1. Introduction

Fluid-structure interaction (FSI) phenomenon is ubiquitous in natural and engineering systems, in which a movable or deformable structure and an internal or surrounding fluid are coupled to influence the behaviour of each other (Dowell & Hall Reference Dowell and Hall2001; Griffith & Patankar Reference Griffith and Patankar2020). The FSI problems may be further categorized into two subsets, i.e. fluid-rigid structure interaction and fluid-flexible structure interaction (Hua, Zhu & Lu Reference Hua, Zhu and Lu2014). The typical examples for the former scenario includes flow past a bluff body, e.g. cylinder (Prasanth & Mittal Reference Prasanth and Mittal2008), flat plate (Yang & Strganac Reference Yang and Strganac2013), sphere (Govardhan & Williamson Reference Govardhan and Williamson2005; Rajamuni, Thompson & Hourigan Reference Rajamuni, Thompson and Hourigan2018) and other non-streamlined bodies (Derakhshandeh & Alam Reference Derakhshandeh and Alam2019), with the vortex-induced vibration (VIV) induced on bodies interacting with an external fluid flow (Williamson & Govardhan Reference Williamson and Govardhan2004; Choi, Jeon & Kim Reference Choi, Jeon and Kim2008; Raissi et al. Reference Raissi, Wang, Triantafyllou and Karniadakis2019). The systems involving fluid-flexible structure interaction are also commonplace, e.g. swimming fish (Liu et al. Reference Liu, Ren, Dong, Akanyeti, Liao and Lauder2017), flying birds or insects (Shyy et al. Reference Shyy, Kang, Chirarattananon, Ravi and Liu2016), plant reconfiguration or flapping in a flow (Leclercq & de Langre Reference Leclercq and de Langre2018) and vibrating vocal fold (Li et al. Reference Li, Chen, Chang and Luo2019). Due to its important significance for understanding the fundamental principles in nature and the extensive engineering applications, currently, FSI is a topic of great attention in the fluid mechanics community (Dowell & Hall Reference Dowell and Hall2001; Griffith & Patankar Reference Griffith and Patankar2020).

A concern for the FSI system is how to achieve the hydrodynamic advantages or performance enhancements by means of manipulation of surrounding fluid flows (Lighthill Reference Lighthill1975; Alben Reference Alben2009; Shoele & Mittal Reference Shoele and Mittal2016). One interesting example is represented by biological flight and swimming. Fish could generate favourable flow structures for locomotion by adjusting the movement or deformation of their body and appendages (Wu Reference Wu1961, Reference Wu1971; Triantafyllou, Triantafyllou & Yue Reference Triantafyllou, Triantafyllou and Yue2000; Alben & Shelley Reference Alben and Shelley2005; Li & Lu Reference Li and Lu2012). For example, previous experimental observations (Müller et al. Reference Müller, Van Den Heuvel, Stamhuis and Videler1997; Nauen & Lauder Reference Nauen and Lauder2002) and numerical studies (Li & Lu Reference Li and Lu2012; Liu et al. Reference Liu, Ren, Dong, Akanyeti, Liao and Lauder2017) have revealed that the ring-like vortical structures formed in the wake of fish swimming possess intrinsic connections with the optimization of thrust generation and power consumption. In the flight of insects, by adopting appropriate flapping kinematics, the leading-edge vortex (LEV) stays attached to and moving with the surface of the wing, which leads to the high lift in the low ![]() $Re$ flow region (Ford & Babinsky Reference Ford and Babinsky2013; Eldredge & Jones Reference Eldredge and Jones2019).

$Re$ flow region (Ford & Babinsky Reference Ford and Babinsky2013; Eldredge & Jones Reference Eldredge and Jones2019).

Beside these active flow controls for the optimal propulsion, swimming and flying animals may achieve hydrodynamic advantages from the passive flexible deformation of the propulsors (tail fins and wings) due to flow-induced loads. Results from the experimental (Mazaheri & Ebrahimi Reference Mazaheri and Ebrahimi2010; Nakata et al. Reference Nakata, Liu, Tanaka, Nishihashi, Wang and Sato2011), numerical (Kang et al. Reference Kang, Aono, Cesnik and Shyy2011; Zhu, He & Zhang Reference Zhu, He and Zhang2014; Wang, Huang & Lu Reference Wang, Huang and Lu2020) and theoretical (Michelin & Smith Reference Michelin and Smith2009; Alon Tzezana & Breuer Reference Alon Tzezana and Breuer2019; Alaminos-Quesada & Fernandez-Feria Reference Alaminos-Quesada and Fernandez-Feria2020) studies have shown that the proper flexibility of the fin or wing is found to bear performance benefits, such as thrust enhancement, drag reduction, energy saving, etc. Furthermore, as a possible strategy to reduce the drag and resist breakage, the plants living in flow-dominated habitats are able to reduce their frontal area or reshape themselves in a more streamlined fashion, which is referred to as ‘reconfiguration’ (Alben, Shelley & Zhang Reference Alben, Shelley and Zhang2002; Schouveiler & Eloy Reference Schouveiler and Eloy2013; Alvarado et al. Reference Alvarado, Comtet, de Langre and Hosoi2017; Leclercq & de Langre Reference Leclercq and de Langre2018). Compared with active flow controls, the shape self-adaptation due to flow-induced reconfiguration of flexible structure does not need the intervention of the control system or the energy input, which may be an elegant and deft way to the aero/hydrodynamic performance of the FSI system.

Not surprisingly, the flow controls by the passive deformation and flapping of flexible structures in a natural system are found universally, as they have survived the tests of evolution over millions of years and reached a high level of adaptability and effectiveness. Therefore, it is particularly worthwhile to import these novel ideas which originate from nature into technological applications, such as flow control of vortex shedding behind bluff bodies. The bluff body flow control is not only encountered in numerous natural scenarios (Triantafyllou et al. Reference Triantafyllou, Triantafyllou and Yue2000; Alvarado et al. Reference Alvarado, Comtet, de Langre and Hosoi2017; Leclercq & de Langre Reference Leclercq and de Langre2018), but also of practical interest to many fields of engineering (Choi et al. Reference Choi, Jeon and Kim2008; Dong, Triantafyllou & Karniadakis Reference Dong, Triantafyllou and Karniadakis2008; Fan et al. Reference Fan, Yang, Wang, Triantafyllou and Karniadakis2020). When the fluid flows around the bluff body, the boundary layer is likely to separate into Kármán vortices alternately shedding in the wake, which would cause the increase in differential pressure resistance (form drag). The more severe the separation at the hind side, the greater the form drag. Meanwhile, the asymmetric vortex shedding would induce large unsteady side forces that, in turn, may lead to structural vibrations if the body is flexibly mounted. Therefore, for reducing drag and suppressing VIV, controls of vortex shedding characteristics of flow over a bluff body have attracted significant attention in the past (Zhao Reference Zhao2021). Many flow control techniques have been proposed in (i) passive form and (ii) active form. The first approach includes the splitter plate (Anderson & Szewczyk Reference Anderson and Szewczyk1997; Gilliéron & Kourta Reference Gilliéron and Kourta2010), segmented trailing edges (Deshpande & Sharma Reference Deshpande and Sharma2012), dimples and grooves (Bearman & Harvey Reference Bearman and Harvey1993), etc. In these methods, global changes in the surface shape may be required for practical situations. However, it seems hard to implement under some circumstances. In the latter approach, such as blowing and suction (Schatzman et al. Reference Schatzman, Wilson, Arad, Seifert and Shtendel2014), synthetic jets (Glezer & Amitay Reference Glezer and Amitay2002), rotary oscillations (Palkin et al. Reference Palkin, Hadžiabdić, Mullyadzhanov and Hanjalić2018), the intervention of a complex control system or/and the energy input are necessary, limiting the applicability of this approach.

As a passive flow control technique, installing splitter plates behind a bluff body has been investigated by numerous experiments and simulations in the past (Anderson & Szewczyk Reference Anderson and Szewczyk1997; Gilliéron & Kourta Reference Gilliéron and Kourta2010; Wu et al. Reference Wu, Qiu, Shu and Zhao2014; Sunil, Kumar & Poddar Reference Sunil, Kumar and Poddar2022). A splitter plate, attached downstream, inhibits the interaction between the separating shear layers, thereby delaying vortex shedding and resulting in a weaker Kármán vortex street in the wake (Sunil et al. Reference Sunil, Kumar and Poddar2022). This reduces the fluctuating lift and drag acting on the bluff body. Earlier studies were mainly limited to the rigid plates. Recently, inspired by the drag-reducing mechanism of passive flexibility in natural systems, particular attention has been devoted to the flexible splitter plate (Lācis et al. Reference Lācis, Brosse, Ingremeau, Mazzino, Lundell, Kellay and Bagheri2014; Wu et al. Reference Wu, Qiu, Shu and Zhao2014; Sunil et al. Reference Sunil, Kumar and Poddar2022). It is found that a filament, with proper flexibility and length, may bring about more performance benefits in suppressing/weakening the vortex shedding as compared with a rigid splitter plate with the same length (Wu et al. Reference Wu, Qiu, Shu and Zhao2014; Sunil et al. Reference Sunil, Kumar and Poddar2022). In addition, some studies have found that installing two or multiple flexible filaments behind a bluff body, referred to as ‘hairy coating’, can offer more drag reduction under specific conditions than a single filament (Favier et al. Reference Favier, Dauptain, Basso and Bottaro2009; Niu & Hu Reference Niu and Hu2011; Deng, Mao & Xie Reference Deng, Mao and Xie2019). Favier et al. (Reference Favier, Dauptain, Basso and Bottaro2009) and Niu & Hu (Reference Niu and Hu2011) have performed the numerical and experimental investigations, respectively, on the passive flow control by using this self-adaptive hairy coating. They have shown that a sizable drag reduction can be achieved at the optimum combination of the considered parameters, e.g. hair length, rigidity, and density. The primary mechanism for drag reduction is the bending, adhesion and reinforcement of hairs trailing the bluff body, which reduces wake width and traps ‘dead water’ (Niu & Hu Reference Niu and Hu2011).

