1. Introduction

Vortex rings are ubiquitous across many scales, playing key roles in systems such as starting jets for propulsion (Krueger & Gharib Reference Krueger and Gharib2003), aquatic locomotion in organisms such as fish (Akanyeti et al. Reference Akanyeti, Putney, Yanagitsuru, Lauder, Stewart and Liao2017), squid (Gosline & Demont Reference Gosline and Demont1985; Anderson & DeMont Reference Anderson and DeMont2000; Bartol et al. Reference Bartol, Krueger, Stewart and Thompson2009), salps (Linden & Turner Reference Linden and Turner2004) and jellyfish (Ichikawa & Mochizuki Reference Ichikawa and Mochizuki2008; Dabiri Reference Dabiri2009; Costello et al. Reference Costello, Colin, Dabiri, Gemmell, Lucas and Sutherland2021; Gemmell et al. Reference Gemmell, Du Clos, Colin, Sutherland and Costello2021). They are also seen in respiratory flows such as coughing (Simha & Rao Reference Simha and Rao2020), and cardiac flows in the left ventricle (Pierrakos & Vlachos Reference Pierrakos and Vlachos2006). A distinguishing feature of many of these systems is that fluid is pushed out of a flexible structure which is linked to high efficiency due to the interaction of the flexible structure with the surrounding fluid (Wang et al. Reference Wang, Tang and Zhang2022). Dabiri (Reference Dabiri2009) proposed that flexible living structures, such as those found in marine animals and the heart, operate under optimal conditions of vortex formation, making them highly efficient. Therefore, understanding the dynamics and formation of isolated vortex rings generated from flexible structures could provide further insight into engineering higher efficiency systems that leverage this phenomenon.

Vortex rings are typically generated in experiments by expelling fluid through a sharp-edged nozzle or orifice into another larger body of fluid using a piston. The formation process of vortex rings from rigid nozzles has been well studied. Didden (Reference Didden1979) identified several key parameters governing vortex ring formation, including the nozzle diameter (

![]() $D$

), the piston stroke length (

$D$

), the piston stroke length (

![]() $L$

) and the velocity history of the piston motion

$L$

) and the velocity history of the piston motion

![]() $U_p(t)$

. For short piston stroke to diameter ratios

$U_p(t)$

. For short piston stroke to diameter ratios

![]() ${L}/{D}={U_{p}(t) t}/{D}$

, a single vortex ring forms, entraining all the expelled fluid given an impulsive piston motion. Gharib et al. (Reference Gharib, Rambod and Shariff1998) identified a limiting stroke ratio (

${L}/{D}={U_{p}(t) t}/{D}$

, a single vortex ring forms, entraining all the expelled fluid given an impulsive piston motion. Gharib et al. (Reference Gharib, Rambod and Shariff1998) identified a limiting stroke ratio (

![]() ${L}/{D}$

) ranging from 3.6 to 4.5 below which a single vortex ring is formed, and any larger stroke ratio results in additional expelled fluid forming a trailing jet behind the vortex ring, making it a limited process. Further studies have shown that different nozzle geometries and velocity flow profiles can alter the critical

${L}/{D}$

) ranging from 3.6 to 4.5 below which a single vortex ring is formed, and any larger stroke ratio results in additional expelled fluid forming a trailing jet behind the vortex ring, making it a limited process. Further studies have shown that different nozzle geometries and velocity flow profiles can alter the critical

![]() ${L}/{D}$

value at which a vortex ring will pinch-off and no longer gain circulation (Gharib et al. Reference Gharib, Rambod and Shariff1998; Dabiri & Gharib Reference Dabiri and Gharib2005; Krieg & Mohseni Reference Krieg and Mohseni2021). Dabiri & Gharib (Reference Dabiri and Gharib2005) demonstrated that by forcing a circular nozzle exit to reduce in area as fluid was being expelled, vortex ring pinch-off could be delayed until

${L}/{D}$

value at which a vortex ring will pinch-off and no longer gain circulation (Gharib et al. Reference Gharib, Rambod and Shariff1998; Dabiri & Gharib Reference Dabiri and Gharib2005; Krieg & Mohseni Reference Krieg and Mohseni2021). Dabiri & Gharib (Reference Dabiri and Gharib2005) demonstrated that by forcing a circular nozzle exit to reduce in area as fluid was being expelled, vortex ring pinch-off could be delayed until

![]() ${L}/{D}\approx {}8$

, due to changes in the output velocity and shear layer development. Similarly, Limbourg & Nedić (Reference Limbourg and Nedić2021c

) showed that the formation process for orifice-generated vortex rings differs from those produced by a nozzle due to geometrical effects. Limbourg & Nedić (Reference Limbourg and Nedić2021a

) and Limbourg & Nedić (Reference Limbourg and Nedić2021b

) provided a correction to the traditional slug flow model to account for contraction effects at an orifice outlet, which can predict formation times that are consistent with observations for nozzle geometries. Krieg & Mohseni (Reference Krieg and Mohseni2021) found that pinch-off is determined by the characteristic velocity of the vortex ring relative to the feeding velocity of the liquid. Similar to Dabiri & Gharib (Reference Dabiri and Gharib2005), Krieg & Mohseni (Reference Krieg and Mohseni2021) showed that vortex ring pinch-off could be delayed up to a value of

${L}/{D}\approx {}8$

, due to changes in the output velocity and shear layer development. Similarly, Limbourg & Nedić (Reference Limbourg and Nedić2021c

) showed that the formation process for orifice-generated vortex rings differs from those produced by a nozzle due to geometrical effects. Limbourg & Nedić (Reference Limbourg and Nedić2021a

) and Limbourg & Nedić (Reference Limbourg and Nedić2021b

) provided a correction to the traditional slug flow model to account for contraction effects at an orifice outlet, which can predict formation times that are consistent with observations for nozzle geometries. Krieg & Mohseni (Reference Krieg and Mohseni2021) found that pinch-off is determined by the characteristic velocity of the vortex ring relative to the feeding velocity of the liquid. Similar to Dabiri & Gharib (Reference Dabiri and Gharib2005), Krieg & Mohseni (Reference Krieg and Mohseni2021) showed that vortex ring pinch-off could be delayed up to a value of

![]() $t^*\approx {}8$

for a continually accelerating feeding velocity so that the vortex ring could not outpace the feeding source. Their work provided valuable insights into predicting pinch-off timing under time varying output velocity programs.

$t^*\approx {}8$

for a continually accelerating feeding velocity so that the vortex ring could not outpace the feeding source. Their work provided valuable insights into predicting pinch-off timing under time varying output velocity programs.

Hydrodynamic impulse can be used to quantify the fluid thrust generated by a vortex ring, which is the summation of fluid impulse from the change in fluid inertia and fluid pressure (Saffman Reference Saffman1993). The total thrust supplied by a starting jet is primarily controlled by the momentum flux, and secondarily by the pressure change at the nozzle exit. The change in momentum flux is directly affected by the vortex generator as it is the integration of

![]() $\rho _{f}U_{e}^2$

, where

$\rho _{f}U_{e}^2$

, where

![]() $U_{e}$

is the fluid velocity distributed across the nozzle exit being produced by the pump or propeller and

$U_{e}$

is the fluid velocity distributed across the nozzle exit being produced by the pump or propeller and

![]() $\rho_{f}$

is the fluid density. For a rigid nozzle, this cannot be easily altered without changing the input to the system from the vortex generator. However, the pressure change,

$\rho_{f}$

is the fluid density. For a rigid nozzle, this cannot be easily altered without changing the input to the system from the vortex generator. However, the pressure change,

![]() $p - p_{\infty }$

, where

$p - p_{\infty }$

, where

![]() $p_{\infty }$

is the ambient fluid pressure, is affected by several factors including the fluid acceleration, nozzle geometry and duration of the velocity being expelled (Krueger & Gharib Reference Krueger and Gharib2003; Krieg & Mohseni Reference Krieg and Mohseni2013; Gao et al. Reference Gao, Wang, Yu and Chyu2020; Limbourg & Nedić Reference Limbourg and Nedić2021c

). These factors are all closely related to the vortex ring formation process, and help describe the increase in impulse by forming a single vortex ring. It was determined that the maximum thrust normalised by momentum flux could be achieved at

$p_{\infty }$

is the ambient fluid pressure, is affected by several factors including the fluid acceleration, nozzle geometry and duration of the velocity being expelled (Krueger & Gharib Reference Krueger and Gharib2003; Krieg & Mohseni Reference Krieg and Mohseni2013; Gao et al. Reference Gao, Wang, Yu and Chyu2020; Limbourg & Nedić Reference Limbourg and Nedić2021c

). These factors are all closely related to the vortex ring formation process, and help describe the increase in impulse by forming a single vortex ring. It was determined that the maximum thrust normalised by momentum flux could be achieved at

![]() $t^* \approx {} 4$

, for an impulsively started piston, due to the increase in pressure rise at the nozzle exit when a vortex ring pinches off (Krueger & Gharib Reference Krueger and Gharib2003). This effect has been shown to be magnified for orifice geometries due to the radial component of velocity at the edge of an orifice which is negligible in the case of a nozzle (Krieg & Mohseni Reference Krieg and Mohseni2013; Limbourg & Nedić Reference Limbourg and Nedić2021c

). Notably, thrust can also be increased with a faster fluid acceleration for the same

$t^* \approx {} 4$

, for an impulsively started piston, due to the increase in pressure rise at the nozzle exit when a vortex ring pinches off (Krueger & Gharib Reference Krueger and Gharib2003). This effect has been shown to be magnified for orifice geometries due to the radial component of velocity at the edge of an orifice which is negligible in the case of a nozzle (Krieg & Mohseni Reference Krieg and Mohseni2013; Limbourg & Nedić Reference Limbourg and Nedić2021c

). Notably, thrust can also be increased with a faster fluid acceleration for the same

![]() $t^*$

value, as would be expected based on the increased fluid momentum (Krueger & Gharib Reference Krueger and Gharib2003). Gao et al. (Reference Gao, Wang, Yu and Chyu2020) stated that the total impulse depends on the fluid deceleration as well, which can create a stopping vortex near the nozzle exit which favourably contributes to the pressure impulse. Additionally, Yin & Gad-El-Hak (Reference Yin and Gad-El-Hak2021) demonstrated that, for a pumping jet style propeller, refilling the body creates positive momentum and a stopping vortex within the body cavity.

$t^*$

value, as would be expected based on the increased fluid momentum (Krueger & Gharib Reference Krueger and Gharib2003). Gao et al. (Reference Gao, Wang, Yu and Chyu2020) stated that the total impulse depends on the fluid deceleration as well, which can create a stopping vortex near the nozzle exit which favourably contributes to the pressure impulse. Additionally, Yin & Gad-El-Hak (Reference Yin and Gad-El-Hak2021) demonstrated that, for a pumping jet style propeller, refilling the body creates positive momentum and a stopping vortex within the body cavity.

When applied to aquatic vehicles, it has been demonstrated that pulsed jet propulsion can achieve a much higher efficiency compared with steady-state jets of equivalent volume. The benefits stem from the added mass and entrainment effects from forming a series of vortex rings, which depends on formation length, fluid acceleration and Reynolds number (Siekmann Reference Siekmann1963; Krueger & Gharib Reference Krueger and Gharib2005; Dabiri Reference Dabiri2009; Moslemi & Krueger Reference Moslemi and Krueger2010, Reference Moslemi and Krueger2011; Bujard et al. Reference Bujard, Giorgio-Serchi and Weymouth2021; Baskaran & Mulleners Reference Baskaran and Mulleners2022). The increase in efficiency associated with creating sequences of vortex rings is due to a combination of increased pressure impulse per pulse as well as the interactions of each pulse with one another (Krueger & Gharib Reference Krueger and Gharib2005). However, Qin et al. (Reference Qin, Liu and Xiang2018) showed the vortex–vortex interactions of a pulsed jet could either increase circulation by as much as 10 % or reduce it by 20 % depending on the spacing of each vortex ring with one another. For instance, Xu & Dabiri (Reference Xu and Dabiri2020) showed that controlling contraction frequencies in jellyfish with micro-controllers could triple their swimming speed, while only creating a twofold increase in cost of transport, likely due to beneficial vortex interactions. In general, jet powered aquatic robotics show promise in that the impulsive motion of a starting jet can provide thrust almost instantaneously compared with several seconds for a traditional propeller to reach the desired thrust (Krieg & Mohseni Reference Krieg and Mohseni2013). This type of propulsion can enable low speed manoeuvring such as sideways translation, zero radius turns (yaw), all because there is no external fluid manipulator simply an internal jetting cavity (Krieg & Mohseni Reference Krieg and Mohseni2013). Although there are many achievements in terms of jet propelled robotics, there is limited research into the effect of utilising flexible structures to increase efficiency and maximise thrust per pulse from these types of aquatic vehicles.

Jellyfish and squid have been shown to be among the most efficient swimmers, attributed to their flexible, deformable bodies creating desirable movement kinematics (Costello et al. Reference Costello, Colin, Dabiri, Gemmell, Lucas and Sutherland2021). Jellyfish locomotion encompasses three parts: suction thrust during contraction, passive energy recapture during relaxation and a wall effect created by the interaction with counter rotating vortices left in their wake (Gemmell et al. Reference Gemmell, Du Clos, Colin, Sutherland and Costello2021). Squid exhibit similar swimming kinematics as well. Anderson et al. (2001) showed that squid utilise two distinct modes of locomotion, alternating between small bursts of fluid that create individual vortex rings, and larger jets that generate multiple vortex structures at the expense of efficiency for additional force. Xiaobo et al. (Reference Xiaobo, Wei, Qiang and Jun2021) numerically demonstrated that in the case of a soft bodied jet propulsor, with geometry similar to a squid, sucking liquid into the body has the same effect as pushing water out by increasing positive momentum within the body, which is likely related to a squid’s swimming efficiency. Numerical simulations of jellyfish revealed that synchronising contractions with the natural wave speed of the bell margin results in a maximum in thrust efficiency, related to the resonant frequency of varied stiffness bodies (Hoover et al. Reference Hoover, Xu, Gemmell, Colin, Costello, Dabiri and Miller2021).

The impact of employing flexible flaps and hinges to manipulate the flow produced by starting jets has been studied as well. Many nature-inspired researchers have shown that a specific amount of flexibility enhances thrust generation or efficiency in terms of a flapping wing or fin model (Kang et al. Reference Kang, Aono, Cesnik and Shyy2011; Marais et al. Reference Marais, Thiria, Wesfreid and Godoy-Diana2012; Dewey et al. Reference Dewey, Boschitsch, Moored, Stone and Smits2013; Park et al. Reference Park, Park, Lee, Cho and Choi2016; Medina & Kan Reference Medina and Kan2018; David et al. Reference David, Govardhan and Arakeri2019; Leroy-Calatayud et al. Reference Leroy-Calatayud, Pezzulla, Mulleners, Keiser and Reis2021; Li et al. Reference Li, Jaiman and Khoo2021). All of these studies indicate that a specific level of flexibility increases thrust production or power efficiency in flapping wing or fin models, attributed to the alignment of shed vortices and surface deformations. However, the number of studies relating flexibility to thrust generation from a starting jet is still somewhat lacking, with most findings showing that indefinitely decreasing stiffness increases thrust efficiency. Das et al. (Reference Das, Govardhan and Arakeri2018) showed that flexible flaps installed at the outlet of a rectangular channel could amplify fluid impulse by a factor of two while utilising the same energy input, due to rearrangement of vorticity of the jet. Jung et al. (Reference Jung, Song and Kim2021) demonstrated that by using everting flexible elastic sheets at a nozzle exit, the fluid impulse of a jet could be enhanced by as much as 14 times, with increased bending rigidity of the sheets.

Studies of flow within a flexible tube have been investigated, but with very limited application to jet or vortex flows. The majority of studies focus on flexible tubes with rigid circular supports at either end (Lin & Morgan Reference Lin and Morgan1956; Kraus Reference Kraus1967; Païdoussis Reference Païdoussis1998). Through the use of shell theory coupled with hydrodynamic equations, the natural frequency and vibration mode of a submerged cylindrical shell can be predicted (Kraus Reference Kraus1967). The hydrodynamics and inertial effects within the thin shell significantly alter the frequency and mode shapes resulting from the thin shell, but this can be accounted for using a mass and speed ratio relation of the shell and the fluid (Païdoussis Reference Païdoussis1998). Additionally, the length to radius ratio (

![]() $L/R$

) and wall thickness to radius ratio (

$L/R$

) and wall thickness to radius ratio (

![]() $h/R$

) have a large impact on the stability on the resulting deformations relative to the velocity of the fluid being expelled (Paak et al. Reference Paak, Païdoussis and Misra2014). Specifically, Paak et al. (Reference Paak, Païdoussis and Misra2014) showed that, for clamped–free boundary conditions, the output velocity can excite periodic, multi-mode or chaotic vibration depending on the velocity ratio

$h/R$

) have a large impact on the stability on the resulting deformations relative to the velocity of the fluid being expelled (Paak et al. Reference Paak, Païdoussis and Misra2014). Specifically, Paak et al. (Reference Paak, Païdoussis and Misra2014) showed that, for clamped–free boundary conditions, the output velocity can excite periodic, multi-mode or chaotic vibration depending on the velocity ratio

![]() $U=u_b/c_s$

, where

$U=u_b/c_s$

, where

![]() $u_b$

is the bulk fluid velocity and

$u_b$

is the bulk fluid velocity and

![]() $c_s$

is the wave speed on the cylinder surface. Choi & Park (Reference Choi and Park2022) found that there is an optimal stiffness for a circular nozzle to maximise thrust for jet flows, rather than indefinitely increased thrust for a decreased stiffness. Their work derived an optimal flexibility condition, relating the stiffness of the nozzle to the acceleration of the fluid being expelled. In a subsequent study, their work showed that these concepts could be applied with single pulsed jet flows (Choi & Park Reference Choi and Park2024). However, these concepts have yet to be analysed with respect to the wake formation of single vortex rings to maximise pressure impulse and thus ejected volume. Additionally, the effect of stopping vortices has not yet been accounted for in these models in terms of finding an optimal stiffness relative to the fluid generation apparatus.

