise effective slope are also provided. Frontal solidity, originally introduced by Schlichting (Reference Schlichting1936), is defined as the ratio of the total frontal projected area of the roughness in the direction perpendicular to the flow to the total plan area of the roughness in the direction parallel to the flow. For the cases being considered in this study, it is observed that the frontal solidity is equal to the steepness of the roughness element. Napoli, Armenio & De Marchis (Reference Napoli, Armenio and De Marchis2008) proposed an alternative to frontal solidity known as the streamwise effective slope,

$\varLambda$, and streamwise effective slope are also provided. Frontal solidity, originally introduced by Schlichting (Reference Schlichting1936), is defined as the ratio of the total frontal projected area of the roughness in the direction perpendicular to the flow to the total plan area of the roughness in the direction parallel to the flow. For the cases being considered in this study, it is observed that the frontal solidity is equal to the steepness of the roughness element. Napoli, Armenio & De Marchis (Reference Napoli, Armenio and De Marchis2008) proposed an alternative to frontal solidity known as the streamwise effective slope, ![]() $ES_x$, which depends on the gradient of the wall roughness element and is mathematically defined as

$ES_x$, which depends on the gradient of the wall roughness element and is mathematically defined as

where, ![]() $L_x$ and

$L_x$ and ![]() $L_z$ are the streamwise and spanwise domain lengths, respectively, and

$L_z$ are the streamwise and spanwise domain lengths, respectively, and ![]() $y_w$ is the wall location. It has been previously shown by Napoli et al. (Reference Napoli, Armenio and De Marchis2008) and MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) that

$y_w$ is the wall location. It has been previously shown by Napoli et al. (Reference Napoli, Armenio and De Marchis2008) and MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) that

It can also be shown that for the roughness configurations being considered in this study all three parameters ![]() $\varLambda$,

$\varLambda$, ![]() $ES_x$ and

$ES_x$ and ![]() $\sigma$ are related as

$\sigma$ are related as

Table 1. Summary of simulations (values in parentheses denote the corresponding inner-scaled values for amplitude, ![]() $a$ and wavelength,

$a$ and wavelength, ![]() $\lambda$). The bulk Reynolds number (

$\lambda$). The bulk Reynolds number (![]() ${Re}$), friction Reynolds number (

${Re}$), friction Reynolds number (![]() ${Re}_\tau$) and friction velocity (

${Re}_\tau$) and friction velocity (![]() $u_\tau$) are listed for all cases. Additional topographical parameters such as steepness (

$u_\tau$) are listed for all cases. Additional topographical parameters such as steepness (![]() $\sigma = 2a/\lambda$), streamwise effective slope (

$\sigma = 2a/\lambda$), streamwise effective slope (![]() $ES_x$) and frontal solidity (

$ES_x$) and frontal solidity (![]() $\varLambda$) are also provided. Here

$\varLambda$) are also provided. Here ![]() $T^{*} = Tu_\tau /\delta$ is the non-dimensional sampling period over which the averages have been collected for each of the runs;

$T^{*} = Tu_\tau /\delta$ is the non-dimensional sampling period over which the averages have been collected for each of the runs; ![]() $\delta$ and

$\delta$ and ![]() $U_b$ denote the channel half-height and the bulk velocity, respectively.

$U_b$ denote the channel half-height and the bulk velocity, respectively.

The present study shows a non-negligible dependence of the drag acting on the roughness element on the roughness wavelength in the sparse and nominally dense regimes which have not been analysed previously in the literature at such high ![]() ${Re}_\tau$. Interestingly, simulations by MacDonald et al. (Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018) and Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) have also shown a dependence on roughness wavelength for the dense roughness regime, indicating that this behaviour might not be regime specific. While previous studies have explored the possibility that the roughness wavelength is an important length scale when analysing flows past roughness, these studies have been at relatively low Reynolds numbers. Previous studies have looked at the effects of roughness on the wall shear stress and roughness function in the sparse regime (e.g. Chan et al. Reference Chan, Macdonald, Chung, Hutchins and Ooi2015, Reference Chan, MacDonald, Chung, Hutchins and Ooi2018; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2015; MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) but the relationship between the dynamics of the shear layer interacting with the roughness has been largely unexplored.

${Re}_\tau$. Interestingly, simulations by MacDonald et al. (Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018) and Forooghi et al. (Reference Forooghi, Stroh, Magagnato, Jakirlić and Frohnapfel2017) have also shown a dependence on roughness wavelength for the dense roughness regime, indicating that this behaviour might not be regime specific. While previous studies have explored the possibility that the roughness wavelength is an important length scale when analysing flows past roughness, these studies have been at relatively low Reynolds numbers. Previous studies have looked at the effects of roughness on the wall shear stress and roughness function in the sparse regime (e.g. Chan et al. Reference Chan, Macdonald, Chung, Hutchins and Ooi2015, Reference Chan, MacDonald, Chung, Hutchins and Ooi2018; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2015; MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) but the relationship between the dynamics of the shear layer interacting with the roughness has been largely unexplored.

2.3. Computational set-up

Figure 1(a) gives a schematic representation of the computational domain with figure 1(b) showing an enlarged view of the computational mesh. The top and bottom walls are symmetric around the midplane, i.e. ![]() $y = \delta$. This enables averaging of the data across the top and bottom halves of the domain. Figure 1(a) also provides information about the various geometric parameters used to define the channel and surface roughness geometries. In general

$y = \delta$. This enables averaging of the data across the top and bottom halves of the domain. Figure 1(a) also provides information about the various geometric parameters used to define the channel and surface roughness geometries. In general ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ are used to indicate streamwise, vertical (wall-normal for smooth wall) and spanwise directions with the corresponding velocity components being

$z$ are used to indicate streamwise, vertical (wall-normal for smooth wall) and spanwise directions with the corresponding velocity components being ![]() $u$,

$u$, ![]() $v$ and

$v$ and ![]() $w$, respectively.

$w$, respectively.

