1. Introduction

It is well-known that adding a small amount of polymer additives in turbulent flows can lead to a significant drag reduction (Toms Reference Toms1948). Extensive studies have been performed to address this phenomenon in wall-bounded flows through theoretical, experimental and numerical approaches (Procaccia, L’vov & Benzi Reference Procaccia, L’vov and Benzi2008; White & Mungal Reference White and Mungal2008). However, the effects of polymer additives on heat transport in turbulent thermal convection remain less understood despite many processes involving heat transfer in nature, e.g. in oils, melts and molten magma, as well as those prevalent in industrial processes such as polymer solutions and emulsions, concerning non-Newtonian flows (Denn Reference Denn2004). These flows exhibit distinctive rheological properties, like viscoelasticity, plasticity, shear thinning and shear thickening. Among them, the viscoelastic behaviour of non-Newtonian fluids determines surprising and complex rheological properties and flow dynamics, which can lead to different unexpected fluid-flow phenomena, such as elasto-inertial turbulence (Samanta et al. Reference Samanta, Dubief, Holzner, Schafer, Morozov, Wagner and Hof2013; Li, Sureshkumar & Khomami Reference Li, Sureshkumar and Khomami2015; Sid, Terrapon & Dubief Reference Sid, Terrapon and Dubief2018; Song et al. Reference Song, Lin, Liu, Lu and Khomami2021; Dubief, Terrapon & Hof Reference Dubief, Terrapon and Hof2023) and elastic turbulence (Groisman & Steinberg Reference Groisman and Steinberg2000; Steinberg Reference Steinberg2021; Datta et al. Reference Datta2022; Song et al. Reference Song, Liu, Lu and Khomami2022, Reference Song, Lin, Zhu, Wan, Liu, Lu and Khomami2023a ,Reference Song, Zhu, Lin, Liu and Khomami b ). Therefore, studying the thermal convection in viscoelastic fluids can deepen our understanding of the interplay between the fluid viscoelasticity and convective processes. Such insights are crucial for various applications, ranging from geophysical and astrophysical phenomena such as mantle convection, to industrial processes such as polymer processing and thermal management systems.

As a canonical system to study thermal convection, Rayleigh–Bénard (RB) convection of Newtonian fluids has been studied extensively over the past decades (Bodenschatz, Pesch & Ahlers Reference Bodenschatz, Pesch and Ahlers2000; Ahlers, Grossmann & Lohse Reference Ahlers, Grossmann and Lohse2009; Lohse & Xia Reference Lohse and Xia2010; Chillà & Schumacher Reference Chillà and Schumacher2012; Xia Reference Xia2013; Shishkina Reference Shishkina2021; Lohse & Shishkina Reference Lohse and Shishkina2024). In RB convection, the flow is driven by buoyancy forces due to the temperature difference

![]() $\varDelta$

between a hot bottom plate and a cold top plate. The main dimensionless control parameters in RB convection are the Rayleigh number

$\varDelta$

between a hot bottom plate and a cold top plate. The main dimensionless control parameters in RB convection are the Rayleigh number

![]() $Ra$

, Prandtl number

$Ra$

, Prandtl number

![]() $Pr$

, and aspect ratio of the container

$Pr$

, and aspect ratio of the container

![]() $\Gamma$

, defined as

$\Gamma$

, defined as

Here,

![]() $g$

denotes the gravitational acceleration,

$g$

denotes the gravitational acceleration,

![]() $\alpha$

the thermal expansion coefficient,

$\alpha$

the thermal expansion coefficient,

![]() $\nu$

the kinematic viscosity, and

$\nu$

the kinematic viscosity, and

![]() $\kappa$

the thermal diffusivity, and

$\kappa$

the thermal diffusivity, and

![]() $H$

and

$H$

and

![]() $D$

are the height and width of the container, respectively. Studies of this system have focused mainly on: (i) the flow structures, identifying kinetic and thermal boundary layers (BLs), and an approximately homogeneous bulk flow (Grossmann & Lohse Reference Grossmann and Lohse2000; Ahlers et al. Reference Ahlers, Grossmann and Lohse2009); and (ii) the dependence of the global heat transport, quantified by the Nusselt number

$D$

are the height and width of the container, respectively. Studies of this system have focused mainly on: (i) the flow structures, identifying kinetic and thermal boundary layers (BLs), and an approximately homogeneous bulk flow (Grossmann & Lohse Reference Grossmann and Lohse2000; Ahlers et al. Reference Ahlers, Grossmann and Lohse2009); and (ii) the dependence of the global heat transport, quantified by the Nusselt number

![]() $Nu$

, and momentum transport, characterised by the Reynolds number

$Nu$

, and momentum transport, characterised by the Reynolds number

![]() $Re$

, on the different control parameters mentioned above. The Nusselt number is defined as the ratio of the total heat flux in the flow to the molecular heat conduction, which for an incompressible flow is

$Re$

, on the different control parameters mentioned above. The Nusselt number is defined as the ratio of the total heat flux in the flow to the molecular heat conduction, which for an incompressible flow is

Here,

![]() $u_z$

is the vertical velocity, and

$u_z$

is the vertical velocity, and

![]() $\theta$

is the temperature, while

$\theta$

is the temperature, while

![]() $\langle \cdots \rangle _{A,t}$

denotes the horizontal-plane and time average at any distance between the heated and cooled plates.

$\langle \cdots \rangle _{A,t}$

denotes the horizontal-plane and time average at any distance between the heated and cooled plates.

As regards complex fluids, some studies also considered RB convection of viscoelastic fluids, focusing on the effects of fluid elasticity on two critical Rayleigh numbers:

![]() $Ra_{c1}$

for the transition from conduction to convective flow, and

$Ra_{c1}$

for the transition from conduction to convective flow, and

![]() $Ra_{c2}$

for the onset of chaotic flows from stationary conditions. Moreover, pattern formations at small and moderate

$Ra_{c2}$

for the onset of chaotic flows from stationary conditions. Moreover, pattern formations at small and moderate

![]() $Ra$

have been studied through linear (Green Reference Green1968; Vest & Arpaci Reference Vest and Arpaci1969; Sokolov & Tanner Reference Sokolov and Tanner1972) or nonlinear stability analysis (Park & Ryu Reference Park and Ryu2001), or via numerical simulations (Wang et al. Reference Wang, Cheng, Zhang, Zheng, Cai and Siginer2023; Zheng et al. Reference Zheng, Boutaous, Xin, Siginer and Cai2023).

$Ra$

have been studied through linear (Green Reference Green1968; Vest & Arpaci Reference Vest and Arpaci1969; Sokolov & Tanner Reference Sokolov and Tanner1972) or nonlinear stability analysis (Park & Ryu Reference Park and Ryu2001), or via numerical simulations (Wang et al. Reference Wang, Cheng, Zhang, Zheng, Cai and Siginer2023; Zheng et al. Reference Zheng, Boutaous, Xin, Siginer and Cai2023).

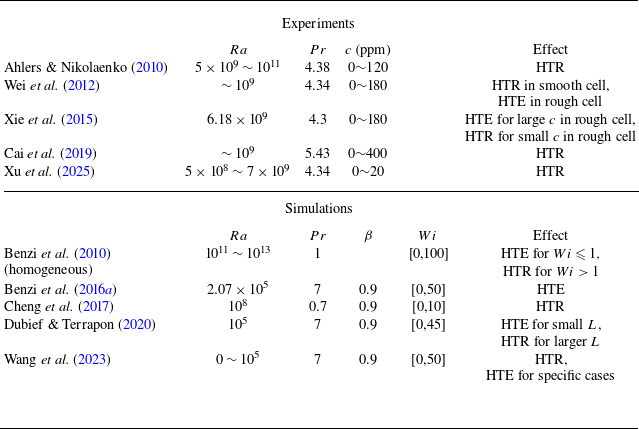

Table 1. Parameters in previous studies of turbulent RB convection with polymer additives. The fourth column gives the polymer concentration

![]() $c$

in the experiments or the viscosity ratio

$c$

in the experiments or the viscosity ratio

![]() $\beta$

in the simulations. The Weissenberg number

$\beta$

in the simulations. The Weissenberg number

![]() $Wi$

is given only for simulations (except for Benzi et al. (Reference Benzi, Ching and De Angelis2010), which defines

$Wi$

is given only for simulations (except for Benzi et al. (Reference Benzi, Ching and De Angelis2010), which defines

![]() $Wi$

using the

$Wi$

using the

![]() $\mathrm{r.m.s.}$

velocity and a large length scale of the flow in the absence of polymers, other data are adapted to the same definition using the free-fall velocity and domain height), since to measure it in experiments is challenging. In the last column, HTE means heat transfer enhancement, HTR means heat transfer reduction, and

$\mathrm{r.m.s.}$

velocity and a large length scale of the flow in the absence of polymers, other data are adapted to the same definition using the free-fall velocity and domain height), since to measure it in experiments is challenging. In the last column, HTE means heat transfer enhancement, HTR means heat transfer reduction, and

![]() $L$

is the extensibility parameter. Here, we provide only a list of literature specifically discussing the modification of the heat transfer in turbulent RB convection with polymers, while omitting numerous studies focused on pattern formation, onset of convection and other issues.

$L$

is the extensibility parameter. Here, we provide only a list of literature specifically discussing the modification of the heat transfer in turbulent RB convection with polymers, while omitting numerous studies focused on pattern formation, onset of convection and other issues.

The effect of polymer additives on turbulent RB convection has received attention only in recent years. Table 1 lists the studies of turbulent RB convection with polymer additives, and the corresponding range of parameters examined. Here, the Weissenberg number

![]() $Wi$

, which is commonly used in viscoelastic flow to quantify the elastic effects of polymer solutions, is defined as

$Wi$

, which is commonly used in viscoelastic flow to quantify the elastic effects of polymer solutions, is defined as

where

![]() $\lambda$

is the relaxation time scale of the polymers, and

$\lambda$

is the relaxation time scale of the polymers, and

![]() $U$

is the relevant flow velocity. In terms of experimental studies, Ahlers & Nikolaenko (Reference Ahlers and Nikolaenko2010) did the first experiments at

$U$

is the relevant flow velocity. In terms of experimental studies, Ahlers & Nikolaenko (Reference Ahlers and Nikolaenko2010) did the first experiments at

![]() $Ra$

spanning from

$Ra$

spanning from

![]() $5\times 10^9$

to

$5\times 10^9$

to

![]() $10^{11}$

to investigate the turbulent heat transport modifications by polymers. They found heat transport reduction (HTR), and that HTR amount increases with polymer concentration

$10^{11}$

to investigate the turbulent heat transport modifications by polymers. They found heat transport reduction (HTR), and that HTR amount increases with polymer concentration

![]() $c$

up to

$c$

up to

![]() $10\,\%$

. Later, RB convection with polyethylene oxide (PEO) solutions was studied for

$10\,\%$

. Later, RB convection with polyethylene oxide (PEO) solutions was studied for

![]() $Ra \sim 10^9$

and

$Ra \sim 10^9$

and

![]() $Pr \approx 4.34$

for both smooth and rough plates (Wei, Ni & Xia Reference Wei, Ni and Xia2012). In the smooth cell, HTR was observed, whereas heat transport enhancement (HTE) was found in the rough cell. Moreover, a maximum HTR saturation state was observed as polymer concentration

$Pr \approx 4.34$

for both smooth and rough plates (Wei, Ni & Xia Reference Wei, Ni and Xia2012). In the smooth cell, HTR was observed, whereas heat transport enhancement (HTE) was found in the rough cell. Moreover, a maximum HTR saturation state was observed as polymer concentration

![]() $c$

increases. Based on these observations, Xie et al. (Reference Xie, Huang, Funfschilling, Li, Ni and Xia2015) further analysed the HTE mechanism within the rough cell. Their analysis revealed that the polymer additives can enhance coherent heat fluxes while suppressing incoherent heat fluxes within the bulk region, leading to the HTE. In the BL region, the plume emission rate is strongly suppressed. Thus whether HTE or HTR takes place depends on the competition between these two effects. Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019) found HTR in their experiments at similar

$c$

increases. Based on these observations, Xie et al. (Reference Xie, Huang, Funfschilling, Li, Ni and Xia2015) further analysed the HTE mechanism within the rough cell. Their analysis revealed that the polymer additives can enhance coherent heat fluxes while suppressing incoherent heat fluxes within the bulk region, leading to the HTE. In the BL region, the plume emission rate is strongly suppressed. Thus whether HTE or HTR takes place depends on the competition between these two effects. Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019) found HTR in their experiments at similar

![]() $Ra\sim 10^9$

, and concluded that the reduction is related to the smaller size of large-scale circulation (LSC) in polymer solutions. In a recent study, Xu et al. (Reference Xu, Liu, Li and Xia2025) also found an HTR in a cylindrical cell, and revealed that the addition of polymers re-establishes the cylindrical symmetry of the large-scale structures, leading to a larger flow coherence.

$Ra\sim 10^9$

, and concluded that the reduction is related to the smaller size of large-scale circulation (LSC) in polymer solutions. In a recent study, Xu et al. (Reference Xu, Liu, Li and Xia2025) also found an HTR in a cylindrical cell, and revealed that the addition of polymers re-establishes the cylindrical symmetry of the large-scale structures, leading to a larger flow coherence.

As mentioned above, the HTR saturate state was observed in high-

![]() $Ra$

experiments (Wei et al. Reference Wei, Ni and Xia2012; Cai et al. Reference Cai, Wei, Tang, Liu, Li and Li2019). This behaviour is reminiscent of the maximum drag reduction (MDR) asymptote caused by polymer additives in other wall-bounded turbulent flows, such as channel, pipe and plane Couette flows (Toms Reference Toms1948; Lumley Reference Lumley1969; Virk Reference Virk1975). The cornerstone work by Samanta et al. (Reference Samanta, Dubief, Holzner, Schafer, Morozov, Wagner and Hof2013) proposed that the dynamics of MDR is driven by an elasto-inertial instability that can even eliminate the Newtonian turbulence, and the MDR asymptote flow state can be interpreted as a self-sustained elasto-inertial turbulence, where the polymer stretching acts to suppress the small-scale vortices and turbulent fluctuations. This interpretation has gained traction, while it is not yet conclusive that the MDR asymptote is solely governed by elasto-inertial turbulence (Dubief et al. Reference Dubief, Terrapon and Hof2023). In addition, the kinetic energy spectrum in the elasto-inertial turbulence has a scaling exponent approximately

$Ra$

experiments (Wei et al. Reference Wei, Ni and Xia2012; Cai et al. Reference Cai, Wei, Tang, Liu, Li and Li2019). This behaviour is reminiscent of the maximum drag reduction (MDR) asymptote caused by polymer additives in other wall-bounded turbulent flows, such as channel, pipe and plane Couette flows (Toms Reference Toms1948; Lumley Reference Lumley1969; Virk Reference Virk1975). The cornerstone work by Samanta et al. (Reference Samanta, Dubief, Holzner, Schafer, Morozov, Wagner and Hof2013) proposed that the dynamics of MDR is driven by an elasto-inertial instability that can even eliminate the Newtonian turbulence, and the MDR asymptote flow state can be interpreted as a self-sustained elasto-inertial turbulence, where the polymer stretching acts to suppress the small-scale vortices and turbulent fluctuations. This interpretation has gained traction, while it is not yet conclusive that the MDR asymptote is solely governed by elasto-inertial turbulence (Dubief et al. Reference Dubief, Terrapon and Hof2023). In addition, the kinetic energy spectrum in the elasto-inertial turbulence has a scaling exponent approximately

![]() $-14/3$

, which is distinctly different from the Kolmogorov scaling

$-14/3$

, which is distinctly different from the Kolmogorov scaling

![]() $-5/3$

for inertial turbulence, but close to the scaling for elastic turbulence

$-5/3$

for inertial turbulence, but close to the scaling for elastic turbulence

![]() $-3.5$

; see Groisman & Steinberg (Reference Groisman and Steinberg2000), Fouxon & Lebedev (Reference Fouxon and Lebedev2003), Dubief, Terrapon & Soria (Reference Dubief, Terrapon and Soria2013) and Steinberg (Reference Steinberg2019). However, this spectral universality and associated turbulent dynamics of elasto-inertial turbulence have not been examined in natural thermal convection systems so far.