$c_s$

is the wave speed on the cylinder surface. Choi & Park (Reference Choi and Park2022) found that there is an optimal stiffness for a circular nozzle to maximise thrust for jet flows, rather than indefinitely increased thrust for a decreased stiffness. Their work derived an optimal flexibility condition, relating the stiffness of the nozzle to the acceleration of the fluid being expelled. In a subsequent study, their work showed that these concepts could be applied with single pulsed jet flows (Choi & Park Reference Choi and Park2024). However, these concepts have yet to be analysed with respect to the wake formation of single vortex rings to maximise pressure impulse and thus ejected volume. Additionally, the effect of stopping vortices has not yet been accounted for in these models in terms of finding an optimal stiffness relative to the fluid generation apparatus.

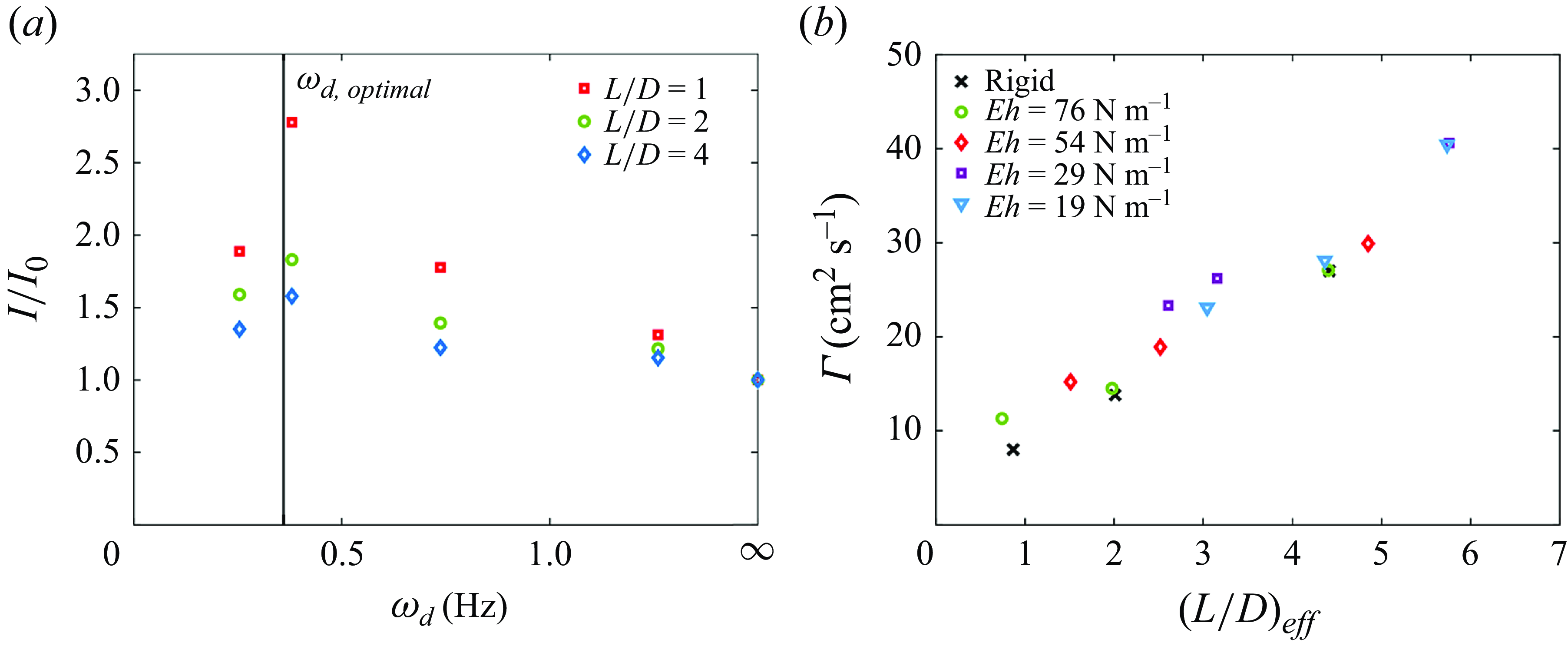

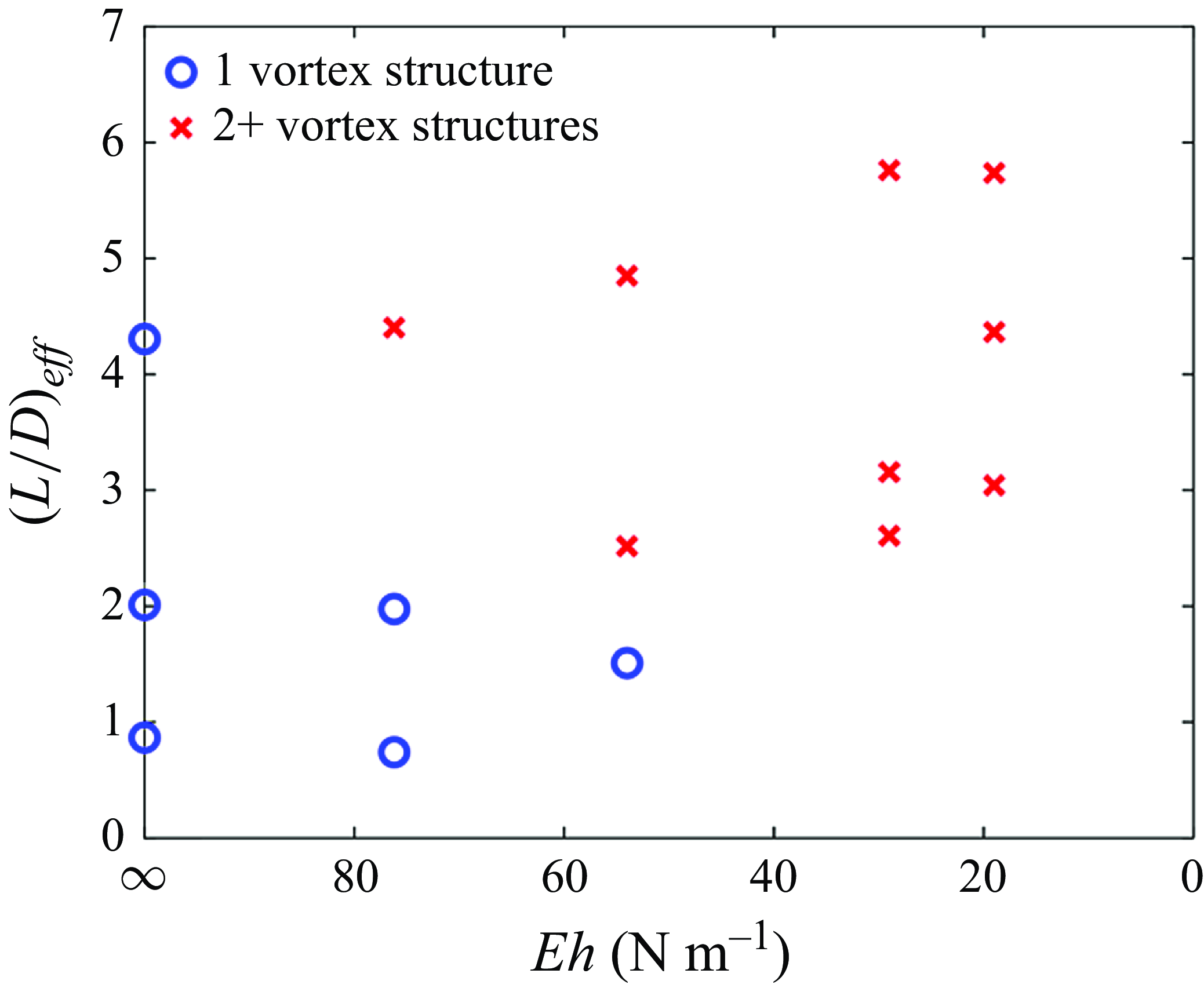

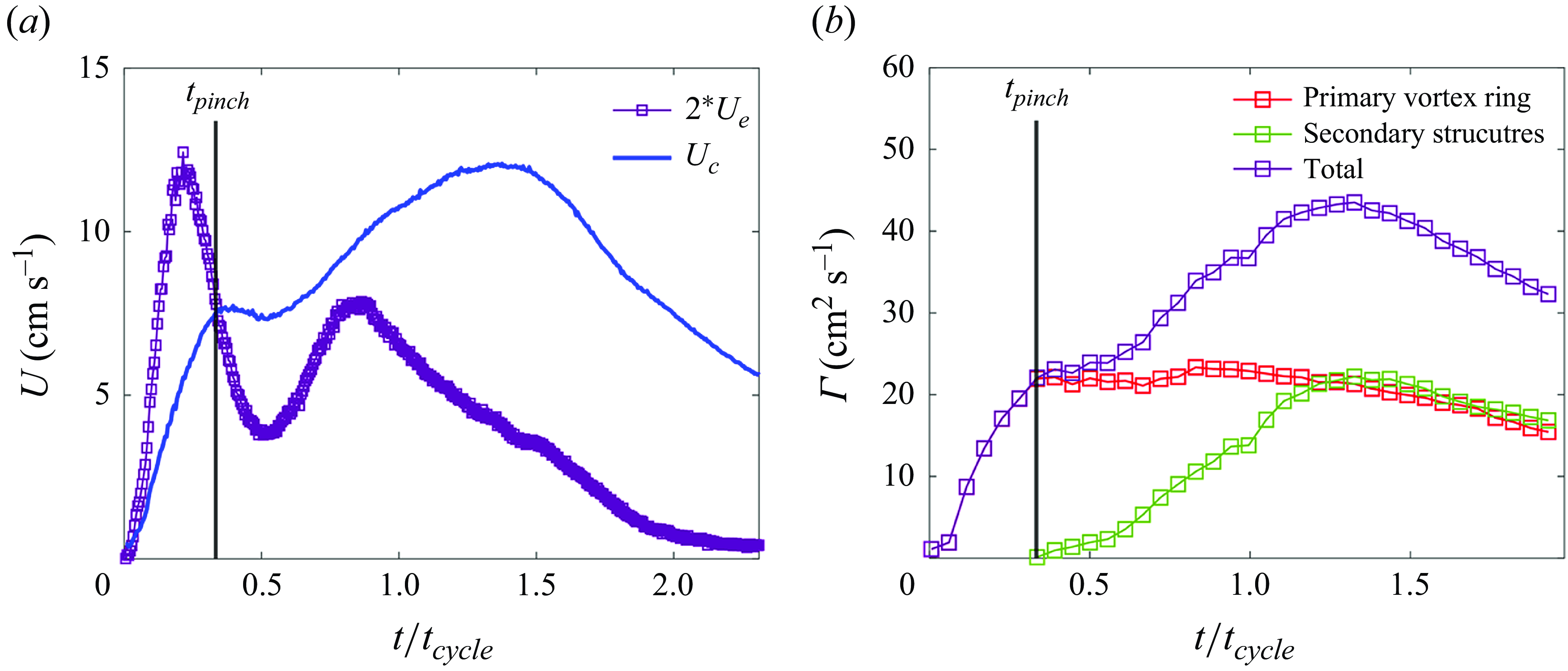

In this study, we experimentally investigate vortex ring formation through nozzles of varied flexibility, aiming to find the optimal nozzle stiffness (optimal condition) to maximise thrust (normalised hydrodynamic impulse) with a fixed kinematic input to the nozzle. A novel experimental method for determining the optimal nozzle stiffness condition for increased thrust based on the optimal timing condition given by Choi & Park (Reference Choi and Park2022, Reference Choi and Park2024) is proposed based on measured material properties for the flexible nozzles and their corresponding damped natural frequencies relative to the fluid acceleration in §§ 3.1 and 3.2. The measured circulation is related to the effective formation length (

![]() ${L}/{D}_{eff}$

) from the different nozzles of varied stiffness in § 3.2. In § 3.3, the vortices generated by the different flexible nozzles are studied using finite time Lypunov exponent (FTLE) fields to experimentally determine primary vortex ring pinch-off and verified by the predicted pinch-off time from the work of Krieg & Mohseni (Reference Krieg and Mohseni2021). The vorticity distribution between the primary vortex ring is delineated from the rest of the flow, and used to further understand the optimal conditions to maximise the normalised hydrodynamic impulse for the current flow characteristics. Lastly in § 3.4, particle image velocimetry is performed within the flexible nozzles to quantify the stopping vortex formed at the end of the nozzle deformations, which provides a fuller picture of the performance of these nozzles in a pulsed jet framework.

${L}/{D}_{eff}$

) from the different nozzles of varied stiffness in § 3.2. In § 3.3, the vortices generated by the different flexible nozzles are studied using finite time Lypunov exponent (FTLE) fields to experimentally determine primary vortex ring pinch-off and verified by the predicted pinch-off time from the work of Krieg & Mohseni (Reference Krieg and Mohseni2021). The vorticity distribution between the primary vortex ring is delineated from the rest of the flow, and used to further understand the optimal conditions to maximise the normalised hydrodynamic impulse for the current flow characteristics. Lastly in § 3.4, particle image velocimetry is performed within the flexible nozzles to quantify the stopping vortex formed at the end of the nozzle deformations, which provides a fuller picture of the performance of these nozzles in a pulsed jet framework.

2. Methods

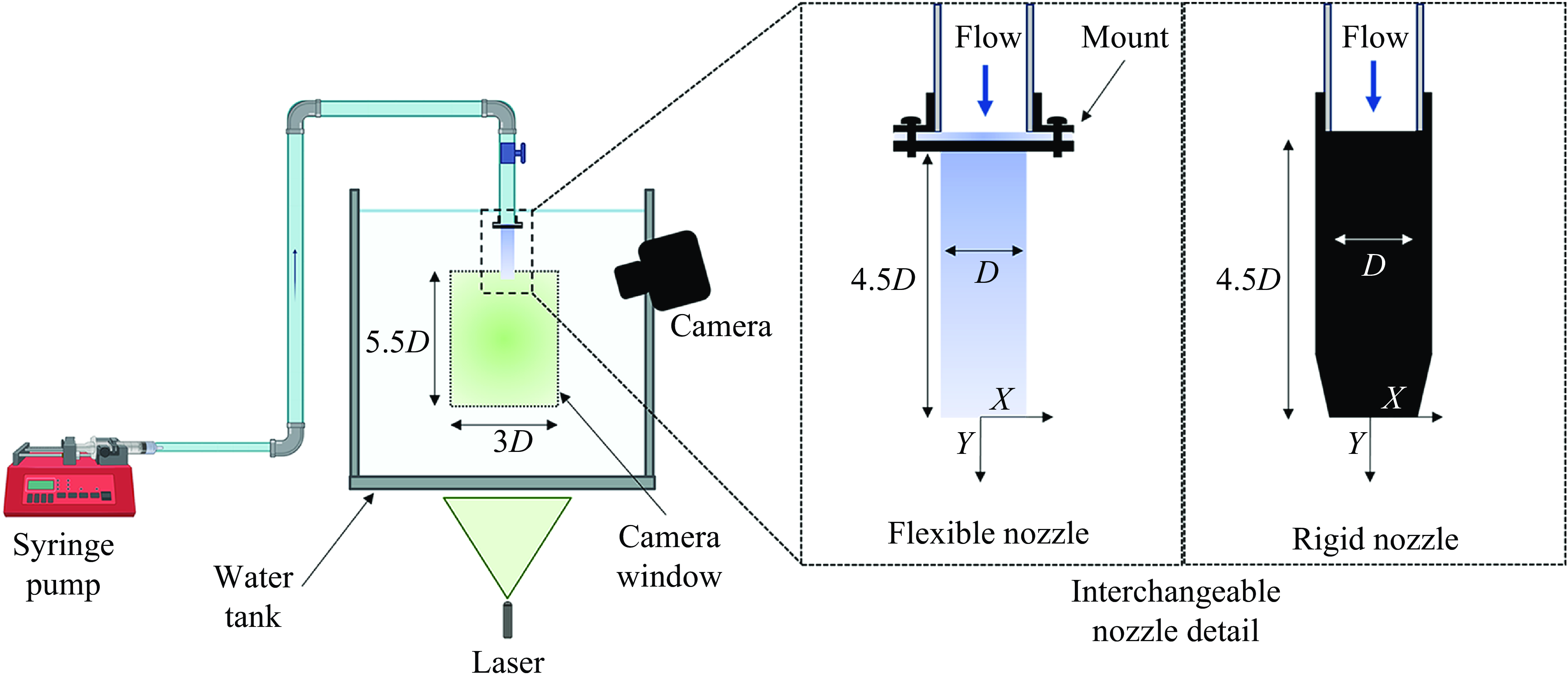

2.1. Experimental set-up

Experiments were conducted in a 46 cm

![]() $\times$

46 cm

$\times$

46 cm

![]() $\times$

46 cm free-surface water tank filled with water to a height of 41 cm. An Aladdin NE-1000 syringe pump was used to generate the vortex flows. A 140 ml Monoject syringe was connected to a 1′ SCH40 PVC pipe (inner diameter

$\times$

46 cm free-surface water tank filled with water to a height of 41 cm. An Aladdin NE-1000 syringe pump was used to generate the vortex flows. A 140 ml Monoject syringe was connected to a 1′ SCH40 PVC pipe (inner diameter

![]() $(ID)$

= 2.66 cm) with flexible tubing. Nozzles with diameter (

$(ID)$

= 2.66 cm) with flexible tubing. Nozzles with diameter (

![]() $D$

= 2.55 cm) and length (

$D$

= 2.55 cm) and length (

![]() $L_{nozzle} = 11.5$

cm) were installed at the end of the pipe to eject fluid downward in the centre of the tank, 14 cm below the water surface. Further description of the nozzle adapters will be discussed in § 2.2. A schematic of the experimental set-up is shown in figure 1. The origin of the coordinate system used for calculations and defining coordinate directions is defined by the centre of the nozzle exit with the positive

$L_{nozzle} = 11.5$

cm) were installed at the end of the pipe to eject fluid downward in the centre of the tank, 14 cm below the water surface. Further description of the nozzle adapters will be discussed in § 2.2. A schematic of the experimental set-up is shown in figure 1. The origin of the coordinate system used for calculations and defining coordinate directions is defined by the centre of the nozzle exit with the positive

![]() $Y$

direction oriented vertically downward in the flow direction, as shown in figure 1 nozzle detail.

