1. Introduction

Riblets, consisting of streamwise periodic grooves, are a well-known passive technique to reduce the drag on surfaces where experiments and simulations have reported maximums of between

![]() $6\,\%\!-\!9\, \%$

reductions in the skin-friction drag in a variety of conditions (Walsh Reference Walsh1983; Walsh & Lindemann Reference Walsh and Lindemann1984; Dinkelacker, Nitschke-Kowsky & Reif Reference Dinkelacker, Nitschke-Kowsky and Reif1988; Viswanath & Mukund Reference Viswanath and Mukund1995; Bechert et al. Reference Bechert, Bruse, Hage, Van der Hoeven and Hoppe1997; Bechert et al. Reference Bechert, Bruse, Hage and Meyer2000; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011; Chamorro, Arndt & Sotiropoulos Reference Chamorro, Arndt and Sotiropoulos2013; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019, Reference Raayai-Ardakani and McKinley2020; Raayai-Ardakani Reference Raayai-Ardakani2022; Wong et al. Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024). In larger-scale experiments with model or full-scale vehicles, riblets have also proven to be effective; In tests with a high-speed buoyancy propelled vehicle (MOBY-D), Choi (Reference Choi1990a

) reported a

$6\,\%\!-\!9\, \%$

reductions in the skin-friction drag in a variety of conditions (Walsh Reference Walsh1983; Walsh & Lindemann Reference Walsh and Lindemann1984; Dinkelacker, Nitschke-Kowsky & Reif Reference Dinkelacker, Nitschke-Kowsky and Reif1988; Viswanath & Mukund Reference Viswanath and Mukund1995; Bechert et al. Reference Bechert, Bruse, Hage, Van der Hoeven and Hoppe1997; Bechert et al. Reference Bechert, Bruse, Hage and Meyer2000; García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011; Chamorro, Arndt & Sotiropoulos Reference Chamorro, Arndt and Sotiropoulos2013; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019, Reference Raayai-Ardakani and McKinley2020; Raayai-Ardakani Reference Raayai-Ardakani2022; Wong et al. Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024). In larger-scale experiments with model or full-scale vehicles, riblets have also proven to be effective; In tests with a high-speed buoyancy propelled vehicle (MOBY-D), Choi (Reference Choi1990a

) reported a

![]() $3.4\, \%$

reduction in the frictional drag and Szodruch (Reference Szodruch1991) showed that an Airbus 320 covered with

$3.4\, \%$

reduction in the frictional drag and Szodruch (Reference Szodruch1991) showed that an Airbus 320 covered with

![]() $70\, \%$

riblets can deliver almost a

$70\, \%$

riblets can deliver almost a

![]() $2\, \%$

reduction in total drag. Walsh et al. (Reference Walsh, Sellers and McGinley1989) also report that a V-groove plate of 5.83 ft by 1 ft placed at about 6.2 ft aft of the nose of a modified Gates Learjet model 28/29 twin-jet business jet experienced a maximum of

$2\, \%$

reduction in total drag. Walsh et al. (Reference Walsh, Sellers and McGinley1989) also report that a V-groove plate of 5.83 ft by 1 ft placed at about 6.2 ft aft of the nose of a modified Gates Learjet model 28/29 twin-jet business jet experienced a maximum of

![]() $6\, \%$

reduction as measured by on-board boundary layer (BL) wake rakes attached to the plane. Other passive drag reduction techniques such as travelling waves (Du, Symeonidis & Karniadakis Reference Du, Symeonidis and Karniadakis2002; Nguyen, Ricco & Pironti Reference Nguyen, Ricco and Pironti2021), the use of curved surfaces (Banchetti, Luchini & Quadrio Reference Banchetti, Luchini and Quadrio2020), superhydrophobic surfaces (Lee, Choi & Kim Reference Lee, Choi and Kim2016), polymer additives (White & Mungal Reference White and Mungal2008), and large eddy breakup devices (Walsh, Anders & Hefner Reference Walsh, Anders and Hefner1987) are also being investigated for different aero/hydrodynamic applications.

$6\, \%$

reduction as measured by on-board boundary layer (BL) wake rakes attached to the plane. Other passive drag reduction techniques such as travelling waves (Du, Symeonidis & Karniadakis Reference Du, Symeonidis and Karniadakis2002; Nguyen, Ricco & Pironti Reference Nguyen, Ricco and Pironti2021), the use of curved surfaces (Banchetti, Luchini & Quadrio Reference Banchetti, Luchini and Quadrio2020), superhydrophobic surfaces (Lee, Choi & Kim Reference Lee, Choi and Kim2016), polymer additives (White & Mungal Reference White and Mungal2008), and large eddy breakup devices (Walsh, Anders & Hefner Reference Walsh, Anders and Hefner1987) are also being investigated for different aero/hydrodynamic applications.

The majority of studies on drag reduction with riblets have been focused on turbulent flows, and the literature on the effect of riblets in laminar flow conditions have been sparse. Two mechanisms have been identified for the drag reduction with riblets; The first one, applicable to both laminar and turbulent flows, is the presence of slow and near quiescent flow inside the grooves (Bacher & Smith Reference Bacher and Smith1986; Wallace & Balint Reference Wallace and Balint1988; Baron, Quadrio & Vigevano Reference Baron, Quadrio and Vigevano1993; Chu & Karniadakis Reference Chu and Karniadakis1993; Djenidi et al. Reference Djenidi, Anselmet, Liandrat and Fulachier1994; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019). This slow-moving fluid causes the shear stress inside the grooves to be lower than that of the smooth reference and only close to the peaks of the grooves shear stresses larger than the smooth surface are reported (Khan Reference Khan1986; Choi, Moin & Kim Reference Choi, Moin and Kim1993; Chu & Karniadakis Reference Chu and Karniadakis1993; Park & Wallace Reference Park and Wallace1994; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2019; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021; Raayai-Ardakani Reference Raayai-Ardakani2022). This spanwise shear stress distribution can reduce the average shear stress experienced by the riblets and result in an overall reduction in the frictional drag. The second mechanism, only applicable to turbulent flows, is related to the ability of the drag-reducing riblets to adjust the spanwise flow and quasi-streamwise turbulent vortices (Choi et al. Reference Choi, Moin and Kim1993; Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1995; Djenidi & Antonia Reference Djenidi and Antonia1996; Lee & Lee Reference Lee and Lee2001). Djenidi & Antonia (Reference Djenidi and Antonia1996) report that drag-reducing riblets experience weaker quasi-streamwise vortices compared with the smooth wall that results in a less effective transport of momentum to the wall. Goldstein et al. (Reference Goldstein, Handler and Sirovich1995) report that the quasi-streamwise vortices are pushed away from the wall in the presence of drag-reducing riblets. El-Samni, Chun & Yoon (Reference El-Samni, Chun and Yoon2007) show that vortices penetrate rectangular drag-increasing riblets. Viswanath (Reference Viswanath2002) and Caram & Ahmed (Reference Caram and Ahmed1991) report a lower level of Reynolds shear stress close to the wall and Lancey & Reidy (Reference Lancey and Reidy1989) measured reductions in the velocity and pressure fluctuations at the wall. Taking the combined importance of the flow retardation inside the grooves and the relocation of the cross-sectional flow into account, Luchini, Manzo & Pozzi (Reference Luchini, Manzo and Pozzi1991) and Luchini (Reference Luchini1995) present a linear protrusion height model where the ability of the riblets in reducing/increasing the drag is related to the difference between the apparent origin of the streamwise flow inside the grooves and the origin of the spanwise flow, both obtained using Stokesflow calculations for a given riblet (Luchini Reference Luchini1995; Bechert et al. Reference Bechert, Bruse, Hage, Van der Hoeven and Hoppe1997; Grüneberger & Hage Reference Grüneberger and Hage2011). Wong et al. (Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024) have taken the modelling further and offer a viscous vortex model where the turbulent scale is allowed to interact with a non-vanishing riblet size to accurately predict the drag performance of the riblets in the viscous limit (using direct numerical simulations).