Figure 1. (![]() $a$) Computational domain for turbulent channel flow simulation with sinusoidal walls at the top and bottom boundaries. (

$a$) Computational domain for turbulent channel flow simulation with sinusoidal walls at the top and bottom boundaries. (![]() $b$) Enlarged view of the computational mesh in the

$b$) Enlarged view of the computational mesh in the ![]() $x$–

$x$–![]() $y$ plane showing the spectral elements for the

$y$ plane showing the spectral elements for the ![]() $a^{+} = 18$,

$a^{+} = 18$, ![]() $\lambda = {\rm \pi}/8$ case. Each spectral element contains eight GLL points each in the

$\lambda = {\rm \pi}/8$ case. Each spectral element contains eight GLL points each in the ![]() $x$ and

$x$ and ![]() $y$ directions.

$y$ directions.

The fully developed turbulent channel flow is considered homogeneous in the streamwise and spanwise directions, enabling the use of periodic boundary conditions to increase the computational efficiency. No-slip wall boundary conditions are applied at the top and bottom walls. Identical domain sizes are used for all simulations in this study. All cases except case 4 use the exact same grid with the exception of the shape of the sinusoidal roughness. Case 4 uses a grid with more points in the streamwise direction to increase the number of points available to resolve each individual sinusoidal roughness element. The details of the grids are given in table 2.

Table 2. Details of the computational grid for the DNS runs being presented in this study. The case numbers represent the corresponding runs from table 1. Here ![]() $L_{i}$ indicates the mean domain extent in the

$L_{i}$ indicates the mean domain extent in the ![]() $i$th coordinate direction, with

$i$th coordinate direction, with ![]() $N_{el,i}$ and

$N_{el,i}$ and ![]() $N_{i}$ referring to the number of grid elements and the total number of grid points in the

$N_{i}$ referring to the number of grid elements and the total number of grid points in the ![]() $i$th coordinate direction;

$i$th coordinate direction; ![]() $\Delta x_{min}$ and

$\Delta x_{min}$ and ![]() $\Delta x_{max}$ denote the minimum and maximum grid spacing in the streamwise (

$\Delta x_{max}$ denote the minimum and maximum grid spacing in the streamwise (![]() $x$) direction. The minimum and maximum grid spacings in the

$x$) direction. The minimum and maximum grid spacings in the ![]() $y$ and

$y$ and ![]() $z$ directions are the same for all cases. The minimum and maximum grid spacings in inner units for the

$z$ directions are the same for all cases. The minimum and maximum grid spacings in inner units for the ![]() $y$ direction are

$y$ direction are ![]() $0.29$ and

$0.29$ and ![]() $1.9$, respectively. Similarly, for the

$1.9$, respectively. Similarly, for the ![]() $z$ direction the corresponding inner-scaled values are

$z$ direction the corresponding inner-scaled values are ![]() $2.27$ and

$2.27$ and ![]() $7.40$, respectively.

$7.40$, respectively.

Although not long enough to capture the long wavelength outer-layer structures (Kim & Adrian Reference Kim and Adrian1999; Adrian, Meinhart & Tomkins Reference Adrian, Meinhart and Tomkins2000; Monty et al. Reference Monty, Stewart, Williams and Chong2007; Smits, McKeon & Marusic Reference Smits, McKeon and Marusic2011) the domain length in the streamwise direction is sufficient to correctly capture the near-wall low-frequency longitudinal streaks (Aubry et al. Reference Aubry, Holmes, Lumley and Stone1988) and preliminary simulations run for the smooth-wall mesh at ![]() ${Re}_\tau =590$ matched the results of Moser, Kim & Mansour (Reference Moser, Kim and Mansour1999).

${Re}_\tau =590$ matched the results of Moser, Kim & Mansour (Reference Moser, Kim and Mansour1999).

For the smooth-wall turbulent channel case, the simulation was conducted at a sub-Kolmogorov grid resolution with the Kolmogorov length scale, ![]() $\eta =\nu ^{3/4}/\bar {\varepsilon }^{1/4}$, where

$\eta =\nu ^{3/4}/\bar {\varepsilon }^{1/4}$, where ![]() $\bar {\varepsilon }$ is the temporally averaged dissipation rate of turbulent kinetic energy. The variation of the Kolmogorov scale relative to the grid spacing in the

$\bar {\varepsilon }$ is the temporally averaged dissipation rate of turbulent kinetic energy. The variation of the Kolmogorov scale relative to the grid spacing in the ![]() $y$ direction is given in figure 2. The smallest distance between two grid points, given by the Gauss–Legendre–Lobatto (GLL) quadrature, occurred at the wall with a value of

$y$ direction is given in figure 2. The smallest distance between two grid points, given by the Gauss–Legendre–Lobatto (GLL) quadrature, occurred at the wall with a value of ![]() $4.051 \times 10^{-4} \delta$ (

$4.051 \times 10^{-4} \delta$ (![]() $0.2899$ in inner units). Similarly, the largest distance between two GLL points in the grid occurred at the centreline and was

$0.2899$ in inner units). Similarly, the largest distance between two GLL points in the grid occurred at the centreline and was ![]() $2.643 \times 10^{-3} \delta$ (

$2.643 \times 10^{-3} \delta$ (![]() $1.892$ in inner units).

$1.892$ in inner units).

Figure 2. Ratio of element averaged wall-normal grid-spacing, ![]() $\Delta y$, to that of the element averaged Kolmogorov length scale,

$\Delta y$, to that of the element averaged Kolmogorov length scale, ![]() $\eta$.

$\eta$.

Direct numerical simulations were performed for a total of six channel cases with one smooth-wall case and five wavy-wall cases where the amplitude, ![]() $a$, and wavelength,

$a$, and wavelength, ![]() $\lambda$, of the roughness was varied to generate different roughness profiles and examine the effect of these parameters on mean flow quantities and turbulence statistics. The vertical displacement of the sinusoidal surface at the bottom wall,

$\lambda$, of the roughness was varied to generate different roughness profiles and examine the effect of these parameters on mean flow quantities and turbulence statistics. The vertical displacement of the sinusoidal surface at the bottom wall, ![]() $y_w$, relative to the surface of a smooth wall is given by

$y_w$, relative to the surface of a smooth wall is given by

where ![]() $\tilde {x}=\text {mod}(x,\lambda )$. A summary of the geometric as well as flow parameters for all geometries which are a part of this study has been provided in table 1. To resolve each roughness element adequately, at least 32 points have been used to capture the individual elements in the streamwise direction. The short wavelength associated with the roughness element in case 4 made it necessary to employ a more resolved grid for this case. Care was taken to ensure that the maximum streamwise grid-spacing was always below 10 wall units, as shown in table 1.