$Y$

direction oriented vertically downward in the flow direction, as shown in figure 1 nozzle detail.

Figure 1. Schematic of the experimental set-up used for generating the vortex flows with NE-1000 Aladdin pump. A 1 mm thick laser sheet is used to illuminate a two-dimensional plane of the tank. Interchangeable nozzle detail is also shown for mounting the rigid and flexible nozzles.

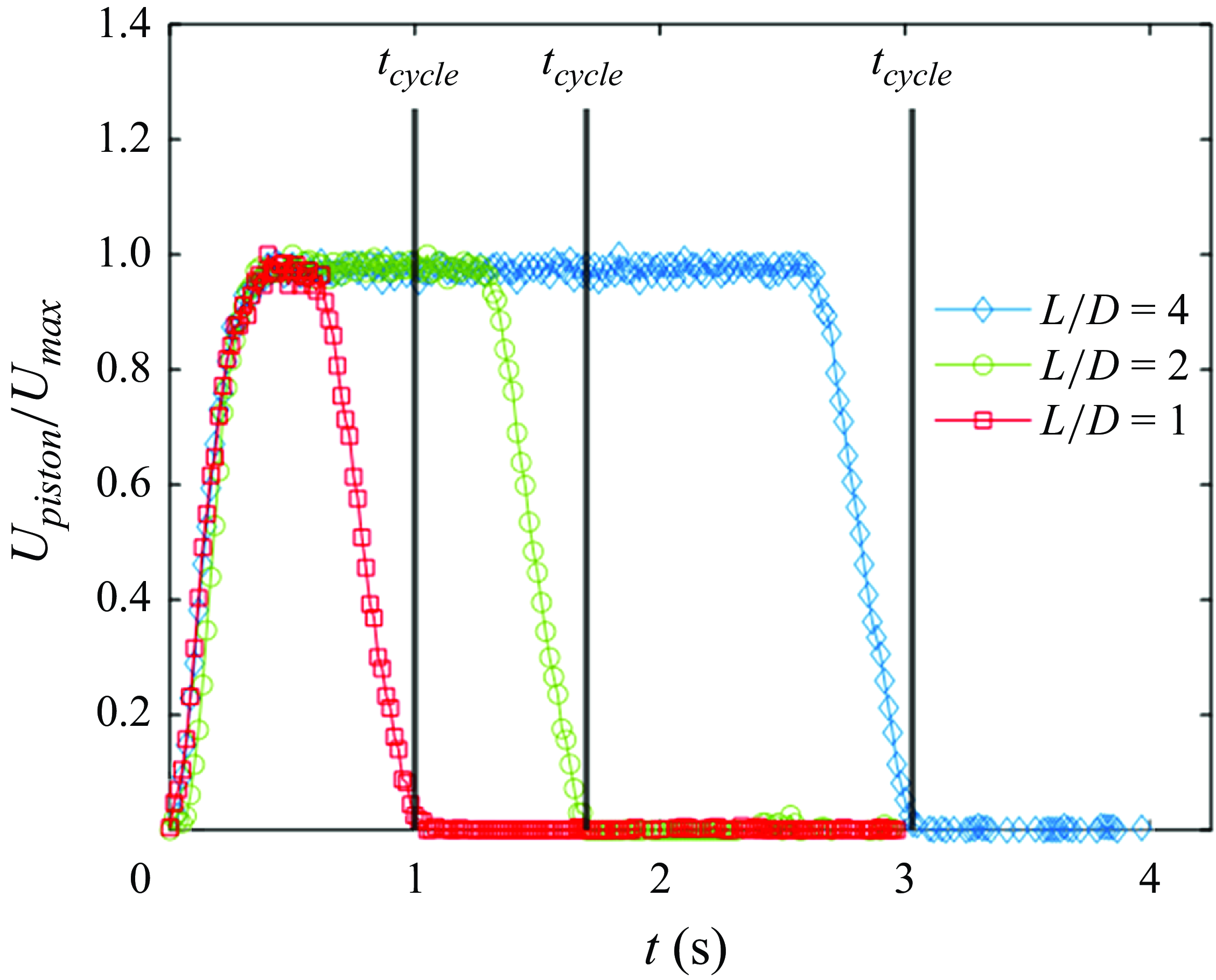

The syringe pump velocity profiles were defined using the Windows Command Prompt Program, in combination with an Excel spreadsheet to format the input data, to control the velocity (

![]() $U_{piston}$

) and duration (

$U_{piston}$

) and duration (

![]() $t_{cycle}$

) of the syringe piston motion. Three syringe piston velocity programs were selected corresponding to formation lengths,

$t_{cycle}$

) of the syringe piston motion. Three syringe piston velocity programs were selected corresponding to formation lengths,

![]() ${L}/{D} = \int _{0}^ {t_{cycle}}{U_{piston}(t)}/{D}{\rm d}t = 1,2, 4$

, ensuring the rigid nozzle would produce a single vortex ring with negligible trailing wake at the maximal ejected volume (Gharib et al. Reference Gharib, Rambod and Shariff1998). Each profile had an impulsively started piston motion measured at the syringe pump. The input diameter-based Reynolds Number (

${L}/{D} = \int _{0}^ {t_{cycle}}{U_{piston}(t)}/{D}{\rm d}t = 1,2, 4$

, ensuring the rigid nozzle would produce a single vortex ring with negligible trailing wake at the maximal ejected volume (Gharib et al. Reference Gharib, Rambod and Shariff1998). Each profile had an impulsively started piston motion measured at the syringe pump. The input diameter-based Reynolds Number (

![]() ${Re}_{D} = {U_{piston}{D_{piston}}}/{\nu }$

), where

${Re}_{D} = {U_{piston}{D_{piston}}}/{\nu }$

), where

![]() $\nu$

is the kinematic viscosity of room temperature water, was held constant at 1000. The programmed piston velocity profiles were verified by imaging the rear edge of the piston and tracking the displacement over time using an in-house MATLAB script. In brief, the tracking was accomplished by converting the videos to images, reducing each image to the area of interest, passing a Canny edge detection filter over the images, and binarising the images using a threshold value (Canny Reference Canny1986). Each piston velocity profile was imaged 5 times to ensure repeatability and was averaged over these trials and is plotted in figure 2. The mean steady-state piston velocity data for each

$\nu$

is the kinematic viscosity of room temperature water, was held constant at 1000. The programmed piston velocity profiles were verified by imaging the rear edge of the piston and tracking the displacement over time using an in-house MATLAB script. In brief, the tracking was accomplished by converting the videos to images, reducing each image to the area of interest, passing a Canny edge detection filter over the images, and binarising the images using a threshold value (Canny Reference Canny1986). Each piston velocity profile was imaged 5 times to ensure repeatability and was averaged over these trials and is plotted in figure 2. The mean steady-state piston velocity data for each

![]() ${L}/{D}$

is 1.68 cm s−1 with 95 % confidence interval of

${L}/{D}$

is 1.68 cm s−1 with 95 % confidence interval of

![]() $\pm 0.01$

cm s−1 from a one sample t test.

$\pm 0.01$

cm s−1 from a one sample t test.

Figure 2. Measured syringe pump piston velocity by syringe motion normalised by the programmed maximum velocity for the pump (

![]() $U_{max}$

).

$U_{max}$

).

2.2. Nozzle construction and characterisation

A rigid nozzle was 3D printed out of PLA plastic with a layer height of 0.03 mm. The rigid nozzle was manufactured to be the same length (

![]() $L_{nozzle}=11.5$

cm) as the flexible nozzles, with the only difference being a bevelled edge of 25 degrees at the exit. This nozzle design was selected to be consistent with previous studies in vortex ring literature (Gharib et al. Reference Gharib, Rambod and Shariff1998; Krueger & Gharib Reference Krueger and Gharib2003; Dabiri & Gharib Reference Dabiri and Gharib2005).

$L_{nozzle}=11.5$

cm) as the flexible nozzles, with the only difference being a bevelled edge of 25 degrees at the exit. This nozzle design was selected to be consistent with previous studies in vortex ring literature (Gharib et al. Reference Gharib, Rambod and Shariff1998; Krueger & Gharib Reference Krueger and Gharib2003; Dabiri & Gharib Reference Dabiri and Gharib2005).

The flexible nozzles were moulded from SmoothOn SortaClear 40A two-part liquid silicone. The selected nozzle construction method was adopted from Choi & Park (Reference Choi and Park2022), using a pour mould method over a 2.55 cm diameter (

![]() $D$

) aluminium rod press fit into a 3D printed base to create the mounting surface for the flexible nozzles. Figure 1 shows a complete flexible nozzle with the integrated mounting surface, and figure 3(a) shows an isometric view of the flexible nozzle geometry. After curing, the nozzles were cut to a length (

$D$

) aluminium rod press fit into a 3D printed base to create the mounting surface for the flexible nozzles. Figure 1 shows a complete flexible nozzle with the integrated mounting surface, and figure 3(a) shows an isometric view of the flexible nozzle geometry. After curing, the nozzles were cut to a length (

![]() $L_{nozzle}$

) of 11.5 cm measured from the top of the nozzle base to the edge of the nozzle exit, resulting in an aspect ratio (

$L_{nozzle}$

) of 11.5 cm measured from the top of the nozzle base to the edge of the nozzle exit, resulting in an aspect ratio (

![]() ${L_{nozzle}}/{D}$

) of 4.55. This aspect ratio was chosen to ensure all of the fluid ejected was initially contained within the nozzle. This is in contrast to Choi & Park (Reference Choi and Park2022, Reference Choi and Park2024), where a aspect ratio of 2 was used (ejected fluid slug not initially fully contained within flexible nozzle). The stiffness of the flexible nozzles was controlled by adding different mass percentages (

${L_{nozzle}}/{D}$

) of 4.55. This aspect ratio was chosen to ensure all of the fluid ejected was initially contained within the nozzle. This is in contrast to Choi & Park (Reference Choi and Park2022, Reference Choi and Park2024), where a aspect ratio of 2 was used (ejected fluid slug not initially fully contained within flexible nozzle). The stiffness of the flexible nozzles was controlled by adding different mass percentages (

![]() $\%ma = 15\,\% - 50\,\%$

) of SmoothOn silicone thinner relative to the base liquid silicone mixture.

$\%ma = 15\,\% - 50\,\%$

) of SmoothOn silicone thinner relative to the base liquid silicone mixture.

The flexible nozzles were mounted to the experimental set-up using a 3D printed part that clamped onto the base of the nozzle using bolts, shown in figure 1. This set-up was used to reduce stress concentrations from forming at the edges of the nozzle which could potentially affect the nozzle deformation behaviour. Additionally, the mount created a consistent rigid boundary condition between the different nozzles to ensure repeatability of the experiment. After a nozzle was clamped onto the mount, it was installed onto the outlet pipe using an interference fit. The rigid nozzle was similarly installed with an interference fit on the outlet pipe.

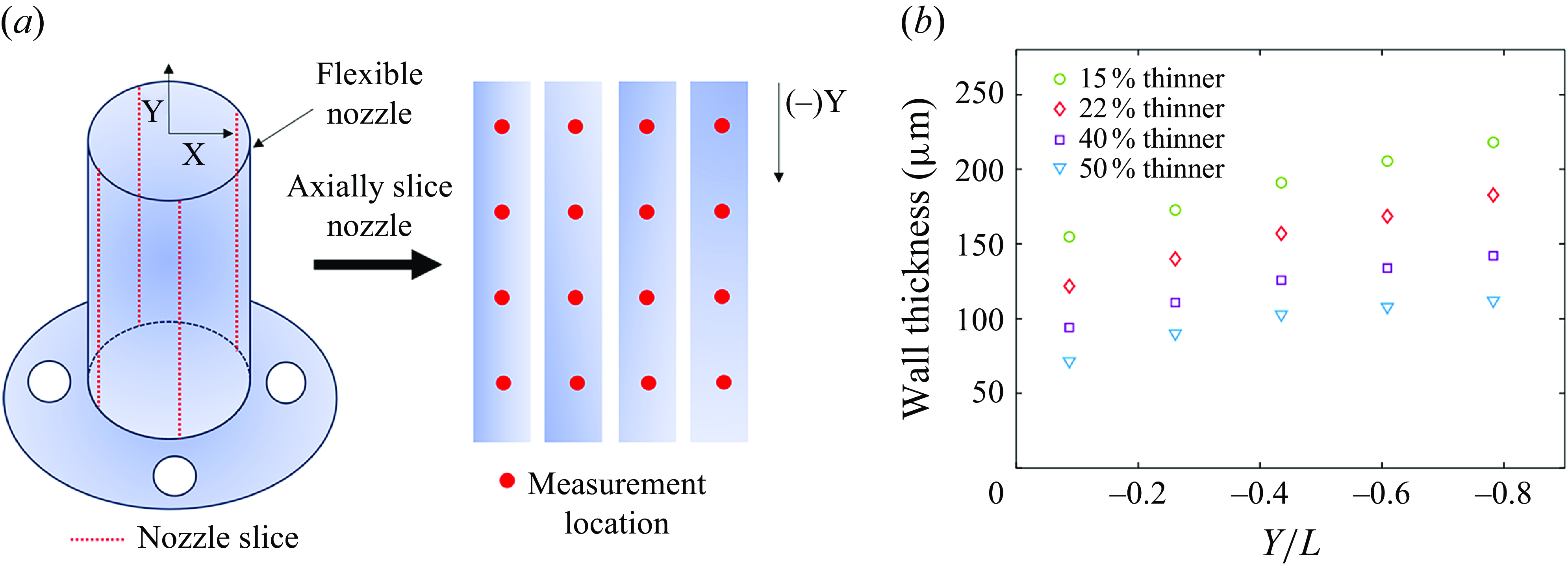

For each nozzle, a representative nozzle was made to be sliced into strips to measure the mean nozzle wall thickness (

![]() $h$

) using an Olympus BX60 microscope with a 10

$h$

) using an Olympus BX60 microscope with a 10

![]() $\,\times\,$

power lens. The wall thickness was measured at a total of 16 locations for each nozzle, at 4 streamwise locations 2.5 cm apart and 4 equally spaced azimuthal locations around the nozzle circumference at each streamwise height as shown in figure 3(a). The wall thickness variation was negligible with a maximum azimuthal variation of 4.1 % for the manufactured nozzles. The wall thickness varied approximately linearly along each nozzle’s length due to the pour moulding manufacturing method. The spatial distribution of the wall thickness along the nozzle length (

$\,\times\,$

power lens. The wall thickness was measured at a total of 16 locations for each nozzle, at 4 streamwise locations 2.5 cm apart and 4 equally spaced azimuthal locations around the nozzle circumference at each streamwise height as shown in figure 3(a). The wall thickness variation was negligible with a maximum azimuthal variation of 4.1 % for the manufactured nozzles. The wall thickness varied approximately linearly along each nozzle’s length due to the pour moulding manufacturing method. The spatial distribution of the wall thickness along the nozzle length (

![]() $L$

) is plotted in figure 3(b). The thickness decreased at an average rate of 17.7 µm/

$L$

) is plotted in figure 3(b). The thickness decreased at an average rate of 17.7 µm/

![]() $D^{-1}$

along the streamwise direction of the nozzle. The total change in thickness was approximately constant between the different nozzles, thus the thickness was averaged over the measured locations for each nozzle. Mean wall thickness (

$D^{-1}$

along the streamwise direction of the nozzle. The total change in thickness was approximately constant between the different nozzles, thus the thickness was averaged over the measured locations for each nozzle. Mean wall thickness (

![]() $h$

) varied from 188.4 to 96.8 µm across the different nozzles, and the nozzle inner diameter was held constant.

$h$

) varied from 188.4 to 96.8 µm across the different nozzles, and the nozzle inner diameter was held constant.

Figure 3. Nozzle wall thickness measurement schematic and variation in wall thickness. (a) Schematic indicating the cut sections used for measuring nozzle wall thickness. The nozzles were cut along their streamwise direction to create 4 strips that were measured at 4 streamwise locations along the nozzle’s length. (b) Distribution of measured nozzle thickness along the length (

![]() $L$

) of the nozzles. The labelled per cent values in the legend correspond to the %ma of silicone thinner added to the mixture to mould each nozzle.

$L$

) of the nozzles. The labelled per cent values in the legend correspond to the %ma of silicone thinner added to the mixture to mould each nozzle.