$-3.5$

; see Groisman & Steinberg (Reference Groisman and Steinberg2000), Fouxon & Lebedev (Reference Fouxon and Lebedev2003), Dubief, Terrapon & Soria (Reference Dubief, Terrapon and Soria2013) and Steinberg (Reference Steinberg2019). However, this spectral universality and associated turbulent dynamics of elasto-inertial turbulence have not been examined in natural thermal convection systems so far.

Regarding the numerical studies, polymer chains in turbulent flows are generally modelled as dumbbells composed of two beads connected by the elastic Hookean linear spring Oldrold-B model with an infinite extensibility or a nonlinear elastic entropic spring with finite extensibility, which is known as the finitely extensible nonlinear elastic-Peterlin (FENE-P) model (Bird et al. Reference Bird, Curtiss, Armstrong and Hassager1987). The FENE-P model can overcome several limitations of the Oldroyd-B model, including: (i) the possibility of singular extensional viscosity or stress in extensional flows, due to the absence of an upper bound on the polymer extensibility; (ii) the inability to reproduce the shear-thinning behaviour commonly observed in most polymer solutions (Dubief et al. Reference Dubief, Terrapon and Hof2023).

In the pioneering work of Benzi, Ching & De Angelis (Reference Benzi, Ching and De Angelis2010), homogeneous turbulent thermal convection with polymer additives was studied using direct numerical simulations (DNS) based on the FENE-P model, and then a simplified shell model was used to understand the phenomenon. The DNS were performed under periodic boundary conditions driven by a constant temperature gradient, which mimics the bulk region of RB convection, and the HTE were observed for

![]() $Wi\lt 1$

. With shell model caculations, a transition from HTE to HTR at

$Wi\lt 1$

. With shell model caculations, a transition from HTE to HTR at

![]() $Wi\gt 1$

was obtained with increasing

$Wi\gt 1$

was obtained with increasing

![]() $Wi$

. These authors speculated that the addition of polymers would increase the drag within the BL, leading to a decrease in

$Wi$

. These authors speculated that the addition of polymers would increase the drag within the BL, leading to a decrease in

![]() $Nu$

. The overall modulation of the heat transfer would then depend on the balance between the contribution from the BLs and bulk region. Moreover, they highlighted three intriguing and promising approaches to observe HTE: (i) increasing

$Nu$

. The overall modulation of the heat transfer would then depend on the balance between the contribution from the BLs and bulk region. Moreover, they highlighted three intriguing and promising approaches to observe HTE: (i) increasing

![]() $Ra$

, where heat transfer becomes dominated by the bulk region; (ii) artificially reducing the energy dissipation contribution from the BL, which is the approach explored in the experimental work of Xie et al. (Reference Xie, Huang, Funfschilling, Li, Ni and Xia2015) and already validated by their studies; and (iii) utilising a slender domain to shift the the main transport towards the bulk region.

$Ra$

, where heat transfer becomes dominated by the bulk region; (ii) artificially reducing the energy dissipation contribution from the BL, which is the approach explored in the experimental work of Xie et al. (Reference Xie, Huang, Funfschilling, Li, Ni and Xia2015) and already validated by their studies; and (iii) utilising a slender domain to shift the the main transport towards the bulk region.

Later, Benzi, Ching & De Angelis (Reference Benzi, Ching and De Angelis2016a

) performed simulations over a range of

![]() $Wi$

from

$Wi$

from

![]() $0$

to

$0$

to

![]() $50$

, at

$50$

, at

![]() $Ra=2.07\times 10^5$

,

$Ra=2.07\times 10^5$

,

![]() $Pr=7$

, by using the Oldroyd-B model. They observed HTE, and that the HTE amount first increases and then decreases with increasing

$Pr=7$

, by using the Oldroyd-B model. They observed HTE, and that the HTE amount first increases and then decreases with increasing

![]() $Wi$

, which was attributed to the combined effects of decreasing viscous energy dissipation and increasing energy dissipation due to the polymers. Cheng et al. (Reference Cheng, Zhang, Cai, Li and Li2017) explored a range of

$Wi$

, which was attributed to the combined effects of decreasing viscous energy dissipation and increasing energy dissipation due to the polymers. Cheng et al. (Reference Cheng, Zhang, Cai, Li and Li2017) explored a range of

![]() $Wi$

from

$Wi$

from

![]() $0$

to

$0$

to

![]() $10$

within a two-dimensional enclosed RB cell with Oldroyd-B polymers at

$10$

within a two-dimensional enclosed RB cell with Oldroyd-B polymers at

![]() $Ra=10^8$

and

$Ra=10^8$

and

![]() $Pr=0.7$

. These authors observed that the HTR behaves non-monotonically with

$Pr=0.7$

. These authors observed that the HTR behaves non-monotonically with

![]() $Wi$

(first increasing and then decreasing). They concluded that this non-monotonic behaviour results primarily from the contribution of elastic stresses to the turbulent kinetic energy, which absorbs energy from the turbulence for small

$Wi$

(first increasing and then decreasing). They concluded that this non-monotonic behaviour results primarily from the contribution of elastic stresses to the turbulent kinetic energy, which absorbs energy from the turbulence for small

![]() $Wi$

, while releasing stored energy to small-scale motions for relatively large

$Wi$

, while releasing stored energy to small-scale motions for relatively large

![]() $Wi$

. Dubief & Terrapon (Reference Dubief and Terrapon2020) investigated the effects of the FENE-P polymer chain extensibility parameter

$Wi$

. Dubief & Terrapon (Reference Dubief and Terrapon2020) investigated the effects of the FENE-P polymer chain extensibility parameter

![]() $L$

. In their simulations,

$L$

. In their simulations,

![]() $Wi$

ranges from 0 to 45, and

$Wi$

ranges from 0 to 45, and

![]() $L$

spans from 10 to 100 at

$L$

spans from 10 to 100 at

![]() $Ra=10^5$

,

$Ra=10^5$

,

![]() $Pr=7$

. They reported that polymers with small

$Pr=7$

. They reported that polymers with small

![]() $L$

lead to HTE, whereas polymers with larger

$L$

lead to HTE, whereas polymers with larger

![]() $L$

(

$L$

(

![]() $L\gtrsim 50$

) result in HTR. The mechanism underlying HTE involves an increase in the number of convection cells, while in the case of HTR, the LSC slows down simultaneously. Recently, Wang et al. (Reference Wang, Cheng, Zhang, Zheng, Cai and Siginer2023) found similar HTR for additional configurations at lower

$L\gtrsim 50$

) result in HTR. The mechanism underlying HTE involves an increase in the number of convection cells, while in the case of HTR, the LSC slows down simultaneously. Recently, Wang et al. (Reference Wang, Cheng, Zhang, Zheng, Cai and Siginer2023) found similar HTR for additional configurations at lower

![]() $Ra$

, except for some particular parameters where multiple pairs of LSC exist, leading to HTE.

$Ra$

, except for some particular parameters where multiple pairs of LSC exist, leading to HTE.

In all these studies, based on simulations and experiments, researchers speculated that the effects of polymers on the BL and bulk regions differ significantly. Whether the total heat transfer is enhanced or reduced depends mainly on the contributions of these two regions. To elucidate the effects of polymers on a laminar BL flow, Benzi, Ching & Chu (Reference Benzi, Ching and Chu2012) generalised the classical Prandtl–Blasius–Pohlhausen theory to Oldroyd-B viscoelatic flows at moderate

![]() $Ra$

. Their analysis demonstrated that the stretching of polymers induces a space-dependent effective viscosity, increasing near the plate, and vanishing away from it. Such an increase leads to an enhancement of friction drag, and thus results in the reduction of the heat transport in the BL region. Moreover, the effective viscosity increases with

$Ra$

. Their analysis demonstrated that the stretching of polymers induces a space-dependent effective viscosity, increasing near the plate, and vanishing away from it. Such an increase leads to an enhancement of friction drag, and thus results in the reduction of the heat transport in the BL region. Moreover, the effective viscosity increases with

![]() $Wi$

and viscosity ratio

$Wi$

and viscosity ratio

![]() $\gamma$

, therefore the amount of the HTR and drag enhancement increases as well. Here,

$\gamma$

, therefore the amount of the HTR and drag enhancement increases as well. Here,

![]() $\gamma$

is the ratio of polymer viscosity to zero-shear-rate viscosity of polymer solutions (

$\gamma$

is the ratio of polymer viscosity to zero-shear-rate viscosity of polymer solutions (

![]() $\gamma =1-\beta$

, where

$\gamma =1-\beta$

, where

![]() $\beta$

is used in our simulation, as defined below.) Later, Benzi et al. (Reference Benzi, Ching, Yu and Wang2016b

) extended their theoretical framework to FENE-P modelled polymer solutions. They suggested that HTR occurs for polymers with large extensibility parameter

$\beta$

is used in our simulation, as defined below.) Later, Benzi et al. (Reference Benzi, Ching, Yu and Wang2016b

) extended their theoretical framework to FENE-P modelled polymer solutions. They suggested that HTR occurs for polymers with large extensibility parameter

![]() $L$

, while HTE should be observed for small

$L$

, while HTE should be observed for small

![]() $L$

. Moreover, they concluded that heat transport is enhanced when the region of substantial polymer stretching moves outside the thermal BL. These conclusions have been confirmed by Dubief & Terrapon (Reference Dubief and Terrapon2020) at low Rayleigh number

$L$

. Moreover, they concluded that heat transport is enhanced when the region of substantial polymer stretching moves outside the thermal BL. These conclusions have been confirmed by Dubief & Terrapon (Reference Dubief and Terrapon2020) at low Rayleigh number

![]() $Ra = 10^5$

, where they observed that in cases of HTE, the first normal stress difference is predominantly concentrated inside the plumes within the bulk region, while in cases of HTR, the magnitudes of the first normal stress difference inside the plumes and BL are similar. However, we have not found any evidence of this phenomenon at high

$Ra = 10^5$

, where they observed that in cases of HTE, the first normal stress difference is predominantly concentrated inside the plumes within the bulk region, while in cases of HTR, the magnitudes of the first normal stress difference inside the plumes and BL are similar. However, we have not found any evidence of this phenomenon at high

![]() $Ra$

in the literature.

$Ra$

in the literature.

As summarised in table 1, previous experimental investigations have focused primarily on high-

![]() $Ra$

(

$Ra$

(

![]() $10^9{\sim}10^{10}$

) situations, whereas simulations in the existing literature have been limited predominantly to lower

$10^9{\sim}10^{10}$

) situations, whereas simulations in the existing literature have been limited predominantly to lower

![]() $Ra$

values, typically smaller than

$Ra$

values, typically smaller than

![]() $10^6$

, due to the difficulties associated with the numerical simulations of viscoelastic flows (Alves, Oliveira & Pinho Reference Alves, Oliveira and Pinho2021). This leads to a gap in

$10^6$

, due to the difficulties associated with the numerical simulations of viscoelastic flows (Alves, Oliveira & Pinho Reference Alves, Oliveira and Pinho2021). This leads to a gap in

![]() $Ra$

values of several orders between experimental and numerical studies. Moreover, previous numerical studies on turbulent RB convection with polymer additives focused mainly on the dependence on

$Ra$

values of several orders between experimental and numerical studies. Moreover, previous numerical studies on turbulent RB convection with polymer additives focused mainly on the dependence on

![]() $Wi$

, viscosity ratio

$Wi$

, viscosity ratio

![]() $\beta$

, or extensibility parameter

$\beta$

, or extensibility parameter

![]() $L$

, while the specific effects of

$L$

, while the specific effects of

![]() $Ra$

on the heat and momentum transfer modifications, flow structures and turbulent velocity, temperature and elastic stress statistics remain unclear. To fill this gap, we have therefore performed three-dimensional DNS over a broad range of

$Ra$

on the heat and momentum transfer modifications, flow structures and turbulent velocity, temperature and elastic stress statistics remain unclear. To fill this gap, we have therefore performed three-dimensional DNS over a broad range of

![]() $Ra$

spanning from

$Ra$

spanning from

![]() $10^6$

to

$10^6$

to

![]() $10^{10}$

at

$10^{10}$

at

![]() $Pr=4.3$

while keeping moderate

$Pr=4.3$

while keeping moderate

![]() $Wi$

, namely,

$Wi$

, namely,

![]() $Wi=5$

and

$Wi=5$

and

![]() $10$

. This work seeks to provide understanding of the role played by the Rayleigh number in turbulent RB convection of viscoelastic fluids, with particular interest in the heat-transport modifications, changes of thermal plumes and BLs, and kinetic and thermal energy dissipation rates.

$10$

. This work seeks to provide understanding of the role played by the Rayleigh number in turbulent RB convection of viscoelastic fluids, with particular interest in the heat-transport modifications, changes of thermal plumes and BLs, and kinetic and thermal energy dissipation rates.

The paper is organised as follows. The physical problem, governing equations, numerical methods and computational details are described in § 2. The flow structures and statistic profiles are shown in § 3. The polymer effects on heat flux, dissipation rate and energy spectrum are discussed separately in § 4. Finally, the main conclusions are summarised in § 5.

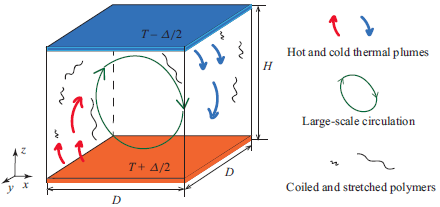

Figure 1. Sketch of viscoelastic RB convection in a parallelepiped geometry.

2. Physical problem and computational details

2.1. Governing equations

A sketch of RB convection with polymer additives in a parallelepiped geometry with

![]() $\Gamma =1$

, i.e. a cube, is shown in figure 1. The FENE-P viscoelastic constitutive model is used to model the contribution of polymer additives to the total stress. The orientation and extension of polymer molecules are described by the end-to-end vectors

$\Gamma =1$

, i.e. a cube, is shown in figure 1. The FENE-P viscoelastic constitutive model is used to model the contribution of polymer additives to the total stress. The orientation and extension of polymer molecules are described by the end-to-end vectors

![]() $q_i$

, and represented in the statistical model by the phase-averaged configuration tensor denoted by

$q_i$

, and represented in the statistical model by the phase-averaged configuration tensor denoted by

![]() $C_{ij} = \langle q_iq_j \rangle$

. The FENE-P model is frequently used in DNS of viscoelastic flows due to its physical connection with real viscoelastic liquids, specifically dilute solutions of high molecular weight, finitely extensible flexible polymers in a theta solvent. In this model, interactions between polymer chains are not considered. Although it is not easy to compare the relaxation time in the FENE-P model against real experiments, it can qualitatively capture the relevant experimental results (White & Mungal Reference White and Mungal2008; Larson & Desai Reference Larson and Desai2015; Xi Reference Xi2019; Ching Reference Ching2024; Serafini et al. Reference Serafini, Battista, Gualtieri and Casciola2024). The FENE-P model is closed by three control parameters: (i) the maximum polymer chain extensibility parameter

$C_{ij} = \langle q_iq_j \rangle$

. The FENE-P model is frequently used in DNS of viscoelastic flows due to its physical connection with real viscoelastic liquids, specifically dilute solutions of high molecular weight, finitely extensible flexible polymers in a theta solvent. In this model, interactions between polymer chains are not considered. Although it is not easy to compare the relaxation time in the FENE-P model against real experiments, it can qualitatively capture the relevant experimental results (White & Mungal Reference White and Mungal2008; Larson & Desai Reference Larson and Desai2015; Xi Reference Xi2019; Ching Reference Ching2024; Serafini et al. Reference Serafini, Battista, Gualtieri and Casciola2024). The FENE-P model is closed by three control parameters: (i) the maximum polymer chain extensibility parameter

![]() $L$

; (ii) the Weissenberg number

$L$

; (ii) the Weissenberg number

![]() $Wi$

, here defined by

$Wi$

, here defined by

![]() $Wi \equiv \lambda U_{ff} /H$

, where

$Wi \equiv \lambda U_{ff} /H$

, where

![]() $U_{ff} \equiv \sqrt {g\alpha \Delta H}$

is the characteristic free-fall velocity; and (iii) the viscosity ratio

$U_{ff} \equiv \sqrt {g\alpha \Delta H}$

is the characteristic free-fall velocity; and (iii) the viscosity ratio

![]() $\beta =\nu _s / (\nu _s+\nu _p)$

, which is the ratio of the solvent viscosity to the total zero-shear rate viscosity of the polymer solution (subscripts

$\beta =\nu _s / (\nu _s+\nu _p)$

, which is the ratio of the solvent viscosity to the total zero-shear rate viscosity of the polymer solution (subscripts

![]() $s$

and

$s$

and

![]() $p$

represent solvent and polymer, respectively). The maximum polymer chain extensibility remains constant throughout all simulations. Thus polymer chain scission is not captured in our simulations. We choose a commonly used value

$p$

represent solvent and polymer, respectively). The maximum polymer chain extensibility remains constant throughout all simulations. Thus polymer chain scission is not captured in our simulations. We choose a commonly used value

![]() $L=50$

, which implies moderate extensibility. Viscosity ratio can be regarded as a measure of polymer concentration by assuming that the viscosity depends only on the polymer concentration. In our DNS,

$L=50$

, which implies moderate extensibility. Viscosity ratio can be regarded as a measure of polymer concentration by assuming that the viscosity depends only on the polymer concentration. In our DNS,

![]() $\beta$

is fixed at

$\beta$

is fixed at

![]() $0.9$

for viscoelastic fluids (

$0.9$

for viscoelastic fluids (

![]() $\beta =1$

for Newtonian), which denotes dilute polymer solutions.