Riblets as drag-reducing agents affect the near-wall BL and, thus, have been mainly explored as a means of reducing the skin-friction drag, especially in zero-pressure gradient conditions (Walsh & Weinstein Reference Walsh and Weinstein1979; Abu Dinkelacker et al. Reference Dinkelacker, Nitschke-Kowsky and Reif1988; Choi et al. Reference Choi, Moin and Kim1993; Chu & Karniadakis Reference Chu and Karniadakis1993; Bechert et al. Reference Bechert, Bruse, Hage, Van der Hoeven and Hoppe1997; Chamorro et al. Reference Chamorro, Arndt and Sotiropoulos2013; Hou, Hokmabad & Ghaemi Reference Hou, Hokmabad and Ghaemi2017; Abu Rowin & Ghaemi Reference Abu Rowin and Ghaemi2019; Endrikat et al. Reference Endrikat, Newton, Modesti, García-Mayoral, Hutchins and Chung2022; Wong et al. Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024). There are only reports of a few cases for well-defined adverse and favourable pressure gradient BL (Choi Reference Choi1990; Nieuwstadt et al. Reference Nieuwstadt, Wolthers, Leijdens, Krishna Prasad and Schwarz-van Manen1993; Debisschop & Nieuwstadt Reference Debisschop and Nieuwstadt1996; Klumpp et al. Reference Klumpp, Guldner, Meinke and Schröder2010b

) and wake studies (Caram & Ahmed Reference Caram and Ahmed1989, Reference Caram and Ahmed1991, Reference Caram and Ahmed1992; Coustols Reference Coustols1989; Subashchandar, Rajeev & Sundaram Reference Subashchandar, Rajeev and Sundaram1995; Sundaram, Viswanath & Rudrakumar Reference Sundaram, Viswanath and Rudrakumar1996; Subaschandar, Kumar & Sundaram Reference Subaschandar, Kumar and Sundaram1999; Chamorro et al. Reference Chamorro, Arndt and Sotiropoulos2013) available so far. These experimental designs were focused on exploring the effect of asymptotic BLs, zero and well-defined pressure gradients, as well as wakes of the airfoils, and not aimed at identifying or decoupling the impact of the skin-friction-reducing techniques on the other components of the drag. The impact of riblets on the pressure distribution, pressure drag and, if applicable, lift is relatively unexplored (Van den Berg Reference Van den Berg1988; Choi Reference Choi1990; Nieuwstadt et al. Reference Nieuwstadt, Wolthers, Leijdens, Krishna Prasad and Schwarz-van Manen1993b

). In the past few years the effect of skin-friction reducing techniques on other drag components, such as pressure drag, have been exhibited numerically for applications ranging from transonic flight and modern UAVs (unmanned aerial vehicles) (Banchetti et al. Reference Banchetti, Luchini and Quadrio2020; Nguyen et al. Reference Nguyen, Ricco and Pironti2021; Cacciatori et al. Reference Cacciatori, Brignoli, Mele, Gattere, Monti and Quadrio2022; Quadrio et al. Reference Quadrio, Chiarini, Banchetti, Gatti, Memmolo and Pirozzoli2022). The ability of riblets in altering the pressure distribution around an airfoil has been recently shown using numerical simulations (Mele & Tognaccini Reference Mele and Tognaccini2012; Mele et al. Reference Mele, Tognaccini, Catalano and de Rosa2020; Cacciatori et al. Reference Cacciatori, Brignoli, Mele, Gattere, Monti and Quadrio2022) where the changes in the shear stress of a riblet-covered aircraft compared with a smooth body are a function of the position along the aircraft (Mele, Tognaccini & Catalano Reference Mele, Tognaccini and Catalano2016). In addition, under the pressure distribution caused by a constant angle of attack of

![]() $2.25^{\circ }$

, riblets offer a

$2.25^{\circ }$

, riblets offer a

![]() $4\, \%$

reduction in drag and a

$4\, \%$

reduction in drag and a

![]() $5\, \%$

increase in lift. However, to keep the lift coefficient constant, the riblet-covered aircraft needs to be operated at a lower angle of attack of

$5\, \%$

increase in lift. However, to keep the lift coefficient constant, the riblet-covered aircraft needs to be operated at a lower angle of attack of

![]() $2.09^{\circ }$

, with potential for over

$2.09^{\circ }$

, with potential for over

![]() $9\, \%$

reduction in drag (Mele et al. Reference Mele, Tognaccini and Catalano2016).

$9\, \%$

reduction in drag (Mele et al. Reference Mele, Tognaccini and Catalano2016).

Previous reports with riblets applied directly to airfoils or body--wing combinations have been focused to cases with

![]() $\textit{Re}_{{c}}\gt 10^{5}$

(the Reynolds number based on the chord length) as well as transonic conditions. Coustols (Reference Coustols1989) reports that using wake measurements at a distance of 0.5

$\textit{Re}_{{c}}\gt 10^{5}$

(the Reynolds number based on the chord length) as well as transonic conditions. Coustols (Reference Coustols1989) reports that using wake measurements at a distance of 0.5

![]() $c$

away from the body leads to viscous drag reductions of

$c$

away from the body leads to viscous drag reductions of

![]() $2.7\, \%$

for an LC100D airfoil, with riblets of

$2.7\, \%$

for an LC100D airfoil, with riblets of

![]() $s=h=152\,\unicode {x03BC}\textrm {m}$

(

$s=h=152\,\unicode {x03BC}\textrm {m}$

(

![]() $h^{+}=10$

) covering between

$h^{+}=10$

) covering between

![]() $0.2\lt x/c\lt 0.95$

at angles of attack of below 3

$0.2\lt x/c\lt 0.95$

at angles of attack of below 3

![]() $^{\circ }$

and

$^{\circ }$

and

![]() $\textit{Re}_c \approx 5.3 {-} 7.95 \times 10^5$

. Sundaram et al. (Reference Sundaram, Viswanath and Rudrakumar1996) perform experiments with a NACA 0012 foil at

$\textit{Re}_c \approx 5.3 {-} 7.95 \times 10^5$

. Sundaram et al. (Reference Sundaram, Viswanath and Rudrakumar1996) perform experiments with a NACA 0012 foil at

![]() $\textit{Re}_c = 10^6$

, covered with riblets of

$\textit{Re}_c = 10^6$

, covered with riblets of

![]() $s=h=152\,\unicode {x03BC}\textrm {m}$

(

$s=h=152\,\unicode {x03BC}\textrm {m}$

(

![]() $10\lt h^{+}\lt 15)$

in the

$10\lt h^{+}\lt 15)$

in the

![]() $0.12 \lt x/c \lt 0.96$

segment of the airfoil, where a

$0.12 \lt x/c \lt 0.96$

segment of the airfoil, where a

![]() $16\, \%$

drag reduction was inferred from the wake survey for angles of attack less than 6

$16\, \%$

drag reduction was inferred from the wake survey for angles of attack less than 6

![]() $^{\circ }$

. Caram & Ahmed (Reference Caram and Ahmed1991) also used wake surveys reporting a total reduction in drag of