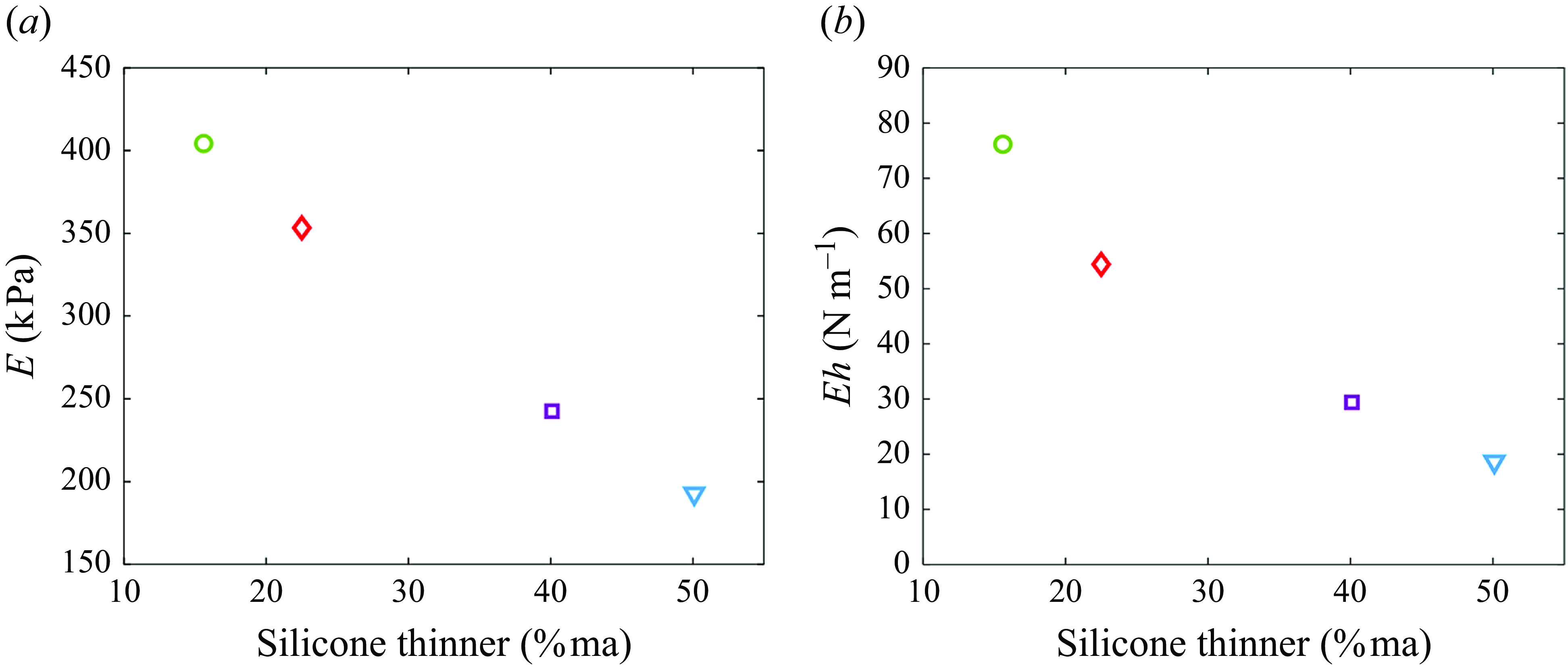

Young’s modulus was calculated by completing tensile tests on 5 mm thick dog bone samples prepared with cross-sectional geometry as described in ASTM D412-16 standard test methods for vulcanised rubber and thermoplastic elastomers – tension (AST 2021). The tests were completed on an Instron 312 series frame with a 25 kN load cell. For each nozzle, 8 tensile tests were completed from two different batches of silicone, one batch from the silicone used for the experimental nozzle, and second batch from the silicone used for the representative nozzle. The maximum variation in

![]() $E$

between the two sets was negligible, with the maximum being 4.2 %. Young’s modulus (

$E$

between the two sets was negligible, with the maximum being 4.2 %. Young’s modulus (

![]() $E$

) varied from 404 to 193 kPa, as shown in figure 4(a).

$E$

) varied from 404 to 193 kPa, as shown in figure 4(a).

Figure 4. Material properties measured with varied %ma thinner (a) Young’s modulus (

![]() $E$

) averaged over 8 samples from each %ma of silicone thinner added to the nozzle mixtures. (b) Value of

$E$

) averaged over 8 samples from each %ma of silicone thinner added to the nozzle mixtures. (b) Value of

![]() $E$

multiplied by the mean wall thickness (

$E$

multiplied by the mean wall thickness (

![]() $h$

), defining the characteristic stiffness of the varied %ma thinner nozzles.

$h$

), defining the characteristic stiffness of the varied %ma thinner nozzles.

The representative characteristic stiffness parameter was chosen to be Young’s modulus (

![]() $E$

) multiplied by the mean wall thickness (

$E$

) multiplied by the mean wall thickness (

![]() $h$

), which is plotted in figure 4(b). Overall, a set of 5 nozzles were tested with characteristic stiffness parameter

$h$

), which is plotted in figure 4(b). Overall, a set of 5 nozzles were tested with characteristic stiffness parameter

![]() $Eh$

= 19, 29, 54, 78 and

$Eh$

= 19, 29, 54, 78 and

![]() $Eh = \infty\,\rm N\, m^-{^1}$

(rigid). Table 1 summarises the parameters studied in this experiment.

$Eh = \infty\,\rm N\, m^-{^1}$

(rigid). Table 1 summarises the parameters studied in this experiment.

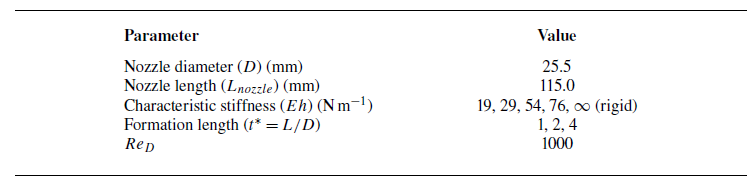

Table 1. Experimental parameters.

2.3. Velocity field measurements

Particle image velocimetry (PIV) was conducted to quantify the velocity vector fields beneath the nozzles. Images were sampled at 60 Hz with a resolution of 1080

![]() $\,\times\,$

1920 pixels. A total of 600 image pairs were analysed for each experimental run. The camera was triggered to start simultaneously with the initiation of the pump using an in-house LabVIEW program via a MyDAQ (National Instruments). Hollow glass sphere particles with mean diameter of 10 µm, and average density of 1.10 g ml−1 were used to seed the tank (Potters’ Industries Sphericel, 110P8). A 532 nm continuous wavelength laser and a convex cylindrical lens were mounted underneath the tank to illuminate a 1 mm vertical sheet passing through the centre cross-section of the nozzle in either the XY or XZ plane as defined in figure 1, with the Z direction being out of the page. Cross-correlation of the image pairs was completed using a multiple pass interrogation method with successive reductions in window sizes using the open-source software PIVlab (Thielicke & Sonntag 2021; Thielicke Reference Thielicke2022). For a field of view of 5.5

$\,\times\,$

1920 pixels. A total of 600 image pairs were analysed for each experimental run. The camera was triggered to start simultaneously with the initiation of the pump using an in-house LabVIEW program via a MyDAQ (National Instruments). Hollow glass sphere particles with mean diameter of 10 µm, and average density of 1.10 g ml−1 were used to seed the tank (Potters’ Industries Sphericel, 110P8). A 532 nm continuous wavelength laser and a convex cylindrical lens were mounted underneath the tank to illuminate a 1 mm vertical sheet passing through the centre cross-section of the nozzle in either the XY or XZ plane as defined in figure 1, with the Z direction being out of the page. Cross-correlation of the image pairs was completed using a multiple pass interrogation method with successive reductions in window sizes using the open-source software PIVlab (Thielicke & Sonntag 2021; Thielicke Reference Thielicke2022). For a field of view of 5.5

![]() $D$

$D$

![]() $\times$

3

$\times$

3

![]() $D$

, a final interrogation window size of 64

$D$

, a final interrogation window size of 64

![]() $\,\times\,$

64 pixels with 50 % overlap was chosen. This resulted in a vector space of 59

$\,\times\,$

64 pixels with 50 % overlap was chosen. This resulted in a vector space of 59

![]() $\,\times\,$

32 vectors with a vector spacing of 0.098

$\,\times\,$

32 vectors with a vector spacing of 0.098

![]() $D$

. The time interval between image pairs,

$D$

. The time interval between image pairs,

![]() $\Delta t$

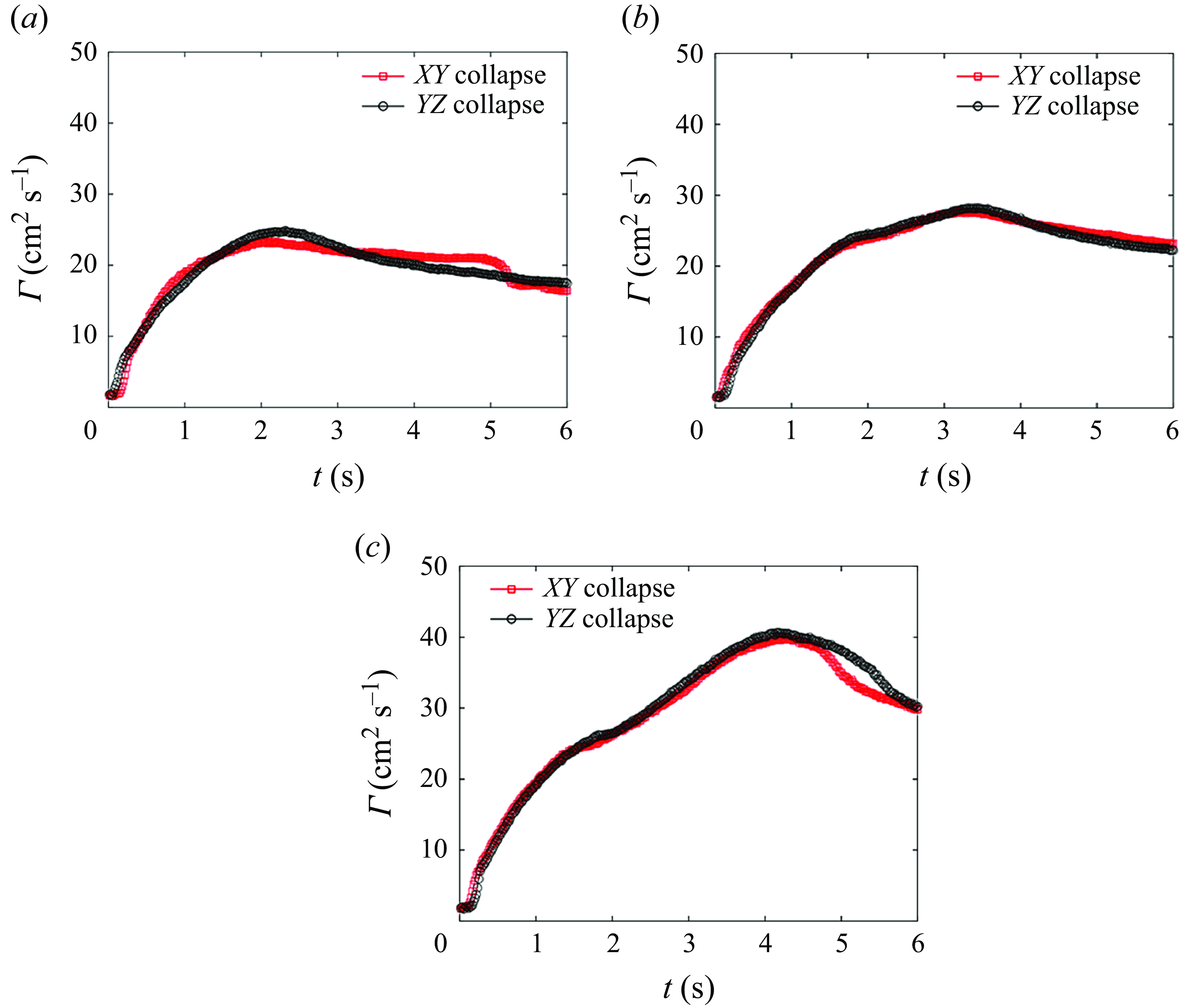

, was 0.0167 s and the particle motion between image pairs was limited to approximately 1/4 of the window size to ensure the accuracy of the cross-correlation (Willert & Gharib Reference Willert and Gharib1991). As the flexible nozzles were found to deform about a preferential axis, PIV was performed both perpendicular (XY plane), and parallel (XZ plane), to this preferential axis to ensure axisymmetry in our results (see Appendix A for further details). For each nozzle, 10 trials were completed, with 5 trials from each plane. In subsequent plots, the average of these 10 trials is plotted unless otherwise noted. The mean maximum spatially averaged velocity measured

$\Delta t$

, was 0.0167 s and the particle motion between image pairs was limited to approximately 1/4 of the window size to ensure the accuracy of the cross-correlation (Willert & Gharib Reference Willert and Gharib1991). As the flexible nozzles were found to deform about a preferential axis, PIV was performed both perpendicular (XY plane), and parallel (XZ plane), to this preferential axis to ensure axisymmetry in our results (see Appendix A for further details). For each nozzle, 10 trials were completed, with 5 trials from each plane. In subsequent plots, the average of these 10 trials is plotted unless otherwise noted. The mean maximum spatially averaged velocity measured

![]() $0.019D$

below the rigid nozzle outlet was calculated to be 3.97 cm s−1 across all ejected volumes, with a 95 % confidence interval of

$0.019D$

below the rigid nozzle outlet was calculated to be 3.97 cm s−1 across all ejected volumes, with a 95 % confidence interval of

![]() $\pm$

0.1 cm s−1 based on a one sample t test. All reported confidence intervals hereon represent the 95 % confidence interval based on a one sample t test. The flexible nozzles altered the measured exit velocity, which is discussed in § 3, where the

$\pm$

0.1 cm s−1 based on a one sample t test. All reported confidence intervals hereon represent the 95 % confidence interval based on a one sample t test. The flexible nozzles altered the measured exit velocity, which is discussed in § 3, where the

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzle had the largest variation, with mean maximum spatial averaged velocity of 6.40 cm s−1 and confidence interval

$Eh = 29\,\rm N\,m^-{^1}$

nozzle had the largest variation, with mean maximum spatial averaged velocity of 6.40 cm s−1 and confidence interval

![]() $\pm$

0.3 cm s−1.

$\pm$

0.3 cm s−1.

2.4. Nozzle deformation measurements

To track the side deformation of the flexible nozzles, the particles were removed from the tank, and the laser sheet was used to illuminate the longitudinal centre cross-section of the nozzle in the XY and XZ planes. The camera imaged the centre plane deformations, which were used for nozzle tracking with an in-house MATLAB edge detection code. The same image processing steps were applied to these images as was used to determine the syringe pump velocity profiles. Two time sets were considered, forced vibration when the pump was active, and free vibration when the pump had stopped moving and the nozzle was freely oscillating. The bottom millimetre of the nozzle was used as a representative point to track the position over time. Fast Fourier transforms (FFTs) were completed in MATLAB to find the repeated oscillations frequencies from the free vibration positional datasets. The single-side amplitude spectrum of the position data, or the occurrence of each frequency in the positive domain, was calculated using a sampling period of 0.0167 sec and sample length of 600 samples (10 s). The single sided amplitude spectrum was plotted to find a peak in frequency occurrences to estimate the damped natural frequency of (

![]() $\omega _{d}$

) of the nozzles. The deformation viewed from beneath the nozzle (YZ plane) was also imaged.

$\omega _{d}$

) of the nozzles. The deformation viewed from beneath the nozzle (YZ plane) was also imaged.

2.5. FTLE fields and ridges

The predicted material boundaries of the generated vortex rings were identified by detecting ridges within the FTLE field using the LCS Matlab Kit V2 by the Biological Propulsion Laboratory at the California Institute of Technology (Shadden et al. Reference Shadden, Dabiri and Marsden2006; Peng & Dabiri Reference Peng and Dabiri2009; Dabiri Reference Dabiri2021). The FTLE fields are directly derived from the velocity fields generated from PIV by either initiating fluid particle tracking forward or backward in time. This process yields both positive (forward) pFTLE and negative (backward) nFTLE fields. The FTLE field is computed by

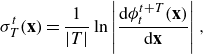

\begin{equation} \sigma _{T}^{t}(\mathbf{x}) = \frac {1}{|T|} \ln \left | \frac {{\rm d}\phi ^{t+T}_{t}(\mathbf{x})}{{\rm d}\mathbf{x}} \right |, \end{equation}

\begin{equation} \sigma _{T}^{t}(\mathbf{x}) = \frac {1}{|T|} \ln \left | \frac {{\rm d}\phi ^{t+T}_{t}(\mathbf{x})}{{\rm d}\mathbf{x}} \right |, \end{equation}

where

![]() $ \sigma _{T}^{t}(\mathbf{x})$

represents the scalar FTLE field, or how much particles nearby a point diverge, and

$ \sigma _{T}^{t}(\mathbf{x})$

represents the scalar FTLE field, or how much particles nearby a point diverge, and

![]() $\phi^{t+T}_{t}(\mathbf{x})$

signifies the flow map of particles from their location at signifies the flow map of particles from their location at

$\phi^{t+T}_{t}(\mathbf{x})$

signifies the flow map of particles from their location at signifies the flow map of particles from their location at

![]() $\mathbf{x}$

at time

$\mathbf{x}$

at time

![]() $t$

to

$t$

to

![]() $t+T$

and

$t+T$

and

![]() $|T|$

represents the integration time used to track the particle motion, with

$|T|$

represents the integration time used to track the particle motion, with

![]() $T\lt 0$

, indicating backward time and

$T\lt 0$

, indicating backward time and

![]() $T\gt 0$

, corresponding to forward time. After obtaining the FTLE fields, regions of local maxima, or ridges, were identified to pinpoint regions where fluid transport is restricted or intensified. These ridges are known as Lagrangian coherent structures (LCS), which are valuable for analysing vortex ring pinch-off. Negative LCS (nLCS), found from the ridges within a nFTLE field, indicate an attractive material lines in the flow field, while positive LCS (pLCS), found from ridges within a pFTLE field, indicate repelling material lines. When a nLCS and pLCS combine to form a closed loop, it signifies the formation of a pinched-off vortex ring (Shadden et al. Reference Shadden, Dabiri and Marsden2006). The presence of a pLCS on a vortex ring’s rear edge suggests that further fluid entry into the enclosed structure of the vortex ring from the vortex generator is unlikely, and the vortex ring will not gain additional vorticity. The integration length

$T\gt 0$

, corresponding to forward time. After obtaining the FTLE fields, regions of local maxima, or ridges, were identified to pinpoint regions where fluid transport is restricted or intensified. These ridges are known as Lagrangian coherent structures (LCS), which are valuable for analysing vortex ring pinch-off. Negative LCS (nLCS), found from the ridges within a nFTLE field, indicate an attractive material lines in the flow field, while positive LCS (pLCS), found from ridges within a pFTLE field, indicate repelling material lines. When a nLCS and pLCS combine to form a closed loop, it signifies the formation of a pinched-off vortex ring (Shadden et al. Reference Shadden, Dabiri and Marsden2006). The presence of a pLCS on a vortex ring’s rear edge suggests that further fluid entry into the enclosed structure of the vortex ring from the vortex generator is unlikely, and the vortex ring will not gain additional vorticity. The integration length

![]() $|T|$

chosen for the data analysed within this paper corresponds to 1 s, or 60 image frames. A step size of 1 and time step of 0.0167 s per frame were used.

$|T|$

chosen for the data analysed within this paper corresponds to 1 s, or 60 image frames. A step size of 1 and time step of 0.0167 s per frame were used.