$\tilde {x}=\text {mod}(x,\lambda )$. A summary of the geometric as well as flow parameters for all geometries which are a part of this study has been provided in table 1. To resolve each roughness element adequately, at least 32 points have been used to capture the individual elements in the streamwise direction. The short wavelength associated with the roughness element in case 4 made it necessary to employ a more resolved grid for this case. Care was taken to ensure that the maximum streamwise grid-spacing was always below 10 wall units, as shown in table 1.

The computational approach consisted of two main simulation stages. In the first stage, the flow was initialised using a laminar channel flow solution with some initial perturbations to accelerate the transition to turbulence. The skin friction values were monitored as a function of time to determine the statistical convergence of the fully turbulent flow. Once the flow was past the initial transient phase and had reached statistical convergence of the wall shear stress, a second stage was initiated in which in situ time-averaging of the flow field was performed to extract mean flow and turbulent statistics. These statistics were then monitored to ensure that statistical convergence was achieved for the entire flow field.

2.4. Averaging of flow data

The velocity components of the turbulent flow, e.g. ![]() $u$, were decomposed into their time-averaged flow component

$u$, were decomposed into their time-averaged flow component ![]() $\bar {u}$ and a fluctuating part

$\bar {u}$ and a fluctuating part ![]() $u'$, so that

$u'$, so that

following Reynolds decomposition. Homogeneity in the ![]() $x$ and

$x$ and ![]() $z$ directions for the smooth-wall case enabled spatial averaging of all flow quantities leading to one-dimensional distributions which only depend on the

$z$ directions for the smooth-wall case enabled spatial averaging of all flow quantities leading to one-dimensional distributions which only depend on the ![]() $y$ coordinate. For the sinusoidal rough-wall cases, the statistics remain homogeneous in the

$y$ coordinate. For the sinusoidal rough-wall cases, the statistics remain homogeneous in the ![]() $z$ direction while becoming periodic in the

$z$ direction while becoming periodic in the ![]() $x$ direction with a wavelength of

$x$ direction with a wavelength of ![]() $\lambda$. Thus the two-dimensional flow field was averaged in the spanwise direction and averaged for each value of

$\lambda$. Thus the two-dimensional flow field was averaged in the spanwise direction and averaged for each value of ![]() $y_w$ across a wavelength giving one-dimensional profiles varying with

$y_w$ across a wavelength giving one-dimensional profiles varying with ![]() $\tilde {y}_w = y - y_w$. In general, an over-bar here indicates temporal averaging of a given quantity and

$\tilde {y}_w = y - y_w$. In general, an over-bar here indicates temporal averaging of a given quantity and ![]() $\langle \cdot \rangle$ indicates additional wavelength averaging that has been performed on the time-averaged quantities. The

$\langle \cdot \rangle$ indicates additional wavelength averaging that has been performed on the time-averaged quantities. The ![]() $\lambda$-periodicity of the wavy-wall cases also enables us to define

$\lambda$-periodicity of the wavy-wall cases also enables us to define ![]() $\tilde {x} = \text {mod}(x,\lambda )$, which acts as a non-dimensional distance ranging from

$\tilde {x} = \text {mod}(x,\lambda )$, which acts as a non-dimensional distance ranging from ![]() $0$ to

$0$ to ![]() $1$.

$1$.

One-dimensional profiles of wavelength-averaged quantities were obtained by averaging points at a constant vertical distance from the wall, specifically at constant ![]() $\tilde {y} = y - y_w$. The non-dimensional sampling period,

$\tilde {y} = y - y_w$. The non-dimensional sampling period, ![]() $T^{*} = Tu_\tau /\delta$ for each of the cases has been provided in table 1. Each of the cases have been spatially and temporally averaged for at least one flow through time,

$T^{*} = Tu_\tau /\delta$ for each of the cases has been provided in table 1. Each of the cases have been spatially and temporally averaged for at least one flow through time, ![]() $T_f = L_x/U_b$.

$T_f = L_x/U_b$.

3. Results

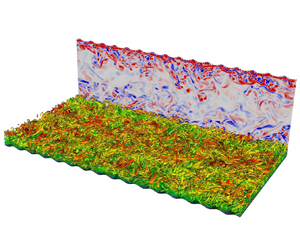

3.1. Instantaneous velocity fields

Figure 3(a–l) present example instantaneous fields of ![]() $u/U_b$ and

$u/U_b$ and ![]() $v/U_b$ for each of the cases. As expected, increasing the amplitude of roughness corresponds to an increase in

$v/U_b$ for each of the cases. As expected, increasing the amplitude of roughness corresponds to an increase in ![]() $u/U_b$ due to the increased confinement of the flow, however, otherwise there is little qualitative difference in

$u/U_b$ due to the increased confinement of the flow, however, otherwise there is little qualitative difference in ![]() $u/U_b$, as can be seen from figure 3(a,c,e,g,k). Compared with the smooth-wall case, there is a corresponding increase in the granularity of the

$u/U_b$, as can be seen from figure 3(a,c,e,g,k). Compared with the smooth-wall case, there is a corresponding increase in the granularity of the ![]() $v$ component near the wall, as shown in figure 3(b,d,f,h,j,l), which is particularly noticeable with an increase in

$v$ component near the wall, as shown in figure 3(b,d,f,h,j,l), which is particularly noticeable with an increase in ![]() $a$. There also appears to be a qualitative increase in the scale of

$a$. There also appears to be a qualitative increase in the scale of ![]() $v$ fluctuations near the centreline with increased

$v$ fluctuations near the centreline with increased ![]() $a$. However, quantitative investigation of such flow features by, for example, employing coherence analysis is beyond the scope of the present paper.