$\beta =1$

for Newtonian), which denotes dilute polymer solutions.

The chosen reference scales for the non-dimensionalisation are the height of the domain

![]() $H$

, the temperature difference between the plates

$H$

, the temperature difference between the plates

![]() $\varDelta$

, the characteristic free-fall velocity

$\varDelta$

, the characteristic free-fall velocity

![]() $U_{ff}$

, pressure

$U_{ff}$

, pressure

![]() $\rho U_{ff}^2$

, and stress

$\rho U_{ff}^2$

, and stress

![]() $\mu _p U_{ff}/ H$

. Non-dimensional temperature

$\mu _p U_{ff}/ H$

. Non-dimensional temperature

![]() $\theta$

, velocity

$\theta$

, velocity

![]() $u_i$

(where

$u_i$

(where

![]() $i=x,y,z$

represent the three coordinate directions), pressure

$i=x,y,z$

represent the three coordinate directions), pressure

![]() $p$

, polymer stress

$p$

, polymer stress

![]() $\tau _{ij}$

and time

$\tau _{ij}$

and time

![]() $t$

are obtained by using these scales. The dimensionless governing equations for the incompressible FENE-P fluid are as follows:

$t$

are obtained by using these scales. The dimensionless governing equations for the incompressible FENE-P fluid are as follows:

where the polymer stress

![]() $\tau _{ij}$

is related to the conformation tensor

$\tau _{ij}$

is related to the conformation tensor

![]() $C_{ij}$

via

$C_{ij}$

via

The function

![]() $f(C_{kk})$

, known as the Peterlin function, is defined as

$f(C_{kk})$

, known as the Peterlin function, is defined as

and

![]() $\delta _{ij}$

in (2.2) and (2.5) denotes the Kronecker symbol.

$\delta _{ij}$

in (2.2) and (2.5) denotes the Kronecker symbol.

In the above equations, the trace of the conformation tensor

![]() $C_{kk}$

represents the square of the average polymer-chain extension. It should be noted that for dilute polymer concentrations, the effect of polymer additives on the thermodynamic properties can be ignored, except for the fluid viscosity (Rubinstein & Colby Reference Rubinstein and Colby2003). No-slip boundary and constant temperature conditions are applied at the bottom and top plates, whereas periodic boundary conditions are applied in the wall-parallel horizontal directions.

$C_{kk}$

represents the square of the average polymer-chain extension. It should be noted that for dilute polymer concentrations, the effect of polymer additives on the thermodynamic properties can be ignored, except for the fluid viscosity (Rubinstein & Colby Reference Rubinstein and Colby2003). No-slip boundary and constant temperature conditions are applied at the bottom and top plates, whereas periodic boundary conditions are applied in the wall-parallel horizontal directions.

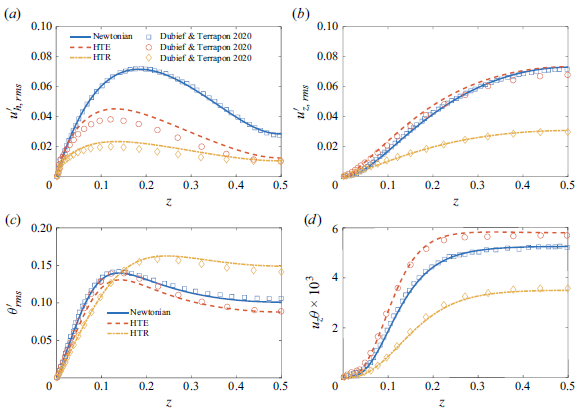

Figure 2. Comparison of statistics profiles from our simulations with the results of Dubief & Terrapon (Reference Dubief and Terrapon2020) for the Newtonian flow and non-Newtonian flows with an HTE flow state at

![]() $Wi=10$

,

$Wi=10$

,

![]() $L=25$

and an HTR flow state at

$L=25$

and an HTR flow state at

![]() $Wi=40$

,

$Wi=40$

,

![]() $L=100$

. The other control parameters are fixed at

$L=100$

. The other control parameters are fixed at

![]() $Ra=10^5$

,

$Ra=10^5$

,

![]() $Pr=7$

,

$Pr=7$

,

![]() $\beta =0.9$

and

$\beta =0.9$

and

![]() $\Gamma = 16$

. Root mean square (r.m.s.) of (a) horizontal velocity

$\Gamma = 16$

. Root mean square (r.m.s.) of (a) horizontal velocity

![]() $u^{\prime }_{h,{rms}}$

, (b) vertical velocity

$u^{\prime }_{h,{rms}}$

, (b) vertical velocity

![]() $u^{\prime }_{z,{rms}}$

, (c) temperature fluctuations

$u^{\prime }_{z,{rms}}$

, (c) temperature fluctuations

![]() $\theta _{{rms}}^{\prime }$

. (d) Mean heat flux

$\theta _{{rms}}^{\prime }$

. (d) Mean heat flux

![]() $\langle u_z\theta \rangle$

across the half-gap.

$\langle u_z\theta \rangle$

across the half-gap.

2.2. Numerical method and validations

The equations introduced above are solved via an in-house viscoelastic solver based on the open source AFiD code (Verzicco & Orlandi Reference Verzicco and Orlandi1996; van der Poel et al. Reference van der Poel, Ostilla-Mónico, Donners and Verzicco2015b

). The AFiD code is an energy-conserving second-order finite difference code that has been proven to be a versatile Navier–Stokes solver for wall-bounded turbulent flows (Verzicco & Orlandi Reference Verzicco and Orlandi1996). Moreover, the code is parallelised using a two-dimensional pencil domain decomposition strategy, allowing it to effectively handle large-scale computations (van der Poel et al. Reference van der Poel, Ostilla-Mónico, Donners and Verzicco2015b

). The code uses a staggered grid for the spatial discretization, with velocities located on the cell faces, and the other variables (pressure, conformation tensor and elastic stress) at the cell centre, except temperature, which is collocated with the vertical velocity

![]() $u_z$

. In the new version of the code, all spatial derivatives are approximated by using the second-order central finite differences except for the advection term in (2.3), where a Kurganov–Tadmor scheme (Vaithianathan et al. Reference Vaithianathan, Robert, Brasseur and Collins2006; Lin et al. Reference Lin, Wan, Zhu, Liu, Lu and Khomami2022) is used; indeed, the hyperbolic nature of this equation requires a special treatment of the convective term to ensure numerical convergence, especially at high

$u_z$

. In the new version of the code, all spatial derivatives are approximated by using the second-order central finite differences except for the advection term in (2.3), where a Kurganov–Tadmor scheme (Vaithianathan et al. Reference Vaithianathan, Robert, Brasseur and Collins2006; Lin et al. Reference Lin, Wan, Zhu, Liu, Lu and Khomami2022) is used; indeed, the hyperbolic nature of this equation requires a special treatment of the convective term to ensure numerical convergence, especially at high

![]() $Wi$

(Min, Yoo & Choi Reference Min, Yoo and Choi2001). Specifically, the Kurganov–Tadmor scheme is a modified central difference scheme that ensures the symmetric-positive-definite property of

$Wi$

(Min, Yoo & Choi Reference Min, Yoo and Choi2001). Specifically, the Kurganov–Tadmor scheme is a modified central difference scheme that ensures the symmetric-positive-definite property of

![]() $C_{ij}$

based on flux limiters. The tensor

$C_{ij}$

based on flux limiters. The tensor

![]() $C_{ij}$

at cell interfaces is constructed from the second-order, piecewise, linear approximations based on three potential candidates for approximating the gradients at cell centre: first-order forward and backward schemes, and a second-order central scheme (Vaithianathan et al. Reference Vaithianathan, Robert, Brasseur and Collins2006). In addition, a fractional-step third-order Runge–Kutta (RK3) scheme combined with a Crank–Nicolson scheme for the implicit terms is used for all the time advancements. Specifically, in (2.3), the linear stress relaxation term is treated implicitly to strictly enforce the chain finite maximum extension limit (Vaithianathan & Collins Reference Vaithianathan and Collins2003; Dubief et al. Reference Dubief, Terrapon, White, Shaqfeh, Moin and Lele2005; Song et al. Reference Song, Lin, Liu, Lu and Khomami2021). To this end, this algorithm is numerically stable and preserves the positive definiteness as well as the boundedness of the polymer conformation tensor (

$C_{ij}$

at cell interfaces is constructed from the second-order, piecewise, linear approximations based on three potential candidates for approximating the gradients at cell centre: first-order forward and backward schemes, and a second-order central scheme (Vaithianathan et al. Reference Vaithianathan, Robert, Brasseur and Collins2006). In addition, a fractional-step third-order Runge–Kutta (RK3) scheme combined with a Crank–Nicolson scheme for the implicit terms is used for all the time advancements. Specifically, in (2.3), the linear stress relaxation term is treated implicitly to strictly enforce the chain finite maximum extension limit (Vaithianathan & Collins Reference Vaithianathan and Collins2003; Dubief et al. Reference Dubief, Terrapon, White, Shaqfeh, Moin and Lele2005; Song et al. Reference Song, Lin, Liu, Lu and Khomami2021). To this end, this algorithm is numerically stable and preserves the positive definiteness as well as the boundedness of the polymer conformation tensor (

![]() $0\lt C_{ii}\lt L^2$

).

$0\lt C_{ii}\lt L^2$

).

To validate the code, we compare our DNS results with the three-dimensional numerical simulations of Dubief & Terrapon (Reference Dubief and Terrapon2020) at

![]() $Ra=10^5$

,

$Ra=10^5$

,

![]() $Pr=7$

,

$Pr=7$

,

![]() $\beta =0.9$

and

$\beta =0.9$

and

![]() $\Gamma = 16$

using the same grid resolutions. The results of the statistical profiles for velocities, temperature and heat flux are shown in figure 2, which are in good agreement with their results. Additionally, we compared the heat transfer modification (HTM), defined as

$\Gamma = 16$

using the same grid resolutions. The results of the statistical profiles for velocities, temperature and heat flux are shown in figure 2, which are in good agreement with their results. Additionally, we compared the heat transfer modification (HTM), defined as

![]() $HTM=(Nu^V-Nu^N)/Nu^N\times 100\,\%$

. In our simulations, the HTM is

$HTM=(Nu^V-Nu^N)/Nu^N\times 100\,\%$

. In our simulations, the HTM is

![]() $14.4\,\%$

for the HTE flow state, and

$14.4\,\%$

for the HTE flow state, and

![]() $-31.4\,\%$

for the HTR flow state, closely matching their results

$-31.4\,\%$

for the HTR flow state, closely matching their results

![]() $11\,\%$

and

$11\,\%$

and

![]() $-31\,\%$

, respectively. The small quantitative differences may be attributed to the different numerical schemes, specifically the inclusion of an artificial diffusion term in their code. Moreover, the present DNS results of the heat transport modification for highly turbulent thermal convection with polymer additives agree quantitatively with previous experiments in a similar parameter range. Specifically, our DNS at

$-31\,\%$

, respectively. The small quantitative differences may be attributed to the different numerical schemes, specifically the inclusion of an artificial diffusion term in their code. Moreover, the present DNS results of the heat transport modification for highly turbulent thermal convection with polymer additives agree quantitatively with previous experiments in a similar parameter range. Specifically, our DNS at

![]() $10^{9} \leqslant Ra\leqslant 10^{10}$

,

$10^{9} \leqslant Ra\leqslant 10^{10}$

,

![]() $Pr=4.3$

give an HTR approximately

$Pr=4.3$

give an HTR approximately

![]() $9\,\%{\sim}15\,\%$

, which is quite close to the

$9\,\%{\sim}15\,\%$

, which is quite close to the

![]() $10\,\%{\sim}12\,\%$

measured in the experiments by Ahlers & Nikolaenko (Reference Ahlers and Nikolaenko2010), Wei et al. (Reference Wei, Ni and Xia2012) and Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019) for similar parameters

$10\,\%{\sim}12\,\%$

measured in the experiments by Ahlers & Nikolaenko (Reference Ahlers and Nikolaenko2010), Wei et al. (Reference Wei, Ni and Xia2012) and Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019) for similar parameters

![]() $10^{9}\leqslant Ra\leqslant 7\times 10^{10}$

,

$10^{9}\leqslant Ra\leqslant 7\times 10^{10}$

,

![]() $Pr=4.3$

. For further validation cases and details of the code, we refer to Song, Xu & Shishkina (Reference Song, Xu and Shishkina2025).

$Pr=4.3$

. For further validation cases and details of the code, we refer to Song, Xu & Shishkina (Reference Song, Xu and Shishkina2025).

2.3. Simulation parameters

In our simulations, we explore the range of

![]() $Ra$

spanning from

$Ra$

spanning from

![]() $10^6$

to

$10^6$

to

![]() $10^{10}$

at fixed

$10^{10}$

at fixed

![]() $Pr=4.3$

, corresponding to pure water at

$Pr=4.3$

, corresponding to pure water at

![]() $40\,^\circ$

C. We consider a moderate level of elasticity:

$40\,^\circ$

C. We consider a moderate level of elasticity:

![]() $Wi=5$

and

$Wi=5$

and

![]() $Wi=10$

, with

$Wi=10$

, with

![]() $Wi=0$

representing Newtonian flow.

$Wi=0$

representing Newtonian flow.