3. Results and discussion

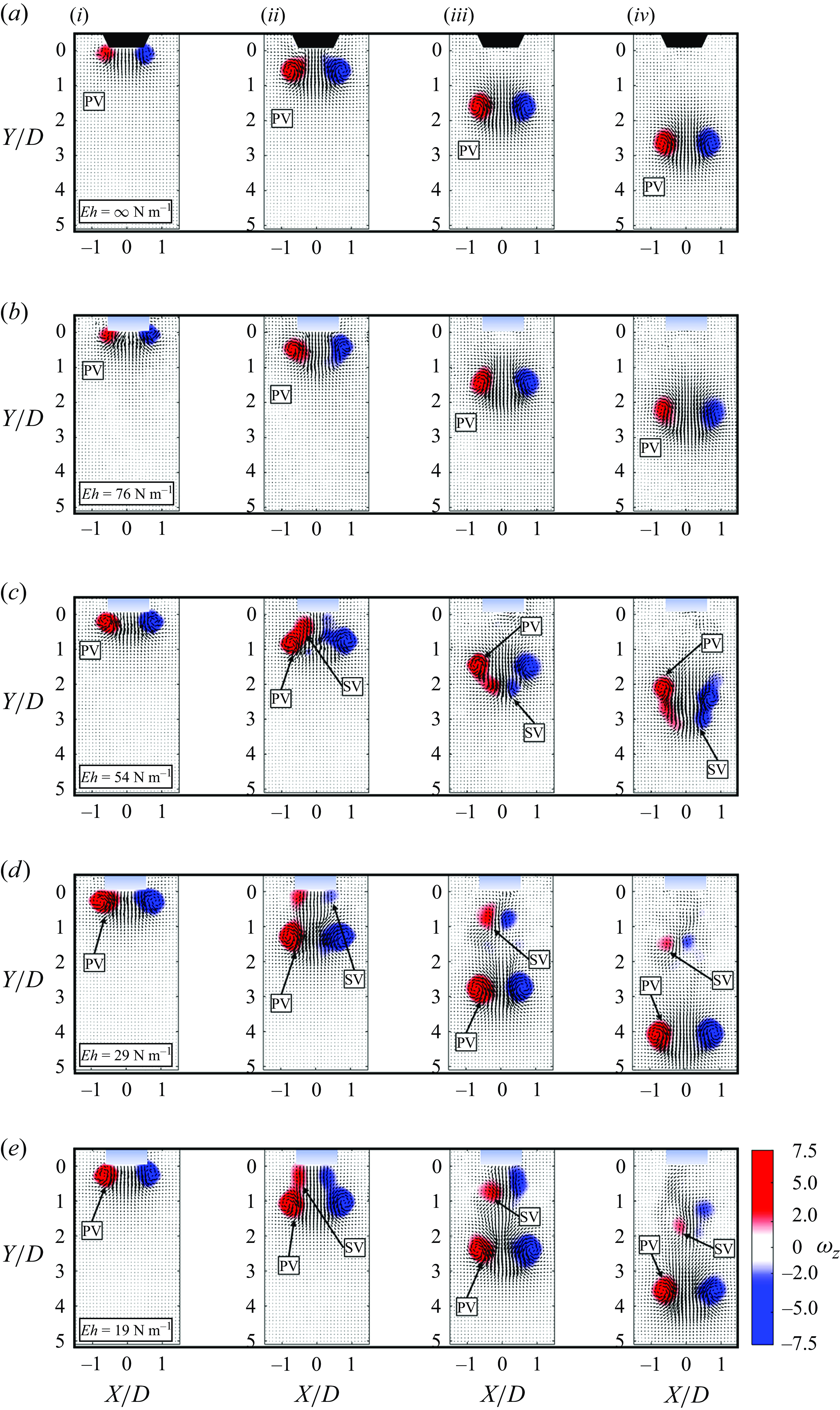

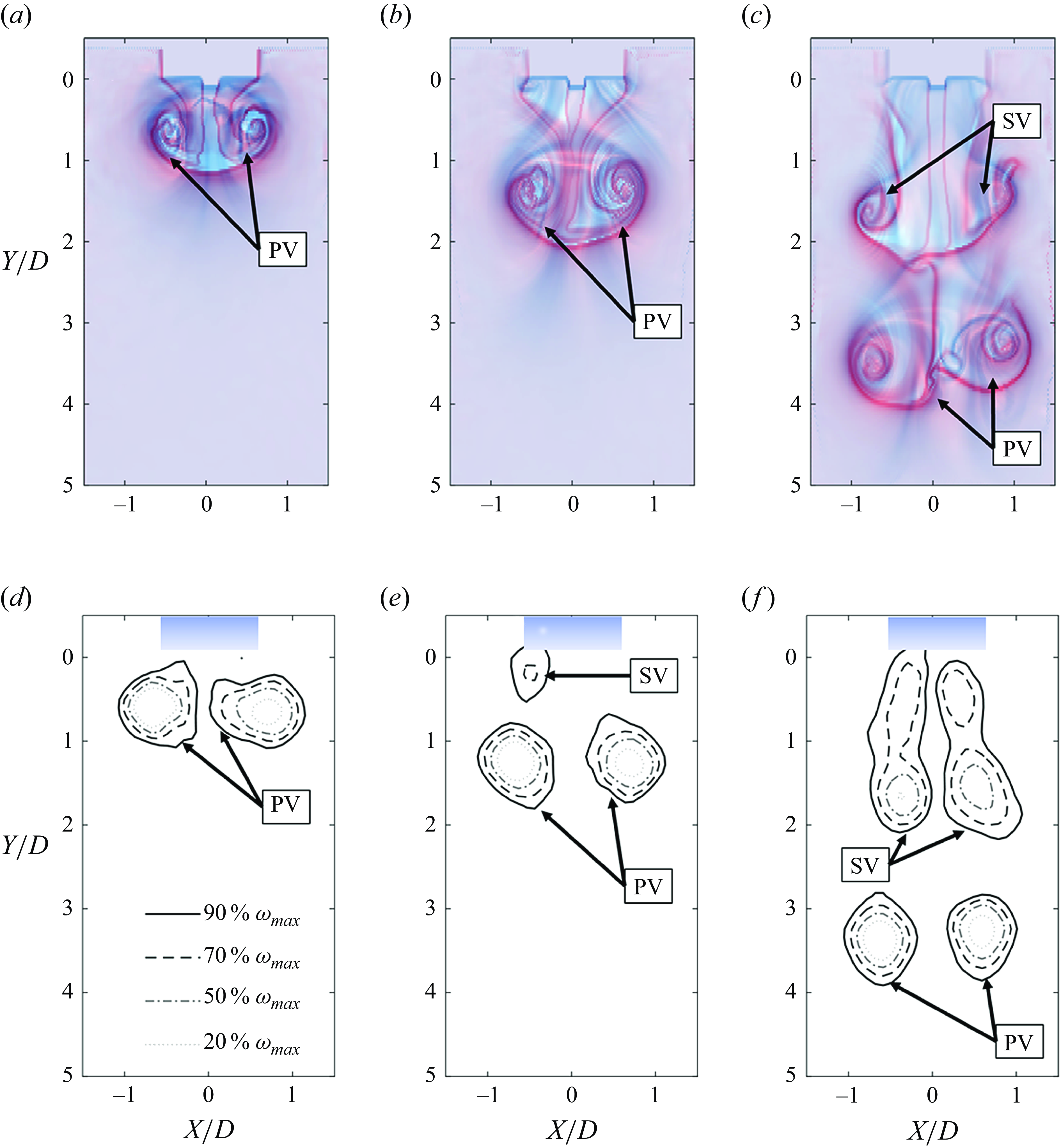

3.1. Changes in flow characteristics due to nozzle flexibility

First, we examine how the development of the vortical structures in the flow fields is influenced by the fluid structure interaction as the characteristic stiffness parameter (

![]() $Eh$

) is varied for the given input flow parameters. Figure 5(a) illustrates the flow development from the

$Eh$

) is varied for the given input flow parameters. Figure 5(a) illustrates the flow development from the

![]() $Eh = \infty\,\rm N\,m^-{^1}$

(rigid) nozzle for

$Eh = \infty\,\rm N\,m^-{^1}$

(rigid) nozzle for

![]() ${L}/{D}=2$

from (i)

${L}/{D}=2$

from (i)

![]() $t/t_{cycle}=0.41$

to (iv)

$t/t_{cycle}=0.41$

to (iv)

![]() $t/t_{cycle}=3$

, where

$t/t_{cycle}=3$

, where

![]() $t_{cycle}$

is the time when the pump stops for each

$t_{cycle}$

is the time when the pump stops for each

![]() ${L}/{D}$

. The nozzle position relative to the flow field is shown as the black trapezoid at the top of each frame. As the fluid is expelled from the nozzle, the shear layer rolls up, forming a single primary vortex (PV) ring as it enters the quiescent tank. The plots show a cross-section cut across the middle of the ring, which is displayed as a single counter rotating vortex pair of opposite sign vorticity. This is consistent with Gharib et al. (Reference Gharib, Rambod and Shariff1998), wherein the ejected fluid from impulsive piston motion will form a single vortex ring for

${L}/{D}$

. The nozzle position relative to the flow field is shown as the black trapezoid at the top of each frame. As the fluid is expelled from the nozzle, the shear layer rolls up, forming a single primary vortex (PV) ring as it enters the quiescent tank. The plots show a cross-section cut across the middle of the ring, which is displayed as a single counter rotating vortex pair of opposite sign vorticity. This is consistent with Gharib et al. (Reference Gharib, Rambod and Shariff1998), wherein the ejected fluid from impulsive piston motion will form a single vortex ring for

![]() ${L}/{D} \lt 4$

. However, this behaviour changes when

${L}/{D} \lt 4$

. However, this behaviour changes when

![]() $Eh$

is sufficiently low enough (flexible enough) to perturb the input flow conditions.

$Eh$

is sufficiently low enough (flexible enough) to perturb the input flow conditions.

Figure 5(b–e; i – iv) shows the flexible nozzle (

![]() $Eh$

= 76, 54, 29, 19 N m–1) flow fields, under the same input kinematic flow conditions from the pump (

$Eh$

= 76, 54, 29, 19 N m–1) flow fields, under the same input kinematic flow conditions from the pump (

![]() ${L}/{D} \lt 2$

). As

${L}/{D} \lt 2$

). As

![]() $Eh$

decreases (becomes more flexible) the flow structures begin to deviate from the rigid case. For

$Eh$

decreases (becomes more flexible) the flow structures begin to deviate from the rigid case. For

![]() $Eh = 76\,\rm N\,m^-{^1}$

the vortex cores are slightly elongated, but become approximately circular after

$Eh = 76\,\rm N\,m^-{^1}$

the vortex cores are slightly elongated, but become approximately circular after

![]() $t/t_{cycle}$

= 1. It is understood that the alteration is due to small-scale oscillations (

$t/t_{cycle}$

= 1. It is understood that the alteration is due to small-scale oscillations (

![]() $\approx {0.02D}$

) of the flexible nozzle. As

$\approx {0.02D}$

) of the flexible nozzle. As

![]() $Eh$

is lowered further, the deformation of the nozzles becomes an order of magnitude more pronounced (up to

$Eh$

is lowered further, the deformation of the nozzles becomes an order of magnitude more pronounced (up to

![]() $\approx {0.19D}$

), multiple distinct vortex structures form, and the PV begins to significantly differ from the rigid case. For

$\approx {0.19D}$

), multiple distinct vortex structures form, and the PV begins to significantly differ from the rigid case. For

![]() $Eh = 54\,\rm N\,m^-{^1}$

in figure 5(c), two cores form, where the secondary vorticity eventually leap frogs through the PV core, but the two cores do not separate from one another. The formation of this second core of vorticity corresponds to the nozzle oscillations and rapid collapse at

$Eh = 54\,\rm N\,m^-{^1}$

in figure 5(c), two cores form, where the secondary vorticity eventually leap frogs through the PV core, but the two cores do not separate from one another. The formation of this second core of vorticity corresponds to the nozzle oscillations and rapid collapse at

![]() $t=t_{cycle}$

, which is examined further below. For

$t=t_{cycle}$

, which is examined further below. For

![]() $Eh = 29\,\rm N\,m^-{^1}$

in figure 5(d), the PV separates from the nozzle prior to

$Eh = 29\,\rm N\,m^-{^1}$

in figure 5(d), the PV separates from the nozzle prior to

![]() $t/t_{cycle} = 1$

. A weak secondary vortex (SV) structure forms, and separates from the nozzle at

$t/t_{cycle} = 1$

. A weak secondary vortex (SV) structure forms, and separates from the nozzle at

![]() $t/t_{cycle}$

= 2. Notably the PV travels significantly further than the rigid case reaching

$t/t_{cycle}$

= 2. Notably the PV travels significantly further than the rigid case reaching

![]() $2.8D$

compared with

$2.8D$

compared with

![]() $1.6D$

at

$1.6D$

at

![]() $t/t_{cycle} = 2$

, defined by the averaged location of peak vorticity between the positive and negative cores. For the most flexible nozzle,

$t/t_{cycle} = 2$

, defined by the averaged location of peak vorticity between the positive and negative cores. For the most flexible nozzle,

![]() $Eh = 19\,\rm N\,m^-{^1}$

, two separate vortex structures also form, but the SV is slightly larger than that produced by the

$Eh = 19\,\rm N\,m^-{^1}$

, two separate vortex structures also form, but the SV is slightly larger than that produced by the

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzle. Interestingly, in this case, the PV travels a shorter distance of

$Eh = 29\,\rm N\,m^-{^1}$

nozzle. Interestingly, in this case, the PV travels a shorter distance of

![]() $2.4D$

below the nozzle at

$2.4D$

below the nozzle at

![]() $t/t_{cycle} = 2$

compared with the slightly stiffer

$t/t_{cycle} = 2$

compared with the slightly stiffer

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzle. Similar trends are observed at the other ejected volumes (

$Eh = 29\,\rm N\,m^-{^1}$

nozzle. Similar trends are observed at the other ejected volumes (

![]() ${L}/{D} = 1, 4$

), see Supplementary Material 1.

${L}/{D} = 1, 4$

), see Supplementary Material 1.

Figure 5. Vorticity and vector fields measured for (i)

![]() $t/t_{cycle}=0.41$

, (ii)

$t/t_{cycle}=0.41$

, (ii)

![]() $t/t_{cycle}=1$

, (iii)

$t/t_{cycle}=1$

, (iii)

![]() $t/t_{cycle}=2$

and (iv)

$t/t_{cycle}=2$

and (iv)

![]() $t/t_{cycle}=3$

for each nozzle given the same kinematic input from the pump for

$t/t_{cycle}=3$

for each nozzle given the same kinematic input from the pump for

![]() ${L}/{D} = 2$

. (a) Rigid nozzle (

${L}/{D} = 2$

. (a) Rigid nozzle (

![]() $Eh = \infty\,\rm N\,m^-{^1}$

); (b)

$Eh = \infty\,\rm N\,m^-{^1}$

); (b)

![]() $Eh=76\,\rm N\,m^-{^1}$

; (c)

$Eh=76\,\rm N\,m^-{^1}$

; (c)

![]() $Eh=54\,\rm N\,m^-{^1}$

; (d)

$Eh=54\,\rm N\,m^-{^1}$

; (d)

![]() $Eh= 29\,\rm N\,m^-{^1}$

; (e)

$Eh= 29\,\rm N\,m^-{^1}$

; (e)

![]() $Eh=19\,\rm N\,m^-{^1}$

.

$Eh=19\,\rm N\,m^-{^1}$

.