$a$. However, quantitative investigation of such flow features by, for example, employing coherence analysis is beyond the scope of the present paper.

Figure 3. Colour contours of fully developed streamwise (a,c,e,g,i,k) and vertical (b,d,f,h,j,l) velocity fields for the six cases being analysed in this study. The colour bars at the top of (a,c,e,g,i,k) and (b,d,f,h,j,l) are for the streamwise and vertical velocity, respectively. (a) Smooth wall; (b) smooth wall; (c) ![]() $a^{+} = 9$,

$a^{+} = 9$, ![]() $\lambda = {\rm \pi}/8$; (d)

$\lambda = {\rm \pi}/8$; (d) ![]() $a^{+} = 9$,

$a^{+} = 9$, ![]() $\lambda = {\rm \pi}/8$; (e)

$\lambda = {\rm \pi}/8$; (e) ![]() $a^{+} = 9$,

$a^{+} = 9$, ![]() $\lambda = {\rm \pi}/16$; (f)

$\lambda = {\rm \pi}/16$; (f) ![]() $a^{+} = 9$,

$a^{+} = 9$, ![]() $\lambda = {\rm \pi}/16$; (g)

$\lambda = {\rm \pi}/16$; (g) ![]() $a^{+} = 9$,

$a^{+} = 9$, ![]() $\lambda = {\rm \pi}/32$; (h)

$\lambda = {\rm \pi}/32$; (h) ![]() $a^{+} = 9$,

$a^{+} = 9$, ![]() $\lambda = {\rm \pi}/32$; (i)

$\lambda = {\rm \pi}/32$; (i) ![]() $a^{+} = 18$,

$a^{+} = 18$, ![]() $\lambda = {\rm \pi}/8$; (j)

$\lambda = {\rm \pi}/8$; (j) ![]() $a^{+} = 18$,

$a^{+} = 18$, ![]() $\lambda = {\rm \pi}/8$; (k)

$\lambda = {\rm \pi}/8$; (k) ![]() $a^{+} = 36$,

$a^{+} = 36$, ![]() $\lambda = {\rm \pi}/8$; (l)

$\lambda = {\rm \pi}/8$; (l) ![]() $a^{+} = 36$,

$a^{+} = 36$, ![]() $\lambda = {\rm \pi}/8$.

$\lambda = {\rm \pi}/8$.

3.2. Mean velocity

The spatially averaged one-dimensional profiles of the mean streamwise velocity, ![]() $\langle u \rangle ^{+}$, for all cases are shown in figure 4(a). There are noticeable effects of wavelength and amplitude on these profiles that are consistent with well-established effects of roughness on the mean streamwise velocity. In particular, the increase in the total drag force acting on the wall due to the pressure drag on the surface area normal to the flow results in a corresponding reduction in the magnitude of

$\langle u \rangle ^{+}$, for all cases are shown in figure 4(a). There are noticeable effects of wavelength and amplitude on these profiles that are consistent with well-established effects of roughness on the mean streamwise velocity. In particular, the increase in the total drag force acting on the wall due to the pressure drag on the surface area normal to the flow results in a corresponding reduction in the magnitude of ![]() $\langle u \rangle ^{+}$ profiles; an effect represented by the roughness function defined in (1.2). Note that the Reynolds numbers considered in these simulations were not large enough to obtain a fully logarithmic overlap layer. However, there is an approximately logarithmic region evident in figure 4(a) initiating at a

$\langle u \rangle ^{+}$ profiles; an effect represented by the roughness function defined in (1.2). Note that the Reynolds numbers considered in these simulations were not large enough to obtain a fully logarithmic overlap layer. However, there is an approximately logarithmic region evident in figure 4(a) initiating at a ![]() $\tilde {y}^{+}$ location that is dependent on the dimensions of the roughness elements. The slope of this approximately logarithmic region is also affected by the presence of the roughness. The change in the slope is most prominently seen for the green curve (

$\tilde {y}^{+}$ location that is dependent on the dimensions of the roughness elements. The slope of this approximately logarithmic region is also affected by the presence of the roughness. The change in the slope is most prominently seen for the green curve (![]() $a^{+} = 36$,

$a^{+} = 36$, ![]() $\lambda = {\rm \pi}/8$ case) in figure 4(a).

$\lambda = {\rm \pi}/8$ case) in figure 4(a).

Figure 4. Analysis of streamwise and wall-normal mean velocity components for all cases: (![]() $a$) spatially averaged one-dimensional profiles of the mean streamwise velocity,

$a$) spatially averaged one-dimensional profiles of the mean streamwise velocity, ![]() $\langle u \rangle ^{+}$; (

$\langle u \rangle ^{+}$; (![]() $b$) modified scaling for

$b$) modified scaling for ![]() $\langle u \rangle ^{+}$ following (1.2); (

$\langle u \rangle ^{+}$ following (1.2); (![]() $c$) spatially averaged one-dimensional profiles of the mean velocity component in the

$c$) spatially averaged one-dimensional profiles of the mean velocity component in the ![]() $\tilde {y}$ direction,

$\tilde {y}$ direction, ![]() $\langle v \rangle ^{+}$; (

$\langle v \rangle ^{+}$; (![]() $d$) effect of steepness on

$d$) effect of steepness on ![]() $\langle v \rangle ^{+}$. The vertical lines in (

$\langle v \rangle ^{+}$. The vertical lines in (![]() $b$) indicate the wall-normal locations corresponding to

$b$) indicate the wall-normal locations corresponding to ![]() $(\tilde {y} - a)/\lambda = 0.3$ based on (

$(\tilde {y} - a)/\lambda = 0.3$ based on (![]() $d$) after which the effect of the roughness is negligible and all profiles collapse. The filled-in square, triangle and diamond shapes on the

$d$) after which the effect of the roughness is negligible and all profiles collapse. The filled-in square, triangle and diamond shapes on the ![]() $x$-axis in (

$x$-axis in (![]() $a$) and (

$a$) and (![]() $b$) show the location of the viscous scaled semiamplitude in the corresponding coordinate scale for

$b$) show the location of the viscous scaled semiamplitude in the corresponding coordinate scale for ![]() $a^{+} = 9$,

$a^{+} = 9$, ![]() $a^{+} = 18$ and

$a^{+} = 18$ and ![]() $a^{+} = 36$ cases, respectively.