In classical Newtonian RB convection, the mesh resolution should be adequate to resolve the Kolmogorov

![]() $\eta _K^*\equiv (\nu ^3/\varepsilon _u^*)^{1/4}$

and Batchelor

$\eta _K^*\equiv (\nu ^3/\varepsilon _u^*)^{1/4}$

and Batchelor

![]() $\eta _B^*\equiv (\nu \kappa ^2/\varepsilon _u^*)^{1/4}$

length scales, where

$\eta _B^*\equiv (\nu \kappa ^2/\varepsilon _u^*)^{1/4}$

length scales, where

![]() $\varepsilon _u^*$

represents the kinetic energy dissipation rate, with

$\varepsilon _u^*$

represents the kinetic energy dissipation rate, with

![]() $^*$

indicating dimensional quantities. The dimensionless forms of these two length scales are calculated by

$^*$

indicating dimensional quantities. The dimensionless forms of these two length scales are calculated by

where the dimensionless kinetic energy dissipation rate is given by

![]() $\varepsilon _u(\boldsymbol{x},t)=\sqrt {Pr/Ra}\,[\partial _i u_j(\boldsymbol{x},t)]^2$

(Scheel, Emran & Schumacher Reference Scheel, Emran and Schumacher2013). We ensure adequate grid resolution in all directions by requiring that the maximal value of the ratio of the mesh size to the local Kolmogorov

$\varepsilon _u(\boldsymbol{x},t)=\sqrt {Pr/Ra}\,[\partial _i u_j(\boldsymbol{x},t)]^2$

(Scheel, Emran & Schumacher Reference Scheel, Emran and Schumacher2013). We ensure adequate grid resolution in all directions by requiring that the maximal value of the ratio of the mesh size to the local Kolmogorov

![]() $h_{{max}}/{\eta _K}$

and Batchelor

$h_{{max}}/{\eta _K}$

and Batchelor

![]() $h_{{max}}/{\eta _B}$

microscales is smaller than 3, which was found empirically to be acceptable (Verzicco Reference Verzicco and Camussi2003; Shishkina et al. Reference Shishkina, Stevens, Grossmann and Lohse2010), where

$h_{{max}}/{\eta _B}$

microscales is smaller than 3, which was found empirically to be acceptable (Verzicco Reference Verzicco and Camussi2003; Shishkina et al. Reference Shishkina, Stevens, Grossmann and Lohse2010), where

![]() $h_{{max}}=\max ( \Delta x, \Delta y, \Delta z )$

. For all the cases, the mesh width fulfils these requirements (see table 2,

$h_{{max}}=\max ( \Delta x, \Delta y, \Delta z )$

. For all the cases, the mesh width fulfils these requirements (see table 2,

![]() $h_{{max}}/\eta _K$

and

$h_{{max}}/\eta _K$

and

![]() $h_{{max}}/\eta _B$

). Notably, according to Stevens, Verzicco & Lohse (Reference Stevens, Verzicco and Lohse2010), higher resolution in the horizontal direction is necessary to resolve the plume dynamics in the BL. Further, we check the number of mesh points inside the thermal and viscous BLs (see table 2,

$h_{{max}}/\eta _B$

). Notably, according to Stevens, Verzicco & Lohse (Reference Stevens, Verzicco and Lohse2010), higher resolution in the horizontal direction is necessary to resolve the plume dynamics in the BL. Further, we check the number of mesh points inside the thermal and viscous BLs (see table 2,

![]() $N_{\theta }$

and

$N_{\theta }$

and

![]() $N_v$

) to ensure adequate resolutions inside the BL. The resolutions in our DNS fully satisfy the requirements for minimal mesh points suggested by Shishkina et al. (Reference Shishkina, Stevens, Grossmann and Lohse2010).

$N_v$

) to ensure adequate resolutions inside the BL. The resolutions in our DNS fully satisfy the requirements for minimal mesh points suggested by Shishkina et al. (Reference Shishkina, Stevens, Grossmann and Lohse2010).

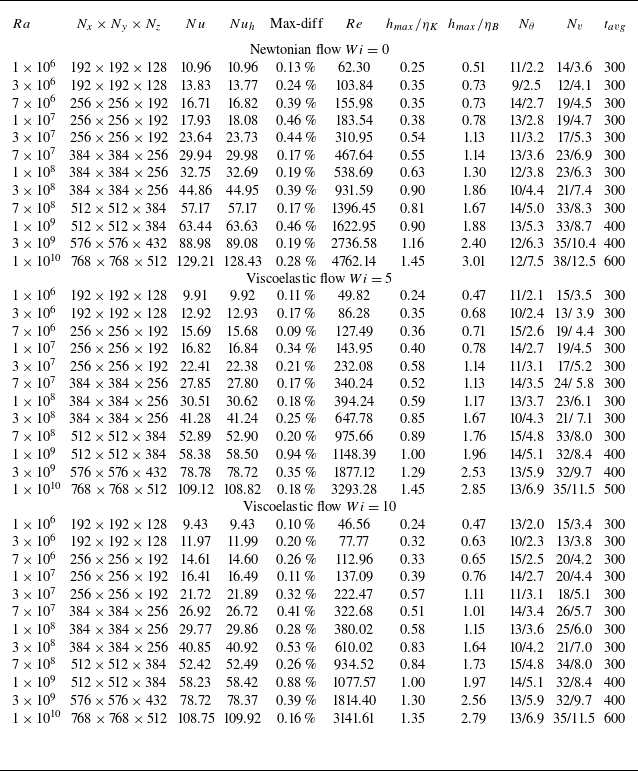

Table 2. Simulation parameters. Columns from left to right indicate

![]() $Ra$

, grid resolution, spatiotemporal averaged Nusselt number (

$Ra$

, grid resolution, spatiotemporal averaged Nusselt number (

![]() $Nu$

) determined by averaging the results from four methods, Nusselt number

$Nu$

) determined by averaging the results from four methods, Nusselt number

![]() $Nu_h$

computed by using half of the statistical time (Stevens et al. Reference Stevens, Verzicco and Lohse2010), maximum difference between four methods (Max-diff), Reynolds number

$Nu_h$

computed by using half of the statistical time (Stevens et al. Reference Stevens, Verzicco and Lohse2010), maximum difference between four methods (Max-diff), Reynolds number

![]() $Re$

, the maximum value of the ratio of the local mesh size

$Re$

, the maximum value of the ratio of the local mesh size

![]() $h_{{max}}=\max ( \Delta x, \Delta y, \Delta z )$

to the local Kolmogorov

$h_{{max}}=\max ( \Delta x, \Delta y, \Delta z )$

to the local Kolmogorov

![]() $\eta _K$

and Batchelor

$\eta _K$

and Batchelor

![]() $ \eta _B$

length scales, the number of grid points inside the thermal BL,

$ \eta _B$

length scales, the number of grid points inside the thermal BL,

![]() $N_{\theta }$

, and viscous BL,

$N_{\theta }$

, and viscous BL,

![]() $N_{v}$

(actual resolution/requirement; Shishkina et al. Reference Shishkina, Stevens, Grossmann and Lohse2010), and the statistical averaging time

$N_{v}$

(actual resolution/requirement; Shishkina et al. Reference Shishkina, Stevens, Grossmann and Lohse2010), and the statistical averaging time

![]() $t_{{avg}}$

in the free-fall time units.

$t_{{avg}}$

in the free-fall time units.

In a viscoelastic flow, the typical length is similar or even larger than those in a Newtonian fluid (Benzi et al. Reference Benzi, Ching and De Angelis2010; Wei et al. Reference Wei, Ni and Xia2012; Cheng et al. Reference Cheng, Zhang, Cai, Li and Li2017), therefore, for viscoelastic flows we use the same mesh resolutions as in the corresponding Newtonian flows. In table 2, we similarly provide

![]() $h_{{max}}/\eta _K$

,

$h_{{max}}/\eta _K$

,

![]() $h_{{max}}/ \eta _B$

and the mesh points inside the BL with the minimal mesh points according to Shishkina et al. (Reference Shishkina, Stevens, Grossmann and Lohse2010). The Kolmogorov and Batchelor length scales are defined using the Newtonian solvent dissipation rate

$h_{{max}}/ \eta _B$

and the mesh points inside the BL with the minimal mesh points according to Shishkina et al. (Reference Shishkina, Stevens, Grossmann and Lohse2010). The Kolmogorov and Batchelor length scales are defined using the Newtonian solvent dissipation rate

![]() $\varepsilon _u^{[s]}$

, excluding polymer dissipation

$\varepsilon _u^{[s]}$

, excluding polymer dissipation

![]() $\varepsilon _u^{[p]}$

, as

$\varepsilon _u^{[p]}$

, as

![]() $\eta _K^*=(\nu _s^3/\varepsilon _u^{[s]^*})^{1/4}$

and

$\eta _K^*=(\nu _s^3/\varepsilon _u^{[s]^*})^{1/4}$

and

![]() $\eta _B^*= (\nu _s \kappa ^2/\varepsilon _u^{[s]^*})^{1/4}$

. Their dimensionless forms are

$\eta _B^*= (\nu _s \kappa ^2/\varepsilon _u^{[s]^*})^{1/4}$

. Their dimensionless forms are

where

To start the simulation of a Newtonian flow, the temperature field is initialised by a linear profile, and the velocity field is initialised with random fluctuation of maximum amplitude 0.001 to trigger the transition to the chaotic turbulent motion. In the viscoelastic cases, the temperature and velocity flow fields are initialised with those of the corresponding Newtonian flows in the statistically stationary state, while the initial conformation tensor is set to the unit tensor, corresponding to the equilibrium state. Statistical data are collected after the flow reaches a statistically stationary state, determined by the convergence of

![]() $Nu$

and volume-averaged turbulent kinetic energy, which typically happens after at least 500 dimensionless time units for all cases. Table 2 provides the time span

$Nu$

and volume-averaged turbulent kinetic energy, which typically happens after at least 500 dimensionless time units for all cases. Table 2 provides the time span

![]() $t_{{avg}}$

for the statistical data sampling in free-fall time units. In this paper, the statistic profiles presented in § 3.3 are further averaged over horizontal planes (

$t_{{avg}}$

for the statistical data sampling in free-fall time units. In this paper, the statistic profiles presented in § 3.3 are further averaged over horizontal planes (

![]() $xy$

-plane), with a prime indicating fluctuations around this average.

$xy$

-plane), with a prime indicating fluctuations around this average.

We use four different methods to calculate the Nusselt number

![]() $Nu$

. One is the time and volume averaged

$Nu$

. One is the time and volume averaged

![]() $Nu$

:

$Nu$

:

![]() $Nu=1+\sqrt {Ra\, Pr} \langle u_z\theta \rangle$

. The second is derived from the exact relation for the thermal dissipation rate:

$Nu=1+\sqrt {Ra\, Pr} \langle u_z\theta \rangle$

. The second is derived from the exact relation for the thermal dissipation rate:

![]() $Nu=\sqrt {Ra\, Pr} \langle \varepsilon _\theta \rangle$

(Shraiman & Siggia Reference Shraiman and Siggia1990; Grossmann & Lohse Reference Grossmann and Lohse2000). The third and fourth values are obtained from the averages of the temperature gradients at the bottom and top plates, respectively. In table 2, the column

$Nu=\sqrt {Ra\, Pr} \langle \varepsilon _\theta \rangle$

(Shraiman & Siggia Reference Shraiman and Siggia1990; Grossmann & Lohse Reference Grossmann and Lohse2000). The third and fourth values are obtained from the averages of the temperature gradients at the bottom and top plates, respectively. In table 2, the column

![]() $Nu$

shows the average value obtained from these four methods, and the column headed ‘Max-diff’ shows the maximum difference between the results from these four methods. Notably, all differences are within 1

$Nu$

shows the average value obtained from these four methods, and the column headed ‘Max-diff’ shows the maximum difference between the results from these four methods. Notably, all differences are within 1

![]() $\,\%$

, indicating the convergence of our simulations. We have also calculated the average

$\,\%$

, indicating the convergence of our simulations. We have also calculated the average

![]() $Nu_h$

using half of the statistical averaging time. We observe consistency between

$Nu_h$

using half of the statistical averaging time. We observe consistency between

![]() $Nu$

and

$Nu$

and

![]() $Nu_h$

for all cases, confirming that our simulations are indeed well converged, and the averaging times are sufficient. Finally, the Reynolds number

$Nu_h$

for all cases, confirming that our simulations are indeed well converged, and the averaging times are sufficient. Finally, the Reynolds number

![]() $Re$

is defined as

$Re$

is defined as

![]() $Re=U_{{rms}}\sqrt {Ra/Pr}$

, where

$Re=U_{{rms}}\sqrt {Ra/Pr}$

, where

![]() $U_{{rms}}=\sqrt {\langle u_x^2+u_y^2+u_z^2 \rangle }$

is the r.m.s. of the velocity averaged over time and the entire domain.

$U_{{rms}}=\sqrt {\langle u_x^2+u_y^2+u_z^2 \rangle }$

is the r.m.s. of the velocity averaged over time and the entire domain.

3. Results

3.1. Nusselt number and Reynolds number

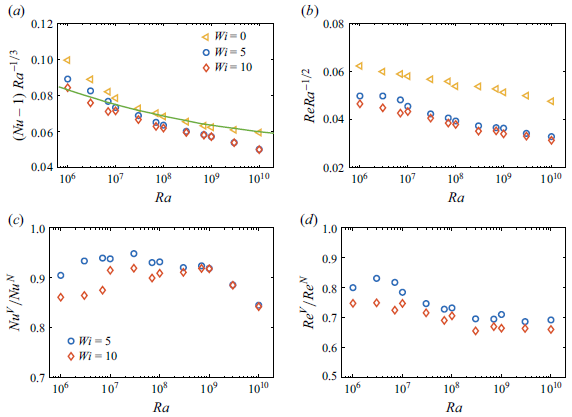

We start by examining the polymer effects on the macroscopic heat and momentum transfer. Figure 3(a) presents the

![]() $Ra$

dependence of the Nusselt number

$Ra$

dependence of the Nusselt number

![]() $Nu$

compensated with

$Nu$

compensated with

![]() $Ra^{1/3}$

, and figure 3(b) presents the Reynolds number

$Ra^{1/3}$

, and figure 3(b) presents the Reynolds number

![]() $Re$

compensated with

$Re$

compensated with

![]() $Ra^{1/2}$

, where these two specific scaling exponents are suggested by Grossmann & Lohse (Reference Grossmann and Lohse2000) for the classical regime of turbulent RB convection at medium

$Ra^{1/2}$

, where these two specific scaling exponents are suggested by Grossmann & Lohse (Reference Grossmann and Lohse2000) for the classical regime of turbulent RB convection at medium

![]() $Ra$

and

$Ra$

and

![]() $Pr \gtrsim 1$

. It is evident that within our parameter ranges, both

$Pr \gtrsim 1$

. It is evident that within our parameter ranges, both

![]() $Nu$

and

$Nu$

and

![]() $Re$

are drastically reduced with the addition of polymer additives, indicating a reduction of the heat and momentum transport. Moreover, comparing to the polymer solutions with small

$Re$

are drastically reduced with the addition of polymer additives, indicating a reduction of the heat and momentum transport. Moreover, comparing to the polymer solutions with small

![]() $Wi$

(

$Wi$

(

![]() $Wi=5$

), we note that the amount of HTR and momentum transport reduction (MTR) increases at larger

$Wi=5$

), we note that the amount of HTR and momentum transport reduction (MTR) increases at larger

![]() $Wi$

(

$Wi$

(

![]() $Wi=10$

). This effect is more pronounced at the lower

$Wi=10$

). This effect is more pronounced at the lower

![]() $Ra$

under investigation, while for

$Ra$

under investigation, while for

![]() $Ra \gt 10^8$

,

$Ra \gt 10^8$

,

![]() $Nu$

is nearly the same at

$Nu$

is nearly the same at

![]() $Wi=5$

and

$Wi=5$

and

![]() $Wi=10$

, likely indicating the onset of a saturation regime. A fit to the data of Newtonian flows yields

$Wi=10$

, likely indicating the onset of a saturation regime. A fit to the data of Newtonian flows yields

![]() $Nu \sim Ra^{0.27}$

and

$Nu \sim Ra^{0.27}$

and

![]() $Re \sim Ra^{0.47}$

. In general, the data follow the theoretical scaling of the Grossmann and Lohse theory (Grossmann & Lohse Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001); see figure 3(a). With polymer additives, the scalings remain similar:

$Re \sim Ra^{0.47}$

. In general, the data follow the theoretical scaling of the Grossmann and Lohse theory (Grossmann & Lohse Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001); see figure 3(a). With polymer additives, the scalings remain similar:

![]() $Nu \sim Ra^{0.26}$

and

$Nu \sim Ra^{0.26}$

and

![]() $Re \sim Ra^{0.45}$

at

$Re \sim Ra^{0.45}$

at

![]() $Wi=5$

, and

$Wi=5$

, and

![]() $Nu \sim Ra^{0.27}$

and

$Nu \sim Ra^{0.27}$

and

![]() $Re \sim Ra^{0.46}$

at

$Re \sim Ra^{0.46}$

at

![]() $Wi=10$

, but the absolute values of

$Wi=10$

, but the absolute values of

![]() $Nu$

and

$Nu$

and

![]() $Re$

are smaller in the viscoelastic case compared to the Newtonian case. These results are consistent with previous experiments of Wei et al. (Reference Wei, Ni and Xia2012) and Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019); these authors found that the scalings of

$Re$

are smaller in the viscoelastic case compared to the Newtonian case. These results are consistent with previous experiments of Wei et al. (Reference Wei, Ni and Xia2012) and Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019); these authors found that the scalings of

![]() $Nu$

versus

$Nu$

versus

![]() $Ra$

, and

$Ra$

, and

![]() $Re$

versus

$Re$

versus

![]() $Ra$

, remain almost unchanged in their parameter ranges (

$Ra$

, remain almost unchanged in their parameter ranges (

![]() $Ra$

span from

$Ra$

span from

![]() $10^9$

to

$10^9$

to

![]() $10^{10}$

at

$10^{10}$

at

![]() $Pr \approx 4.3$

).