More recently, Gao et al. (Reference Gao, Pan, Wang and Tian2020) have proposed a nature-inspired passive control of the bluff body flow for drag reduction. In their experimental study, a trailing closed filament, with a negligible weight and small bending modulus, was ‘hung’ on both edges of the rigid flat plate placed normal to the oncoming flow. The experiment suggests that by adopting such a ‘flexible coating’, a significant drag reduction of approximately 10.0 % is expected under specific conditions. Compared with the existing flow control devices, this device is easy to install and disassemble. Besides, it is supposed to have good adaptability for a wide range of flows, benefiting from its nature of shape self-adaptation.

On the other hand, the study of a rigid-flexible coupling system raises a new kind of FSI problem, in which the closed flexible structure is coupled with not only an external fluid but also an internal fluid to influence the behaviour of each other. This complex interaction may give rise to a rich variety of physical phenomena which are dictated by complex mechanisms. These extended FSI systems are common in a living body in which some fluid volume is inside the thin skins of organisms, and were treated as a flexible ring filled with fluid in a surrounding fluid flow (Jung et al. Reference Jung, Mareck, Shelley and Zhang2006; Shoele & Zhu Reference Shoele and Zhu2010; Kim et al. Reference Kim, Huang, Shin and Sung2012). However, to our knowledge, still very few studies have focused on the dynamics of this coupling system.

At present, the dynamics of the rigid-flexible coupling system remain unclear. Moreover, the in-depth understanding of the corresponding flow control mechanism for drag reduction is still lacking. Inspired by Gao et al. (Reference Gao, Pan, Wang and Tian2020), we perform numerical simulations of viscous flow past a rigid flat plate with a trailing closed flexible filament. In comparison with experimental study, numerical simulations have an advantage in the aspect of quantitative analysis, which is particularly critical for exploring relevant mechanisms underlying the complex behaviour of a system. In this paper, the influence of Reynolds number (![]() $Re$) and length ratio of the filament and flat plate (

$Re$) and length ratio of the filament and flat plate (![]() $Lr$) on the flow patterns and dynamics of the rigid-flexible coupling system have been systematically investigated. The drag reduction and the underlying mechanisms have been examined and revealed as well.

$Lr$) on the flow patterns and dynamics of the rigid-flexible coupling system have been systematically investigated. The drag reduction and the underlying mechanisms have been examined and revealed as well.

The rest of the present paper is organized as follows. The computational model, including physical problem and mathematical formulation, numerical method and validation, is described in § 2. The result and discussion regarding dynamic states of the rigid-flexible coupling system, drag and the flow characteristics, and drag estimate are given from a comprehensive numerical investigation in § 3. Finally, the concluding remarks are addressed in § 4.

2. Computational model

2.1. Physical problem and mathematical formulation

The rigid-flexible coupling system considered in the present study is shown in figure 1(![]() $a$). The rigid flat plate with a trailing closed flexible filament are immersed in a two-dimensional uniform flow with oncoming velocity

$a$). The rigid flat plate with a trailing closed flexible filament are immersed in a two-dimensional uniform flow with oncoming velocity ![]() $U$. The rigid flat plate is fixed and placed normal to the oncoming flow. The two edges of the flexible filament are attached to the edges of the flat plate with simply support boundary conditions. The other parts of the filament can move freely and deform passively due to the flow-structure interactions. The geometry of this system is described by using a dimensionless parameter

$U$. The rigid flat plate is fixed and placed normal to the oncoming flow. The two edges of the flexible filament are attached to the edges of the flat plate with simply support boundary conditions. The other parts of the filament can move freely and deform passively due to the flow-structure interactions. The geometry of this system is described by using a dimensionless parameter ![]() $Lr=L/D$, where

$Lr=L/D$, where ![]() $L$ and

$L$ and ![]() $D$ are the length of the flexible filament and flat plate, respectively. It is noted that

$D$ are the length of the flexible filament and flat plate, respectively. It is noted that ![]() $Lr=1$ corresponds to the situation without the trailing filament.

$Lr=1$ corresponds to the situation without the trailing filament.

Figure 1. Schematic diagram for the rigid-flexible coupling system in a two-dimensional uniform flow (![]() $a$). The rigid flat plate with length

$a$). The rigid flat plate with length ![]() $D$ is fixed and placed normal to the flow with oncoming velocity

$D$ is fixed and placed normal to the flow with oncoming velocity ![]() $U$. The flexible filament, severed as a deformable afterbody, is simply supported on its both edges and attached to the two edges of the flat plate. The geometry of this system is described by using a dimensionless parameter

$U$. The flexible filament, severed as a deformable afterbody, is simply supported on its both edges and attached to the two edges of the flat plate. The geometry of this system is described by using a dimensionless parameter ![]() $Lr=L/D$, where

$Lr=L/D$, where ![]() $L$ is the length of the filament. Note that

$L$ is the length of the filament. Note that ![]() $Lr=1$ corresponds to the situation without the trailing filament. The initial shapes of the filament for the situations with

$Lr=1$ corresponds to the situation without the trailing filament. The initial shapes of the filament for the situations with ![]() $Lr<{\rm \pi} /2$ and

$Lr<{\rm \pi} /2$ and ![]() $Lr \geq {\rm \pi}/2$ are illustrated in figures 1(

$Lr \geq {\rm \pi}/2$ are illustrated in figures 1(![]() $b$) and 1(

$b$) and 1(![]() $c$), respectively. For cases with

$c$), respectively. For cases with ![]() $Lr<{\rm \pi} /2$, the initial area enclosed by the flat plate and filament is set initially to a circular segment with

$Lr<{\rm \pi} /2$, the initial area enclosed by the flat plate and filament is set initially to a circular segment with ![]() $Lr=\theta /{\sin }\theta$, where

$Lr=\theta /{\sin }\theta$, where ![]() $\theta$ is the semi-central angle subtending the arc. While for cases with

$\theta$ is the semi-central angle subtending the arc. While for cases with ![]() $Lr \geq {\rm \pi}/2$, the initial area is set initially to a combination of rectangle and semicircle. According to this definition, the

$Lr \geq {\rm \pi}/2$, the initial area is set initially to a combination of rectangle and semicircle. According to this definition, the ![]() $D^2$-normalized initial enclosed area

$D^2$-normalized initial enclosed area ![]() $\varOmega _0$ can be calculated by (2.5).

$\varOmega _0$ can be calculated by (2.5).

In this system, the fluid flow is governed by the incompressible Navier–Stokes equations,

where ![]() $\boldsymbol {v}=(u,v)$ is the velocity,

$\boldsymbol {v}=(u,v)$ is the velocity, ![]() $p$ the pressure,

$p$ the pressure, ![]() $\rho$ the density of the fluid,

$\rho$ the density of the fluid, ![]() $\mu$ the dynamic viscosity and

$\mu$ the dynamic viscosity and ![]() $\boldsymbol {f}_b$ the body force term. A uniform velocity

$\boldsymbol {f}_b$ the body force term. A uniform velocity ![]() $U$ is set at the inlet boundary and the side boundaries of the fluid computational domain. A Neumann boundary condition is specified at the outlet boundary.

$U$ is set at the inlet boundary and the side boundaries of the fluid computational domain. A Neumann boundary condition is specified at the outlet boundary.

The deformation and motion of flexible filament are described by the structural equation (Doyle Reference Doyle2001; Connell & Yue Reference Connell and Yue2007; Ye et al. Reference Ye, Wei, Huang and Lu2017),

\begin{equation} \rho_s h\frac{\partial^2 \boldsymbol{X}}{\partial t^2} = \frac{\partial}{\partial s}\left[ Eh \left( 1 - \left| \frac{\partial \boldsymbol{X}}{\partial s} \right|^{{-}1} \right) \frac{\partial \boldsymbol{X}}{\partial s} - \frac{\partial}{\partial s} \left.\left( EI (\kappa - \kappa_0) \frac{\partial^2\boldsymbol{X}}{\partial^2 s} \right/ \left| \frac{\partial^2 \boldsymbol{X}}{\partial^2 s} \right| \right) \right] + \boldsymbol{F}_s, \end{equation}

\begin{equation} \rho_s h\frac{\partial^2 \boldsymbol{X}}{\partial t^2} = \frac{\partial}{\partial s}\left[ Eh \left( 1 - \left| \frac{\partial \boldsymbol{X}}{\partial s} \right|^{{-}1} \right) \frac{\partial \boldsymbol{X}}{\partial s} - \frac{\partial}{\partial s} \left.\left( EI (\kappa - \kappa_0) \frac{\partial^2\boldsymbol{X}}{\partial^2 s} \right/ \left| \frac{\partial^2 \boldsymbol{X}}{\partial^2 s} \right| \right) \right] + \boldsymbol{F}_s, \end{equation}

where ![]() $s$ is the Lagrangian coordinate along the plate,

$s$ is the Lagrangian coordinate along the plate, ![]() $h$ is the structure thickness,

$h$ is the structure thickness, ![]() $\boldsymbol {X}(s,t)=(X(s,t),Y(s,t))$ is the position vector of the plates,

$\boldsymbol {X}(s,t)=(X(s,t),Y(s,t))$ is the position vector of the plates, ![]() $\boldsymbol {F}_s$ is the Lagrangian force exerted on the plates by the surrounding fluid and

$\boldsymbol {F}_s$ is the Lagrangian force exerted on the plates by the surrounding fluid and ![]() $\rho _s$ is the structural density;

$\rho _s$ is the structural density; ![]() $Eh$ and

$Eh$ and ![]() $EI$ are the structural stretching and bending rigidity, respectively;

$EI$ are the structural stretching and bending rigidity, respectively; ![]() $\kappa =| {\partial ^2 \boldsymbol {X}}/{\partial ^2 s} |$ is the local curvature of the filament with