$^{\circ }$

. Caram & Ahmed (Reference Caram and Ahmed1991) also used wake surveys reporting a total reduction in drag of

![]() $13.3\, \%$

for riblet-covered NACA 0012 at

$13.3\, \%$

for riblet-covered NACA 0012 at

![]() $\textit{Re}_c = 2.5 \times 10^5$

with riblets of

$\textit{Re}_c = 2.5 \times 10^5$

with riblets of

![]() $s=h=152\,\unicode {x03BC}\textrm {m}$

(

$s=h=152\,\unicode {x03BC}\textrm {m}$

(

![]() $h^{+}=10$

). Subashchandar et al. (Reference Subashchandar, Rajeev and Sundaram1995) and Subaschandar et al. (Reference Subaschandar, Kumar and Sundaram1999) similarly used riblets at

$h^{+}=10$

). Subashchandar et al. (Reference Subashchandar, Rajeev and Sundaram1995) and Subaschandar et al. (Reference Subaschandar, Kumar and Sundaram1999) similarly used riblets at

![]() $\textit{Re}_c = 10^6$

and reported frictional and total reduction of

$\textit{Re}_c = 10^6$

and reported frictional and total reduction of

![]() $13\, \%$

and

$13\, \%$

and

![]() $15\, \%$

, respectively, for a riblet-covered (

$15\, \%$

, respectively, for a riblet-covered (

![]() $s=h=152\,\unicode {x03BC}\textrm {m}$

) symmetric NACA 0012, and

$s=h=152\,\unicode {x03BC}\textrm {m}$

) symmetric NACA 0012, and

![]() $10\, \%$

total for a riblet-covered (

$10\, \%$

total for a riblet-covered (

![]() $s=h=76\,\unicode {x03BC}\textrm {m}$

) cambered GAW(2) airfoil at a

$s=h=76\,\unicode {x03BC}\textrm {m}$

) cambered GAW(2) airfoil at a

![]() $6^{\circ }$

angle of attack. Chamorro et al. (Reference Chamorro, Arndt and Sotiropoulos2013) used DU 96-W-180 airfoils (used for wind turbine blades) with trapezoidal riblets and employed wake measurements at

$6^{\circ }$

angle of attack. Chamorro et al. (Reference Chamorro, Arndt and Sotiropoulos2013) used DU 96-W-180 airfoils (used for wind turbine blades) with trapezoidal riblets and employed wake measurements at

![]() $Re =2.2 \times 10^6$

and angle of attacks ranging from

$Re =2.2 \times 10^6$

and angle of attacks ranging from

![]() $0^{\circ}$

–

$0^{\circ}$

–

![]() $10^{\circ}$

, recording a maximum reduction of about

$10^{\circ}$

, recording a maximum reduction of about

![]() $5\, \%$

for triangular grooves with

$5\, \%$

for triangular grooves with

![]() $s=h=80\,\unicode{x03BC}\textrm {m}$

.

$s=h=80\,\unicode{x03BC}\textrm {m}$

.

In general, the levels of drag reduction captured by riblet surfaces are a function of both the dynamics of the flow (Reynolds number) and the geometry of the textures (spacing, height and shape of the textures). The effect of the spacing of the riblets in turbulent wall units have been considered the longest in the literature since the initial work of Walsh & Weinstein (Reference Walsh and Weinstein1979) and the effect of the height in the turbulent wall units have been added in the later work of Walsh (Reference Walsh1983). However, the effect of the cross-sectional shape of the textures have been generally studied in a more qualitative manner with the tested shapes presented in forms of visual drawings in the reports (Walsh Reference Walsh1980; Walsh & Lindemann Reference Walsh and Lindemann1984; Choi et al. Reference Choi, Gadd, Pearcey, Savill and Svensson1989; Bechert et al. Reference Bechert, Bruse, Hage, Van der Hoeven and Hoppe1997; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021; Rouhi et al. Reference Rouhi, Endrikat, Modesti, Sandberg, Oda, Tanimoto, Hutchins and Chung2022; Wong et al. Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024). Through the definition of the

![]() $\ell _g^{+}$

, or the dimensionless cross-sectional area of the textures in wall units, as suggested by García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011), the effect of shape has been considered in a more quantitative manner. This definition is successful in shifting the experimental and numerical results formerly presented in terms of either the spacing or height of the textures in wall units along abscissa of the reduction curves and collapsing them into nearly similar curves with the maximum levels of reductions taking place at

$\ell _g^{+}$

, or the dimensionless cross-sectional area of the textures in wall units, as suggested by García-Mayoral & Jiménez (Reference García-Mayoral and Jiménez2011), the effect of shape has been considered in a more quantitative manner. This definition is successful in shifting the experimental and numerical results formerly presented in terms of either the spacing or height of the textures in wall units along abscissa of the reduction curves and collapsing them into nearly similar curves with the maximum levels of reductions taking place at

![]() $\ell _g^{+} \approx 10.7$

. The remaining differences in the responses of different riblet profiles are only visible in the value of the reductions reported along the ordinate of the plots (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011; Garcia-Mayoral et al. Reference García-Mayoral, Gómez-de-Segura and Fairhall2019; Endrikat et al. Reference Endrikat, Newton, Modesti, García-Mayoral, Hutchins and Chung2022; Wong et al. Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024). While the

$\ell _g^{+} \approx 10.7$

. The remaining differences in the responses of different riblet profiles are only visible in the value of the reductions reported along the ordinate of the plots (García-Mayoral & Jiménez Reference García-Mayoral and Jiménez2011; Garcia-Mayoral et al. Reference García-Mayoral, Gómez-de-Segura and Fairhall2019; Endrikat et al. Reference Endrikat, Newton, Modesti, García-Mayoral, Hutchins and Chung2022; Wong et al. Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024). While the

![]() $\ell _g^{+} \approx 10.7$

offers a physical parameter to identify the geometric guideline and operating conditions to get the best performance from the riblets, it does not offer any way to identify the best shape(s) to get the largest reduction for all possible riblet profiles with

$\ell _g^{+} \approx 10.7$

offers a physical parameter to identify the geometric guideline and operating conditions to get the best performance from the riblets, it does not offer any way to identify the best shape(s) to get the largest reduction for all possible riblet profiles with

![]() $\ell _g^{+} \approx 10.7$

.

$\ell _g^{+} \approx 10.7$

.

With the advances in manufacturing techniques such as three-dimensional printing, micro-milling and computer-numerically controlled (CNC) machining, new opportunities have opened for design of more optimal shapes for the riblets for different applications. To characterise the shape of the cross-sectional profile of the textures in a unique quantitative manner, Raayai-Ardakani (Reference Raayai-Ardakani2022) introduced a polynomial framework where the shape of the texture is defined using a vector of geometric parameters

![]() $\boldsymbol{\kappa } =$

[

$\boldsymbol{\kappa } =$

[

![]() ${\mathcal {R}} = -\kappa _{1}, \kappa _{2}, \ldots , \kappa _{j}$

] using

${\mathcal {R}} = -\kappa _{1}, \kappa _{2}, \ldots , \kappa _{j}$

] using

![]() ${n_{w}(z)}/{(\lambda /2)} = \sum _{j=0}^{J} \sum _{l=j}^{J} m_{jl}\kappa _{l} ({z}/{(\lambda /2)} )^{j}$

. Here

${n_{w}(z)}/{(\lambda /2)} = \sum _{j=0}^{J} \sum _{l=j}^{J} m_{jl}\kappa _{l} ({z}/{(\lambda /2)} )^{j}$

. Here

![]() $n_{w}$

is the cross-sectional profile of the riblet wall in the normal direction,

$n_{w}$

is the cross-sectional profile of the riblet wall in the normal direction,

![]() $m_{jl}$

are constant coefficients,

$m_{jl}$

are constant coefficients,

![]() $\lambda$

is the spacing of the riblets and

$\lambda$

is the spacing of the riblets and

![]() $\kappa _1 = -{\mathcal {R}}$

with

$\kappa _1 = -{\mathcal {R}}$

with

![]() ${\mathcal {R}} = A/(\lambda /2)$

, the height-to-half-spacing ratio.