$Pr \approx 4.3$

).

Figure 3. (a) Nusselt number

![]() $Nu-1$

compensated with

$Nu-1$

compensated with

![]() $Ra^{-1/3}$

. (b) Reynolds number

$Ra^{-1/3}$

. (b) Reynolds number

![]() $Re$

compensated with

$Re$

compensated with

![]() $Ra^{-1/2}$

. Ratios of (c)

$Ra^{-1/2}$

. Ratios of (c)

![]() $Nu$

and (d)

$Nu$

and (d)

![]() $Re$

for a viscoelastic flow to those for the corresponding Newtonian flow;

$Re$

for a viscoelastic flow to those for the corresponding Newtonian flow;

![]() $N$

and

$N$

and

![]() $V$

represent Newtonian and viscoealstic flows, respectively. The solid line in (a) is the result of the Grossmann–Lohse (Grossmann & Lohse Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001) fit for

$V$

represent Newtonian and viscoealstic flows, respectively. The solid line in (a) is the result of the Grossmann–Lohse (Grossmann & Lohse Reference Grossmann and Lohse2000, Reference Grossmann and Lohse2001) fit for

![]() $Pr=4.38$

from Ahlers et al. (Reference Ahlers2022).

$Pr=4.38$

from Ahlers et al. (Reference Ahlers2022).

Next, we directly compare

![]() $Nu$

and

$Nu$

and

![]() $Re$

of viscoelastic flows with those of Newtonian flows, as shown in figure 3(c,d). The ratio

$Re$

of viscoelastic flows with those of Newtonian flows, as shown in figure 3(c,d). The ratio

![]() $Nu^V/Nu^N$

between Newtonian and viscoelastic flows, lower than 1 for the quenching effect of polymer additives, exhibits a non-monotonic dependence on

$Nu^V/Nu^N$

between Newtonian and viscoelastic flows, lower than 1 for the quenching effect of polymer additives, exhibits a non-monotonic dependence on

![]() $Ra$

. For the Nusselt number ratio (

$Ra$

. For the Nusselt number ratio (

![]() $Nu^V/Nu^N$

), we observe first an increase between

$Nu^V/Nu^N$

), we observe first an increase between

![]() $Ra=10^6$

and

$Ra=10^6$

and

![]() $Ra=10^7$

, followed by a slight decrease as

$Ra=10^7$

, followed by a slight decrease as

![]() $Ra$

rises further from

$Ra$

rises further from

![]() $Ra=10^7$

to

$Ra=10^7$

to

![]() $Ra=10^9$

, with a more pronounced decrease at large

$Ra=10^9$

, with a more pronounced decrease at large

![]() $Ra \geqslant 10^9$

. This non-monotonic behaviour suggests the existence of different heat transfer mechanisms in the low-

$Ra \geqslant 10^9$

. This non-monotonic behaviour suggests the existence of different heat transfer mechanisms in the low-

![]() $Ra$

and large-

$Ra$

and large-

![]() $Ra$

regions. Regarding the ratio of the Reynolds numbers (

$Ra$

regions. Regarding the ratio of the Reynolds numbers (

![]() $Re^V/Re^N$

), a different trend is observed: a gradual decrease is noted for

$Re^V/Re^N$

), a different trend is observed: a gradual decrease is noted for

![]() $Ra\lt 10^9$

, after which it eventually reaches a plateau. It can be inferred that the polymer-induced drag enhancement becomes more pronounced with increasing

$Ra\lt 10^9$

, after which it eventually reaches a plateau. It can be inferred that the polymer-induced drag enhancement becomes more pronounced with increasing

![]() $Ra$

, and the plateau at higher

$Ra$

, and the plateau at higher

![]() $Ra$

indicates that the maximum drag enhancement due to the polymer additives has been achieved. Although there are some fluctuations in the

$Ra$

indicates that the maximum drag enhancement due to the polymer additives has been achieved. Although there are some fluctuations in the

![]() $Nu$

and

$Nu$

and

![]() $Re$

ratios at the low-

$Re$

ratios at the low-

![]() $Ra$

regime (

$Ra$

regime (

![]() $Ra\lesssim 10^7$

), which should be attributed to the sensitivity of these quantities due to the pseudo-laminar flow state, the overall trends remain clear and consistent.

$Ra\lesssim 10^7$

), which should be attributed to the sensitivity of these quantities due to the pseudo-laminar flow state, the overall trends remain clear and consistent.

In order to compare our results with existing experiments, we note that Benzi et al. (Reference Benzi, Ching and De Angelis2016b

) provided a reference for extracting the dependence of the viscosity ratio in the FENE-P model on the polymer concentration

![]() $c$

, based on the experimental measurements of the viscosity of the PEO solution; cf. figure 7 of their paper for details. Since we have relatively large polymer extensibility, when ignoring the shear-thinning behaviour, the kinetic viscosity of the polymer solution

$c$

, based on the experimental measurements of the viscosity of the PEO solution; cf. figure 7 of their paper for details. Since we have relatively large polymer extensibility, when ignoring the shear-thinning behaviour, the kinetic viscosity of the polymer solution

![]() $\nu _{sol}(c)$

for different polymer concentrations

$\nu _{sol}(c)$

for different polymer concentrations

![]() $c$

can be simplified as the zero-shear viscosity

$c$

can be simplified as the zero-shear viscosity

![]() $\nu _s+\nu _p$

in the model. Thus we have a reasonable approximation of the relation between

$\nu _s+\nu _p$

in the model. Thus we have a reasonable approximation of the relation between

![]() $c$

and

$c$

and

![]() $\beta$

. In our DNS,

$\beta$

. In our DNS,

![]() $\beta =0.9$

would therefore correspond to the polymer concentration between 90 (ppm) and 120 (ppm). In our DNS, the ratio of

$\beta =0.9$

would therefore correspond to the polymer concentration between 90 (ppm) and 120 (ppm). In our DNS, the ratio of

![]() $Nu$

in a viscoelastic flow to that in the corresponding Newtonian flow at

$Nu$

in a viscoelastic flow to that in the corresponding Newtonian flow at

![]() $10^9 \leqslant Ra\leqslant 10^{10}$

is approximately

$10^9 \leqslant Ra\leqslant 10^{10}$

is approximately

![]() $0.85{-}0.91$

, very close to the findings of Wei et al. (Reference Wei, Ni and Xia2012), who observed ratio 0.88 for concentration

$0.85{-}0.91$

, very close to the findings of Wei et al. (Reference Wei, Ni and Xia2012), who observed ratio 0.88 for concentration

![]() $c = 120$

(ppm) at

$c = 120$

(ppm) at

![]() $Ra=8.1\times 10^9$

, to the results reported by Ahlers & Nikolaenko (Reference Ahlers and Nikolaenko2010), who found ratio 0.90 for concentration

$Ra=8.1\times 10^9$

, to the results reported by Ahlers & Nikolaenko (Reference Ahlers and Nikolaenko2010), who found ratio 0.90 for concentration

![]() $c = 120$

(ppm) at

$c = 120$

(ppm) at

![]() $Ra=6.74\times 10^{10}$

, and also to the value 0.92 for concentration

$Ra=6.74\times 10^{10}$

, and also to the value 0.92 for concentration

![]() $c = 100$

(ppm) at

$c = 100$

(ppm) at

![]() $Ra=2\times 10^{9}$

reported in Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019).

$Ra=2\times 10^{9}$

reported in Cai et al. (Reference Cai, Wei, Tang, Liu, Li and Li2019).

In what follows, we will focus on two key questions: first, why do the heat and momentum transport decrease, and second, why are the trends non-monotonic? Given that the results for

![]() $Wi=5$

and

$Wi=5$

and

![]() $Wi=10$

yield similar trends, our primary focus will be on the flow cases with

$Wi=10$

yield similar trends, our primary focus will be on the flow cases with

![]() $Wi=10$

.

$Wi=10$

.