$\kappa =| {\partial ^2 \boldsymbol {X}}/{\partial ^2 s} |$ is the local curvature of the filament with ![]() $\kappa _0$ its initial reference value. It is noted that the filament is set to be in an initial stressless reference state, according to (2.3). Moreover, the simple support boundary conditions applied at the edges of the filament are respectively given by

$\kappa _0$ its initial reference value. It is noted that the filament is set to be in an initial stressless reference state, according to (2.3). Moreover, the simple support boundary conditions applied at the edges of the filament are respectively given by

The filament is initially placed at rest in the fluid. The initial shapes of filament for the situations with ![]() $Lr<{\rm \pi} /2$ and

$Lr<{\rm \pi} /2$ and ![]() $Lr \geq {\rm \pi}/2$ are illustrated in figures 1(

$Lr \geq {\rm \pi}/2$ are illustrated in figures 1(![]() $b$) and (

$b$) and (![]() $c$), respectively. For cases with

$c$), respectively. For cases with ![]() $Lr<{\rm \pi} /2$, the enclosed area by the flat plate and filament is set initially to a circular segment; while for cases with

$Lr<{\rm \pi} /2$, the enclosed area by the flat plate and filament is set initially to a circular segment; while for cases with ![]() $Lr<{\rm \pi} /2$, the enclosed area is set initially to a combination of rectangle and semicircle. According to this definition, the relationship between

$Lr<{\rm \pi} /2$, the enclosed area is set initially to a combination of rectangle and semicircle. According to this definition, the relationship between ![]() $D^2$-normalized initial area (

$D^2$-normalized initial area (![]() $\varOmega _0$) and length ratio (

$\varOmega _0$) and length ratio (![]() $Lr$) can be given as

$Lr$) can be given as

\begin{equation} \varOmega_0= \begin{cases} \frac{1}{4}(\theta/{\sin^2}\theta - {\cot}\theta), & \text{if}\ Lr<\frac{1}{2}{\rm \pi} , \\ \frac{1}{2}Lr-\frac{1}{8}{\rm \pi} , & \text{if}\ Lr \ge \frac{1}{2}{\rm \pi} ,\\ \end{cases}\end{equation}

\begin{equation} \varOmega_0= \begin{cases} \frac{1}{4}(\theta/{\sin^2}\theta - {\cot}\theta), & \text{if}\ Lr<\frac{1}{2}{\rm \pi} , \\ \frac{1}{2}Lr-\frac{1}{8}{\rm \pi} , & \text{if}\ Lr \ge \frac{1}{2}{\rm \pi} ,\\ \end{cases}\end{equation}

where ![]() $Lr=\theta /{\sin }\theta$, and

$Lr=\theta /{\sin }\theta$, and ![]() $\theta$ is the semi-central angle subtending the arc. In the present simulations the volume leakage is negligible which is consistent with the experiment of Gao et al. (Reference Gao, Pan, Wang and Tian2020). Thus, the enclosed area

$\theta$ is the semi-central angle subtending the arc. In the present simulations the volume leakage is negligible which is consistent with the experiment of Gao et al. (Reference Gao, Pan, Wang and Tian2020). Thus, the enclosed area ![]() $\varOmega (t) \approx \varOmega _0$, which merely depends on

$\varOmega (t) \approx \varOmega _0$, which merely depends on ![]() $Lr$.

$Lr$.

The characteristic quantities ![]() $\rho$,

$\rho$, ![]() $D$ and

$D$ and ![]() $U$ are chosen to normalize the above equations. Thus, the following dimensionless governing parameters are introduced: the Reynolds number

$U$ are chosen to normalize the above equations. Thus, the following dimensionless governing parameters are introduced: the Reynolds number ![]() $Re=\rho UD/\mu$, the stretching stiffness

$Re=\rho UD/\mu$, the stretching stiffness ![]() $S=Eh/\rho U^{2} D$, the bending stiffness

$S=Eh/\rho U^{2} D$, the bending stiffness ![]() $K=EI/\rho U^{2} D^{3}$, the mass ratio of the plates and the fluid

$K=EI/\rho U^{2} D^{3}$, the mass ratio of the plates and the fluid ![]() $M=\rho _s h/\rho D$, the length ratio of the flexible filament and the rigid plate

$M=\rho _s h/\rho D$, the length ratio of the flexible filament and the rigid plate ![]() $Lr=L/D$.

$Lr=L/D$.

2.2. Numerical method

The governing equations of the fluid-plate problem are solved numerically by an immersed boundary-lattice Boltzmann method for the fluid motion and a finite element method for the deformation of the flexible filament. The lattice Boltzmann equation with the body force model (Guo, Zheng & Shi Reference Guo, Zheng and Shi2002) is employed in present simulations, i.e.

where ![]() $f_i(\boldsymbol {x},t)$ is the distribution function for particles with

$f_i(\boldsymbol {x},t)$ is the distribution function for particles with ![]() $\boldsymbol {e}_i$ at position

$\boldsymbol {e}_i$ at position ![]() $\boldsymbol {x}$ and time

$\boldsymbol {x}$ and time ![]() $t$. The D2Q9 velocity model is applied here. Here

$t$. The D2Q9 velocity model is applied here. Here ![]() ${\rm \Delta} x$ and

${\rm \Delta} x$ and ![]() ${\rm \Delta} t$ are the grid spacing and time step, respectively;

${\rm \Delta} t$ are the grid spacing and time step, respectively; ![]() $\tau$ is relaxation time associated with fluid viscosity (

$\tau$ is relaxation time associated with fluid viscosity (![]() $\nu$), i.e.

$\nu$), i.e. ![]() $\tau ={\nu }/{c_s^2{\rm \Delta} t} + 0.5$, where

$\tau ={\nu }/{c_s^2{\rm \Delta} t} + 0.5$, where ![]() $c_s=({\rm \Delta} x/{\rm \Delta} t)/\sqrt {3}$ is the lattice sound speed. The equilibrium distribution function

$c_s=({\rm \Delta} x/{\rm \Delta} t)/\sqrt {3}$ is the lattice sound speed. The equilibrium distribution function ![]() $f_i^{eq}(\boldsymbol {x},t)$ and the force term

$f_i^{eq}(\boldsymbol {x},t)$ and the force term ![]() $F_i$ are defined as (Guo et al. Reference Guo, Zheng and Shi2002)

$F_i$ are defined as (Guo et al. Reference Guo, Zheng and Shi2002)

where ![]() $\omega _i$ is the weighting factor depending on the lattice model (

$\omega _i$ is the weighting factor depending on the lattice model (![]() $\omega _0=4/9$,

$\omega _0=4/9$, ![]() $\omega _1=\omega _2=\omega _3=\omega _4=1/9$,

$\omega _1=\omega _2=\omega _3=\omega _4=1/9$, ![]() $\omega _5=\omega _6=\omega _7=\omega _8=1/36$), and

$\omega _5=\omega _6=\omega _7=\omega _8=1/36$), and ![]() ${\boldsymbol{\mathsf{I}}}$ is the unit tensor. The density

${\boldsymbol{\mathsf{I}}}$ is the unit tensor. The density ![]() $\rho$ and velocity

$\rho$ and velocity ![]() $v$ can be calculated by

$v$ can be calculated by

The immersed boundary method employed in this study has been extensively used to simulate the FSI problems (Peskin Reference Peskin2002; Mittal & Iaccarino Reference Mittal and Iaccarino2005). The Lagrangian force between the fluid and structure ![]() $\boldsymbol {F}_{s}$ can be calculated by the penalty scheme (Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1993)

$\boldsymbol {F}_{s}$ can be calculated by the penalty scheme (Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1993)

where ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$ are negative large penalty parameters which are selected based on the previous studies (Hua, Zhu & Lu Reference Hua, Zhu and Lu2013; Ye et al. Reference Ye, Wei, Huang and Lu2017; Peng, Huang & Lu Reference Peng, Huang and Lu2018a,Reference Peng, Huang and Luc),

$\beta$ are negative large penalty parameters which are selected based on the previous studies (Hua, Zhu & Lu Reference Hua, Zhu and Lu2013; Ye et al. Reference Ye, Wei, Huang and Lu2017; Peng, Huang & Lu Reference Peng, Huang and Lu2018a,Reference Peng, Huang and Luc), ![]() $\boldsymbol {V}_s=\partial \boldsymbol {X}/\partial t$ is the velocity of Lagrangian material point of the filament, and

$\boldsymbol {V}_s=\partial \boldsymbol {X}/\partial t$ is the velocity of Lagrangian material point of the filament, and ![]() $\boldsymbol {V}_f$ is the fluid velocity at the position

$\boldsymbol {V}_f$ is the fluid velocity at the position ![]() $\boldsymbol {X}$ obtained by interpolation

$\boldsymbol {X}$ obtained by interpolation

The body force term ![]() $\boldsymbol {f}_b$ in (2.1) represents an interaction force between the fluid and the immersed boundary to enforce the no-slip velocity boundary condition. The Lagrangian force is spread to the nearby Eulerian grids by using the expression

$\boldsymbol {f}_b$ in (2.1) represents an interaction force between the fluid and the immersed boundary to enforce the no-slip velocity boundary condition. The Lagrangian force is spread to the nearby Eulerian grids by using the expression

where ![]() $\delta (\boldsymbol {x}-\boldsymbol {X})$ is the Dirac delta function. Note that in the simulations,

$\delta (\boldsymbol {x}-\boldsymbol {X})$ is the Dirac delta function. Note that in the simulations, ![]() $\boldsymbol {f}_b$ is distributed over several Eulerian grids in width by using a smoothed delta function interpolation. Thus, the leakage of internal fluid area enclosed by the flat plate and filament may arise, due to the use of the smoothed approximation to the Dirac delta function (Kim et al. Reference Kim, Huang, Shin and Sung2012; Ye et al. Reference Ye, Wei, Huang and Lu2017).

$\boldsymbol {f}_b$ is distributed over several Eulerian grids in width by using a smoothed delta function interpolation. Thus, the leakage of internal fluid area enclosed by the flat plate and filament may arise, due to the use of the smoothed approximation to the Dirac delta function (Kim et al. Reference Kim, Huang, Shin and Sung2012; Ye et al. Reference Ye, Wei, Huang and Lu2017).