$a^{+} = 36$ cases, respectively.

The influence of the surface roughness on the scaling of the mean streamwise velocity is, therefore, well encapsulated by (1.1) with the roughness effect described by the parameters ![]() $\Delta U^{+}$ and

$\Delta U^{+}$ and ![]() $y_0$, which manifest as the vertical shift in the approximately log layer and change of steepness of the mean velocity profile, respectively. For the present simulations, it was found that the roughness function values tabulated in table 3 provided the best agreement of the mean velocity profiles in the outer layer. It was also found that expressing

$y_0$, which manifest as the vertical shift in the approximately log layer and change of steepness of the mean velocity profile, respectively. For the present simulations, it was found that the roughness function values tabulated in table 3 provided the best agreement of the mean velocity profiles in the outer layer. It was also found that expressing ![]() $y_0 = y_0' + a_*$ provides the best results, where

$y_0 = y_0' + a_*$ provides the best results, where ![]() $y_0'$ is an amplitude-dependent length scale and

$y_0'$ is an amplitude-dependent length scale and ![]() $a_*$ is a constant which provides a shift in the virtual origin to account for the depth of the smooth-wall viscous sublayer which must be exceeded by

$a_*$ is a constant which provides a shift in the virtual origin to account for the depth of the smooth-wall viscous sublayer which must be exceeded by ![]() $a$ for the flow to start exhibiting roughness effects. Using

$a$ for the flow to start exhibiting roughness effects. Using ![]() $y_0'=a/3$ and

$y_0'=a/3$ and ![]() $a_*=5\nu /u_\tau$ brought the most consistent agreement amongst the profiles within the approximately logarithmic region. The roughness function was determined by finding the value of

$a_*=5\nu /u_\tau$ brought the most consistent agreement amongst the profiles within the approximately logarithmic region. The roughness function was determined by finding the value of ![]() $\Delta U^{+}$ which provided the closest collapse of the data with the smooth-wall case once the virtual offset

$\Delta U^{+}$ which provided the closest collapse of the data with the smooth-wall case once the virtual offset ![]() $y_0$ has been applied to the wall-normal coordinate.

$y_0$ has been applied to the wall-normal coordinate.

Table 3. Values of roughness parameters for each of the five roughness configurations.

This resulting agreement is shown in figure 4(b), which shows collapse of the scaled profiles for ![]() $\tilde {y}^{+} -y_0^{+}\gtrapprox 100$. Below this point, the agreement of the rough-wall profiles with the smooth-wall profile becomes dependent on the geometry of the roughness.

$\tilde {y}^{+} -y_0^{+}\gtrapprox 100$. Below this point, the agreement of the rough-wall profiles with the smooth-wall profile becomes dependent on the geometry of the roughness.

A more contemporary approach to study the effect of surface roughness is to correlate the frontal solidity values for the roughness elements with the roughness function based on the density of roughness elements. Using the criterion that any roughness with ![]() $\varLambda < 0.15$ belongs to the sparse regime and roughness with

$\varLambda < 0.15$ belongs to the sparse regime and roughness with ![]() $\varLambda > 0.15$ belongs to the dense regime, cases 2, 3 and 5 correspond to the sparse regime, whereas cases 4 and 6 belong to the dense regime (see table 1). Jiménez (Reference Jiménez2004) and Flack & Schultz (Reference Flack and Schultz2014) have previously observed that the roughness function increases with the solidity in the sparse regime and decreases with the solidity in the dense regime. More recently, Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) and MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) reported that the distinction between the sparse and dense roughness regimes might not be at

$\varLambda > 0.15$ belongs to the dense regime, cases 2, 3 and 5 correspond to the sparse regime, whereas cases 4 and 6 belong to the dense regime (see table 1). Jiménez (Reference Jiménez2004) and Flack & Schultz (Reference Flack and Schultz2014) have previously observed that the roughness function increases with the solidity in the sparse regime and decreases with the solidity in the dense regime. More recently, Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) and MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) reported that the distinction between the sparse and dense roughness regimes might not be at ![]() $\varLambda = 0.15$. While Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) observed that

$\varLambda = 0.15$. While Placidi & Ganapathisubramani (Reference Placidi and Ganapathisubramani2015) observed that ![]() $\varLambda \geq 0.21$ marked the start of the dense regime, MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) noticed that

$\varLambda \geq 0.21$ marked the start of the dense regime, MacDonald et al. (Reference MacDonald, Chan, Chung, Hutchins and Ooi2016) noticed that ![]() $\varLambda \geq 0.18$ indicated the transition between these regimes. This distinction is even more uncertain when considering non-uniform surface roughness configurations (Napoli et al. Reference Napoli, Armenio and De Marchis2008), wherein the start of the dense regime can occur at

$\varLambda \geq 0.18$ indicated the transition between these regimes. This distinction is even more uncertain when considering non-uniform surface roughness configurations (Napoli et al. Reference Napoli, Armenio and De Marchis2008), wherein the start of the dense regime can occur at ![]() $\varLambda$ values as high as

$\varLambda$ values as high as ![]() $0.275$. The wide range of

$0.275$. The wide range of ![]() $\varLambda$ values which mark the beginning of the dense regime, would mean that any uniform roughness with

$\varLambda$ values which mark the beginning of the dense regime, would mean that any uniform roughness with ![]() $0.15 \leq \varLambda \leq 0.25$ can be in either of the two regimes. In their recent review paper, Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) mention that the transition to the dense regime (indicated by a peak in the drag), can lie in a very broad range, i.e.