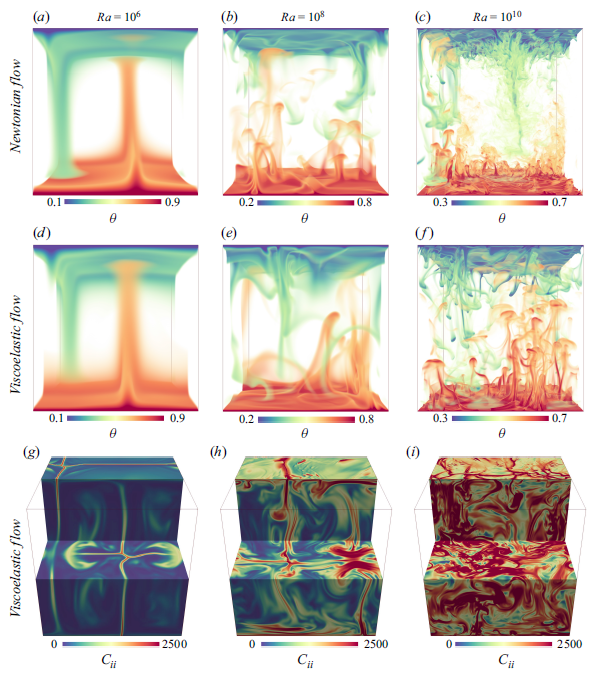

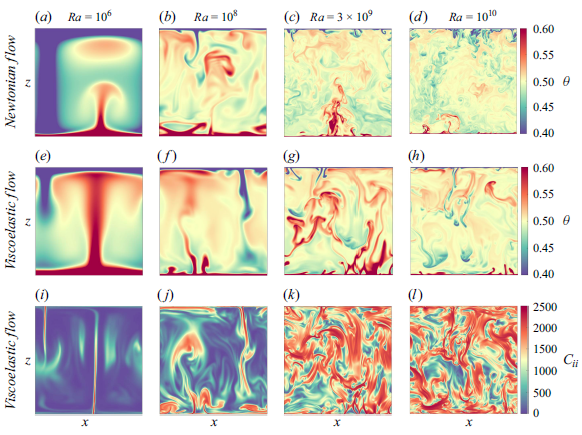

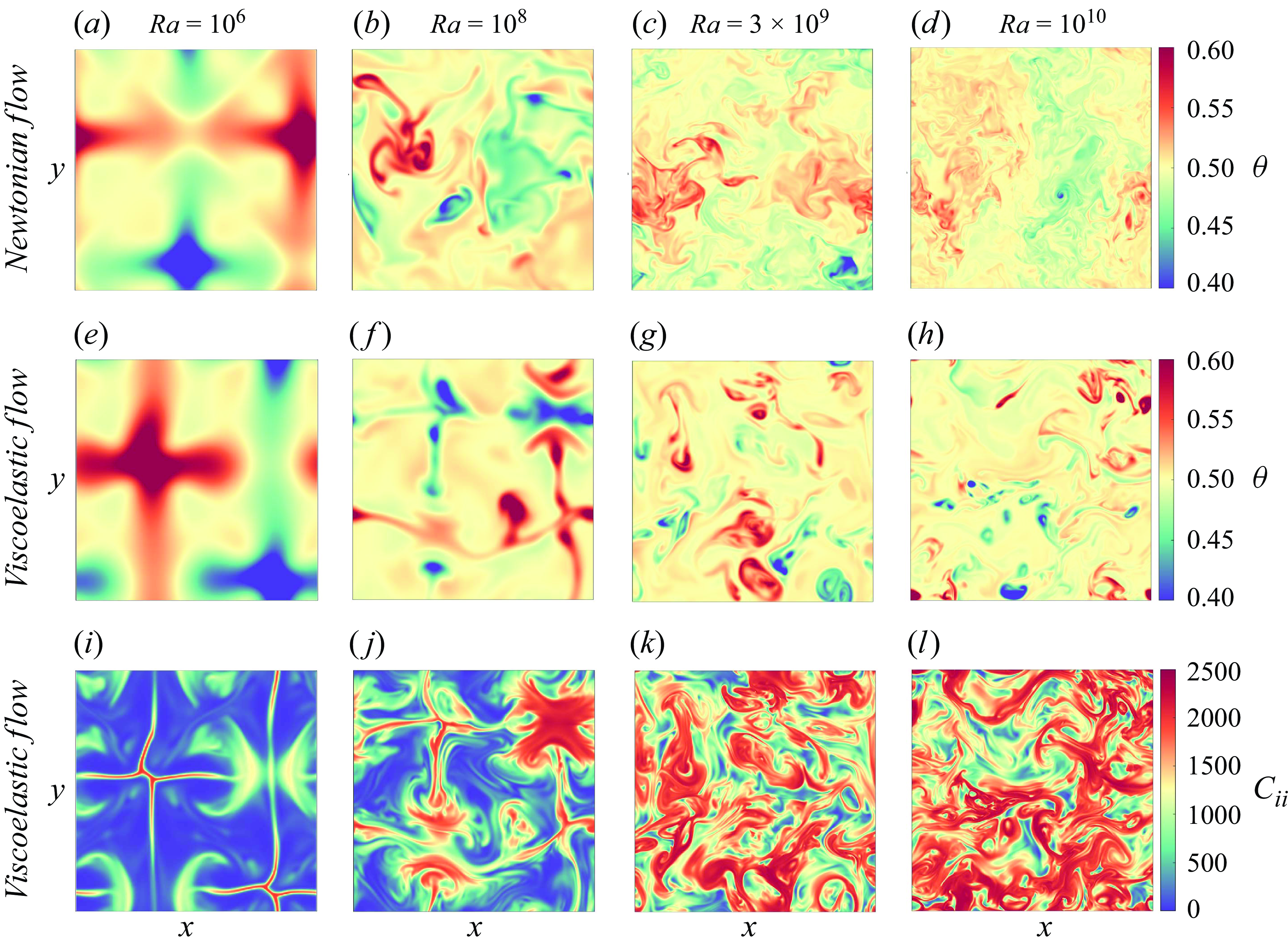

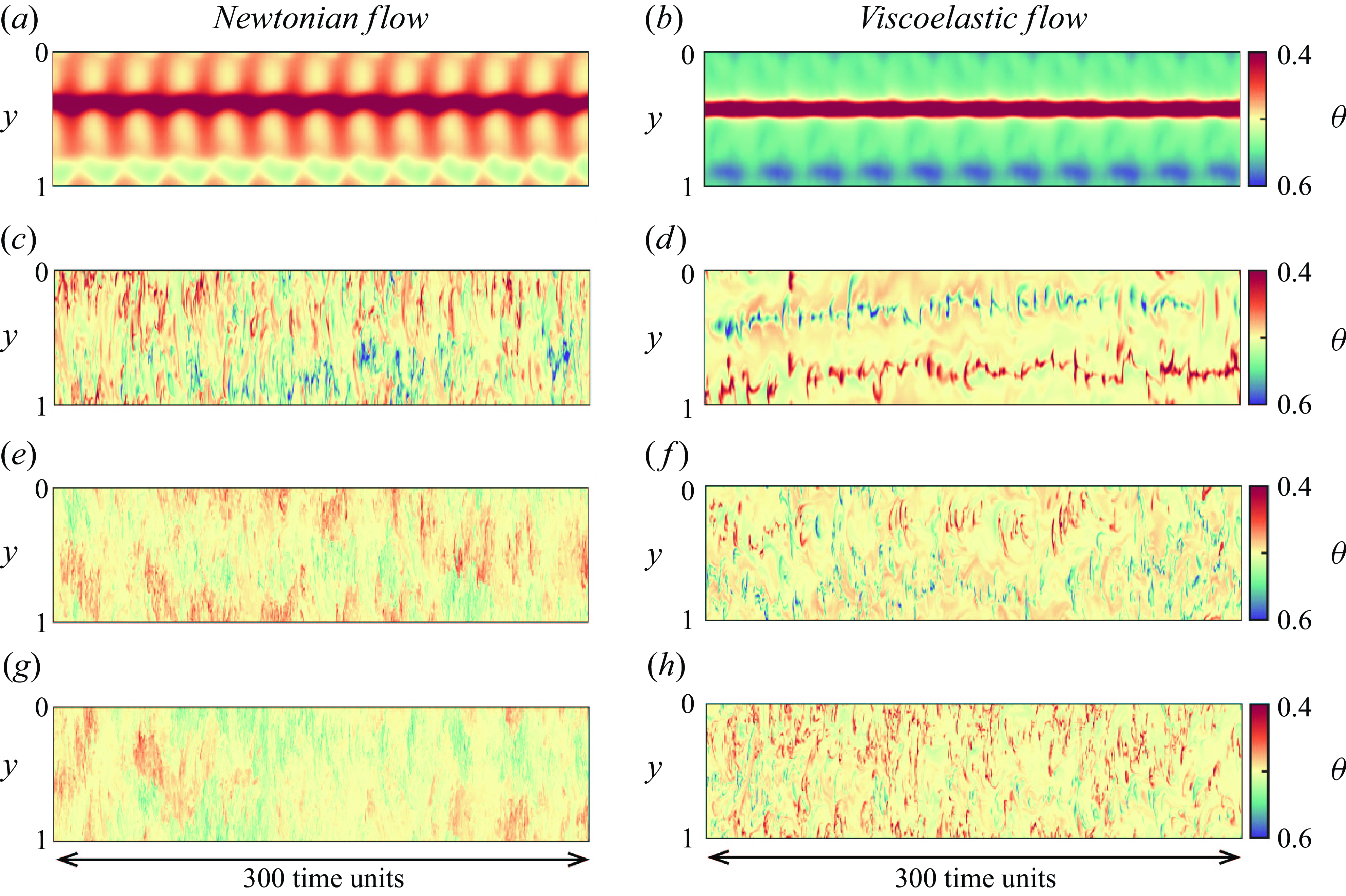

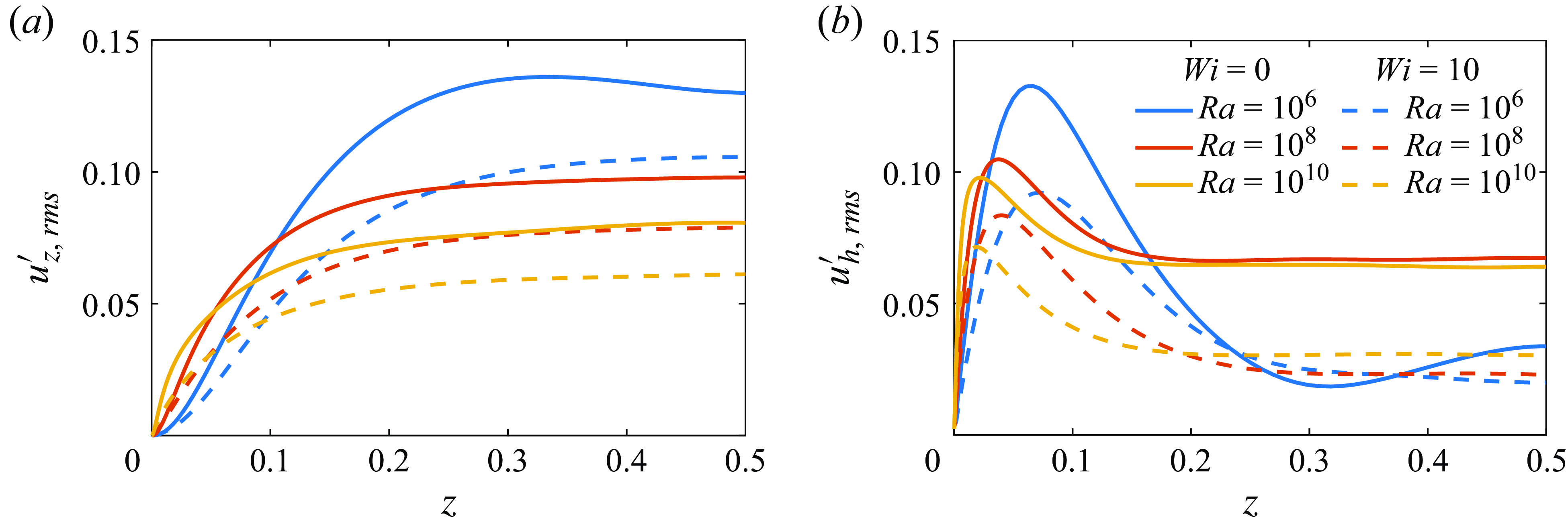

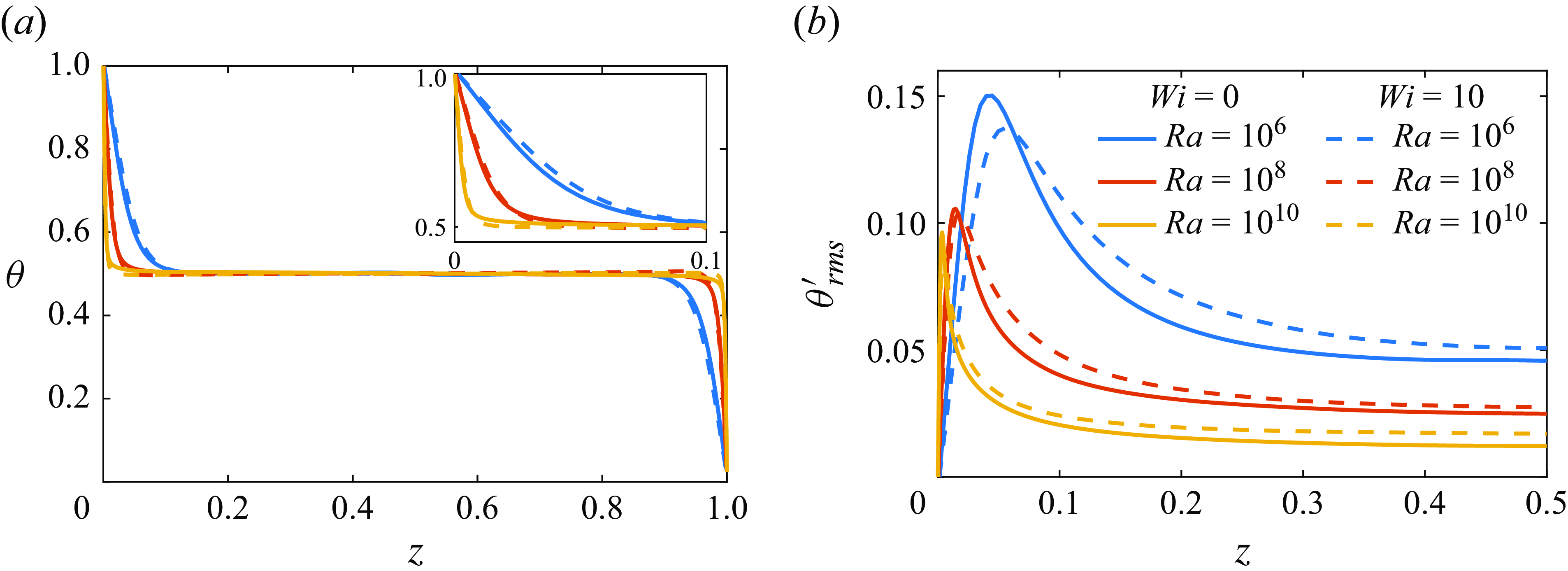

Figure 4. Instantaneous temperature fields of (a,b,c) Newtonian flows and (d,e,f) viscoelastic flows, and (g,h,i) the corresponding trace fields of viscoelastic flows. The columns from left to right represent

![]() $Ra=10^6$

,

$Ra=10^6$

,

![]() $Ra=10^8$

and

$Ra=10^8$

and

![]() $Ra=10^{10}$

, respectively. (The viewing angle of trace fields is rotated

$Ra=10^{10}$

, respectively. (The viewing angle of trace fields is rotated

![]() $30^\circ$

along the horizontal

$30^\circ$

along the horizontal

![]() $x$

-axis for a better visualisation.)

$x$

-axis for a better visualisation.)

3.2. Flow structure

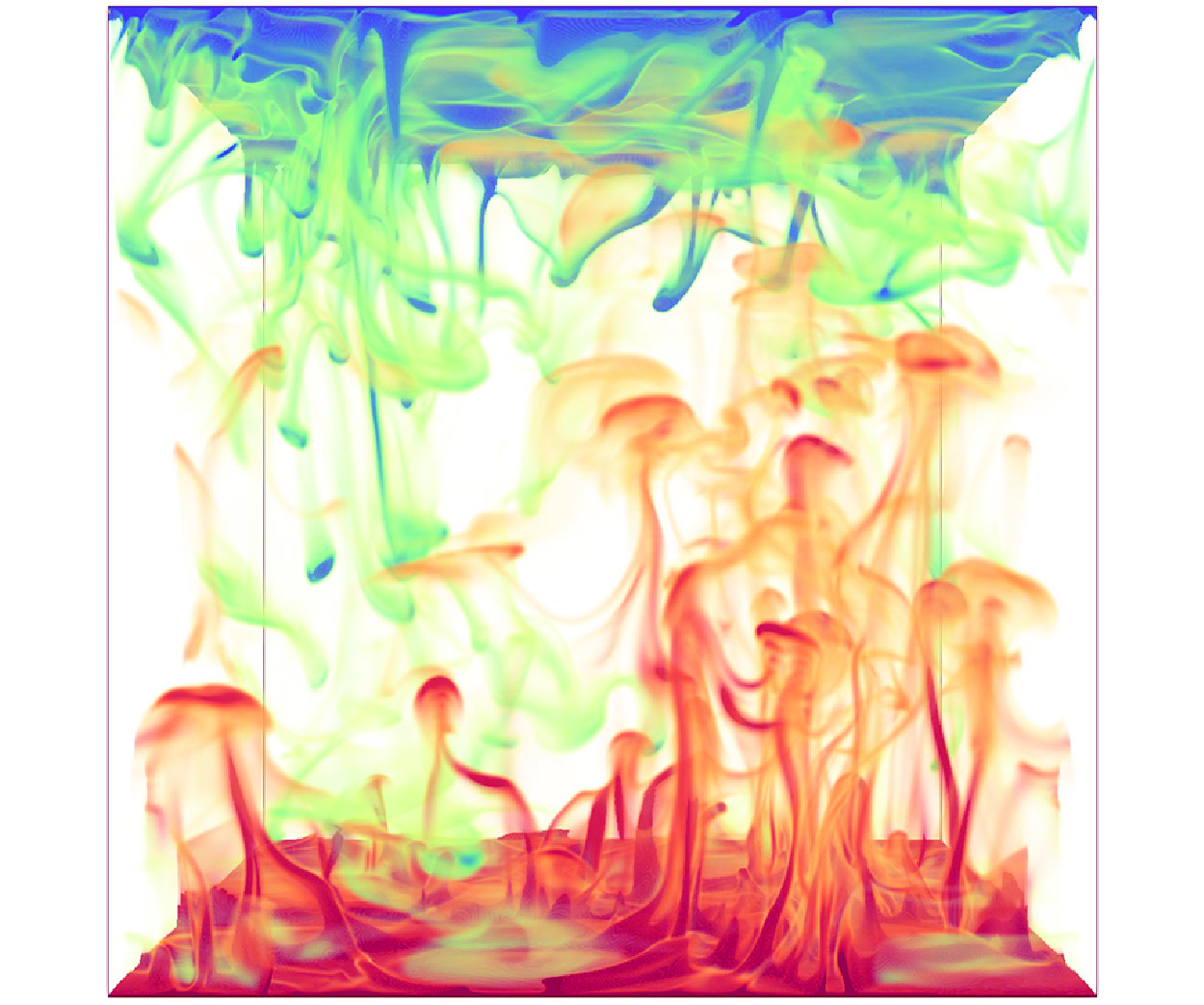

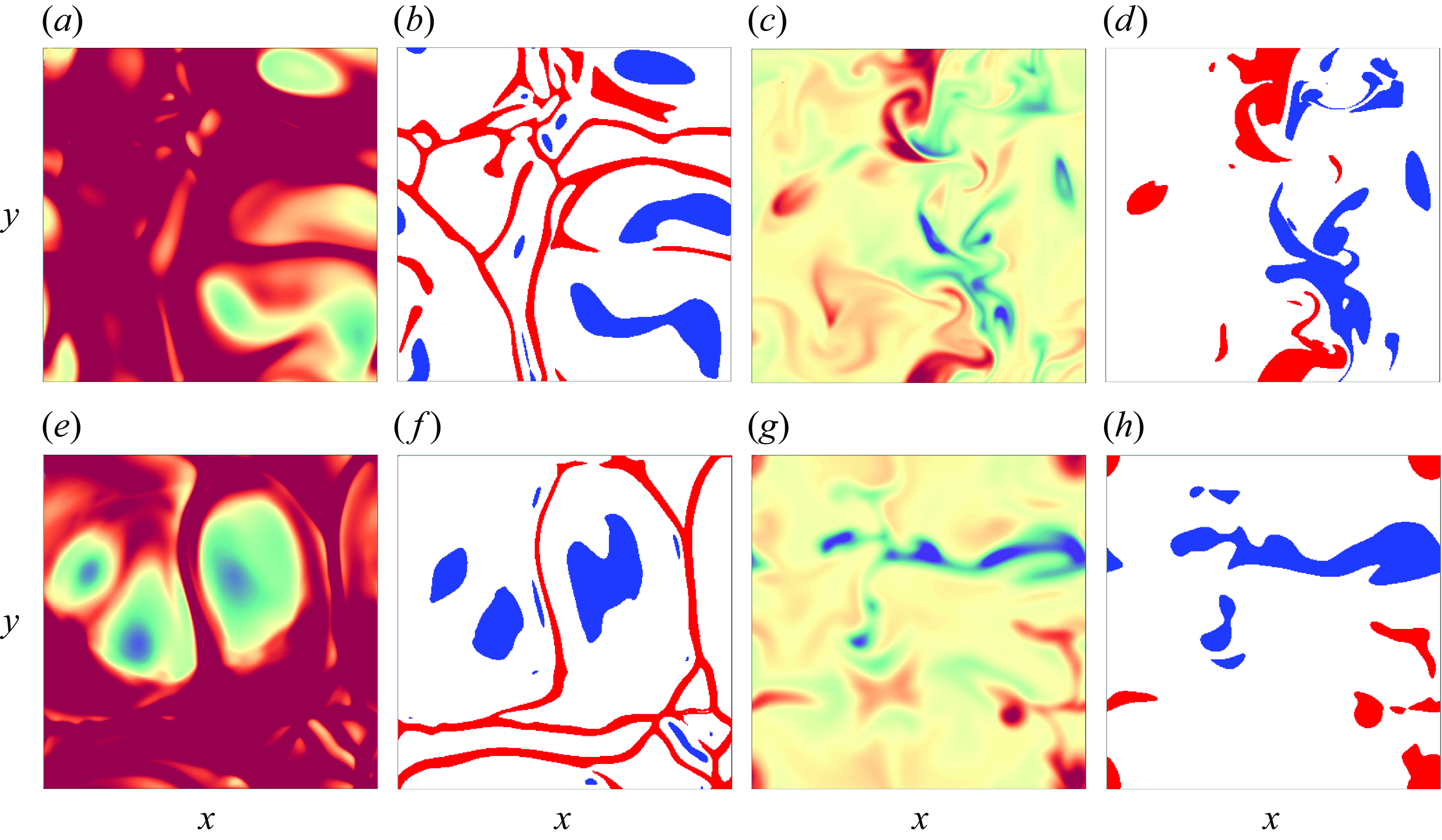

The typical flow structures for both Newtonian and viscoelastic thermal convection are shown in figure 4. At low

![]() $Ra$

(

$Ra$

(

![]() $Ra=10^6$

), the Newtonian and viscoelastic flows exhibit an ascending hot plume and a descending cold plume, which generate an LSC in the bulk region (see figure 4

a,d). These plumes show quasi-periodic wave-like motions (see the supplementary movies 1 and 2) without visible horizontal sweeping. These oscillations may be attributed to plume–vortex interactions. The flow structures of the polymeric flow are similar to those of the Newtonian case, while the plumes become less wavy. With an increase of

$Ra=10^6$

), the Newtonian and viscoelastic flows exhibit an ascending hot plume and a descending cold plume, which generate an LSC in the bulk region (see figure 4

a,d). These plumes show quasi-periodic wave-like motions (see the supplementary movies 1 and 2) without visible horizontal sweeping. These oscillations may be attributed to plume–vortex interactions. The flow structures of the polymeric flow are similar to those of the Newtonian case, while the plumes become less wavy. With an increase of

![]() $Ra$

to

$Ra$

to

![]() $Ra=10^8$

(see figure 4

b), the thermal BL becomes thinner, and more plumes are ejected from the BL. The comparison between Newtonian and viscoelastic flows reveals that the polymer additives change the structure of the plumes: they become thinner, while their stems become elongated and their caps almost reach the opposite plate; see figure 4(b,e). The waviness of these plumes is substantially weakened. This is reminiscent of the flow structures characterising drag reduction in turbulent channel flows, where the near-wall streamwise streaks at the core of the turbulence self-sustaining cycle become more stable in the presence of polymer additives, a calmer phase also denoted as ’hybernation’ (Xi & Graham Reference Xi and Graham2012).