Here we adopt a penalty forcing scheme proposed by Kim et al. (Reference Kim, Huang, Shin and Sung2012) to diminish the area leakage effect. In the scheme, the fluid compressibility ![]() $\beta$ is defined as

$\beta$ is defined as

where ![]() $\varOmega$ is the fluid area enclosed by the plate and filament and

$\varOmega$ is the fluid area enclosed by the plate and filament and ![]() $p$ denotes the pressure. Integrating above the differential relation between

$p$ denotes the pressure. Integrating above the differential relation between ![]() $\varOmega$ and

$\varOmega$ and ![]() $p$, and using Taylor's expansion, the pressure difference between the interior and exterior of the enclosed area can be approximated by

$p$, and using Taylor's expansion, the pressure difference between the interior and exterior of the enclosed area can be approximated by

where ![]() $\varOmega _0$ denotes the initial interior area and the last term of the equation represents historical effects. Thus, the penalty force for area conservation is calculated by using the pressure difference

$\varOmega _0$ denotes the initial interior area and the last term of the equation represents historical effects. Thus, the penalty force for area conservation is calculated by using the pressure difference ![]() ${\rm \Delta} p$ as

${\rm \Delta} p$ as

where ![]() $\boldsymbol {e}_{n}$ represents the local normal unit in the direction from the interior to the exterior of the enclosed area. This force is also added to the structure motion equation (2.3) as an external force term.

$\boldsymbol {e}_{n}$ represents the local normal unit in the direction from the interior to the exterior of the enclosed area. This force is also added to the structure motion equation (2.3) as an external force term.

Equation (2.3) is discretized by a nonlinear finite element method with a co-rotational scheme. A detailed description of the method can be found in Doyle (Reference Doyle2001). The motion of the filament in the present study is regarded as a large-displacement and small-strain deformation problem. By using the co-rotational scheme, the original problem with the geometrical nonlinearities in global coordinates splits into two parts, i.e. the rigid body motion and pure deformation in local coordinates, which are resolved by the coordinate transformation and linear theory, respectively. A detailed description of the above numerical method can be found in our previous papers (Hua et al. Reference Hua, Zhu and Lu2013; Ye et al. Reference Ye, Wei, Huang and Lu2017; Peng et al. Reference Peng, Huang and Lu2018a,Reference Peng, Huang and Luc; Peng, Huang & Lu Reference Peng, Huang and Lu2018b).

2.3. Validation

Based on our convergence studies with different computational domains, the computational domain for fluid flow is chosen as ![]() $20D \times 50D$ in the

$20D \times 50D$ in the ![]() $x$ and

$x$ and ![]() $y$ directions. The domain is large enough so that the blocking effects of the boundaries are not significant. In the

$y$ directions. The domain is large enough so that the blocking effects of the boundaries are not significant. In the ![]() $x$ and

$x$ and ![]() $y$ directions the mesh is uniform with spacing

$y$ directions the mesh is uniform with spacing ![]() ${\rm \Delta} x={\rm \Delta} y=D/100$. The filament is discretized with a mesh size of

${\rm \Delta} x={\rm \Delta} y=D/100$. The filament is discretized with a mesh size of ![]() ${\rm \Delta} s = D/100$. The time step is

${\rm \Delta} s = D/100$. The time step is ![]() ${\rm \Delta} t=T/4000$ for the simulations of fluid flow and filament motion, with

${\rm \Delta} t=T/4000$ for the simulations of fluid flow and filament motion, with ![]() $T=D/U$.

$T=D/U$.

Figure 2(![]() $a$) shows the time histories of the changes in area with and without the penalty forcing strategy for the case with

$a$) shows the time histories of the changes in area with and without the penalty forcing strategy for the case with ![]() $Re=100$,

$Re=100$, ![]() $Lr=2.5$,

$Lr=2.5$, ![]() $K=0.001$,

$K=0.001$, ![]() $S=1000$ and

$S=1000$ and ![]() $M=0.1$. It is seen that the maximum area leakage is

$M=0.1$. It is seen that the maximum area leakage is ![]() $\sim 0.5\,\%$ and

$\sim 0.5\,\%$ and ![]() $\sim 12\,\%$ for the cases with and without the penalty force, respectively. The results indicate when the penalty forcing strategy is adopted, the area conservation is improved significantly and satisfied for the present study.

$\sim 12\,\%$ for the cases with and without the penalty force, respectively. The results indicate when the penalty forcing strategy is adopted, the area conservation is improved significantly and satisfied for the present study.

Figure 2. Validations of the present numerical method. (![]() $a$) The area enclosed by the flat plate and deformable filament,

$a$) The area enclosed by the flat plate and deformable filament, ![]() $\varOmega /\varOmega _0$, as a function of time for cases with and without penalty force, respectively. In these cases,

$\varOmega /\varOmega _0$, as a function of time for cases with and without penalty force, respectively. In these cases, ![]() $Re=100$,

$Re=100$, ![]() $Lr=2.5$,

$Lr=2.5$, ![]() $K=0.001$,

$K=0.001$, ![]() $S=1000$ and

$S=1000$ and ![]() $M=0.1$. (

$M=0.1$. (![]() $b$) The variations of the mean drag coefficient as a function of

$b$) The variations of the mean drag coefficient as a function of ![]() $Lr$ for the cases with

$Lr$ for the cases with ![]() $Re=100$ and

$Re=100$ and ![]() $\beta =5, 10, 50$. (

$\beta =5, 10, 50$. (![]() $c$) The time variations of

$c$) The time variations of ![]() $F_y$ for the cases with

$F_y$ for the cases with ![]() $Lr=2$,

$Lr=2$, ![]() $Re=100$ under different lattice spacings (

$Re=100$ under different lattice spacings (![]() ${\rm \Delta} x=D/200$,

${\rm \Delta} x=D/200$, ![]() $D/100$ and

$D/100$ and ![]() $D/50$) and time steps (

$D/50$) and time steps (![]() ${\rm \Delta} t=T/8000$,

${\rm \Delta} t=T/8000$, ![]() $T/4000$ and

$T/4000$ and ![]() $T/2000$). (

$T/2000$). (![]() $d$) The variations of the mean drag coefficient as a function of

$d$) The variations of the mean drag coefficient as a function of ![]() $S$ for the cases of a flapping ring in a uniform flow. The present results are provided to compare with the previous results (Kim et al. Reference Kim, Huang, Shin and Sung2012). Here,

$S$ for the cases of a flapping ring in a uniform flow. The present results are provided to compare with the previous results (Kim et al. Reference Kim, Huang, Shin and Sung2012). Here, ![]() $K = 0.01$,

$K = 0.01$, ![]() $Re= 100$ and

$Re= 100$ and ![]() $S=6\unicode{x2013}70$.

$S=6\unicode{x2013}70$.

To examine the effect of ![]() $\beta$ on the results of simulations, figure 2(

$\beta$ on the results of simulations, figure 2(![]() $b$) shows the variations of the mean drag coefficient as a function of

$b$) shows the variations of the mean drag coefficient as a function of ![]() $Lr$ for the cases with

$Lr$ for the cases with ![]() $Re=100$ and varying

$Re=100$ and varying ![]() $\beta$, i.e.

$\beta$, i.e. ![]() $\beta =5, 10$ and 50. It is found that the choice of

$\beta =5, 10$ and 50. It is found that the choice of ![]() $\beta$ does not affect the overall drag of the coupling system for all the cases with

$\beta$ does not affect the overall drag of the coupling system for all the cases with ![]() $Lr\in (1,10]$. Whereas, it should be noted that a very small value of

$Lr\in (1,10]$. Whereas, it should be noted that a very small value of ![]() $\beta$ may cause numerical instability, while a very large value of

$\beta$ may cause numerical instability, while a very large value of ![]() $\beta$ may not guarantee volume conservation. In our simulations,

$\beta$ may not guarantee volume conservation. In our simulations, ![]() $\beta =10$, which can ensure the volume conservation and numerical stability at the same time.

$\beta =10$, which can ensure the volume conservation and numerical stability at the same time.

Also, the grid spacing and time step independence studies are performed. Figure 2(![]() $c$) shows the time-dependent

$c$) shows the time-dependent ![]() $F_y$ of the afterbody calculated under the different lattice spacings and time steps for the typical case with

$F_y$ of the afterbody calculated under the different lattice spacings and time steps for the typical case with ![]() $Lr=2$,

$Lr=2$, ![]() $Re=100$. It is confirmed that

$Re=100$. It is confirmed that ![]() ${\rm \Delta} x=D/100$ and

${\rm \Delta} x=D/100$ and ![]() ${\rm \Delta} t=T/4000$ are sufficient to achieve accurate results in the present simulations with

${\rm \Delta} t=T/4000$ are sufficient to achieve accurate results in the present simulations with ![]() $Re=100$. Further verification shows that

$Re=100$. Further verification shows that ![]() ${\rm \Delta} x=D/100$ and

${\rm \Delta} x=D/100$ and ![]() ${\rm \Delta} t=T/4000$ are also sufficient to accurately simulate the flows at higher

${\rm \Delta} t=T/4000$ are also sufficient to accurately simulate the flows at higher ![]() $Re$, e.g.

$Re$, e.g. ![]() $Re=800$ (not shown in figure 2

$Re=800$ (not shown in figure 2![]() $c$). Hence, in all of our simulations,

$c$). Hence, in all of our simulations, ![]() ${\rm \Delta} x=D/100$ and

${\rm \Delta} x=D/100$ and ![]() ${\rm \Delta} t=T/4000$ were adopted.

${\rm \Delta} t=T/4000$ were adopted.

To further validate the present numerical method, we simulate a flexible ring flapping in a uniform flow. Figure 2(![]() $d$) shows the mean drag coefficients of the ring as functions of

$d$) shows the mean drag coefficients of the ring as functions of ![]() $S$ for

$S$ for ![]() $K=0.01$ and

$K=0.01$ and ![]() $Re=100$. It is seen that the present results agree well with those of Kim et al. (Reference Kim, Huang, Shin and Sung2012).