${\mathcal {R}} = A/(\lambda /2)$

, the height-to-half-spacing ratio.

Here, we aim to investigate the possibility of using riblet surfaces on smaller vehicles, such as in the case of smaller unmanned aerial/underwater vehicles that operate at high-Reynolds-number laminar conditions, where the assumption of the periodicity and self-similarity in the streamwise direction is not readily applicable. Previous explorations of the riblets on full airfoils have mainly used surveys of the wakes of the airfoils to measure the profile drag and infer the skin-friction reduction for the airfoils of interest (Caram & Ahmed Reference Caram and Ahmed1989, Reference Caram and Ahmed1991, Reference Caram and Ahmed1992; Coustols Reference Coustols1989; Subashchandar et al. Reference Subashchandar, Rajeev and Sundaram1995; Sundaram et al. Reference Sundaram, Viswanath and Rudrakumar1996; Subaschandar et al. Reference Subaschandar, Kumar and Sundaram1999; Chamorro et al. Reference Chamorro, Arndt and Sotiropoulos2013). Other experimental formats used previously range from the use of one-sided samples (Walsh Reference Walsh1983; Bacher & Smith Reference Bacher and Smith1986; Endrikat et al. Reference Endrikat, Newton, Modesti, García-Mayoral, Hutchins and Chung2022), partial ribletcoverage (Grek, Kozlov & Titarenko Reference Grek, Kozlov and Titarenko1996) and samples installed as part of the tunnel wall (Walsh Reference Walsh1983), or localised high-resolution tomographic particle image velocimetry (PIV) in the middle of a flat riblet (Hou et al. Reference Hou, Hokmabad and Ghaemi2017). These have been instrumental in advancing the physical understanding of the effect of riblets on flow in self-similar and asymptotic conditions. The set-ups of the direct numerical simulations of riblet surfaces have employed periodic domains (Chu & Karniadakis Reference Chu and Karniadakis1993; Goldstein et al. Reference Goldstein, Handler and Sirovich1995; Rouhi et al. Reference Rouhi, Endrikat, Modesti, Sandberg, Oda, Tanimoto, Hutchins and Chung2022; Choi et al. Reference Choi, Moin and Kim1993; Wong et al. Reference Wong, Camobreco, García-Mayoral, Hutchins and Chung2024). Mele & Tognaccini (Reference Mele and Tognaccini2012, Reference Mele and Tognaccini2018) have derived boundary conditions for simulations of riblets and other drag-reducing devices on airfoils in turbulent flows that have been able to provide details on the effect of the drag-reducing devices on the pressure drag as well.

On the other hand, previous exploration of riblets in laminar flows have been sparse and inconsistent. In laminar flows the asymptotic protrusion height model of Luchini (Reference Luchini1995) for a zero-pressure gradient self-similar Blasius BL and using Stokes flow formulation for the flow inside the grooves, predicts a slight increase in the drag force. A domain perturbation and asymptotic expansion formulation of the Blasius equations solved using conformal mapping is able to predict up to about

![]() $1\, \%$

of reduction possible for textures with height-to-half-spacing of less than 0.8 and

$1\, \%$

of reduction possible for textures with height-to-half-spacing of less than 0.8 and

![]() $\textit{Re}_{L} (\lambda /L)^{2}\lt 1$

(Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2019). Numerical and experimental work by Djenidi et al. (Reference Djenidi, Liandrat, Anselmet and Fulachier1989) and Djenidi et al. (Reference Djenidi, Anselmet, Liandrat and Fulachier1994) and the numerical simulations of Raayai-Ardakani & McKinley (Reference Raayai-Ardakani and McKinley2017) have shown the possibility of achieving larger drag reductions in a laminar BL with riblets.

$\textit{Re}_{L} (\lambda /L)^{2}\lt 1$

(Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2019). Numerical and experimental work by Djenidi et al. (Reference Djenidi, Liandrat, Anselmet and Fulachier1989) and Djenidi et al. (Reference Djenidi, Anselmet, Liandrat and Fulachier1994) and the numerical simulations of Raayai-Ardakani & McKinley (Reference Raayai-Ardakani and McKinley2017) have shown the possibility of achieving larger drag reductions in a laminar BL with riblets.

The streamwise development of a BL along a fully textured flat plate and prior to transition to turbulence results in the shear stress response of the surfaces to also depend on the local streamwise direction or the local Reynolds number (Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019). This development is different from that of the axisymmetric Taylor--Couette flows (Greidanus et al. Reference Greidanus, Delfos, Tokgöz and Westerweel2015; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2020; Raayai-Ardakani Reference Raayai-Ardakani2022) or fully developed channel flows (Choi et al. Reference Choi, Moin and Kim1993; Goldstein et al. Reference Goldstein, Handler and Sirovich1995) that have been easily used in drag reduction studies due to their independence from the streamwise direction. Theoretical and numerical studies by Raayai-Ardakani & McKinley (Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019), using fully textured plates with constant cross-sectional profiles, show that the spanwise-averaged shear stress,

![]() $\tau ^*$

(normalised with the wetted cross-sectional contour length), at the leading edge, starts at nearly the same value as that of the smooth reference plate. Then as the BL develops along the plate,

$\tau ^*$

(normalised with the wetted cross-sectional contour length), at the leading edge, starts at nearly the same value as that of the smooth reference plate. Then as the BL develops along the plate,

![]() $\tau ^*$

decreases more than that of the smooth surface. However, the increase in the wetted surface area of the riblets (compared with the smooth) results in the riblets being drag- (and shear-) increasing for certain plate lengths and only become drag-reducing past a point corresponding to

$\tau ^*$

decreases more than that of the smooth surface. However, the increase in the wetted surface area of the riblets (compared with the smooth) results in the riblets being drag- (and shear-) increasing for certain plate lengths and only become drag-reducing past a point corresponding to

![]() $\textit{Re}_{L} (\lambda /L)^{2}\lt 1$

).

$\textit{Re}_{L} (\lambda /L)^{2}\lt 1$

).

With this background, to fill the existing gap in the application of drag-reduction riblets for smaller vehicles, operating at lower Reynolds numbers, we take the following approach.