$Ra=10^8$

(see figure 4

b), the thermal BL becomes thinner, and more plumes are ejected from the BL. The comparison between Newtonian and viscoelastic flows reveals that the polymer additives change the structure of the plumes: they become thinner, while their stems become elongated and their caps almost reach the opposite plate; see figure 4(b,e). The waviness of these plumes is substantially weakened. This is reminiscent of the flow structures characterising drag reduction in turbulent channel flows, where the near-wall streamwise streaks at the core of the turbulence self-sustaining cycle become more stable in the presence of polymer additives, a calmer phase also denoted as ’hybernation’ (Xi & Graham Reference Xi and Graham2012).

At an even higher

![]() $Ra=10^{10}$

(see figure 4

c,f), the polymer additives reduce small-scale structures, making the plumes more coherent. This polymer-induced stabilisation has been reported in homogeneous turbulence (De Angelis et al. Reference De Angelis, Casciola, Benzi and Piva2005), channel and pipe flows (Dubief et al. Reference Dubief, Terrapon and Hof2023), plane Couette flow (Teng et al. Reference Teng, Liu, Lu and Khomami2018), Rayleigh–Taylor turbulence (Boffetta et al. Reference Boffetta, Mazzino, Musacchio and Vozella2010) and Taylor–Couette turbulence (Song et al. Reference Song, Lin, Zhu, Wan, Liu, Lu and Khomami2023b

).