$Re=100$. It is seen that the present results agree well with those of Kim et al. (Reference Kim, Huang, Shin and Sung2012).

In addition, the numerical strategy used in this study has been validated and successfully applied to a wide range of flows, such as the dynamics of fluid flow over flexible filaments (Tian et al. Reference Tian, Luo, Zhu and Lu2010) or loops (Ye et al. Reference Ye, Wei, Huang and Lu2017), and self-propulsion of flapping flexible plates (Hua et al. Reference Hua, Zhu and Lu2013; Peng et al. Reference Peng, Huang and Lu2018a,Reference Peng, Huang and Luc).

3. Results and discussion

In the study, the effects of the length ratio (![]() $1\le Lr \le 10$) and Reynolds number (

$1\le Lr \le 10$) and Reynolds number (![]() $10\le Re\le 800$) are investigated. It is noted that

$10\le Re\le 800$) are investigated. It is noted that ![]() $Lr=1$ corresponds to the situation without the trailing filament. In all our simulations, the mass ratio (

$Lr=1$ corresponds to the situation without the trailing filament. In all our simulations, the mass ratio (![]() $M=0.1)$, bending stiffness (

$M=0.1)$, bending stiffness (![]() $K=0.001)$ and stretching stiffness (

$K=0.001)$ and stretching stiffness (![]() $S=1000)$ are fixed. The mass ratio is fixed at

$S=1000)$ are fixed. The mass ratio is fixed at ![]() $M=0.1$, which matches the case of a flexible afterbody in the wind tunnel (

$M=0.1$, which matches the case of a flexible afterbody in the wind tunnel (![]() $M \sim O(10^{-1}\unicode{x2013}10^{0}$)). A large value of the stretching stiffness S is chosen such that the stretching deformation of the filament can be neglected. We chose a very small bending stiffness

$M \sim O(10^{-1}\unicode{x2013}10^{0}$)). A large value of the stretching stiffness S is chosen such that the stretching deformation of the filament can be neglected. We chose a very small bending stiffness ![]() $K$ so that the filament is fully compliant with the surrounding flow, which is consistent with the previous experiments (Gao et al. Reference Gao, Pan, Wang and Tian2020).

$K$ so that the filament is fully compliant with the surrounding flow, which is consistent with the previous experiments (Gao et al. Reference Gao, Pan, Wang and Tian2020).

3.1. Dynamic states of the rigid-flexible coupling system

In this section we present the dynamic states of the rigid-flexible coupling system in a flow. Based on a variety of simulations for a wide range of parameters considered here, we have identified five typical modes of dynamic behaviours in terms of the filament motion and flow pattern, i.e. static deformation (SD) mode, micro-vibration (MV) mode, multi-frequency flapping (MFF) mode, periodic flapping (PF) mode, and chaotic flapping (CF) mode, respectively.

Figure 3(![]() $a$) shows the instantaneous vorticity contour and shape deformation of the filament for the case with

$a$) shows the instantaneous vorticity contour and shape deformation of the filament for the case with ![]() $Re=10, Lr=2.25$, corresponding to the SD mode. Animations are also given in supplementary movie 1. It is seen that for the SD mode, the filament adapts to the streamlines of the surrounding flow and undergoes a static deformation with the fluid loading. The steady wake downstream of the plate is formed because of the low

$Re=10, Lr=2.25$, corresponding to the SD mode. Animations are also given in supplementary movie 1. It is seen that for the SD mode, the filament adapts to the streamlines of the surrounding flow and undergoes a static deformation with the fluid loading. The steady wake downstream of the plate is formed because of the low ![]() $Re$. Specifically, the shear layers with opposite vorticity formed at the edges of the plate, attached to the reshaped afterbody and then dissipated downstream (see figure 3

$Re$. Specifically, the shear layers with opposite vorticity formed at the edges of the plate, attached to the reshaped afterbody and then dissipated downstream (see figure 3![]() $a$). In addition, the snapshot of the reshaped filament for other cases with

$a$). In addition, the snapshot of the reshaped filament for other cases with ![]() $Re=10$ and

$Re=10$ and ![]() $Lr=1.1, 1.5, 4, 6, 8, 10$ are also plotted with solid green lines in figure 3(

$Lr=1.1, 1.5, 4, 6, 8, 10$ are also plotted with solid green lines in figure 3( ![]() $f$). It is shown that for the SD mode, the filament appears stationary and has reflectional symmetry about its midline, behaving like a rigid body. As

$f$). It is shown that for the SD mode, the filament appears stationary and has reflectional symmetry about its midline, behaving like a rigid body. As ![]() $Lr$ increases, the filament sequentially appears as ‘plate-like’ (e.g.

$Lr$ increases, the filament sequentially appears as ‘plate-like’ (e.g. ![]() $Lr=1.1$), ‘cylinder-like’ (e.g.

$Lr=1.1$), ‘cylinder-like’ (e.g. ![]() $Lr=1.5$) and ‘slender’ (e.g.

$Lr=1.5$) and ‘slender’ (e.g. ![]() $Lr=10$) shapes, which is consistent with experimental observations (Gao et al. Reference Gao, Pan, Wang and Tian2020). It is noted that for the cases with large

$Lr=10$) shapes, which is consistent with experimental observations (Gao et al. Reference Gao, Pan, Wang and Tian2020). It is noted that for the cases with large ![]() $Lr$, the rear part of the filament is squeezed by the surrounding fluid, yielding a rounded tip at the end of the afterbody. Figure 3(

$Lr$, the rear part of the filament is squeezed by the surrounding fluid, yielding a rounded tip at the end of the afterbody. Figure 3(![]() $b$) shows the instantaneous vorticity contour and shape deformation of the filament for the case with

$b$) shows the instantaneous vorticity contour and shape deformation of the filament for the case with ![]() $Re=100, Lr=1.3$, corresponding to the MV mode. A video showing the vortex shedding and filament vibration is also included in supplementary movie 2. As we can see, the shear layers begin to separate at the edges of the flat plate and then form a pair of alternately shedding vortices, i.e. Kármán vortices. The figure also illustrates the development and spatial organization of the Kármán vortices in the far wake. It is seen that the alternate vortices convect downstream parallel to the centreline as two rows of vortices having opposite rotation. A snapshot of the deformation configurations of the filament is shown in figure 3(

$Re=100, Lr=1.3$, corresponding to the MV mode. A video showing the vortex shedding and filament vibration is also included in supplementary movie 2. As we can see, the shear layers begin to separate at the edges of the flat plate and then form a pair of alternately shedding vortices, i.e. Kármán vortices. The figure also illustrates the development and spatial organization of the Kármán vortices in the far wake. It is seen that the alternate vortices convect downstream parallel to the centreline as two rows of vortices having opposite rotation. A snapshot of the deformation configurations of the filament is shown in figure 3(![]() $g$). For the MV mode, the flexible filament experiences a particularly small vibration, along with the alternate shedding of the Kármán vortices. To further describe the dynamics of the filament, figure 4(

$g$). For the MV mode, the flexible filament experiences a particularly small vibration, along with the alternate shedding of the Kármán vortices. To further describe the dynamics of the filament, figure 4(![]() $a$) shows the time variation of the lift coefficient (

$a$) shows the time variation of the lift coefficient (![]() $C_l$) for the overall system and transverse position of the filament midpoint (

$C_l$) for the overall system and transverse position of the filament midpoint (![]() $x_m$) for the case with

$x_m$) for the case with ![]() $Re=100, Lr=1.3$. Here the lift coefficient is defined as

$Re=100, Lr=1.3$. Here the lift coefficient is defined as ![]() $C_l={ \langle F_x \rangle }/{\frac {1}{2}\rho U^2D}$, where

$C_l={ \langle F_x \rangle }/{\frac {1}{2}\rho U^2D}$, where ![]() $\langle q \rangle := ({1}/({t_1-t_0})) \int _{t_0}^{t_1} q(t)\cdot \, {\rm d}t$ and

$\langle q \rangle := ({1}/({t_1-t_0})) \int _{t_0}^{t_1} q(t)\cdot \, {\rm d}t$ and ![]() $q(t)$ is an integrable physical quantity. In the computations,

$q(t)$ is an integrable physical quantity. In the computations, ![]() $t_1-t_0$ is chosen as 10 times

$t_1-t_0$ is chosen as 10 times ![]() $1/f_1$, where

$1/f_1$, where ![]() $f_1$ is the dominant frequency of the integrand. As shown in figure 4(

$f_1$ is the dominant frequency of the integrand. As shown in figure 4(![]() $a$),

$a$), ![]() $C_l$ changes with time periodically around its averaged value zero. It is also seen that the filament vibration amplitude in terms of the peak-to-peak value of

$C_l$ changes with time periodically around its averaged value zero. It is also seen that the filament vibration amplitude in terms of the peak-to-peak value of ![]() $x_m$ is less than

$x_m$ is less than ![]() $0.04D$ (see inset within figure 4

$0.04D$ (see inset within figure 4![]() $a$). According to the power spectrum density (PSD) of

$a$). According to the power spectrum density (PSD) of ![]() $C_l$ (see figure 4

$C_l$ (see figure 4![]() $e$), an isolated frequency (

$e$), an isolated frequency ( ![]() $f_1=0.178$) of lift change, which is equal to that of the vortex shedding and the filament micro-vibration, is observed. Note that compared with the MV mode, the lift for the SD mode case is time invariant, i.e.

$f_1=0.178$) of lift change, which is equal to that of the vortex shedding and the filament micro-vibration, is observed. Note that compared with the MV mode, the lift for the SD mode case is time invariant, i.e. ![]() $C_l=0$, thus, the time variation and PSD of

$C_l=0$, thus, the time variation and PSD of ![]() $C_l$ for the SD mode are not given in figure 4.

$C_l$ for the SD mode are not given in figure 4.