$0.15 \leq \varLambda \leq 0.25$ can be in either of the two regimes. In their recent review paper, Chung et al. (Reference Chung, Hutchins, Schultz and Flack2021) mention that the transition to the dense regime (indicated by a peak in the drag), can lie in a very broad range, i.e. ![]() $0.1 \leq \varLambda \leq 0.3$.

$0.1 \leq \varLambda \leq 0.3$.

While cases 2, 3 and 5 are most certainly in the sparse regime, cases 4 and 6 can be considered nominally dense, since the ![]() $\varLambda$ values for these cases (

$\varLambda$ values for these cases (![]() $\varLambda = 0.2546$) are very close to the limiting values discussed above. The observed trends in

$\varLambda = 0.2546$) are very close to the limiting values discussed above. The observed trends in ![]() $\Delta U^{+}$ for cases 2, 3 and 5 agree well with the previous literature (Jiménez Reference Jiménez2004; Napoli et al. Reference Napoli, Armenio and De Marchis2008; Flack & Schultz Reference Flack and Schultz2014; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2015; MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021) showing an increase in

$\Delta U^{+}$ for cases 2, 3 and 5 agree well with the previous literature (Jiménez Reference Jiménez2004; Napoli et al. Reference Napoli, Armenio and De Marchis2008; Flack & Schultz Reference Flack and Schultz2014; Placidi & Ganapathisubramani Reference Placidi and Ganapathisubramani2015; MacDonald et al. Reference MacDonald, Chan, Chung, Hutchins and Ooi2016; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021) showing an increase in ![]() $\Delta U^{+}$ with increasing

$\Delta U^{+}$ with increasing ![]() $\varLambda$. For roughness in the dense regime, the roughness function is expected to decrease with increasing

$\varLambda$. For roughness in the dense regime, the roughness function is expected to decrease with increasing ![]() $\varLambda$, but this trend is not observed for cases 4 and 6. The roughness function still increases despite the frontal solidity being above the conventional threshold value of

$\varLambda$, but this trend is not observed for cases 4 and 6. The roughness function still increases despite the frontal solidity being above the conventional threshold value of ![]() $\varLambda = 0.15$. It should be noted that this is a relatively small sample size that was used, and it would be very difficult to generalise these trends based on only five cases. However, keeping in view with conventional estimates, cases 4 and 6 will be referred to as being nominally dense hereafter.

$\varLambda = 0.15$. It should be noted that this is a relatively small sample size that was used, and it would be very difficult to generalise these trends based on only five cases. However, keeping in view with conventional estimates, cases 4 and 6 will be referred to as being nominally dense hereafter.

Another important observation is that despite having the same ![]() $\varLambda$ the values of

$\varLambda$ the values of ![]() $\Delta U^{+}$ are vastly different for cases 3 and 5, and cases 4 and 6, indicating that

$\Delta U^{+}$ are vastly different for cases 3 and 5, and cases 4 and 6, indicating that ![]() $\varLambda$ alone is not sufficient to completely capture the effects of surface roughness. The present study provides an analysis of a limited set of roughness element configurations due to the extremely high computational costs associated with these simulations, however, these results reinforce what has previously been observed in the literature. It is extremely difficult to quantify the effects of surface roughness on turbulent flows without considering a combined effect of the geometrical parameters of the roughness. Cases 2, 3, 4 and 5 have shown that regardless of the roughness regime, roughness configurations having the same

$\varLambda$ alone is not sufficient to completely capture the effects of surface roughness. The present study provides an analysis of a limited set of roughness element configurations due to the extremely high computational costs associated with these simulations, however, these results reinforce what has previously been observed in the literature. It is extremely difficult to quantify the effects of surface roughness on turbulent flows without considering a combined effect of the geometrical parameters of the roughness. Cases 2, 3, 4 and 5 have shown that regardless of the roughness regime, roughness configurations having the same ![]() $\varLambda$ (or

$\varLambda$ (or ![]() $\sigma$) values can have different roughness functions and drag values.

$\sigma$) values can have different roughness functions and drag values.

Although the value of ![]() $y_0$ appears to be a function of

$y_0$ appears to be a function of ![]() $a$, the increase in

$a$, the increase in ![]() $\Delta U^{+}$ was related to both decreasing

$\Delta U^{+}$ was related to both decreasing ![]() $\lambda$ and increasing

$\lambda$ and increasing ![]() $a$. We can also examine

$a$. We can also examine ![]() $k_s$, commonly described as a fraction of

$k_s$, commonly described as a fraction of ![]() $a$ (hence a function of only

$a$ (hence a function of only ![]() $a$). To find

$a$). To find ![]() $k_s$, we first note that the values of

$k_s$, we first note that the values of ![]() $\Delta U^{+}$ reflect that the flow was transitionally rough for the majority of the cases examined. Therefore, the

$\Delta U^{+}$ reflect that the flow was transitionally rough for the majority of the cases examined. Therefore, the ![]() $k_s$ and

$k_s$ and ![]() $k_s^{+}$ values for the various rough-wall cases were estimated using Colebrook's interpolation formula (Colebrook Reference Colebrook1939)

$k_s^{+}$ values for the various rough-wall cases were estimated using Colebrook's interpolation formula (Colebrook Reference Colebrook1939)

and the corresponding values are included in table 3. It should, however, be pointed out that case 6 is in the nominally dense regime, and using Colebrook's interpolation formula might not be the best way to obtain ![]() $k_s^{+}$. For fully rough flows, (1.2) is used to estimate

$k_s^{+}$. For fully rough flows, (1.2) is used to estimate ![]() $k_s^{+}$ by substituting

$k_s^{+}$ by substituting ![]() $k_s^{+}$ for

$k_s^{+}$ for ![]() $k^{+}$. Using (1.2) for case 6 with

$k^{+}$. Using (1.2) for case 6 with ![]() $\kappa = 0.40$ and

$\kappa = 0.40$ and ![]() $B = 5.3$, we obtain

$B = 5.3$, we obtain ![]() $k_s^{+} = 134.83$, which is within 5 % of the value obtained using (3.1), further providing evidence that this case lies at the edge of the transitionally rough and fully rough regimes and can be considered nominally rough. As expected,

$k_s^{+} = 134.83$, which is within 5 % of the value obtained using (3.1), further providing evidence that this case lies at the edge of the transitionally rough and fully rough regimes and can be considered nominally rough. As expected, ![]() $k_s$ is dependent on both

$k_s$ is dependent on both ![]() $a$ and

$a$ and ![]() $\lambda$, and not just on the steepness,

$\lambda$, and not just on the steepness, ![]() $\sigma$. Specifically, the same values of either

$\sigma$. Specifically, the same values of either ![]() $a$,

$a$, ![]() $\lambda$ or

$\lambda$ or ![]() $\sigma$ can produce different values of

$\sigma$ can produce different values of ![]() $k_s$ depending on the values of the other topographical parameters. This then defines the scaling problem addressed in the remainder of the paper. Namely, identifying which roughness effects can be attributed to which geometrical parameter.