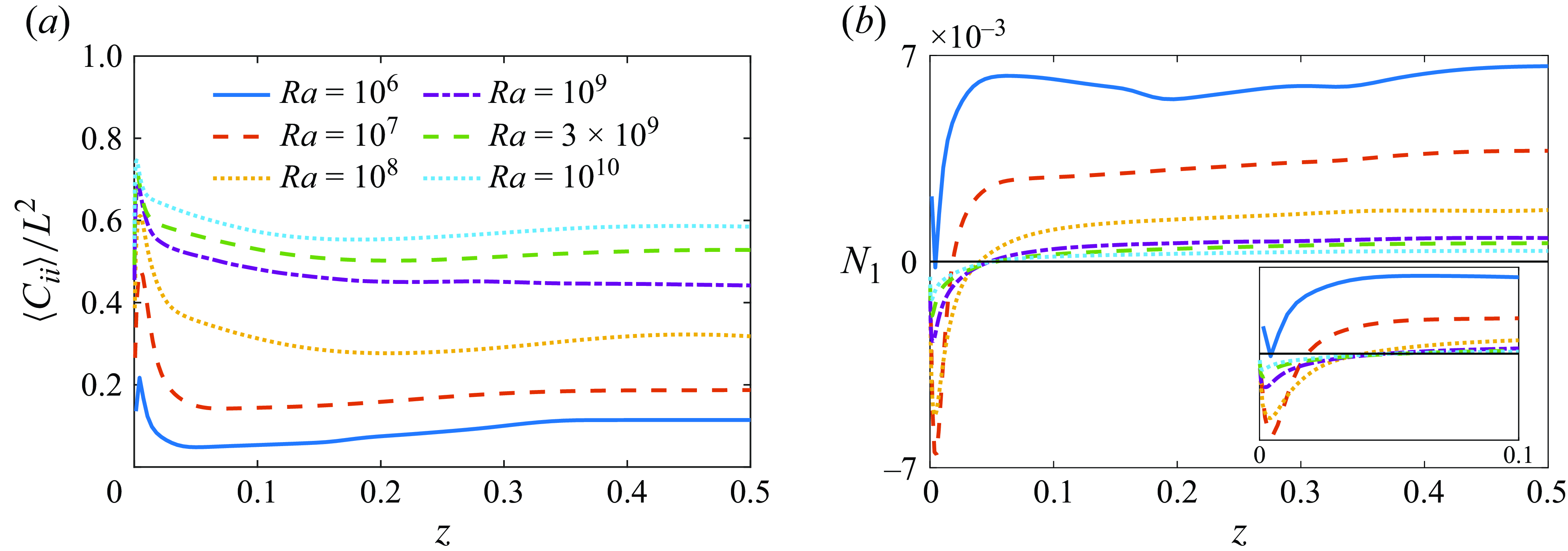

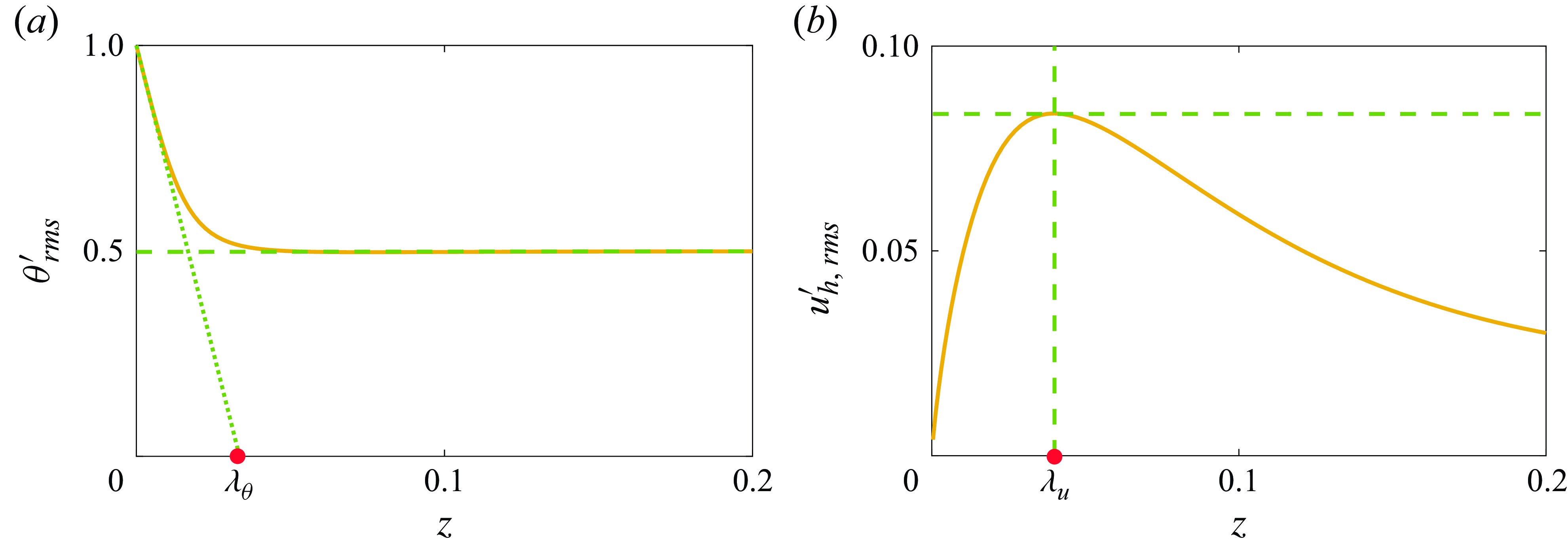

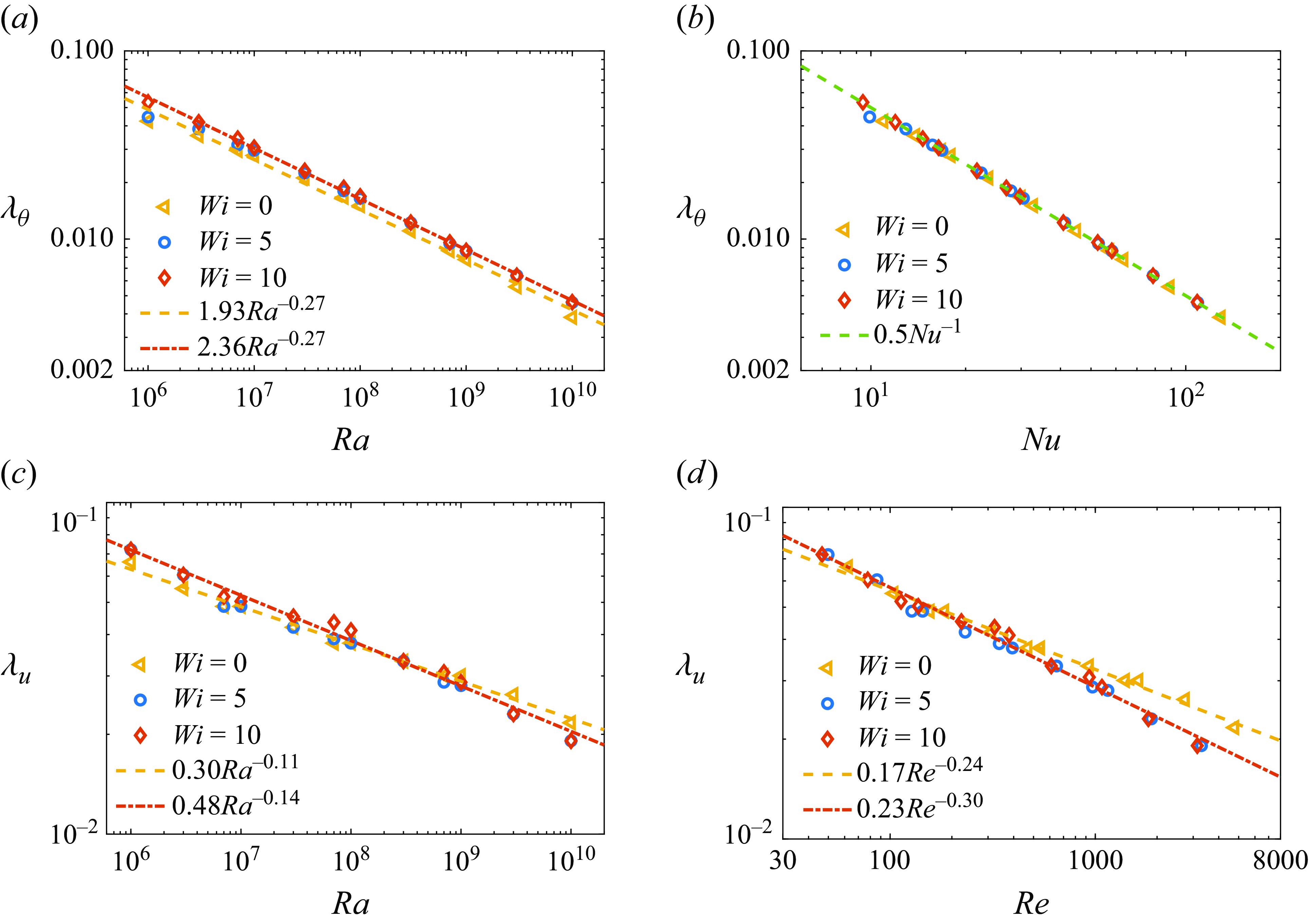

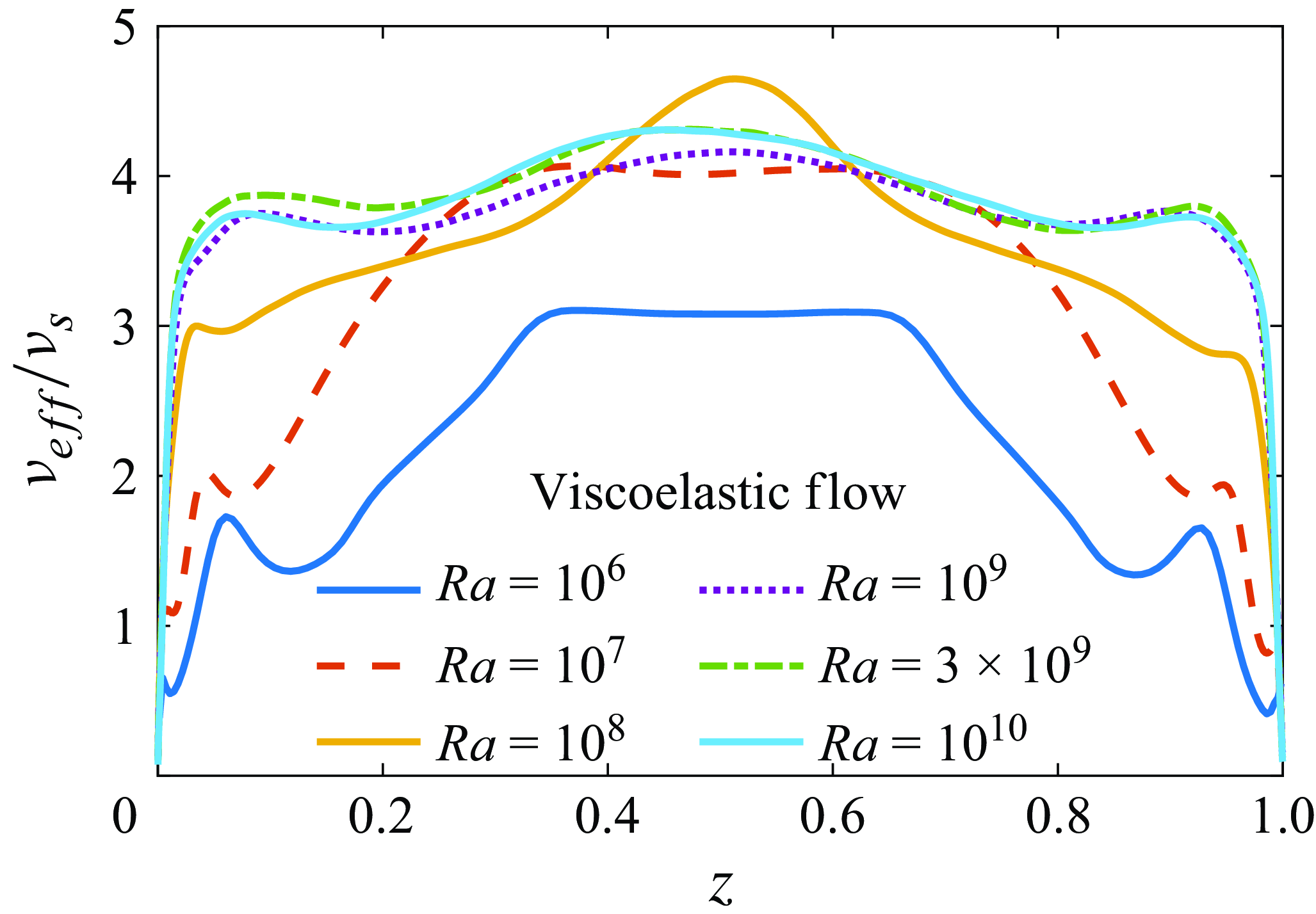

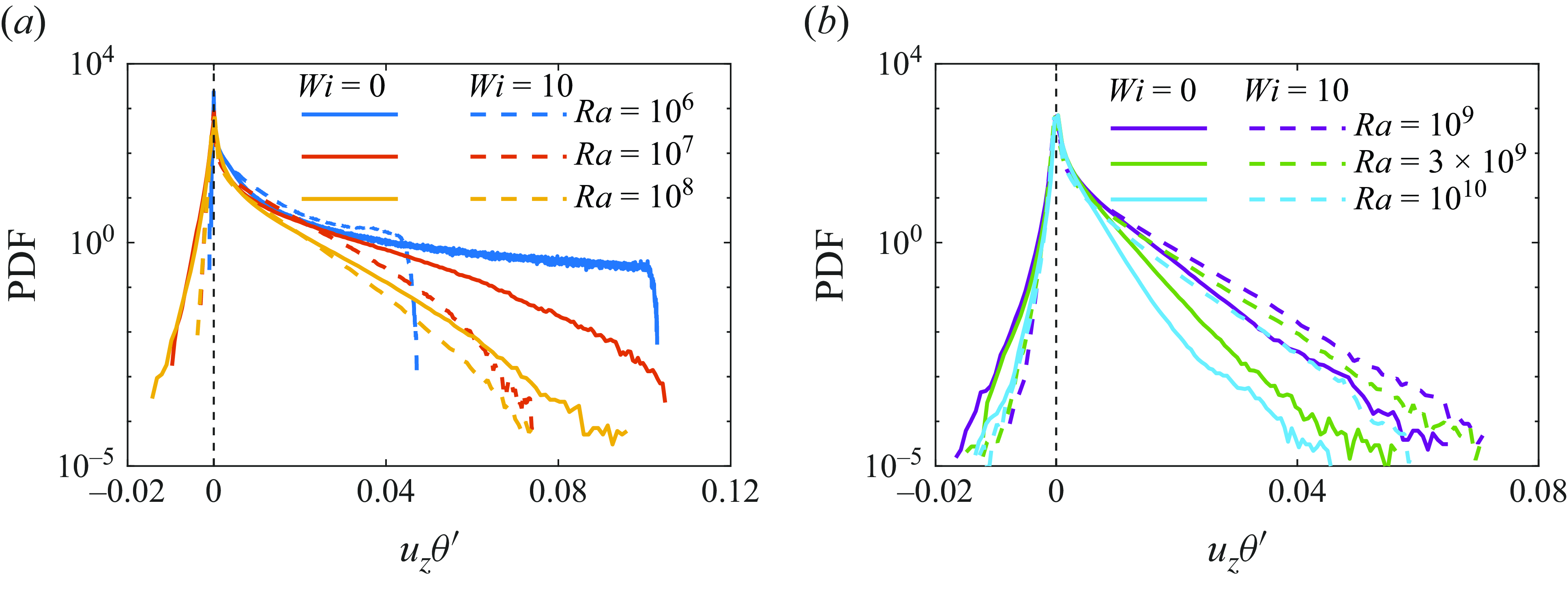

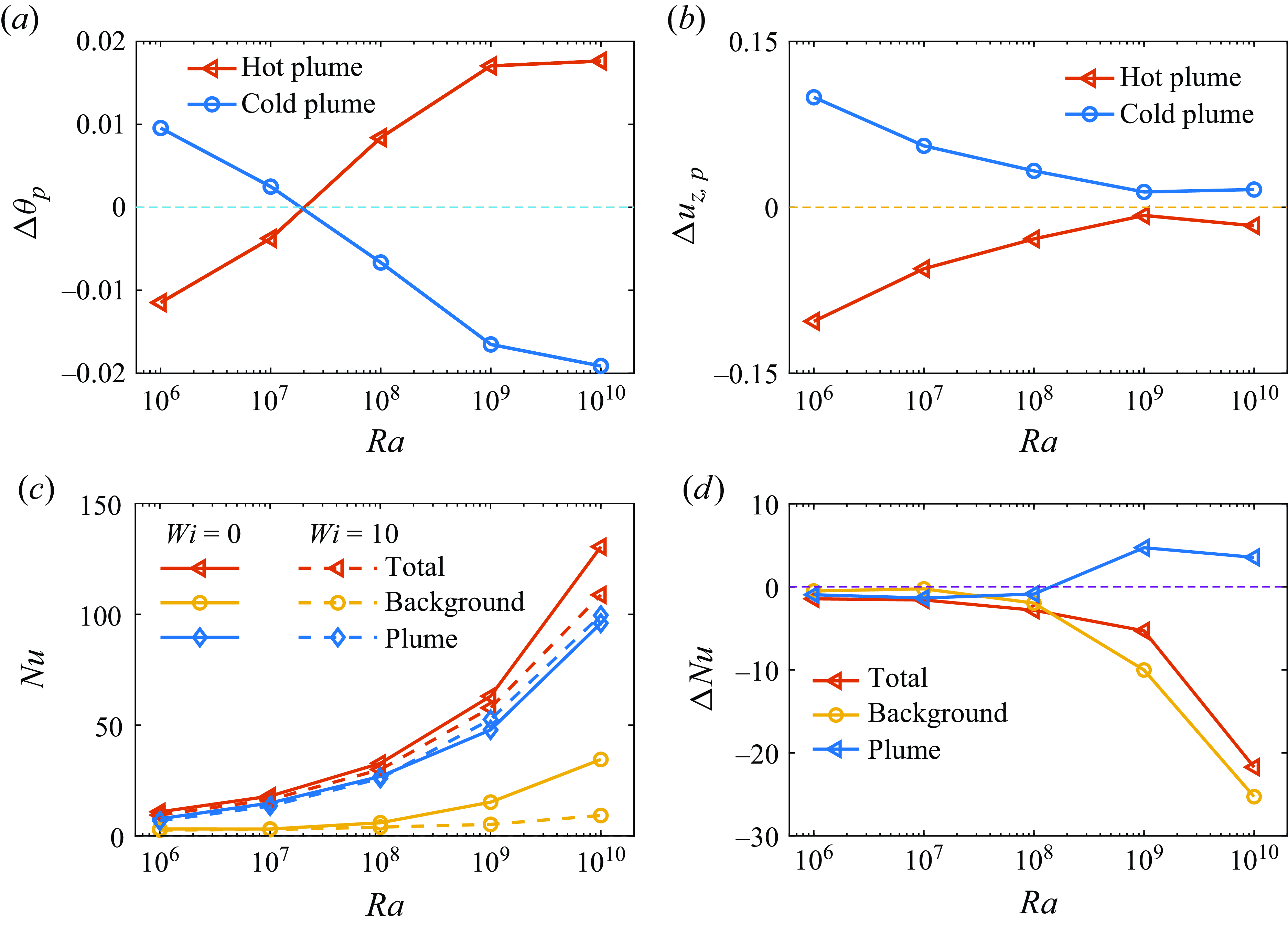

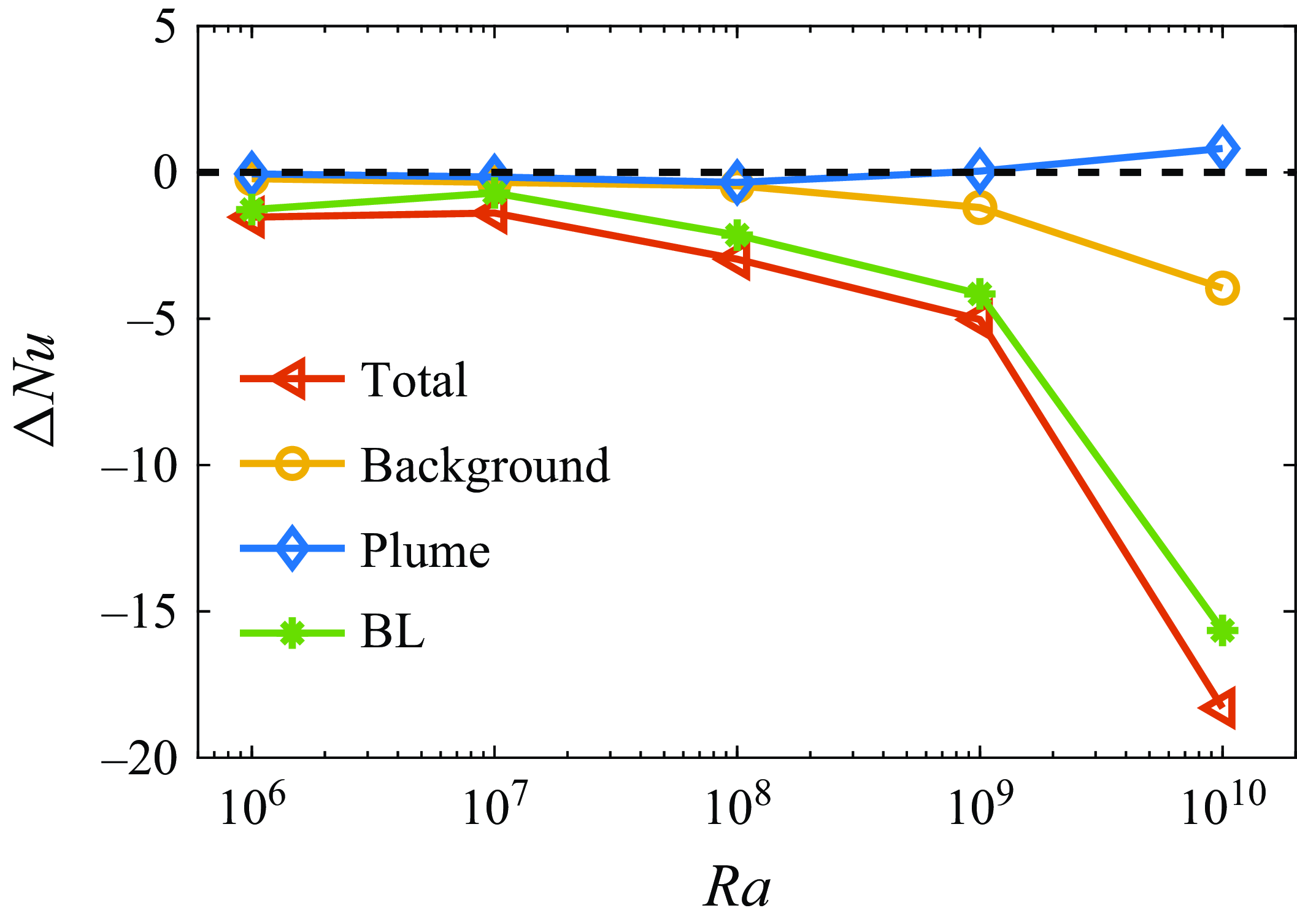

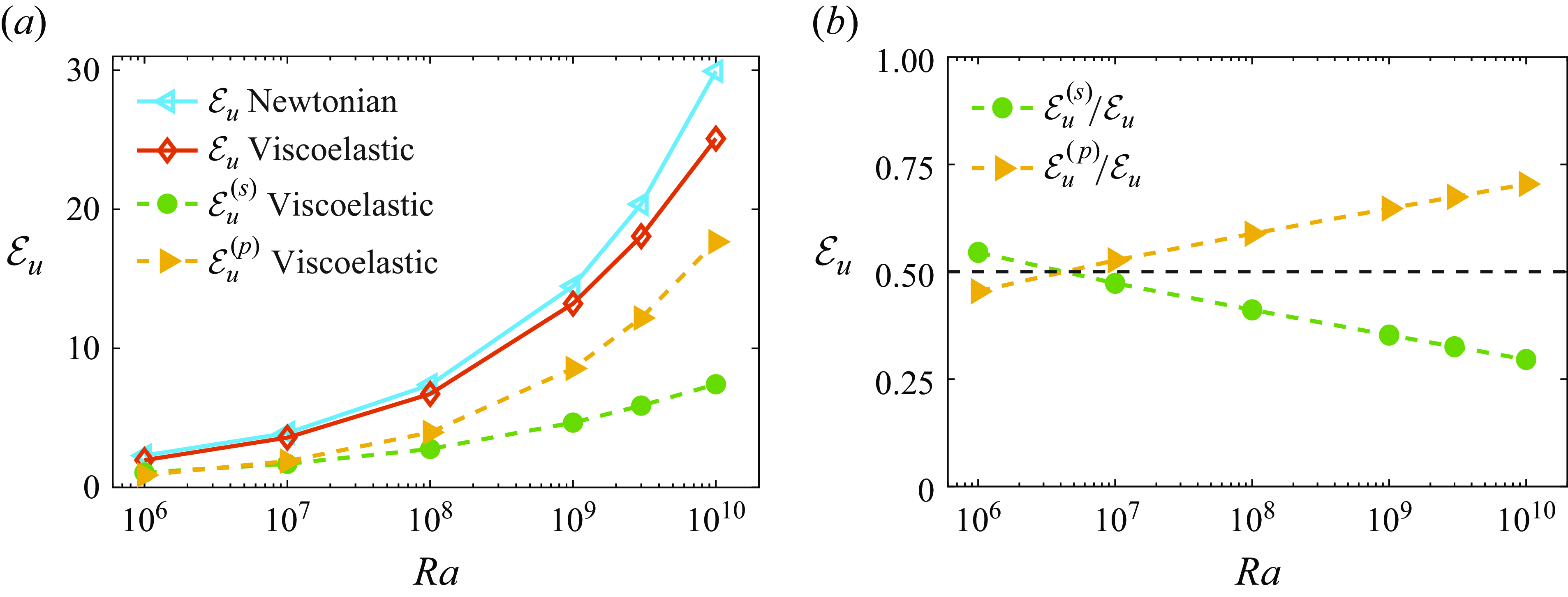

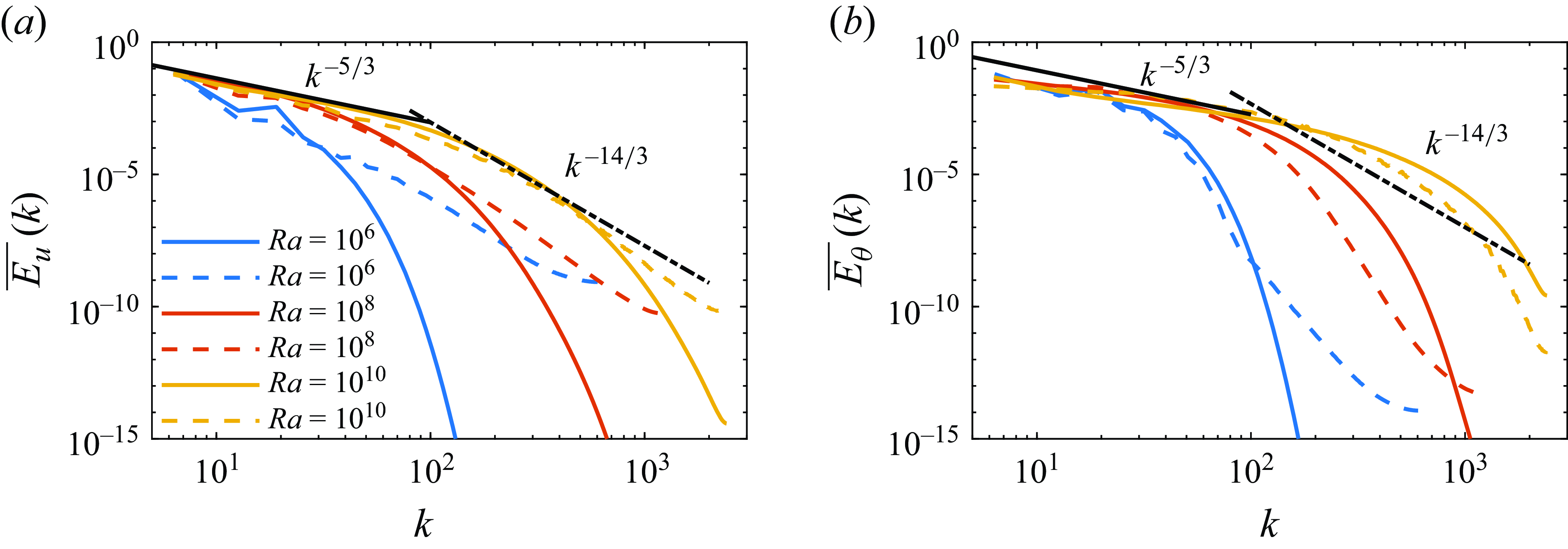

$Ra=10^{10}$