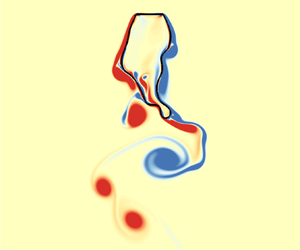

Figure 3. Behaviours of the flow patterns and deformations of filament shapes: (![]() $a$–

$a$–![]() $e$) the instantaneous vorticity contours, and (

$e$) the instantaneous vorticity contours, and ( ![]() $f$–

$f$–![]() $j$) the envelops (solid black lines) of the flexible filaments for five distinct modes with

$j$) the envelops (solid black lines) of the flexible filaments for five distinct modes with ![]() $Re=10$,

$Re=10$, ![]() $Lr=2.25$ (a, f),

$Lr=2.25$ (a, f), ![]() $Re=100$,

$Re=100$, ![]() $Lr=1.3$ (b,g),

$Lr=1.3$ (b,g), ![]() $Lr=2.25$ (c,h),

$Lr=2.25$ (c,h), ![]() $Lr=6$ (d,i) and

$Lr=6$ (d,i) and ![]() $Re=800$,

$Re=800$, ![]() $Lr=9$ (e, j), corresponding to the static deformation (SD), micro-vibration (MV), multi-frequency flapping (MFF), periodic flapping (PF) and chaotic flapping (CF) modes, respectively. Animated visualisations of the dynamic states for these modes have also been provided in supplementary movies available at https://doi.org/10.1017/jfm.2022.466. For the SD mode, the snapshot of the filament deformation shapes for other cases with

$Lr=9$ (e, j), corresponding to the static deformation (SD), micro-vibration (MV), multi-frequency flapping (MFF), periodic flapping (PF) and chaotic flapping (CF) modes, respectively. Animated visualisations of the dynamic states for these modes have also been provided in supplementary movies available at https://doi.org/10.1017/jfm.2022.466. For the SD mode, the snapshot of the filament deformation shapes for other cases with ![]() $Re=10$ and

$Re=10$ and ![]() $Lr=1.1, 1.5, 4, 6, 8, 10$ are also plotted with solid green lines in figure 3(

$Lr=1.1, 1.5, 4, 6, 8, 10$ are also plotted with solid green lines in figure 3( ![]() $f$).

$f$).

Figure 4. Time variations of the lift coefficient ![]() $C_{l}$ (solid line) of the overall system and the transverse position

$C_{l}$ (solid line) of the overall system and the transverse position ![]() $x_m$ (dashed line) of the midpoint of filament (

$x_m$ (dashed line) of the midpoint of filament (![]() $a$–

$a$–![]() $d$), and power spectrum density (PSD) of

$d$), and power spectrum density (PSD) of ![]() $C_{l}(t)$ (

$C_{l}(t)$ (![]() $e$–

$e$–![]() $h$) for cases with

$h$) for cases with ![]() $Re=100$,

$Re=100$, ![]() $Lr=1.3$ (a,e),

$Lr=1.3$ (a,e), ![]() $Lr=2.25$ (b, f),

$Lr=2.25$ (b, f), ![]() $Lr=6$ (c,g) and

$Lr=6$ (c,g) and ![]() $Re=800$,

$Re=800$, ![]() $Lr=9$ (d, h), corresponding to the MV, MFF, PF and CF modes, respectively. Inset: enlargement of the variation of

$Lr=9$ (d, h), corresponding to the MV, MFF, PF and CF modes, respectively. Inset: enlargement of the variation of ![]() $x_m$ versus time for the MV mode with

$x_m$ versus time for the MV mode with ![]() $Re=100$,

$Re=100$, ![]() $Lr=1.3$ (

$Lr=1.3$ (![]() $a$1).

$a$1).

The behaviours of the flow pattern and the filament deformation for the case with ![]() $Re=100$ and

$Re=100$ and ![]() $Lr=2.25$, corresponding to the MFF mode, are shown in figures 3(c,h), and animated in supplementary movie 3. In this case, the Kármán vortex street is also found in the wake of the coupled system (see figure 3

$Lr=2.25$, corresponding to the MFF mode, are shown in figures 3(c,h), and animated in supplementary movie 3. In this case, the Kármán vortex street is also found in the wake of the coupled system (see figure 3![]() $c$). It is noted that the distance between the two rows of vortices having opposite rotation becomes smaller, compared with that for the MV mode cases. Moreover, the filament experiences a flapping motion with a larger amplitude with the pick-to-pick value of

$c$). It is noted that the distance between the two rows of vortices having opposite rotation becomes smaller, compared with that for the MV mode cases. Moreover, the filament experiences a flapping motion with a larger amplitude with the pick-to-pick value of ![]() $x_m \approx 0.34D$, as shown in figures 3(

$x_m \approx 0.34D$, as shown in figures 3(![]() $h$) and 4(

$h$) and 4(![]() $b$). The curve of

$b$). The curve of ![]() $C_l (t)$ in figure 4(

$C_l (t)$ in figure 4(![]() $b$) shows a distinct pick (or valley) near the maximum (or minimum) value of

$b$) shows a distinct pick (or valley) near the maximum (or minimum) value of ![]() $x_m$, indicating the in-phase relation between the variations of

$x_m$, indicating the in-phase relation between the variations of ![]() $C_l$ and

$C_l$ and ![]() $x_m$. As shown in figure 4(

$x_m$. As shown in figure 4(![]() $f$), the PSD of

$f$), the PSD of ![]() $C_l$ suggests multiple discrete frequencies for the filament flapping, e.g.

$C_l$ suggests multiple discrete frequencies for the filament flapping, e.g. ![]() $f_1=0.155$,

$f_1=0.155$, ![]() $f_2=0.472$,

$f_2=0.472$, ![]() $f_3=0.789$, etc., whereas the first frequency

$f_3=0.789$, etc., whereas the first frequency ![]() $f_1$, i.e. vortex shedding frequency, is dominant.

$f_1$, i.e. vortex shedding frequency, is dominant.

As ![]() $Lr$ becomes larger, the dynamic state of the system may switch from the MFF mode to PF mode. Here we use the case with

$Lr$ becomes larger, the dynamic state of the system may switch from the MFF mode to PF mode. Here we use the case with ![]() $Re=100$ and

$Re=100$ and ![]() $Lr=6$ as an example for the PF mode, as shown in figure 3(d,i) and supplementary movie 4. It is seen that for the PF mode, the filament flaps periodically; meanwhile, the separated shear layers become unstable, resulting in periodic alternate shedding of vortices. Different from the multiple discrete frequencies for the filament flapping in the MFF mode, an isolated frequency for the PF mode cases is found, e.g.

$Lr=6$ as an example for the PF mode, as shown in figure 3(d,i) and supplementary movie 4. It is seen that for the PF mode, the filament flaps periodically; meanwhile, the separated shear layers become unstable, resulting in periodic alternate shedding of vortices. Different from the multiple discrete frequencies for the filament flapping in the MFF mode, an isolated frequency for the PF mode cases is found, e.g. ![]() $f_1=0.155$ for

$f_1=0.155$ for ![]() $Lr=6$ and

$Lr=6$ and ![]() $Re=100$, as shown in figure 4(

$Re=100$, as shown in figure 4(![]() $g$). In addition, the phase difference

$g$). In addition, the phase difference ![]() ${\rm \Delta} \varphi$ between the maximum

${\rm \Delta} \varphi$ between the maximum ![]() $C_l$ and the maximum

$C_l$ and the maximum ![]() $x_m$ is about

$x_m$ is about ![]() ${\rm \pi}$, indicating the out-phase relation between time variations of

${\rm \pi}$, indicating the out-phase relation between time variations of ![]() $C_l$ and

$C_l$ and ![]() $x_m$ (see figure 4

$x_m$ (see figure 4![]() $c$).

$c$).

Figures 3(![]() $e$) and 3(

$e$) and 3(![]() $j$) show the behaviours of the flow pattern and the filament deformation for the case with

$j$) show the behaviours of the flow pattern and the filament deformation for the case with ![]() $Re=800, Lr=9$, corresponding to the CF mode. A video showing the dynamics of this case is also provided in supplementary movie 5. Here, we note that even though the flexible afterbody may deform greatly and flap strongly in the CF mode, the self-contact phenomenon has not been observed during the process of the different parts of the afterbody approaching and moving away from each other. Unlike the ordered flow patterns in the MV, MFF and PF modes, the chaotic vortical structures are found in the wake of the coupled system for the CF mode case (see figure 3

$Re=800, Lr=9$, corresponding to the CF mode. A video showing the dynamics of this case is also provided in supplementary movie 5. Here, we note that even though the flexible afterbody may deform greatly and flap strongly in the CF mode, the self-contact phenomenon has not been observed during the process of the different parts of the afterbody approaching and moving away from each other. Unlike the ordered flow patterns in the MV, MFF and PF modes, the chaotic vortical structures are found in the wake of the coupled system for the CF mode case (see figure 3![]() $e$). The shear layers attached to the filament start to roll up at the forepart of the afterbody and then break into eddies with varying sizes irregularly shedding in the wake (see figure 3

$e$). The shear layers attached to the filament start to roll up at the forepart of the afterbody and then break into eddies with varying sizes irregularly shedding in the wake (see figure 3![]() $e$), accompanied by the chaotic flapping of the filament (see figure 3

$e$), accompanied by the chaotic flapping of the filament (see figure 3![]() $j$). Furthermore, the curves of

$j$). Furthermore, the curves of ![]() $C_l(t)$ and

$C_l(t)$ and ![]() $x_m(t)$ illustrate the dynamic disorder of the coupled system, as shown in figure 4(

$x_m(t)$ illustrate the dynamic disorder of the coupled system, as shown in figure 4(![]() $d$). Moreover, figure 4(

$d$). Moreover, figure 4(![]() $h$) shows the PSD of

$h$) shows the PSD of ![]() $C_l$ for the case with

$C_l$ for the case with ![]() $Re=800, Lr=9$. As one can see, figure 4(

$Re=800, Lr=9$. As one can see, figure 4(![]() $h$) shows a broadband spectrum, indicating a non-periodic behaviour of the coupled system. Moreover, a high peak is found at