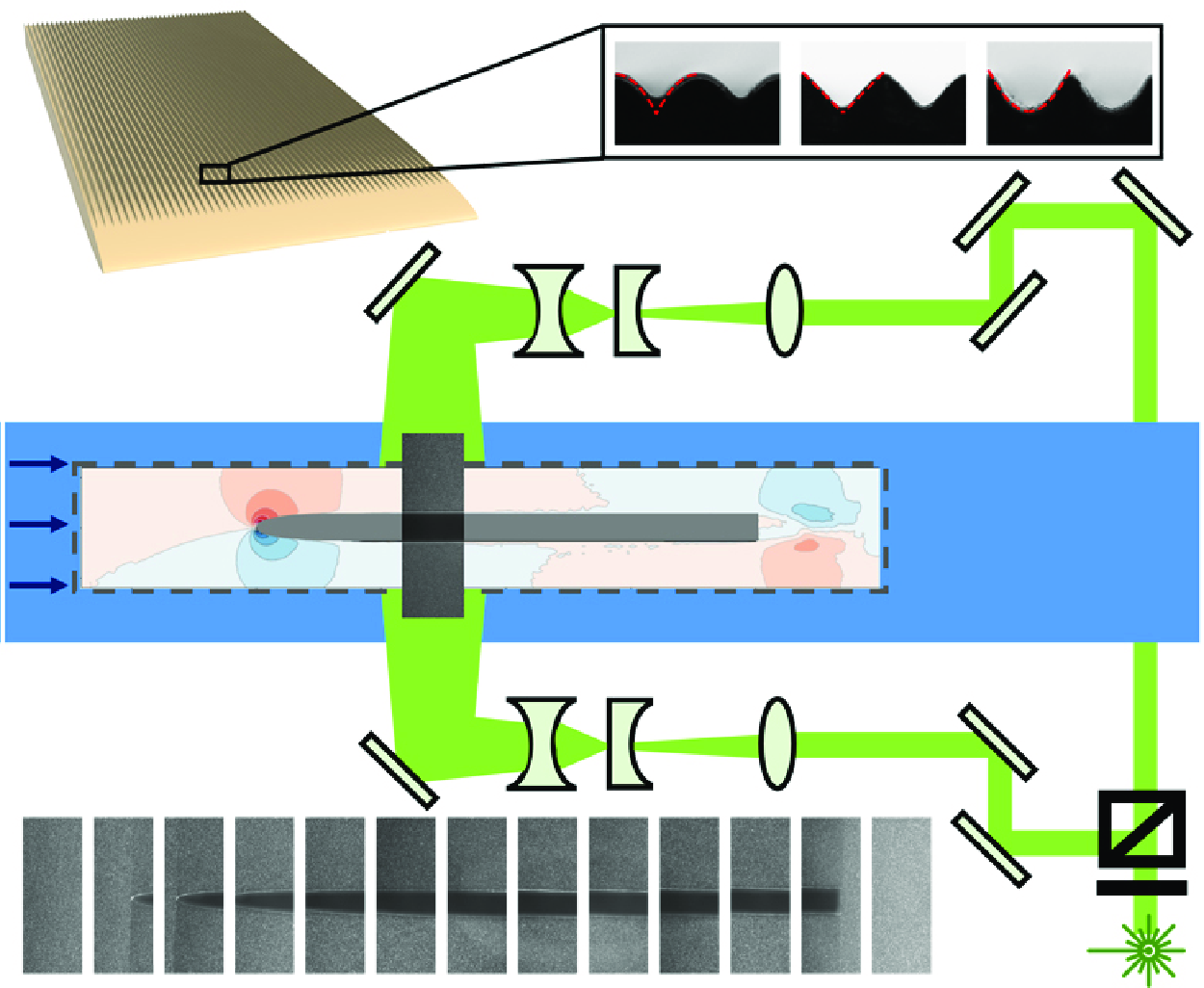

Figure 1. (a) Schematic of a riblet surface with spacing

![]() $\lambda$

and height

$\lambda$

and height

![]() $A$

and a concave cross-sectional profile. (b) Images of the cross-sectional profiles of the riblet samples. For all the samples,

$A$

and a concave cross-sectional profile. (b) Images of the cross-sectional profiles of the riblet samples. For all the samples,

![]() $\lambda = 1$

mm and the respective [

$\lambda = 1$

mm and the respective [

![]() ${\mathcal {R}}, \kappa _2$

] values are listed above each sample. (c) Schematic of the textured sample design and the front view of an actual sample. (d) Schematic of the side view of the sample, including the leading edge of the textured samples and the early part of the Flat region. Three regions, LE, LET and Flat, are shown in the figure as well as the local streamwise and normal directions,

${\mathcal {R}}, \kappa _2$

] values are listed above each sample. (c) Schematic of the textured sample design and the front view of an actual sample. (d) Schematic of the side view of the sample, including the leading edge of the textured samples and the early part of the Flat region. Three regions, LE, LET and Flat, are shown in the figure as well as the local streamwise and normal directions,

![]() $\hat {s}$

and

$\hat {s}$

and

![]() $\hat {n}$

, on either side of the sample. The dashed line corresponds to the location of the trough of the riblets.

$\hat {n}$

, on either side of the sample. The dashed line corresponds to the location of the trough of the riblets.

-

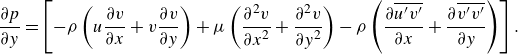

(i) We focus on the riblets on both sides of a finite-sized symmetric hydrofoil operated at global Reynolds numbers of

$\textit{Re}_{L} = 12\,200$

,

$\textit{Re}_{L} = 12\,200$

,

$18\,500$

and

$18\,500$

and

$24\,200$

where the flow can remain laminar.

$24\,200$

where the flow can remain laminar. -

(ii) We take a bio-inspired approach following the pattern of the ribs on the nose of a shark (Lauder et al. Reference Lauder, Wainwright, Domel, Weaver, Wen and Bertoldi2016), and design the riblets to grow from zero height to full size within the curved leading edge of the foil.

-

(iii) We take advantage of the advances in three-dimensional printing techniques in the past decade and print riblets of different cross-sectional shapes embedded on both sides of the foil to have access to drag-reducing, drag-increasing and drag-neutral cases.

-

(iv) To capture the full picture of the flow field around a riblet-covered finite-sized foil, we step away from the earlier experimental formats and use a combined PIV with load measurements. We evaluate both the local and global performance of the riblets and their effect on the development of the BLs, modulating the skin-friction coefficient, and the components of the drag force all compared with a smooth reference.

-

(v) We use the measurements to evaluate the impact of drag-reducing riblet surfaces on the pressure drag and confirm the recently presented numerical evidence for this trend (Mele et al. Reference Mele, Tognaccini and Catalano2016, Reference Mele, Tognaccini, Catalano and de Rosa2020).

This paper is thus organised as follows. In § 2 we discuss the design of the riblets and samples, as well as the experimental procedure and data analysis. In § 3 we first explore the global performance of the riblets in terms of the total drag and then take advantage of a three-tiered force measurement technique to decompose the total drag in terms of friction and pressure drag, as well as contribution from other factors not considered here. We discuss the differences as a function of the shape and size of the riblets (this work is not focused on optimisation of the riblet shapes). Finally, we investigate the local flow behaviour in the presence of the riblets and how the local shear stress and pressure distributions affect the global drag force experienced by the riblet-covered samples. In § 4 we provide a summary of our findings and outline how this localised view of the flow can be used to enhance the designs of drag-reducing riblets for smaller vehicles including the potential for optimisation of the shape of the riblets based on this localised view in the future.