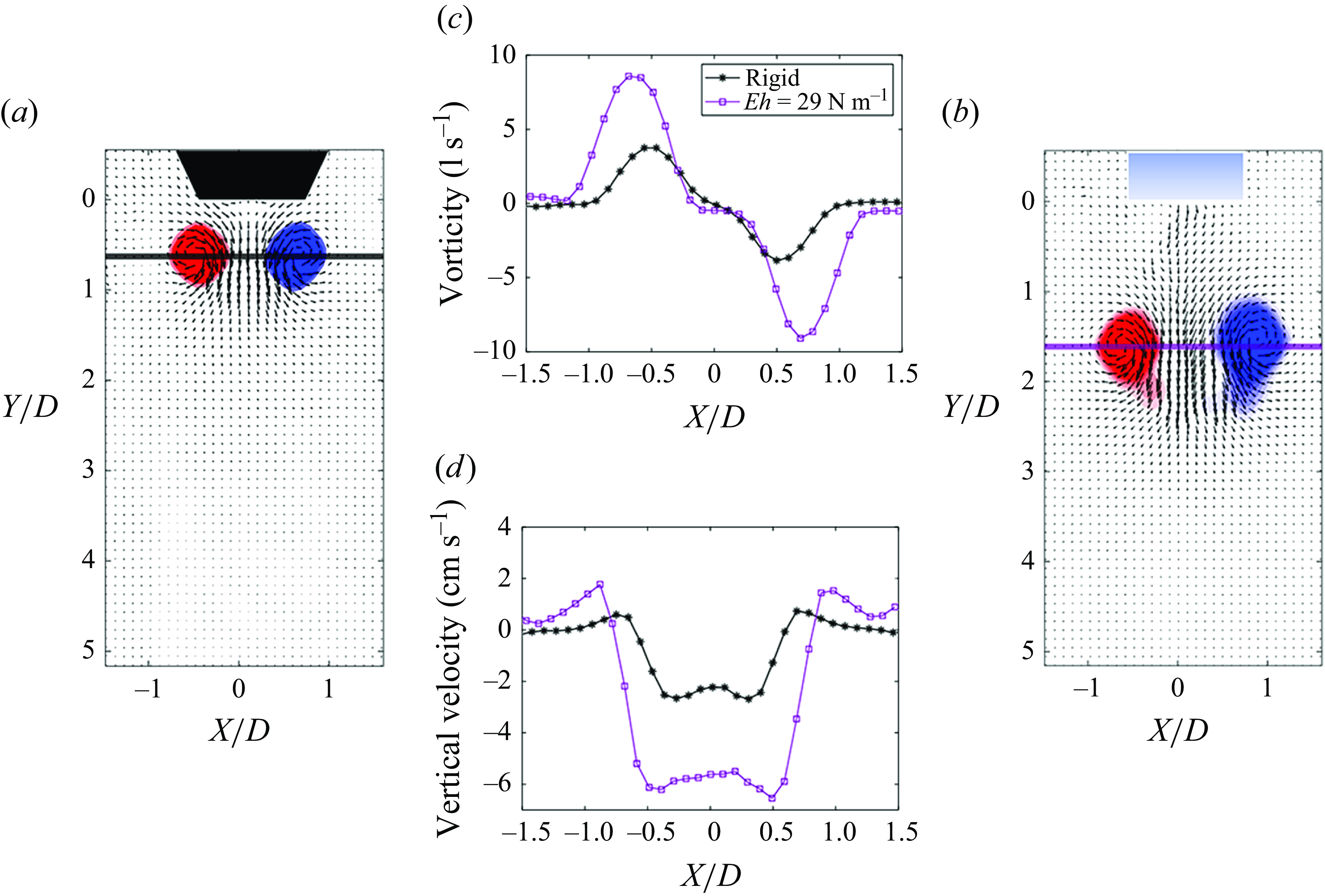

To compare between the vortex rings produced by the different nozzles, we analyse cross-sectional cuts of the vortex rings generated by the

![]() $Eh = \infty\,\rm N\,m^-{^1}$

(rigid) nozzle and the

$Eh = \infty\,\rm N\,m^-{^1}$

(rigid) nozzle and the

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzle, at

$Eh = 29\,\rm N\,m^-{^1}$

nozzle, at

![]() $t/t_{cycle}=2$

for

$t/t_{cycle}=2$

for

![]() ${L}/{D}=1$

. This simplifies the comparison by focusing on single PV structures as shown in the vorticity plots in figures 6(a) and 6(b). Figures 6(c) and 6(d) display the spatial distribution of vorticity and velocity components measured along the cut lines. These cut lines are defined by the vertical (

${L}/{D}=1$

. This simplifies the comparison by focusing on single PV structures as shown in the vorticity plots in figures 6(a) and 6(b). Figures 6(c) and 6(d) display the spatial distribution of vorticity and velocity components measured along the cut lines. These cut lines are defined by the vertical (

![]() $Y$

) location of peak vorticity for each trial. As inferred by the distance travelled by the PV produced from the

$Y$

) location of peak vorticity for each trial. As inferred by the distance travelled by the PV produced from the

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzle, the peak velocity is 2.5 times higher, and the peak vorticity is 2.8 times higher than the rigid nozzle case. Additionally, the wider spatial distribution velocity and vorticity suggests that the

$Eh = 29\,\rm N\,m^-{^1}$

nozzle, the peak velocity is 2.5 times higher, and the peak vorticity is 2.8 times higher than the rigid nozzle case. Additionally, the wider spatial distribution velocity and vorticity suggests that the

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzle not only produces a stronger PV, but a larger PV compared with the rigid nozzle.

$Eh = 29\,\rm N\,m^-{^1}$

nozzle not only produces a stronger PV, but a larger PV compared with the rigid nozzle.

Figure 6. (a) Rigid nozzle PIV vector plot and vorticity at

![]() $t/t_{cycle}=2$

for

$t/t_{cycle}=2$

for

![]() ${L}/{D}=1$

. The solid line represents a cut section of the vortex ring and corresponds to the centred plots of vorticity and velocity; (b)

${L}/{D}=1$

. The solid line represents a cut section of the vortex ring and corresponds to the centred plots of vorticity and velocity; (b)

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzle PIV vector plot and vorticity, with cut line selected by the point of highest vorticity. (c) Vorticity across the vortex ring cut plane for the rigid and

$Eh = 29\,\rm N\,m^-{^1}$

nozzle PIV vector plot and vorticity, with cut line selected by the point of highest vorticity. (c) Vorticity across the vortex ring cut plane for the rigid and

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzles. (d) Vertical velocity across the vortex ring cut plane for the rigid and

$Eh = 29\,\rm N\,m^-{^1}$

nozzles. (d) Vertical velocity across the vortex ring cut plane for the rigid and

![]() $Eh = 29\,\rm N\,m^-{^1}$

nozzles. Legend is the same for (c) and (d).

$Eh = 29\,\rm N\,m^-{^1}$

nozzles. Legend is the same for (c) and (d).

Next we analyse the temporal variation of vortex spacing (

![]() $b$

) and core diameter (

$b$

) and core diameter (

![]() $a$

) for each nozzle, as plotted in figures 7(a) and 7(b) for

$a$

) for each nozzle, as plotted in figures 7(a) and 7(b) for

![]() ${L}/{D}=2$

. The PV ring is tracked for this analysis, with

${L}/{D}=2$

. The PV ring is tracked for this analysis, with

![]() $b$

defined as the distance between the peak vorticity values of each core, and

$b$

defined as the distance between the peak vorticity values of each core, and

![]() $a$

is defined by the distance between the two points bounding 10 % of the maximum vorticity, averaged between the positive and negative cores. As shown in figure 7(a), the flexible nozzles generate vortex rings with wider spacing, with each ring converging to an approximately constant spacing of

$a$

is defined by the distance between the two points bounding 10 % of the maximum vorticity, averaged between the positive and negative cores. As shown in figure 7(a), the flexible nozzles generate vortex rings with wider spacing, with each ring converging to an approximately constant spacing of

![]() ${b}/{D} = 1.41 \pm 0.15$

, compared with

${b}/{D} = 1.41 \pm 0.15$

, compared with

![]() ${b}/{D} = 1.19 \pm 0.13$

for the

${b}/{D} = 1.19 \pm 0.13$

for the

![]() $Eh = \infty\,\rm N\,m^-{^1}$

(rigid) nozzle at

$Eh = \infty\,\rm N\,m^-{^1}$

(rigid) nozzle at

![]() $t=3t_{cycle}$

. The vortex ring core diameter (

$t=3t_{cycle}$

. The vortex ring core diameter (

![]() $a$

) varies slightly with

$a$

) varies slightly with

![]() $Eh$

, with the flexible nozzles all creating larger cores, as shown in figure 7(b). The

$Eh$

, with the flexible nozzles all creating larger cores, as shown in figure 7(b). The

![]() $Eh = 54$

,

$Eh = 54$

,

![]() $29$

and

$29$

and

![]() $19\,\rm N\,m^-{^1}$

nozzles converge to a core diameter of

$19\,\rm N\,m^-{^1}$

nozzles converge to a core diameter of

![]() ${a}/{D} = 1.13 \pm 0.09$

, and the

${a}/{D} = 1.13 \pm 0.09$

, and the

![]() $Eh = 76\,\rm N\,m^-{^1}$

nozzle converges to

$Eh = 76\,\rm N\,m^-{^1}$

nozzle converges to

![]() ${a}/{D} = 1.01 \pm 0.09$

, compared with

${a}/{D} = 1.01 \pm 0.09$

, compared with

![]() ${a}/{D} = 0.82 \pm 0.06$

for

${a}/{D} = 0.82 \pm 0.06$

for

![]() $Eh = \infty\,\rm N\,m^-{^1}$

at

$Eh = \infty\,\rm N\,m^-{^1}$

at

![]() $t=3t_{cycle}$

. Here, the bounds are defined by the 95 % confidence interval for

$t=3t_{cycle}$

. Here, the bounds are defined by the 95 % confidence interval for

![]() ${L}/{D} = 2$

. The other ejected volumes follow the same trends, but with smaller core diameter and spacing for

${L}/{D} = 2$

. The other ejected volumes follow the same trends, but with smaller core diameter and spacing for

![]() ${L}/{D} = 1$

, and larger for

${L}/{D} = 1$

, and larger for

![]() ${L}/{D} = 4$

. Given the larger (

${L}/{D} = 4$

. Given the larger (

![]() $b, a$

), stronger (

$b, a$

), stronger (

![]() $\omega _z$

), and faster moving vortex rings generated by the flexible nozzles, the velocity produced by these nozzles should scale accordingly.

$\omega _z$

), and faster moving vortex rings generated by the flexible nozzles, the velocity produced by these nozzles should scale accordingly.

Figure 7. Primary vortex ring spatial parameters measured for

![]() ${L}/{D}=2$

. Points are plotted every 0.083 sec for clarity. (a) Vortex spacing (

${L}/{D}=2$

. Points are plotted every 0.083 sec for clarity. (a) Vortex spacing (

![]() $b$

), normalised by the nozzle diameter (

$b$

), normalised by the nozzle diameter (

![]() $D$

) over dimensionless time normalised by

$D$

) over dimensionless time normalised by

![]() $t_{cycle}$

. (b) Vortex core diameter (

$t_{cycle}$

. (b) Vortex core diameter (

![]() $a$

), normalised with the nozzle diameter (

$a$

), normalised with the nozzle diameter (

![]() $D$

), measured over time normalised by

$D$

), measured over time normalised by

![]() $t_{cycle}$

. Legend is the same for (a) and (b).

$t_{cycle}$

. Legend is the same for (a) and (b).

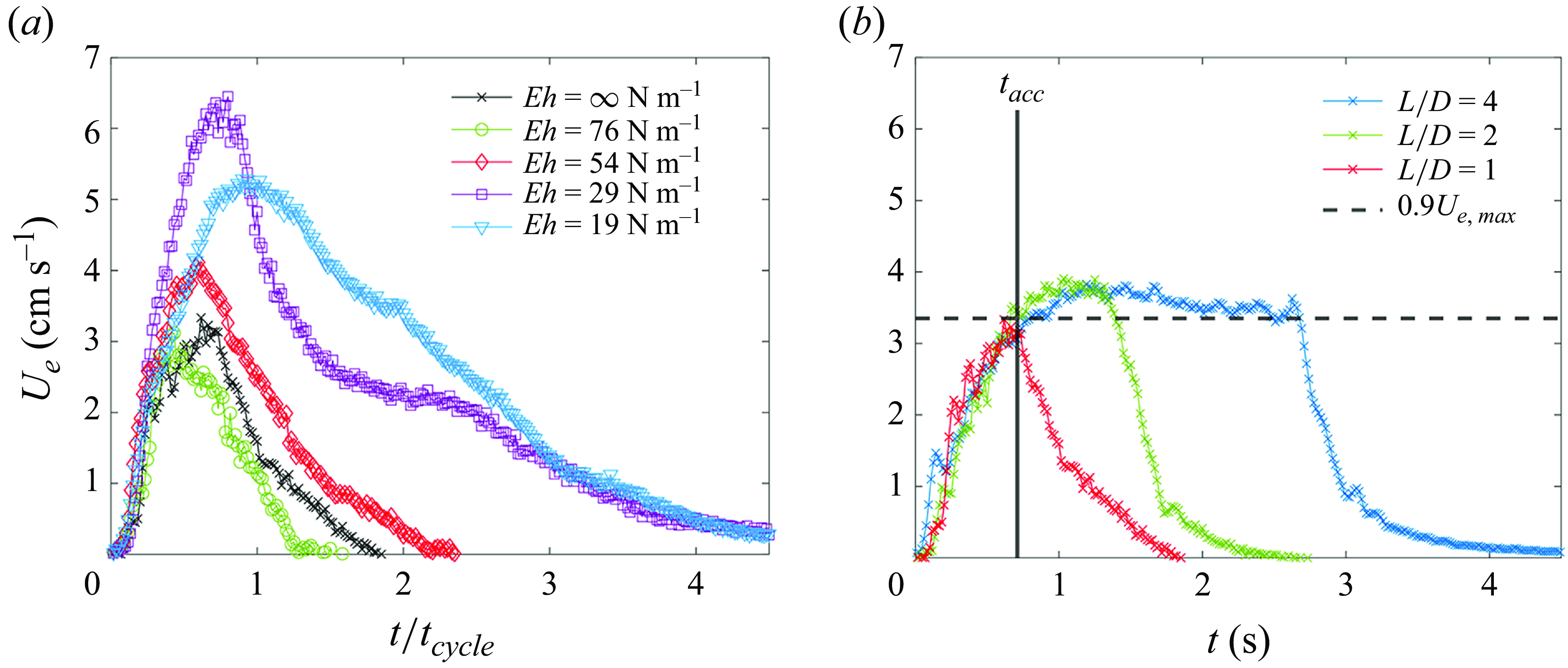

Figure 8. Temporal variation in vertical velocity spatially averaged across the nozzle exit (

![]() $U_e$

) measured

$U_e$

) measured

![]() $0.19D$

below each nozzle: (a)

$0.19D$

below each nozzle: (a)

![]() $U_e$

for

$U_e$

for

![]() ${L}/{D}=1$

across all

${L}/{D}=1$

across all

![]() $Eh$

values for (

$Eh$

values for (

![]() $t/t_{cycle} = 0-4.5$

); (b)

$t/t_{cycle} = 0-4.5$

); (b)

![]() $U_e$

for

$U_e$

for

![]() $Eh\approx \infty\,\rm N\,m^-{^1}$

(rigid), for all

$Eh\approx \infty\,\rm N\,m^-{^1}$

(rigid), for all

![]() ${L}/{D}$

values. Here,

${L}/{D}$

values. Here,

![]() $t_{acc}$

is defined as the time needed for the rigid nozzle to accelerate to 90 % of its maximum velocity.

$t_{acc}$

is defined as the time needed for the rigid nozzle to accelerate to 90 % of its maximum velocity.

The vertical velocity spatially averaged across the nozzle exit (

![]() $U_e$

), measured

$U_e$

), measured

![]() $0.19D$

below the nozzles, is plotted for

$0.19D$

below the nozzles, is plotted for

![]() ${L}/{D}=1$

, in figure 8(a). As expected by the distance travelled by the PV in the vorticity plots in figures 5(a)–5(e),

${L}/{D}=1$

, in figure 8(a). As expected by the distance travelled by the PV in the vorticity plots in figures 5(a)–5(e),

![]() $U_e$

increases as

$U_e$

increases as

![]() $Eh$

is reduced to a maximum at

$Eh$

is reduced to a maximum at

![]() $Eh = 29\,\rm N\,m^-{^1}$

, and declines for

$Eh = 29\,\rm N\,m^-{^1}$

, and declines for

![]() $Eh = 19$

N/m. Furthermore, the time to reach the maximum

$Eh = 19$

N/m. Furthermore, the time to reach the maximum

![]() $U_e$

becomes delayed with decreased

$U_e$

becomes delayed with decreased

![]() $Eh$

. The

$Eh$

. The

![]() $Eh = 19\,\rm N\,m^-{^1}$

nozzle does not accelerate to its peak velocity until

$Eh = 19\,\rm N\,m^-{^1}$

nozzle does not accelerate to its peak velocity until

![]() $t/t_{cycle}=1.0$

, whereas the

$t/t_{cycle}=1.0$

, whereas the

![]() $Eh = 76\,\rm N\,m^-{^1}$

nozzle reaches its peak much quicker at

$Eh = 76\,\rm N\,m^-{^1}$

nozzle reaches its peak much quicker at

![]() $t/t_{cycle}=0.36$

.

$t/t_{cycle}=0.36$

.

To further examine the input flow conditions perturbed by the flexible nozzles, the output velocity from the rigid nozzle (

![]() $Eh = \infty\,\rm N\,m^-{^1}$

) is plotted for all

$Eh = \infty\,\rm N\,m^-{^1}$

) is plotted for all

![]() ${L}/{D}$

values in figure 8(b). To compare the time scales of nozzle deformation with the input fluid flow, we define the time for the rigid nozzle to accelerate to 90 % of

${L}/{D}$

values in figure 8(b). To compare the time scales of nozzle deformation with the input fluid flow, we define the time for the rigid nozzle to accelerate to 90 % of

![]() $U_{e}$

as

$U_{e}$

as

![]() $t_{acc}\approx 0.71$

sec, as shown in figure 8(b). Next, we examine how the nozzle deformations vary with

$t_{acc}\approx 0.71$

sec, as shown in figure 8(b). Next, we examine how the nozzle deformations vary with

![]() $Eh$

to understand the kinematics affecting the flow fields.

$Eh$

to understand the kinematics affecting the flow fields.