$h$) shows a broadband spectrum, indicating a non-periodic behaviour of the coupled system. Moreover, a high peak is found at ![]() $f_1=0.140$ (see figure 4

$f_1=0.140$ (see figure 4![]() $h$), showing the dominant flapping frequency for the filament flapping and vortex shedding. In the discussion above, it is interesting to note that there is an obvious difference in the phase relation between

$h$), showing the dominant flapping frequency for the filament flapping and vortex shedding. In the discussion above, it is interesting to note that there is an obvious difference in the phase relation between ![]() $C_l$ and

$C_l$ and ![]() $x_m$ for the MFF and PF modes. To further illustrate this point, the variations of the phase difference

$x_m$ for the MFF and PF modes. To further illustrate this point, the variations of the phase difference ![]() ${\rm \Delta} \varphi$ between the maximum

${\rm \Delta} \varphi$ between the maximum ![]() $C_l$ and the maximum

$C_l$ and the maximum ![]() $x_m$ as functions of

$x_m$ as functions of ![]() $Lr$ for different

$Lr$ for different ![]() $Re$ are shown in figure 5(

$Re$ are shown in figure 5(![]() $a$). It is seen that the system mode switches from the MFF mode to PF mode as

$a$). It is seen that the system mode switches from the MFF mode to PF mode as ![]() $Lr$ increases, resulting in a jump of

$Lr$ increases, resulting in a jump of ![]() ${\rm \Delta} \varphi$, e.g.

${\rm \Delta} \varphi$, e.g. ![]() ${\rm \Delta} \varphi \approx 0$ for the MFF mode case with

${\rm \Delta} \varphi \approx 0$ for the MFF mode case with ![]() $Re=100$,

$Re=100$, ![]() $Lr=2$ and

$Lr=2$ and ![]() ${\rm \Delta} \varphi \approx {\rm \pi}$ for the PF mode case with

${\rm \Delta} \varphi \approx {\rm \pi}$ for the PF mode case with ![]() $Re=100$,

$Re=100$, ![]() $Lr=7$. Moreover, the root-mean-square (rms) values of the transverse position of the filament midpoint,

$Lr=7$. Moreover, the root-mean-square (rms) values of the transverse position of the filament midpoint, ![]() $x_{m,{rms}}$, as functions of

$x_{m,{rms}}$, as functions of ![]() $Lr$ for various

$Lr$ for various ![]() $Re$, are shown in figure 5(

$Re$, are shown in figure 5(![]() $b$). It is revealed that as the increase of

$b$). It is revealed that as the increase of ![]() $Lr$,

$Lr$, ![]() $x_{m,{rms}}$ follows obviously different variations within different mode regions. For example, when

$x_{m,{rms}}$ follows obviously different variations within different mode regions. For example, when ![]() $Re> 50$, the

$Re> 50$, the ![]() $x_{m,{rms}}$ first increases linearly within the MV mode region (

$x_{m,{rms}}$ first increases linearly within the MV mode region (![]() $Lr<2$), and then experiences an enormous increase by following a logarithmic growth law until reaching its maximum value at

$Lr<2$), and then experiences an enormous increase by following a logarithmic growth law until reaching its maximum value at ![]() $Lr\thickapprox 3.5$. After that,

$Lr\thickapprox 3.5$. After that, ![]() $x_{m,{rms}}$ gradually decreases and stabilizes. Therefore, one can distinguish the boundaries between the distinct modes through the curve profiles of

$x_{m,{rms}}$ gradually decreases and stabilizes. Therefore, one can distinguish the boundaries between the distinct modes through the curve profiles of ![]() ${\rm \Delta} \varphi$ and

${\rm \Delta} \varphi$ and ![]() $x_{m,{rms}}$. Our results indicate that the occurrence of the motion states of the system depends mainly on the length ratio

$x_{m,{rms}}$. Our results indicate that the occurrence of the motion states of the system depends mainly on the length ratio ![]() $Lr$ and Reynolds number

$Lr$ and Reynolds number ![]() $Re$. The phase diagram for the five modes in the

$Re$. The phase diagram for the five modes in the ![]() $H\unicode{x2013}Re$ plane is shown in figure 6. Each symbol in the figure represents a case we simulated. It is seen that the SD mode occurs mainly in the low

$H\unicode{x2013}Re$ plane is shown in figure 6. Each symbol in the figure represents a case we simulated. It is seen that the SD mode occurs mainly in the low ![]() $Re$ region (say

$Re$ region (say ![]() $Re=10$). As

$Re=10$). As ![]() $Re$ increases, the transition from a steady to unsteady state for flow past the coupled system is found at a critical

$Re$ increases, the transition from a steady to unsteady state for flow past the coupled system is found at a critical ![]() $Re \in (25, 50)$ for

$Re \in (25, 50)$ for ![]() $1\le Lr < 4$, or

$1\le Lr < 4$, or ![]() $\in (10, 25)$ for

$\in (10, 25)$ for ![]() $4\leq Lr \leq 10$. In the moderate

$4\leq Lr \leq 10$. In the moderate ![]() $Re$ region (say

$Re$ region (say ![]() $Re=100$), the MV, MFF, PF and CF modes appear in succession as

$Re=100$), the MV, MFF, PF and CF modes appear in succession as ![]() $Lr$ increases from 1.1 to 10; when

$Lr$ increases from 1.1 to 10; when ![]() $Re$ is large enough (say

$Re$ is large enough (say ![]() $Re=800$), only the MV and CF modes occur.

$Re=800$), only the MV and CF modes occur.

Figure 5. (![]() $a$) Phase difference between the peaks of

$a$) Phase difference between the peaks of ![]() $C_l$ and

$C_l$ and ![]() $x_m$, and (

$x_m$, and (![]() $b$) the root-mean-square value of the transverse position of the filament midpoint,

$b$) the root-mean-square value of the transverse position of the filament midpoint, ![]() $x_{m,{rms}}$, as functions of

$x_{m,{rms}}$, as functions of ![]() $Lr$ for various

$Lr$ for various ![]() $Re$.

$Re$.

Figure 6. Overview of the five typical mode regions on the ![]() $Lr\unicode{x2013}Re$ plane, where the symbols

$Lr\unicode{x2013}Re$ plane, where the symbols ![]() $\diamond$,

$\diamond$, ![]() $\square$,

$\square$, ![]() $\circ$,

$\circ$, ![]() $\vartriangle$ and

$\vartriangle$ and ![]() $\triangleright$ represent the SD, MV, MFF, PF and CF modes, respectively. The drag reduction region (DRR) is marked by the grey colour. The

$\triangleright$ represent the SD, MV, MFF, PF and CF modes, respectively. The drag reduction region (DRR) is marked by the grey colour. The ![]() $Lr_{c,{max}}$ (or

$Lr_{c,{max}}$ (or ![]() $Lr_{c,{min}}$) trajectory along which the system experiences a local maximum (or minimum) drag is plotted by the dashed (or dash-dotted) line on the phase plane. The typical cases in figure 3 are marked by the symbols

$Lr_{c,{min}}$) trajectory along which the system experiences a local maximum (or minimum) drag is plotted by the dashed (or dash-dotted) line on the phase plane. The typical cases in figure 3 are marked by the symbols ![]() $\times$.

$\times$.

3.2. Drag and the flow characteristics

The drag acting on the coupled system by the surrounding fluid is further investigated to better understand the relationship between the drag variations and the mode transitions. The jump in the fluid force across the plate or filament at a certain Lagrangian point, i.e ![]() $\boldsymbol {F}_s$, can be decomposed into two parts: one is the normal force

$\boldsymbol {F}_s$, can be decomposed into two parts: one is the normal force ![]() $\boldsymbol {F}^n$ in which the pressure component dominates, the other is the tangential force

$\boldsymbol {F}^n$ in which the pressure component dominates, the other is the tangential force ![]() $\boldsymbol {F}^{\tau }$ which comes from the viscous effects. These forces are defined as

$\boldsymbol {F}^{\tau }$ which comes from the viscous effects. These forces are defined as

where ![]() ${\boldsymbol{\mathsf{I}}}$ is the unit tensor,

${\boldsymbol{\mathsf{I}}}$ is the unit tensor, ![]() ${\boldsymbol{\mathsf{T}}}$ the viscous stress tensor,

${\boldsymbol{\mathsf{T}}}$ the viscous stress tensor, ![]() $\boldsymbol {\tau }$ the unit tangential vector,

$\boldsymbol {\tau }$ the unit tangential vector, ![]() $\boldsymbol {n}$ the unit normal vector and

$\boldsymbol {n}$ the unit normal vector and ![]() $[~]$ denotes the jump in a quantity across the immersed boundary. The system experiences a fluid drag in the

$[~]$ denotes the jump in a quantity across the immersed boundary. The system experiences a fluid drag in the ![]() $y$ direction, i.e

$y$ direction, i.e ![]() $-F_y = -(F_y^n + F_y^{\tau })$. Thus, the corresponding time-averaged drag coefficients are defined as

$-F_y = -(F_y^n + F_y^{\tau })$. Thus, the corresponding time-averaged drag coefficients are defined as ![]() $C_d=-\langle F_y \rangle /\frac {1}{2}\rho U^2D$,

$C_d=-\langle F_y \rangle /\frac {1}{2}\rho U^2D$, ![]() $C_d^{n}=-\langle F_y^n \rangle /\frac {1}{2}\rho U^2D$ and

$C_d^{n}=-\langle F_y^n \rangle /\frac {1}{2}\rho U^2D$ and ![]() $C_d^{\tau }=-\langle F_y^{\tau } \rangle /\frac {1}{2}\rho U^2D$, respectively. Figure 7(

$C_d^{\tau }=-\langle F_y^{\tau } \rangle /\frac {1}{2}\rho U^2D$, respectively. Figure 7(![]() $a$) shows the fluid drag curves versus