2. Methods

2.1. Riblet geometry

For symmetric and periodic riblets, the shape of the cross-sectional profile of the riblets can be defined only for half of each unit that is mirrored and then repeated as needed. Here, we focus on the simplest family of curved riblets defined using a second-order polynomial (Raayai-Ardakani Reference Raayai-Ardakani2022), where for a unit element with spacing

![]() $\lambda$

and height

$\lambda$

and height

![]() $A$

(figure 1

a),

$A$

(figure 1

a),

where

![]() $n_{w}$

is the cross-sectional profile of the riblet wall in the normal direction,

$n_{w}$

is the cross-sectional profile of the riblet wall in the normal direction,

![]() $z$

is the spanwise coordinate,

$z$

is the spanwise coordinate,

![]() $n_{\textit{base}}$

is the height of the surface that the textures are carved from (equal to the height of the peaks of the textures),

$n_{\textit{base}}$

is the height of the surface that the textures are carved from (equal to the height of the peaks of the textures),

![]() ${\mathcal {R}} = A/(\lambda /2)$

is the height-to-half-spacing ratio as a measure of sharpness (Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019, Reference Raayai-Ardakani and McKinley2020; Raayai-Ardakani Reference Raayai-Ardakani2022) and

${\mathcal {R}} = A/(\lambda /2)$

is the height-to-half-spacing ratio as a measure of sharpness (Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019, Reference Raayai-Ardakani and McKinley2020; Raayai-Ardakani Reference Raayai-Ardakani2022) and

![]() $\kappa _2$

is a dimensionless curvature parameter (Raayai-Ardakani Reference Raayai-Ardakani2022). Within this framework,

$\kappa _2$

is a dimensionless curvature parameter (Raayai-Ardakani Reference Raayai-Ardakani2022). Within this framework,

![]() $\vert \kappa _2 \vert \leqslant {\mathcal {R}}$

, where

$\vert \kappa _2 \vert \leqslant {\mathcal {R}}$

, where

![]() $\kappa _2\lt 0$

corresponds to convex textures,

$\kappa _2\lt 0$

corresponds to convex textures,

![]() $\kappa _2\gt 0$

corresponds to concave textures and

$\kappa _2\gt 0$

corresponds to concave textures and

![]() $\kappa _2 = 0$

places the commonly used triangular (V-groove) textures as a subset of this riblet family. We focus on the case of textures with

$\kappa _2 = 0$

places the commonly used triangular (V-groove) textures as a subset of this riblet family. We focus on the case of textures with

![]() $\lambda = 1$

mm and three height-to-half-spacing ratios of 0.5, 1.0 and 1.5, and one concave (

$\lambda = 1$

mm and three height-to-half-spacing ratios of 0.5, 1.0 and 1.5, and one concave (

![]() $\kappa _2 = {\mathcal {R}}$

), one convex (

$\kappa _2 = {\mathcal {R}}$

), one convex (

![]() $\kappa _2 = -{\mathcal {R}}$

) and one triangular case within each family (nine different textures; see figure 1

b). Throughout this paper, the samples are identified using the vector

$\kappa _2 = -{\mathcal {R}}$

) and one triangular case within each family (nine different textures; see figure 1

b). Throughout this paper, the samples are identified using the vector

![]() $\boldsymbol{\kappa } = [ {\mathcal {R}}, \kappa _2]$

. We expect to see a range of drag-reducing, drag-increasing and drag-neutral responses based on the limited previous reports (Walsh & Lindemann Reference Walsh and Lindemann1984; Raayai-Ardakani Reference Raayai-Ardakani2022).

$\boldsymbol{\kappa } = [ {\mathcal {R}}, \kappa _2]$

. We expect to see a range of drag-reducing, drag-increasing and drag-neutral responses based on the limited previous reports (Walsh & Lindemann Reference Walsh and Lindemann1984; Raayai-Ardakani Reference Raayai-Ardakani2022).

Here, we use the variable

![]() $s$

and

$s$

and

![]() $n$

as the local coordinate system, tangential and normal to the surface (figure 1

d), and use the variable

$n$

as the local coordinate system, tangential and normal to the surface (figure 1

d), and use the variable

![]() $\lambda$

instead of the commonly used

$\lambda$

instead of the commonly used

![]() $s$

for spacing of the riblets. In addition, we reserve the variable

$s$

for spacing of the riblets. In addition, we reserve the variable

![]() $t$

for time and use

$t$

for time and use

![]() $h$

for the thickness of the finite-sized samples and employ

$h$

for the thickness of the finite-sized samples and employ

![]() $A$

instead of

$A$

instead of

![]() $h$

for the height of the riblet units. These simple changes compared with the commonly used variables allow us to avoid confusion. In addition, we use the word ‘smooth’ as the opposite of a riblet surface while we use the word ‘flat’ as opposed to a ‘curved’ surface.

$h$

for the height of the riblet units. These simple changes compared with the commonly used variables allow us to avoid confusion. In addition, we use the word ‘smooth’ as the opposite of a riblet surface while we use the word ‘flat’ as opposed to a ‘curved’ surface.

2.2. Textured samples

We use fully textured samples where the riblets are fabricated seamlessly with the samples. The base of the samples has the form of a symmetric slender plate, comprised of a leading edge, and a main body (100 mm in length (L), 50 mm in width (b) and 5 mm in depth (h)). The leading edge is streamlined in the form of an ellipse (similar to the design used by Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023) up to

![]() $x=25 \ \textrm { mm}$

where it asymptotically meets a flat main body that extends to a blunt trailing edge (

$x=25 \ \textrm { mm}$

where it asymptotically meets a flat main body that extends to a blunt trailing edge (

![]() $25\,\textrm{mm} \leqslant x \leqslant 100 \ \textrm { mm}$

; see figure 1

c). The riblets are carved out of the base geometry on both sides of the sample. In this case, with the coordinate system shown in figure 1(c–d), the base height in the main (Flat) region of the body,

$25\,\textrm{mm} \leqslant x \leqslant 100 \ \textrm { mm}$

; see figure 1

c). The riblets are carved out of the base geometry on both sides of the sample. In this case, with the coordinate system shown in figure 1(c–d), the base height in the main (Flat) region of the body,

![]() $\vert y_{\textit{base}} \vert$

, is at half of the thickness,

$\vert y_{\textit{base}} \vert$

, is at half of the thickness,

![]() $h/2$

, on either side. The peaks of the textures reside at this height on either side and the troughs are located at

$h/2$

, on either side. The peaks of the textures reside at this height on either side and the troughs are located at

![]() $\vert y_{\textit{base}} \vert - A$

. However, this is only true for the Flat region of the sample within (

$\vert y_{\textit{base}} \vert - A$

. However, this is only true for the Flat region of the sample within (

![]() $25 \ \textrm { mm} \leqslant x \leqslant 100 \ \textrm { mm}$

) and prior to that, due to the curved nature of the leading edge, the textures appear where there is enough thickness (see figure 1

c–d) and grow to their maximum height

$25 \ \textrm { mm} \leqslant x \leqslant 100 \ \textrm { mm}$

) and prior to that, due to the curved nature of the leading edge, the textures appear where there is enough thickness (see figure 1

c–d) and grow to their maximum height

![]() $A$

at the end of the elliptical leading edge. We call this region ‘leading edge textured’(LET) and the non-riblet segment of the leading edge as LE. At the leading edge of fully riblet-covered flat plates, for at least

$A$

at the end of the elliptical leading edge. We call this region ‘leading edge textured’(LET) and the non-riblet segment of the leading edge as LE. At the leading edge of fully riblet-covered flat plates, for at least

![]() $x/\lambda \lt 9$

, riblets experience larger spanwise-averaged wall shear (normalised with

$x/\lambda \lt 9$

, riblets experience larger spanwise-averaged wall shear (normalised with

![]() $\lambda$

) compared with the smooth reference (Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017), and to mitigate that, we mimic the distribution of the denticles on the nose of sharks (Lauder et al. Reference Lauder, Wainwright, Domel, Weaver, Wen and Bertoldi2016) (which start from smooth in the nose area with ribs appearing later along the body) in the design of the streamlined leading edge of the samples. Thus, instead of enforcing a constant height-to-half-spacing ratio for the textures, we keep the wavelength constant and let the height of the textures grow from zero to the final height,

$\lambda$

) compared with the smooth reference (Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017), and to mitigate that, we mimic the distribution of the denticles on the nose of sharks (Lauder et al. Reference Lauder, Wainwright, Domel, Weaver, Wen and Bertoldi2016) (which start from smooth in the nose area with ribs appearing later along the body) in the design of the streamlined leading edge of the samples. Thus, instead of enforcing a constant height-to-half-spacing ratio for the textures, we keep the wavelength constant and let the height of the textures grow from zero to the final height,

![]() $A$

, at the end of the elliptic area and let the BL evolve with the evolution of the riblets.