$k_s$ depending on the values of the other topographical parameters. This then defines the scaling problem addressed in the remainder of the paper. Namely, identifying which roughness effects can be attributed to which geometrical parameter.

One effect the surface roughness will have is the introduction of a non-zero wall-normal mean velocity, ![]() $\langle v \rangle$. The

$\langle v \rangle$. The ![]() $\langle v \rangle ^{+}$ profiles are presented in figure 4(c). The presence of a non-zero

$\langle v \rangle ^{+}$ profiles are presented in figure 4(c). The presence of a non-zero ![]() $\langle v \rangle$ constitutes a deviation from the smooth-wall case and, therefore, reflects the influence of surface roughness and can be used to define the extent of the roughness sublayer. Notably, figure 4(c) illustrates that the wall-normal location at which

$\langle v \rangle$ constitutes a deviation from the smooth-wall case and, therefore, reflects the influence of surface roughness and can be used to define the extent of the roughness sublayer. Notably, figure 4(c) illustrates that the wall-normal location at which ![]() $\langle v \rangle$ becomes zero does not appear to correlate with an increase in drag (and

$\langle v \rangle$ becomes zero does not appear to correlate with an increase in drag (and ![]() $\Delta U^{+}$).

$\Delta U^{+}$).

To examine the geometric dependence of the location of vanishing ![]() $\langle v \rangle$, figure 4(d) shows the dependence of the profiles of

$\langle v \rangle$, figure 4(d) shows the dependence of the profiles of ![]() $\langle v \rangle ^{+}$ on

$\langle v \rangle ^{+}$ on ![]() $\lambda$ relative to the distance above the peak of the roughness,

$\lambda$ relative to the distance above the peak of the roughness, ![]() $(\tilde {y}-a)/\lambda$. These coordinates reflect the role of steepness in production of the roughness sublayer as it becomes apparent that, for all cases, the influence of roughness is largely confined to

$(\tilde {y}-a)/\lambda$. These coordinates reflect the role of steepness in production of the roughness sublayer as it becomes apparent that, for all cases, the influence of roughness is largely confined to ![]() $0.3\lambda$ above the peak of the roughness amplitude with the greatest deviation from the smooth-walled case occurring for

$0.3\lambda$ above the peak of the roughness amplitude with the greatest deviation from the smooth-walled case occurring for ![]() $(\tilde {y}-a) \lessapprox 0.1 \lambda$. It therefore appears that the extent of the roughness sublayer depends on

$(\tilde {y}-a) \lessapprox 0.1 \lambda$. It therefore appears that the extent of the roughness sublayer depends on ![]() $\lambda$, rather than

$\lambda$, rather than ![]() $a$, as one would intuitively expect. MacDonald et al. (Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018) showed a clear dependence of the roughness function on the wavelength of the roughness element, albeit for very dense two-dimensional roughness geometries (

$a$, as one would intuitively expect. MacDonald et al. (Reference MacDonald, Ooi, García-Mayoral, Hutchins and Chung2018) showed a clear dependence of the roughness function on the wavelength of the roughness element, albeit for very dense two-dimensional roughness geometries (![]() $0.25 < \varLambda < 3.0$). This dependence of the roughness function on not just the roughness amplitude and steepness (solidity) but also on the roughness wavelength for sparse and dense regimes makes it very important to consider the role of roughness wavelength in determining the appropriate length scales for roughness affected turbulent flows. The effect of the roughness wavelength on the flow structures is explored in greater detail in the following sections. To further illustrate this point, the location corresponding to

$0.25 < \varLambda < 3.0$). This dependence of the roughness function on not just the roughness amplitude and steepness (solidity) but also on the roughness wavelength for sparse and dense regimes makes it very important to consider the role of roughness wavelength in determining the appropriate length scales for roughness affected turbulent flows. The effect of the roughness wavelength on the flow structures is explored in greater detail in the following sections. To further illustrate this point, the location corresponding to ![]() $(\tilde {y}-a)=0.3\lambda$ indicated by vertical lines are shown in figure 4(b), and can be seen to closely correspond to the location where each roughness case begins to approximately deviate from the smooth-walled case.

$(\tilde {y}-a)=0.3\lambda$ indicated by vertical lines are shown in figure 4(b), and can be seen to closely correspond to the location where each roughness case begins to approximately deviate from the smooth-walled case.

3.3. Mean vorticity within the roughness

To assess the region of influence for the roughness elements in more detail, figure 5 presents streamtraces of the two-dimensional mean velocity overlaid on contours of the time-averaged spanwise normalised vorticity

presented as isocontours of ![]() $\langle \omega \rangle \lambda /u_\tau$. The flow field around a large-amplitude wavy surface has previously been observed to consist of three regions (Buckles, Hanratty & Adrian Reference Buckles, Hanratty and Adrian1984; Hudson et al. Reference Hudson, Dykhno and Hanratty1996) which were evident in all cases shown in figure 5: (1) a pocket of recirculating flow in the wake of the crest; (2) a boundary layer over the crest; and (3) a shear layer separating from the recirculation region from the flow above the cavity. The shear layer extending across the cavity thickens in the downstream direction and impinges onto the windward portion of the roughness element. With increasing steepness, the shear layer thickens relative to the wavelength and spanwise vorticity near the crest increases in intensity.