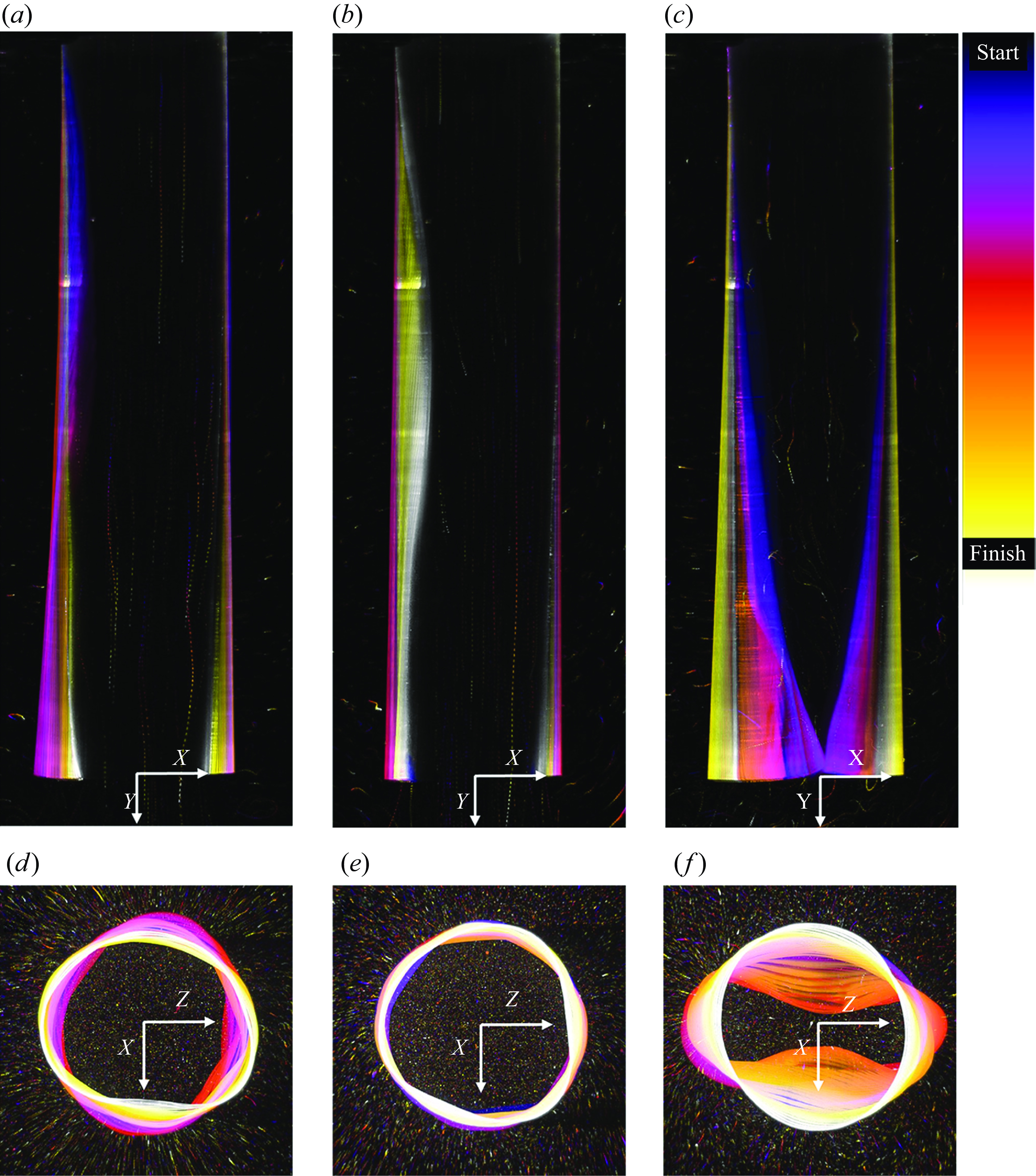

Generally, each of the less stiff (more flexible) nozzles, (

![]() $Eh = 54, 29, 19\,\rm N\,m^-{^1}$

), exhibited similar nozzle deformation kinematics. The deformation is characterised by 3 important time phases: (i) initial tip deflection, (ii) periodic oscillations, (iii) nozzle collapse and return to original state. These three stages are plotted with overlaid time-coloured plot images of the

$Eh = 54, 29, 19\,\rm N\,m^-{^1}$

), exhibited similar nozzle deformation kinematics. The deformation is characterised by 3 important time phases: (i) initial tip deflection, (ii) periodic oscillations, (iii) nozzle collapse and return to original state. These three stages are plotted with overlaid time-coloured plot images of the

![]() $Eh = 54\,\rm N\,m^-{^1}$

nozzle for

$Eh = 54\,\rm N\,m^-{^1}$

nozzle for

![]() ${L}/{D}=4$

in figures 9(a)–9(e). See Supplementary Material 2 for similar plots for each of the flexible nozzles. During phase (i), the initiation of deformation, a travelling wave, or series of travelling waves, propagates down the nozzle. In turn, the first oscillation inward generates the largest deflection at the nozzle tip while the pump is running, defined as

${L}/{D}=4$

in figures 9(a)–9(e). See Supplementary Material 2 for similar plots for each of the flexible nozzles. During phase (i), the initiation of deformation, a travelling wave, or series of travelling waves, propagates down the nozzle. In turn, the first oscillation inward generates the largest deflection at the nozzle tip while the pump is running, defined as

![]() $t_{max\;def}$

. This motion is shown for the

$t_{max\;def}$

. This motion is shown for the

![]() $Eh = 54\,\rm N\,m^-{^1}$

nozzle in figures 9(a) and 9(d). In phase (ii),

$Eh = 54\,\rm N\,m^-{^1}$

nozzle in figures 9(a) and 9(d). In phase (ii),

![]() $t_{max\;def}\lt t\lt t_{cycle}$

, the nozzles return to their initial position but with an over correction, expanding into the opposite plane of the initial tip deflection. These oscillations continue at varying frequencies depending on

$t_{max\;def}\lt t\lt t_{cycle}$

, the nozzles return to their initial position but with an over correction, expanding into the opposite plane of the initial tip deflection. These oscillations continue at varying frequencies depending on

![]() $Eh$

as shown in figures 9(b) and 9(e), until the pump turns off at

$Eh$

as shown in figures 9(b) and 9(e), until the pump turns off at

![]() $t/t_{cycle}=1$

marking the end of phase (ii). In phase (iii),

$t/t_{cycle}=1$

marking the end of phase (ii). In phase (iii),

![]() $t\gt t_{cycle}$

, each less stiff nozzle (

$t\gt t_{cycle}$

, each less stiff nozzle (

![]() $Eh = 54, 29, 19\,\rm N\,m^-{^1}$

) collapses asymmetrically inward due to the decreased pressure from the quick decrease in velocity as the pump shuts off as shown from

$Eh = 54, 29, 19\,\rm N\,m^-{^1}$

) collapses asymmetrically inward due to the decreased pressure from the quick decrease in velocity as the pump shuts off as shown from

![]() $t_{cycle}\lt t\lt 2t_{cycle}$

in figures 9(c) and 9(f). The

$t_{cycle}\lt t\lt 2t_{cycle}$

in figures 9(c) and 9(f). The

![]() $Eh = 54\,\rm N\,m^-{^1}$

nozzle tip immediately reopens after partially collapsing. In contrast, the

$Eh = 54\,\rm N\,m^-{^1}$

nozzle tip immediately reopens after partially collapsing. In contrast, the

![]() $Eh = 29$

and

$Eh = 29$

and

![]() $19\,\rm N\,m^-{^1}$

nozzles fully collapse and remain in the collapsed position for 9 and 25 s, respectively, before reopening and oscillating back to their original position. Each nozzle consistently collapsed on one preferential axis for every trial.

$19\,\rm N\,m^-{^1}$

nozzles fully collapse and remain in the collapsed position for 9 and 25 s, respectively, before reopening and oscillating back to their original position. Each nozzle consistently collapsed on one preferential axis for every trial.

The

![]() $Eh = 76\,\rm N\,m^-{^1}$

nozzle was observed to have different kinematics than the less stiff nozzles. While the pump was moving, small-scale (

$Eh = 76\,\rm N\,m^-{^1}$

nozzle was observed to have different kinematics than the less stiff nozzles. While the pump was moving, small-scale (

![]() $\approx {0.02D}$

) axisymmetric oscillations moved the nozzle slightly inward and outward until the pump stopped. Similar to the other nozzles, the pressure change at the nozzle exit created a small peak in deflection (

$\approx {0.02D}$

) axisymmetric oscillations moved the nozzle slightly inward and outward until the pump stopped. Similar to the other nozzles, the pressure change at the nozzle exit created a small peak in deflection (

![]() $\approx {0.04D}$

) but the

$\approx {0.04D}$

) but the

![]() $Eh = 76\,\rm N\,m^-{^1}$

nozzle did not exhibit any collapse. Afterward, it oscillated back and forth until the viscous forces from the surrounding water damped the nozzle motion to a halt.

$Eh = 76\,\rm N\,m^-{^1}$

nozzle did not exhibit any collapse. Afterward, it oscillated back and forth until the viscous forces from the surrounding water damped the nozzle motion to a halt.

Figure 9. Imaging of the

![]() $Eh = 54\,\rm N\,m^-{^1}$

nozzle for

$Eh = 54\,\rm N\,m^-{^1}$

nozzle for

![]() ${L}/{D} = 4$

. The colour plot scale bar applies to each image, with the start and finish defined as follows in the panel descriptions. (a, d) Nozzle deformation for

${L}/{D} = 4$

. The colour plot scale bar applies to each image, with the start and finish defined as follows in the panel descriptions. (a, d) Nozzle deformation for

![]() $t = $

$t = $

![]() $0 - t_{max\;def}$

. (b, e) Nozzle deformation for

$0 - t_{max\;def}$

. (b, e) Nozzle deformation for

![]() $t = t_{max\;def} - t_{cycle}$

. (c, f) Nozzle deformation for

$t = t_{max\;def} - t_{cycle}$

. (c, f) Nozzle deformation for

![]() $t = t_{cycle} - 2t_{cycle}$

.

$t = t_{cycle} - 2t_{cycle}$

.

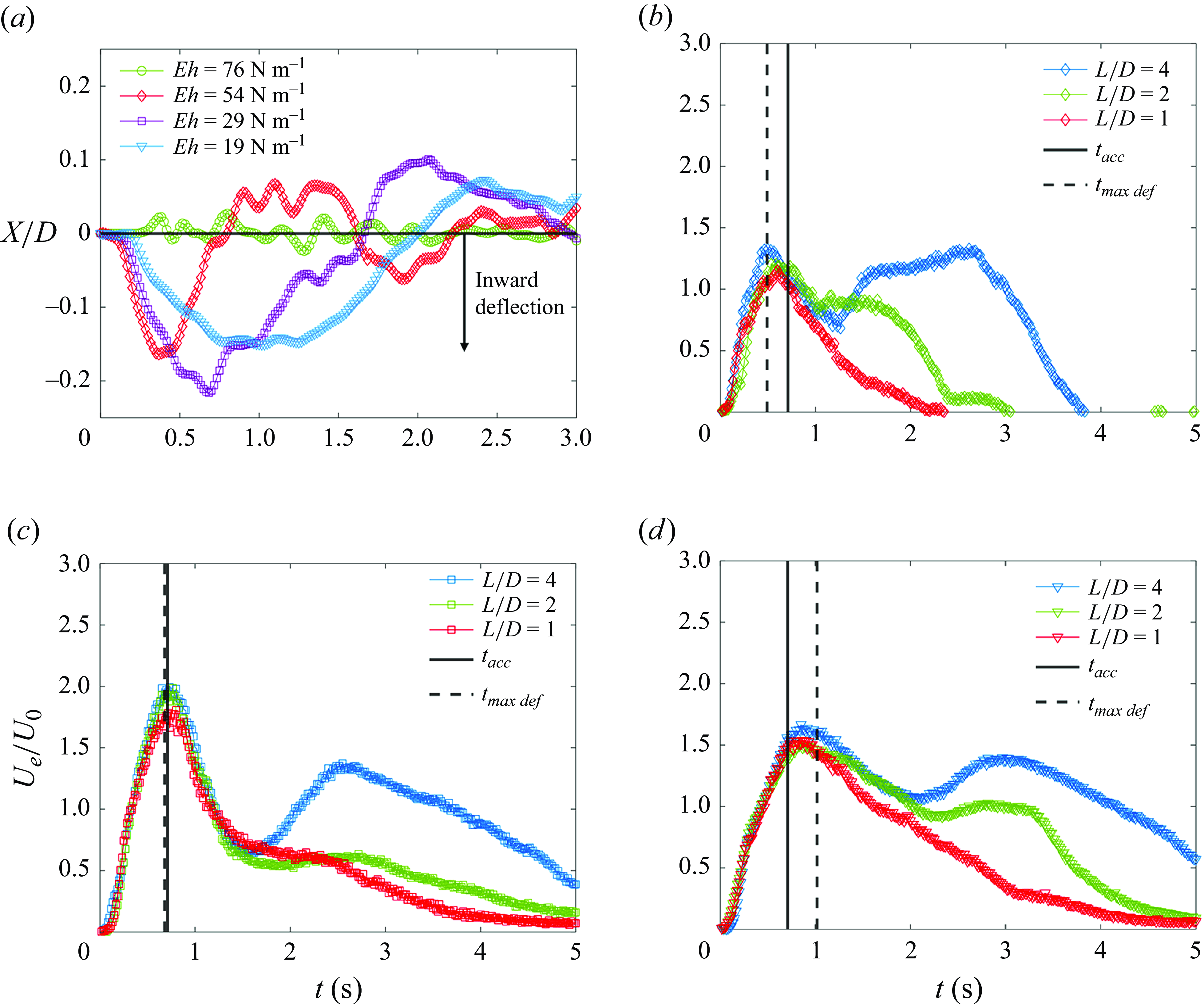

The bottom millimetre of the flexible nozzles was also quantitatively tracked. As expected, reducing the nozzle stiffness resulted in greater maximum deformation magnitudes at

![]() $t=t_{max\;def}$

, ranging from

$t=t_{max\;def}$

, ranging from

![]() $0.02D$

to

$0.02D$

to

![]() $0.19D$

for the

$0.19D$

for the

![]() $Eh = 76$

and

$Eh = 76$

and

![]() $29\,\rm N\,m^-{^1}$

nozzles, respectively. Although the

$29\,\rm N\,m^-{^1}$

nozzles, respectively. Although the

![]() $Eh=19\,\rm N\,m^-{^1}$

nozzle is the least stiff, the peak deformation was lower at only

$Eh=19\,\rm N\,m^-{^1}$

nozzle is the least stiff, the peak deformation was lower at only

![]() $0.15D$

. This will be discussed further in § 3.2. The

$0.15D$

. This will be discussed further in § 3.2. The

![]() $Eh = 54\,\rm N\,m^-{^1}$

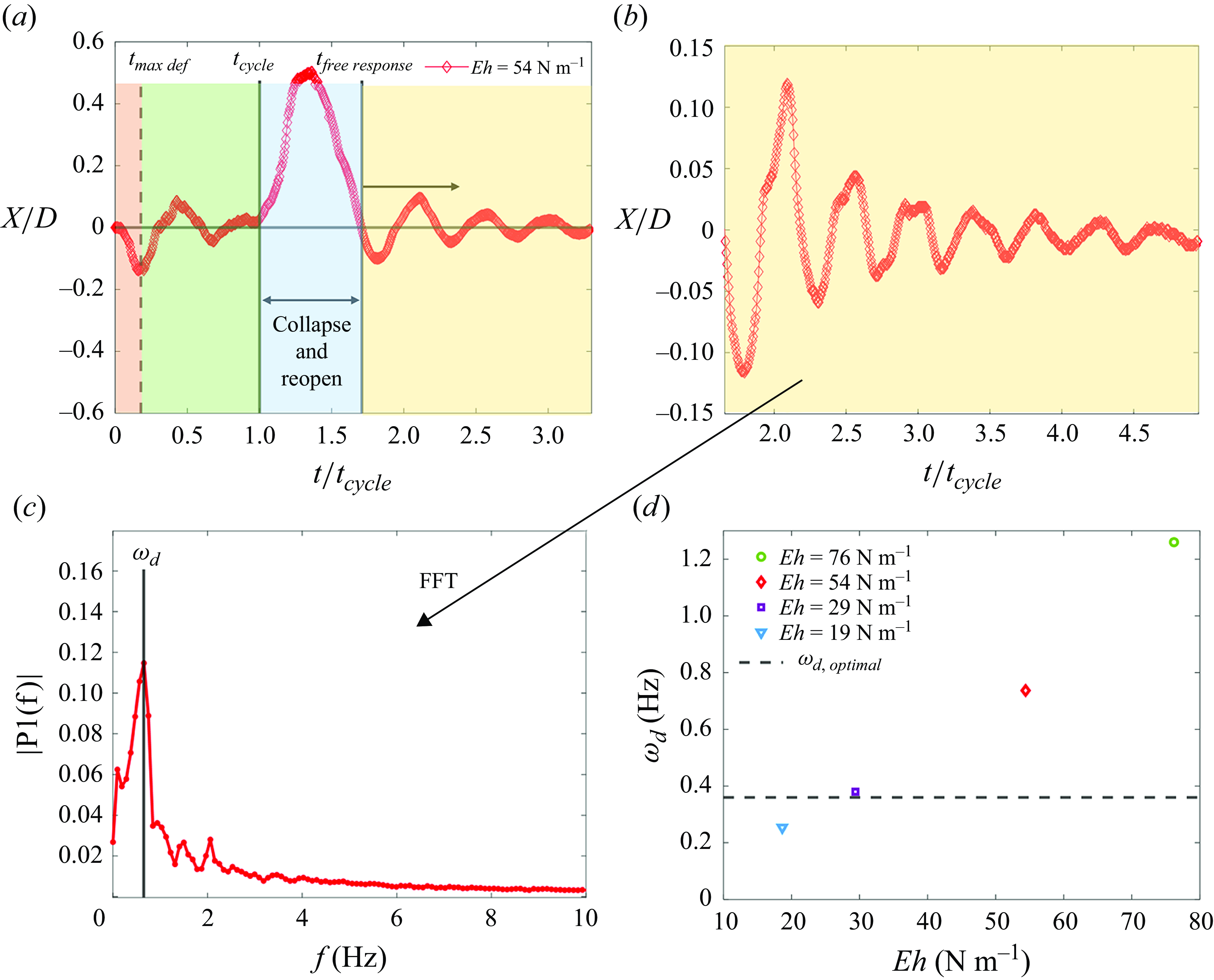

tip deformation is shown in figure 10(a), illustrating the previously described deformation of the nozzle’s bottom millimetre. It is noted that prior to its inward deflection, the nozzle undergoes a small radial expansion due to jet acceleration and the positive internal pressure gradient. However, the magnitude of this deformation is significantly smaller than the large inward deflection and therefore does not appear prominently in figure 10(a). For reference, a plot illustrating the tip deformation of all the flexible nozzles is shown in figure 11(a). In figure 10(a), phases (i), (ii) and (iii) are delineated by orange, blue and green shading. In phase (i), orange, the nozzle tip shape becomes a slightly non-axisymmetric elongated oval at

$Eh = 54\,\rm N\,m^-{^1}$

tip deformation is shown in figure 10(a), illustrating the previously described deformation of the nozzle’s bottom millimetre. It is noted that prior to its inward deflection, the nozzle undergoes a small radial expansion due to jet acceleration and the positive internal pressure gradient. However, the magnitude of this deformation is significantly smaller than the large inward deflection and therefore does not appear prominently in figure 10(a). For reference, a plot illustrating the tip deformation of all the flexible nozzles is shown in figure 11(a). In figure 10(a), phases (i), (ii) and (iii) are delineated by orange, blue and green shading. In phase (i), orange, the nozzle tip shape becomes a slightly non-axisymmetric elongated oval at