$A$

, at the end of the elliptic area and let the BL evolve with the evolution of the riblets.

Riblet samples (and one smooth for comparison) are three-dimensionally printed (Formlabs Form3 3D printer and a photo-polymer resin, figure 1

b--c). After printing, the spacing and height of the riblets are measured using Bruker ContourX-500 Optical Profilometer and analysed with the open-source software package Gwyddion. The measurements are conducted at four different random locations on each side of the samples, with each location covering about

![]() $2.8\ \textrm { mm}^{2}$

of the projected area and containing at least one riblet unit, and the mean of the measurements and their

$2.8\ \textrm { mm}^{2}$

of the projected area and containing at least one riblet unit, and the mean of the measurements and their

![]() $95\, \%$

confidence intervals are reported in table 1. Owing to the limited resolution of the three-dimensional printer, the final height of the riblets are smaller than the design heights and result in lower apparent

$95\, \%$

confidence intervals are reported in table 1. Owing to the limited resolution of the three-dimensional printer, the final height of the riblets are smaller than the design heights and result in lower apparent

![]() ${\mathcal {R}}$

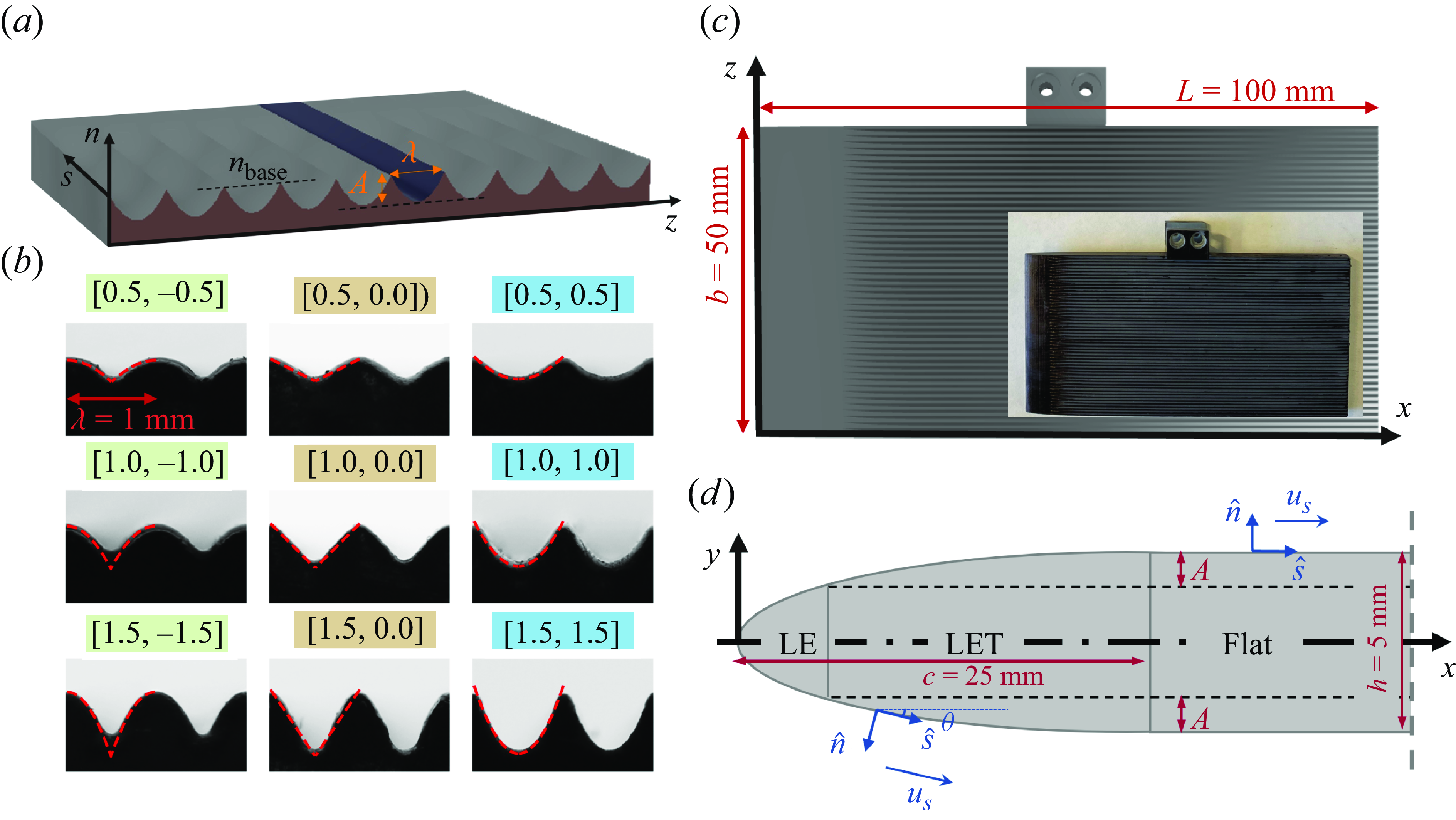

values for the samples, but do not affect the performance of the riblets. Throughout the paper the samples are identified with their design names as listed in the first column of table 1. Even though the experiments are limited to the laminar regime, for completeness, the distributions of the spacing and height of the riblets in wall units are presented in figures 2 and SI.1 of the supplementary material, calculated based on the spanwise-averaged shear stress distribution (discussed in § 3.3). Except for the non-textured leading edge region of the samples,

${\mathcal {R}}$

values for the samples, but do not affect the performance of the riblets. Throughout the paper the samples are identified with their design names as listed in the first column of table 1. Even though the experiments are limited to the laminar regime, for completeness, the distributions of the spacing and height of the riblets in wall units are presented in figures 2 and SI.1 of the supplementary material, calculated based on the spanwise-averaged shear stress distribution (discussed in § 3.3). Except for the non-textured leading edge region of the samples,

![]() $\lambda ^{+}$

is less than

$\lambda ^{+}$

is less than

![]() $24-25$

for all the samples and on both sides, which coincides with the ranges previously identified as drag-reducing (Walsh Reference Walsh1983; Walsh & Lindemann Reference Walsh and Lindemann1984; Bechert et al. Reference Bechert, Bruse, Hage, Van der Hoeven and Hoppe1997).

$24-25$

for all the samples and on both sides, which coincides with the ranges previously identified as drag-reducing (Walsh Reference Walsh1983; Walsh & Lindemann Reference Walsh and Lindemann1984; Bechert et al. Reference Bechert, Bruse, Hage, Van der Hoeven and Hoppe1997).

Table 1. Details of the geometry of the riblets and set-up. The locations of the start of the textures (

![]() $x_{{ LET}}$

) are measured using a caliper (design values in the parenthesis).

$x_{{ LET}}$

) are measured using a caliper (design values in the parenthesis).