$\langle \omega \rangle \lambda /u_\tau$. The flow field around a large-amplitude wavy surface has previously been observed to consist of three regions (Buckles, Hanratty & Adrian Reference Buckles, Hanratty and Adrian1984; Hudson et al. Reference Hudson, Dykhno and Hanratty1996) which were evident in all cases shown in figure 5: (1) a pocket of recirculating flow in the wake of the crest; (2) a boundary layer over the crest; and (3) a shear layer separating from the recirculation region from the flow above the cavity. The shear layer extending across the cavity thickens in the downstream direction and impinges onto the windward portion of the roughness element. With increasing steepness, the shear layer thickens relative to the wavelength and spanwise vorticity near the crest increases in intensity.

Figure 5. Contours of normalised mean vorticity, ![]() $\langle \omega \rangle \lambda / u_\tau$ superimposed with streamtraces of the velocity field for: (a)

$\langle \omega \rangle \lambda / u_\tau$ superimposed with streamtraces of the velocity field for: (a) ![]() $a^{+}=9$,

$a^{+}=9$, ![]() $\lambda ={\rm \pi} /8$; (b)

$\lambda ={\rm \pi} /8$; (b) ![]() $a^{+}=9$,

$a^{+}=9$, ![]() $\lambda ={\rm \pi} /16$; (c)

$\lambda ={\rm \pi} /16$; (c) ![]() $a^{+}=9$,

$a^{+}=9$, ![]() $\lambda ={\rm \pi} /32$; (d)

$\lambda ={\rm \pi} /32$; (d) ![]() $a^{+}=18$,

$a^{+}=18$, ![]() $\lambda ={\rm \pi} /8$; and (e)

$\lambda ={\rm \pi} /8$; and (e) ![]() $a^{+}=36$,

$a^{+}=36$, ![]() $\lambda ={\rm \pi} /8$. Negative contour levels are indicated by dashed contour lines and the location of

$\lambda ={\rm \pi} /8$. Negative contour levels are indicated by dashed contour lines and the location of ![]() $y_0^{\prime\prime}$ for each case is indicated by a dashed blue line. The white line near the roughness trough indicates the contour of zero-vorticity.

$y_0^{\prime\prime}$ for each case is indicated by a dashed blue line. The white line near the roughness trough indicates the contour of zero-vorticity.

A corresponding increase in the size of the recirculation regions can also be observed in the streamline visualisations in figure 5 reflecting the transition from ![]() $k$-type to

$k$-type to ![]() $d$-type roughness with both increasing

$d$-type roughness with both increasing ![]() $a$ and decreasing

$a$ and decreasing ![]() $\lambda$, i.e. correlated to the increase in steepness of the elements. The demarcation between

$\lambda$, i.e. correlated to the increase in steepness of the elements. The demarcation between ![]() $k$- and

$k$- and ![]() $d$-type roughness regimes is not very well defined; however, it has been linked to the relative contributions of the pressure drag and the skin drag to the total drag acting on the wall in a study by Leonardi, Orlandi & Antonia (Reference Leonardi, Orlandi and Antonia2007). Figure 6 provides the roughness function for flows in the fully rough regime over a range of roughness geometries obtained using DNS by Leonardi et al. (Reference Leonardi, Orlandi and Antonia2007). The filled-in red squares indicate a

$d$-type roughness regimes is not very well defined; however, it has been linked to the relative contributions of the pressure drag and the skin drag to the total drag acting on the wall in a study by Leonardi, Orlandi & Antonia (Reference Leonardi, Orlandi and Antonia2007). Figure 6 provides the roughness function for flows in the fully rough regime over a range of roughness geometries obtained using DNS by Leonardi et al. (Reference Leonardi, Orlandi and Antonia2007). The filled-in red squares indicate a ![]() $d$-type roughness since the roughness function is independent of the roughness height. Although the cases being considered in the present study are not in the fully rough regime, the dependence of roughness function on amplitude (and steepness) indicates the presence of a

$d$-type roughness since the roughness function is independent of the roughness height. Although the cases being considered in the present study are not in the fully rough regime, the dependence of roughness function on amplitude (and steepness) indicates the presence of a ![]() $k$-type roughness.

$k$-type roughness.

Figure 6. The variation of roughness function for different roughness geometries using different roughness height to width ratios for flows in the fully rough regime plotted against the inner-scaled roughness height (or amplitude). The filled-in data points have been adapted from Leonardi et al. (Reference Leonardi, Orlandi and Antonia2007) with the solid straight lines following (1.2). The roughness function for the cases considered in the current study have been plotted as individual symbols. The square, triangle and circle symbols indicate cases with the same roughness amplitude (![]() $a^{+} =9$) and wavelengths corresponding to

$a^{+} =9$) and wavelengths corresponding to ![]() $\lambda ={\rm \pi} /8$,

$\lambda ={\rm \pi} /8$, ![]() $\lambda ={\rm \pi} /16$ and

$\lambda ={\rm \pi} /16$ and ![]() $\lambda ={\rm \pi} /32$, respectively. Similarly, the plus and asterisk symbols are used to indicate cases at a constant wavelength (

$\lambda ={\rm \pi} /32$, respectively. Similarly, the plus and asterisk symbols are used to indicate cases at a constant wavelength (![]() $\lambda = {\rm \pi}/8$) with amplitude

$\lambda = {\rm \pi}/8$) with amplitude ![]() $a^{+} = 18$ and

$a^{+} = 18$ and ![]() $a^{+} = 36$, respectively.

$a^{+} = 36$, respectively.

Flow separation can be identified for all wavelengths and wave amplitudes. At lower steepness, the streamlines are diverted lower into the cavity with a corresponding lower reattachment point of the recirculation region. As steepness increases, the reattachment point moves closer to the peak in the surface. These results are consistent with the general observation that the flow inside the recirculation regions with larger steepness appears to be more isolated from the flow above the cavities. The effects of the two-dimensional roughness diminish by ![]() $(y-a)\sim 0.3\lambda$ (see figure 5) which is consistent with the observations for the mean