![]() $t=t_{maxdef}$

. In phase (ii), green, the nozzle quickly returns to an approximately axisymmetric shape with smaller periodic oscillations. In phase (iii), blue, the nozzle collapses from the negative pressure gradient within the nozzle becoming highly non-axisymmetric. The nozzle tracking shown is from the XY plane to clearly show the large collapse. Once the nozzle reopens at

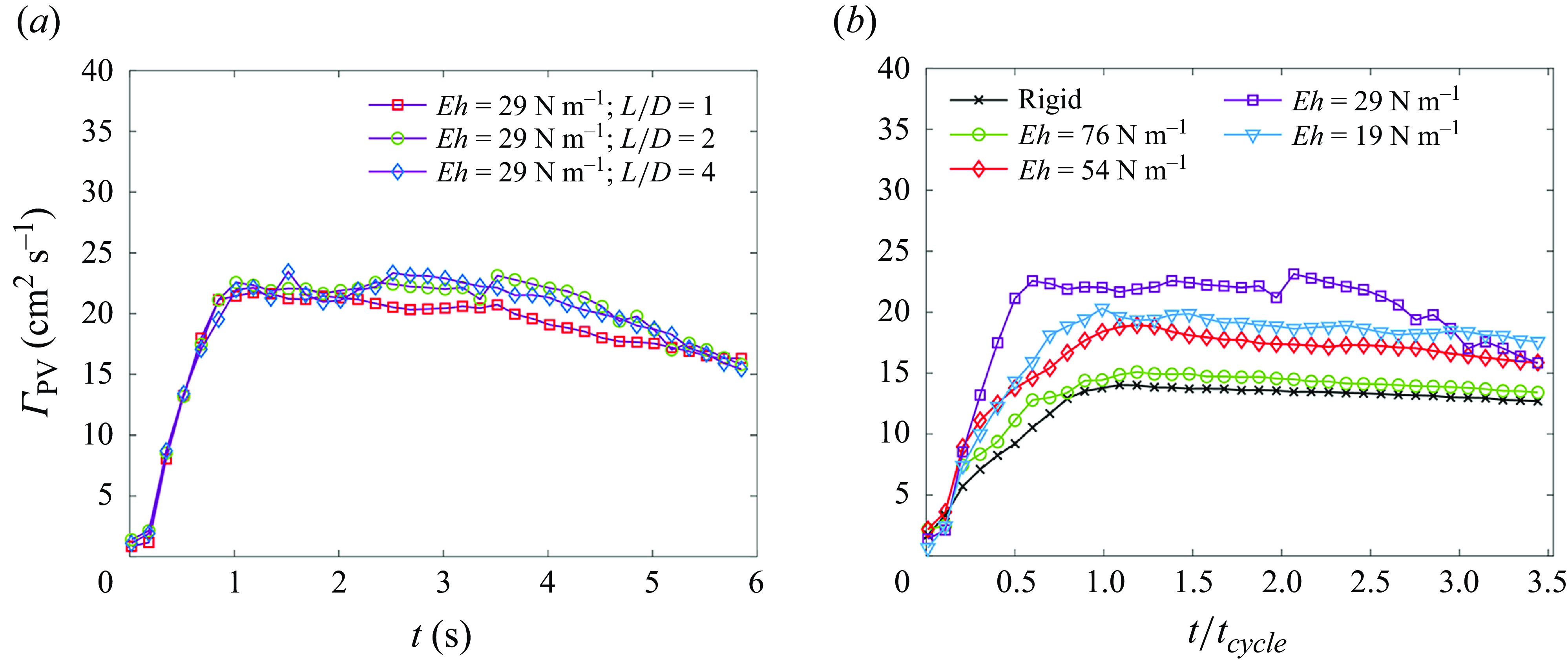

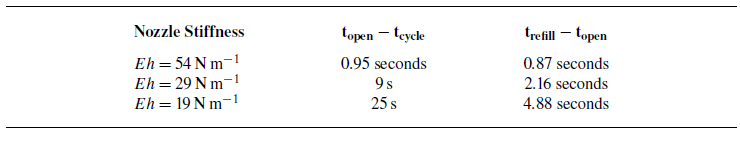

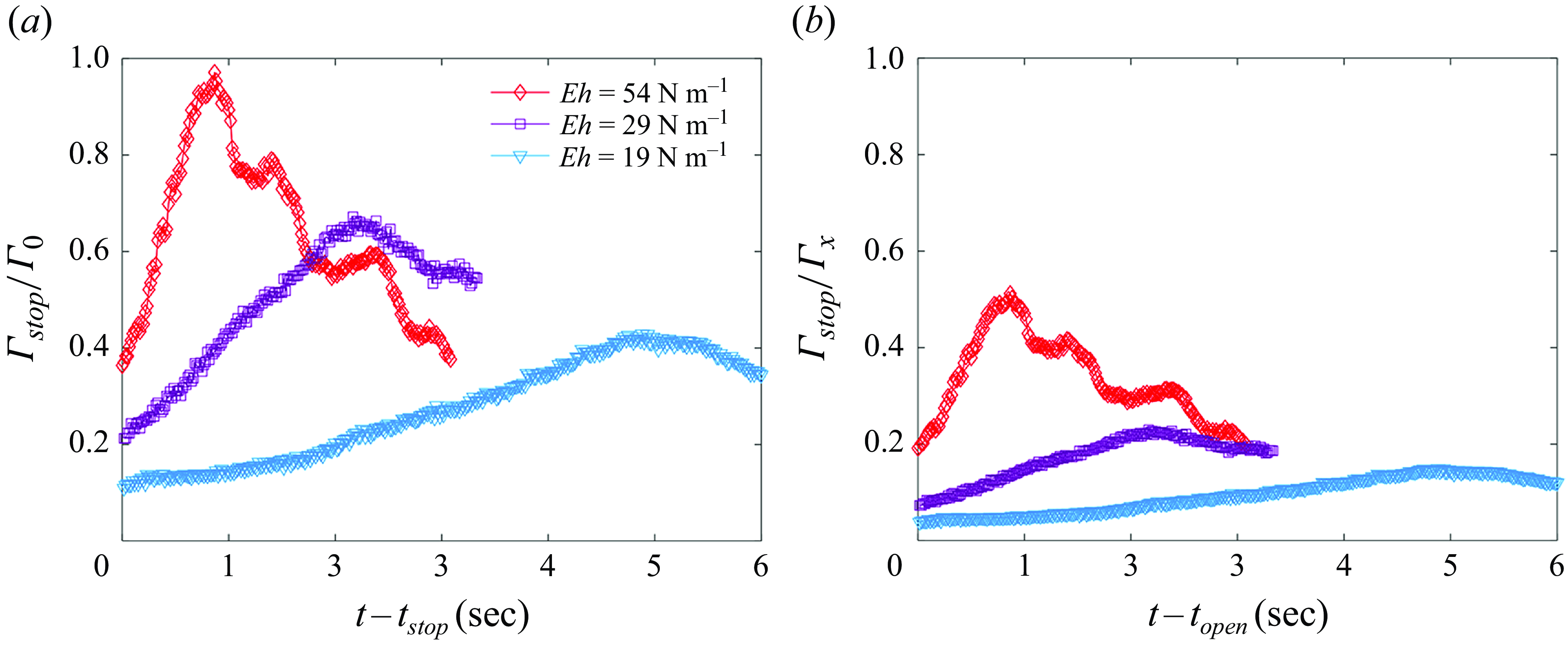

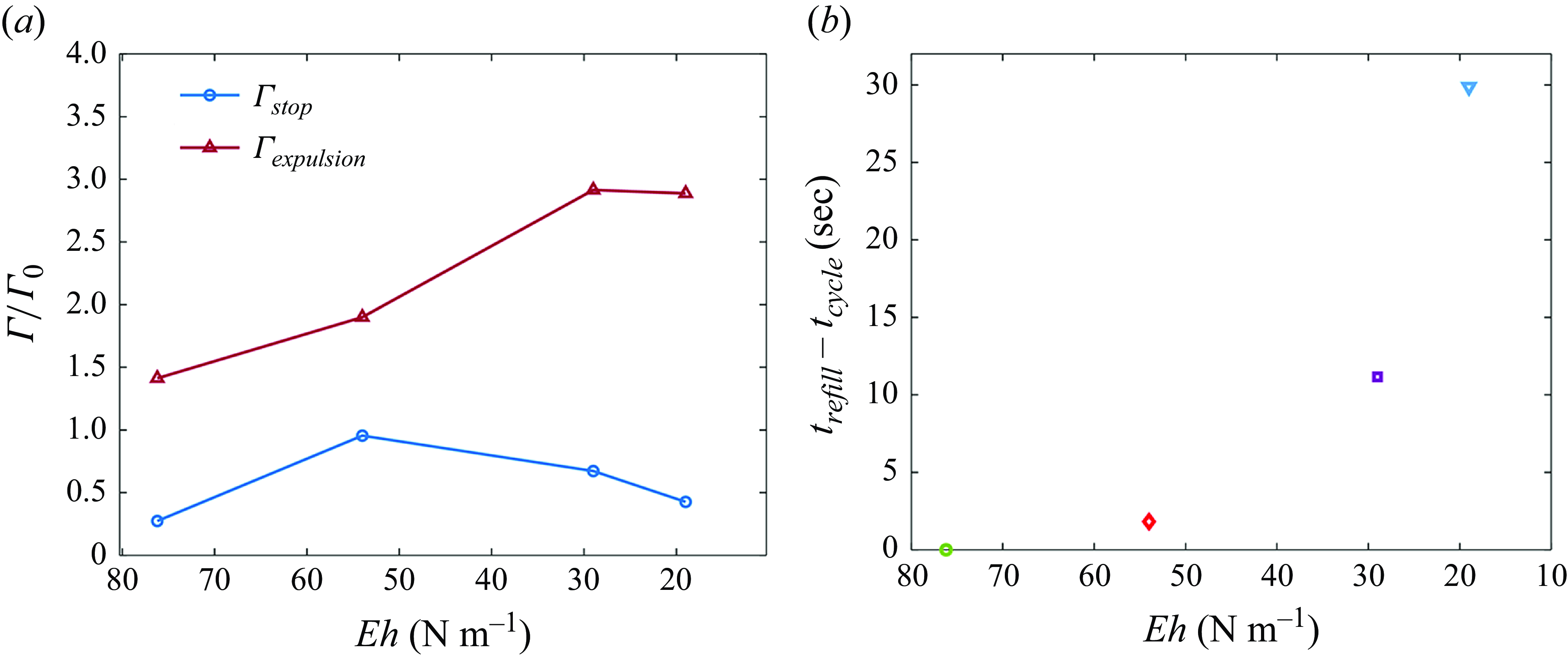

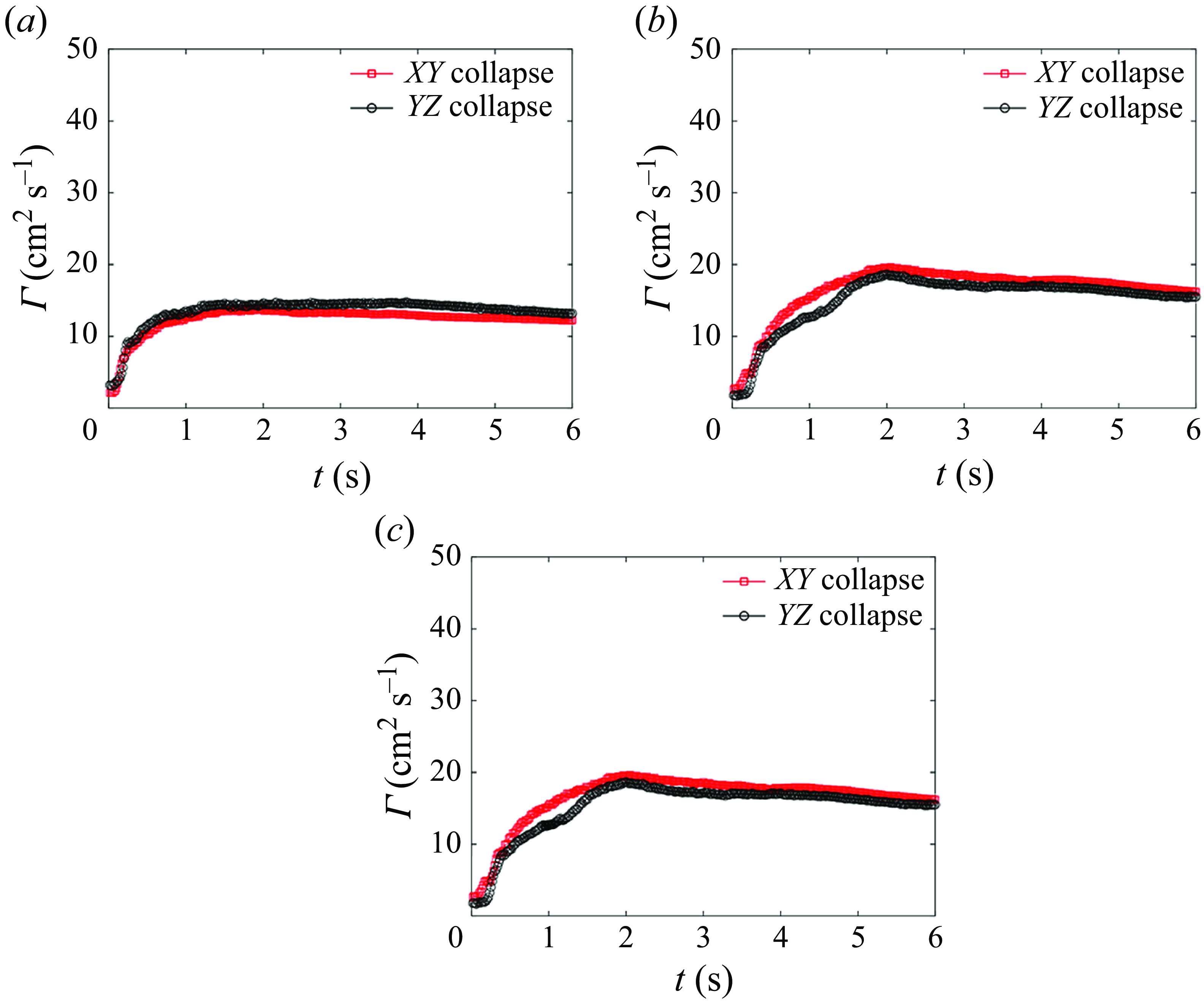

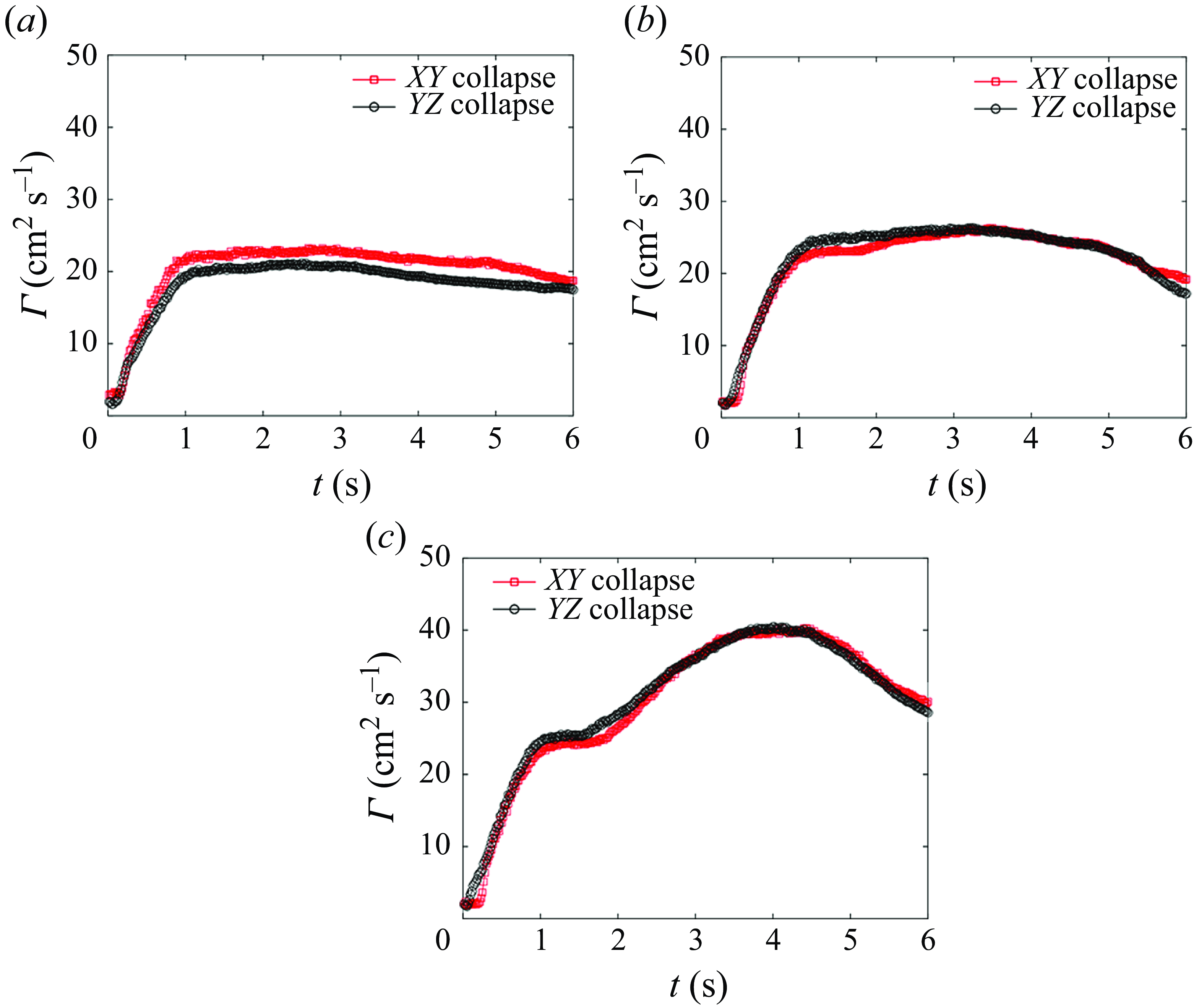

$t=t_{maxdef}$