$a$) shows the fluid drag curves versus ![]() $Lr$ at different

$Lr$ at different ![]() $Re$ for the overall system. Here the drag is normalized by that for the bare plate scenario. It is seen that the drag curves show two distinct tendencies depending on the

$Re$ for the overall system. Here the drag is normalized by that for the bare plate scenario. It is seen that the drag curves show two distinct tendencies depending on the ![]() $Re$. For the flow at a low Reynolds number (say

$Re$. For the flow at a low Reynolds number (say ![]() $Re=10$ or 25), the drag almost monotonically increases with the increase of

$Re=10$ or 25), the drag almost monotonically increases with the increase of ![]() $Lr$. For the higher Reynolds flow (e.g. cases with

$Lr$. For the higher Reynolds flow (e.g. cases with ![]() $Re\ge 50$), the drag first decreases from

$Re\ge 50$), the drag first decreases from ![]() $C_d/C_{d,Lr=1}=1$ as

$C_d/C_{d,Lr=1}=1$ as ![]() $Lr$ increases, and reaches a local minimum at

$Lr$ increases, and reaches a local minimum at ![]() $Lr=Lr_{c,{min}}$. After that, the drag curve shows a sharp rise until the second threshold at

$Lr=Lr_{c,{min}}$. After that, the drag curve shows a sharp rise until the second threshold at ![]() $Lr=Lr_{c,{max}}$, where the system experiences a local maximum drag. When

$Lr=Lr_{c,{max}}$, where the system experiences a local maximum drag. When ![]() $Lr>Lr_{c,{max}}$, the fluid drag generally shows a slow decline as

$Lr>Lr_{c,{max}}$, the fluid drag generally shows a slow decline as ![]() $Lr$ increases. Moreover, we denote the

$Lr$ increases. Moreover, we denote the ![]() $Lr_{c,{min}}$ (or

$Lr_{c,{min}}$ (or ![]() $Lr_{c,{max}}$) trajectory in the

$Lr_{c,{max}}$) trajectory in the ![]() $Lr\unicode{x2013}Re$ plane, as shown in figure 6. It is found that the emergencies of local minimum (or maximum) drags at

$Lr\unicode{x2013}Re$ plane, as shown in figure 6. It is found that the emergencies of local minimum (or maximum) drags at ![]() $L_{c,{min}} \in [1.8, 2]$ (or

$L_{c,{min}} \in [1.8, 2]$ (or ![]() $L_{c,{max}} \in [3.5, 4]$) are often accompanied by the system state transitions. Furthermore, it is interesting to note that benefiting from the passive flow control by using the trailing filament as a deformable afterbody, the system may experience a counterintuitive reduction in fluid drag, corresponding to the scenarios within the grey region (

$L_{c,{max}} \in [3.5, 4]$) are often accompanied by the system state transitions. Furthermore, it is interesting to note that benefiting from the passive flow control by using the trailing filament as a deformable afterbody, the system may experience a counterintuitive reduction in fluid drag, corresponding to the scenarios within the grey region (![]() $C_d/C_{d, Lr=1}<1$) marked in figure 7(

$C_d/C_{d, Lr=1}<1$) marked in figure 7(![]() $a$). Compared with the bare plate, the system enjoys a dramatic drag reduction (up to approximately

$a$). Compared with the bare plate, the system enjoys a dramatic drag reduction (up to approximately ![]() $22\,\%$) at

$22\,\%$) at ![]() $Lr \approx L_{c,{min}}$ for

$Lr \approx L_{c,{min}}$ for ![]() $Re\ge 50$. The considerable reductions in drag are also observed for cases with large

$Re\ge 50$. The considerable reductions in drag are also observed for cases with large ![]() $Lr$ and high

$Lr$ and high ![]() $Re$, e.g.

$Re$, e.g. ![]() $Lr>5$ and

$Lr>5$ and ![]() $Re\geqslant 400$. As shown in figure 6, we denote the drag reduction region (DRR) in the

$Re\geqslant 400$. As shown in figure 6, we denote the drag reduction region (DRR) in the ![]() $Lr\unicode{x2013}Re$ phase plane for the overall system. The critical value of

$Lr\unicode{x2013}Re$ phase plane for the overall system. The critical value of ![]() $Re$, i.e.

$Re$, i.e. ![]() $Re_c$, separating the DRR and drag increase region (DIR) generally depends on

$Re_c$, separating the DRR and drag increase region (DIR) generally depends on ![]() $Lr$. Specifically,

$Lr$. Specifically, ![]() $Re_{c} \in (25,50)$ for

$Re_{c} \in (25,50)$ for ![]() $1\leq Lr\leq 2$ while

$1\leq Lr\leq 2$ while ![]() $Re_{c} \in (100,200)$ for

$Re_{c} \in (100,200)$ for ![]() $4\leq Lr\leq 10$;

$4\leq Lr\leq 10$; ![]() $Re_c$ increases as the increase of

$Re_c$ increases as the increase of ![]() $Lr$ for

$Lr$ for ![]() $2< Lr<4$. The DDR almost covers the region with

$2< Lr<4$. The DDR almost covers the region with ![]() $Re>Re_{c}$ except for the cases with

$Re>Re_{c}$ except for the cases with ![]() $Re=800$,

$Re=800$, ![]() $Lr=1.1$ and 1.3. Compared with the experiment (Gao et al. Reference Gao, Pan, Wang and Tian2020) with a higher

$Lr=1.1$ and 1.3. Compared with the experiment (Gao et al. Reference Gao, Pan, Wang and Tian2020) with a higher ![]() $Re \sim 2700\unicode{x2013}5500$, our simulations also show that the counterintuitive drag reduction due to the flow-induced reconfiguration of filament may arise in the low-moderate

$Re \sim 2700\unicode{x2013}5500$, our simulations also show that the counterintuitive drag reduction due to the flow-induced reconfiguration of filament may arise in the low-moderate ![]() $Re$ (

$Re$ (![]() $\sim 10\unicode{x2013}10^3$) flow region. The experimental data from Gao et al. (Reference Gao, Pan, Wang and Tian2020) with

$\sim 10\unicode{x2013}10^3$) flow region. The experimental data from Gao et al. (Reference Gao, Pan, Wang and Tian2020) with ![]() $Re=4400$ which is based on the speed of uniform inflow

$Re=4400$ which is based on the speed of uniform inflow ![]() $U_{\infty }=1.54$ m s

$U_{\infty }=1.54$ m s![]() $^{-1}$ are plotted in figure 7(

$^{-1}$ are plotted in figure 7(![]() $a$). It is worth noting that, although the numerical results are not in perfect agreement with the experimental data (which to some extent is expected given the higher

$a$). It is worth noting that, although the numerical results are not in perfect agreement with the experimental data (which to some extent is expected given the higher ![]() $Re$ flow in the soap film experiments), similar trends in drag variation have been found in the experiments and present simulations; in particular, the

$Re$ flow in the soap film experiments), similar trends in drag variation have been found in the experiments and present simulations; in particular, the ![]() $Lr_{c,{min}}$ (or

$Lr_{c,{min}}$ (or ![]() $Lr_{c,{max}}$) obtained from the experiment is very close to that from the simulations with

$Lr_{c,{max}}$) obtained from the experiment is very close to that from the simulations with ![]() $Re\ge 400$ (see figure 7

$Re\ge 400$ (see figure 7![]() $a$). The experimental and numerical results have shown together that this kind of device, referred to as a ‘flexible coating’, may have a high level of adaptability and effectiveness for the flow control for reducing drag of the bluff body in a flow.

$a$). The experimental and numerical results have shown together that this kind of device, referred to as a ‘flexible coating’, may have a high level of adaptability and effectiveness for the flow control for reducing drag of the bluff body in a flow.

Figure 7. (![]() $a$) Fluid drag acting on the coupled system normalized by the drag of the isolated rigid plate, i.e.

$a$) Fluid drag acting on the coupled system normalized by the drag of the isolated rigid plate, i.e. ![]() $C_d/C_{d,Lr=1}$ as functions of

$C_d/C_{d,Lr=1}$ as functions of ![]() $Lr$ for various

$Lr$ for various ![]() $Re$. The drag for the system can be decomposed into two parts, i.e. the tangential one

$Re$. The drag for the system can be decomposed into two parts, i.e. the tangential one ![]() $C_d^{\tau }/C_{d,Lr=1}$ (

$C_d^{\tau }/C_{d,Lr=1}$ (![]() $b$) which comes from the viscous effects, and the normal one

$b$) which comes from the viscous effects, and the normal one ![]() $C_d^{n}/C_{d,Lr=1}$ (

$C_d^{n}/C_{d,Lr=1}$ (![]() $c$) in which the pressure component dominates. Inset:

$c$) in which the pressure component dominates. Inset: ![]() $C_d^{n}/C_{d,Lr=1}$ for the rigid plate (

$C_d^{n}/C_{d,Lr=1}$ for the rigid plate (![]() $c1$) and the flexible filament (

$c1$) and the flexible filament (![]() $c2$), respectively. For the overall system,

$c2$), respectively. For the overall system, ![]() $C_d/C_{d,Lr=1}<1$ corresponds to the drag reduction scenarios, which is located in the grey region in figure 7(

$C_d/C_{d,Lr=1}<1$ corresponds to the drag reduction scenarios, which is located in the grey region in figure 7(![]() $a$). Also, the experimental data (Gao et al. Reference Gao, Pan, Wang and Tian2020) with

$a$). Also, the experimental data (Gao et al. Reference Gao, Pan, Wang and Tian2020) with ![]() $Re=4400$, which is based on the speed of uniform inflow

$Re=4400$, which is based on the speed of uniform inflow ![]() $U_{\infty }=1.54$ m s

$U_{\infty }=1.54$ m s![]() $^{-1}$, are plotted in figure 7(

$^{-1}$, are plotted in figure 7(![]() $a$).

$a$).

Further, the drag-reducing effect by using a flexible afterbody is compared with that using a rigid one for the typical cases as listed in table 1. The geometry of a rigid afterbody is represented by the time-averaged shape of a flexible one with identical ![]() $Lr$. It is found that for the cases with