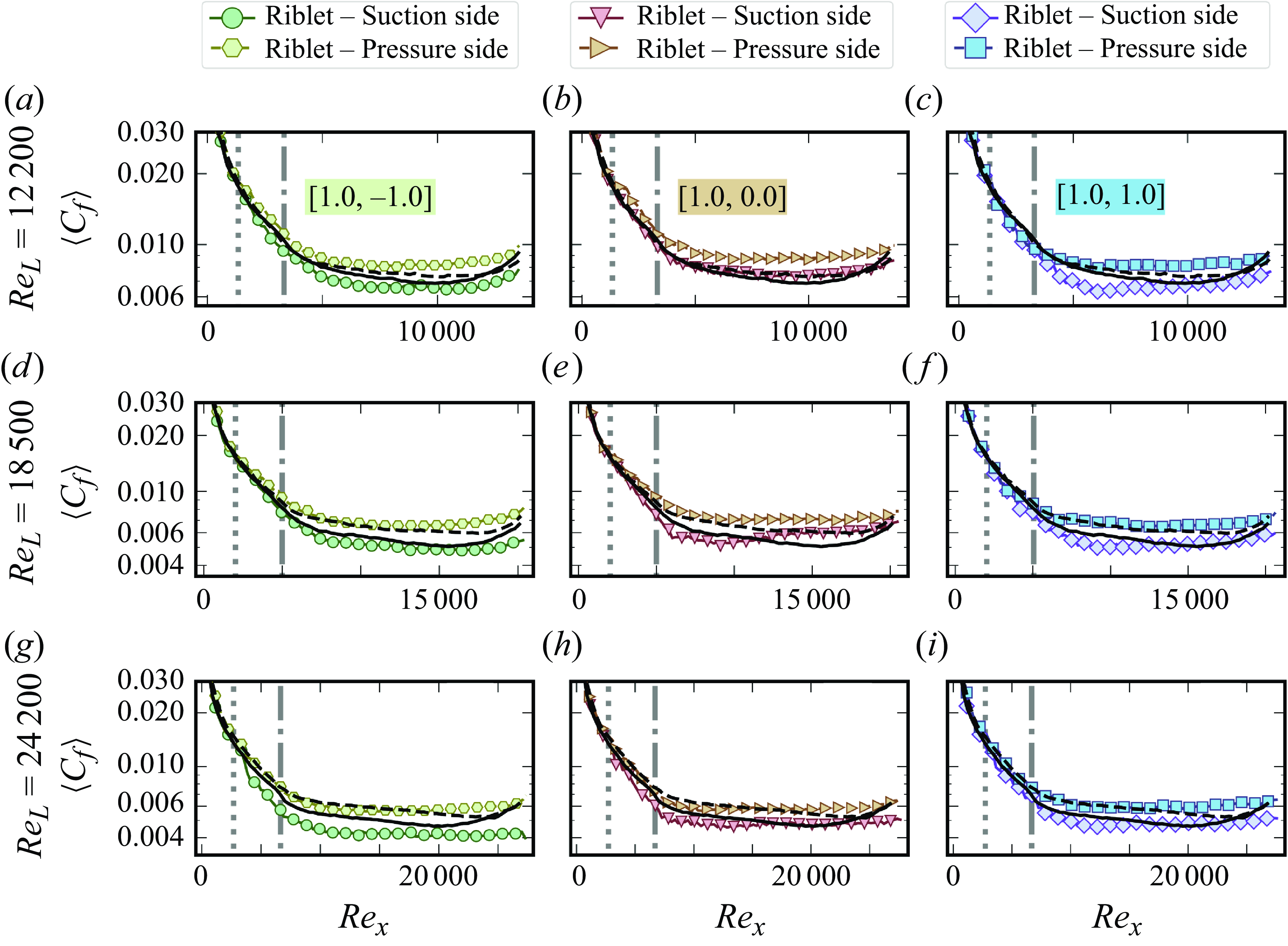

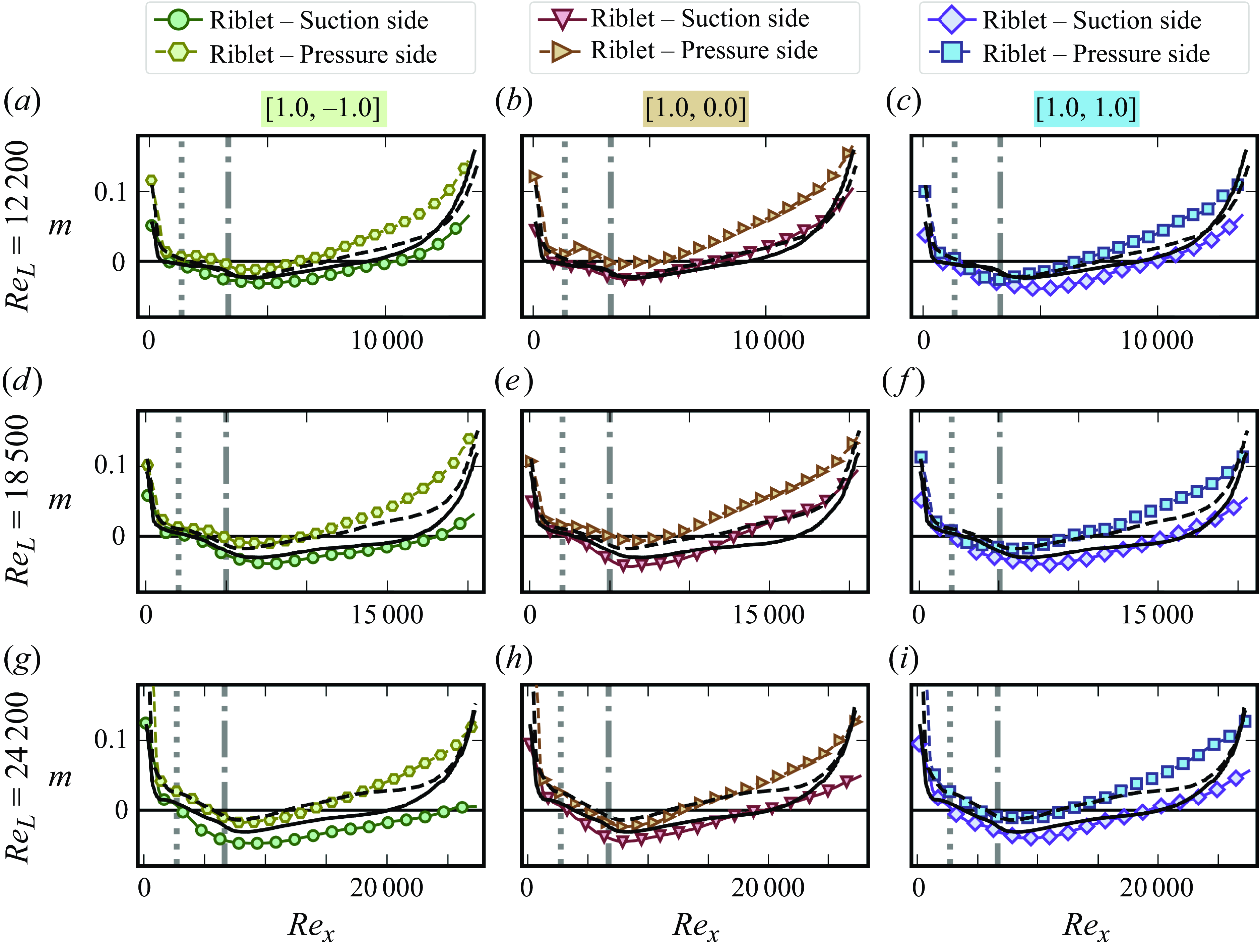

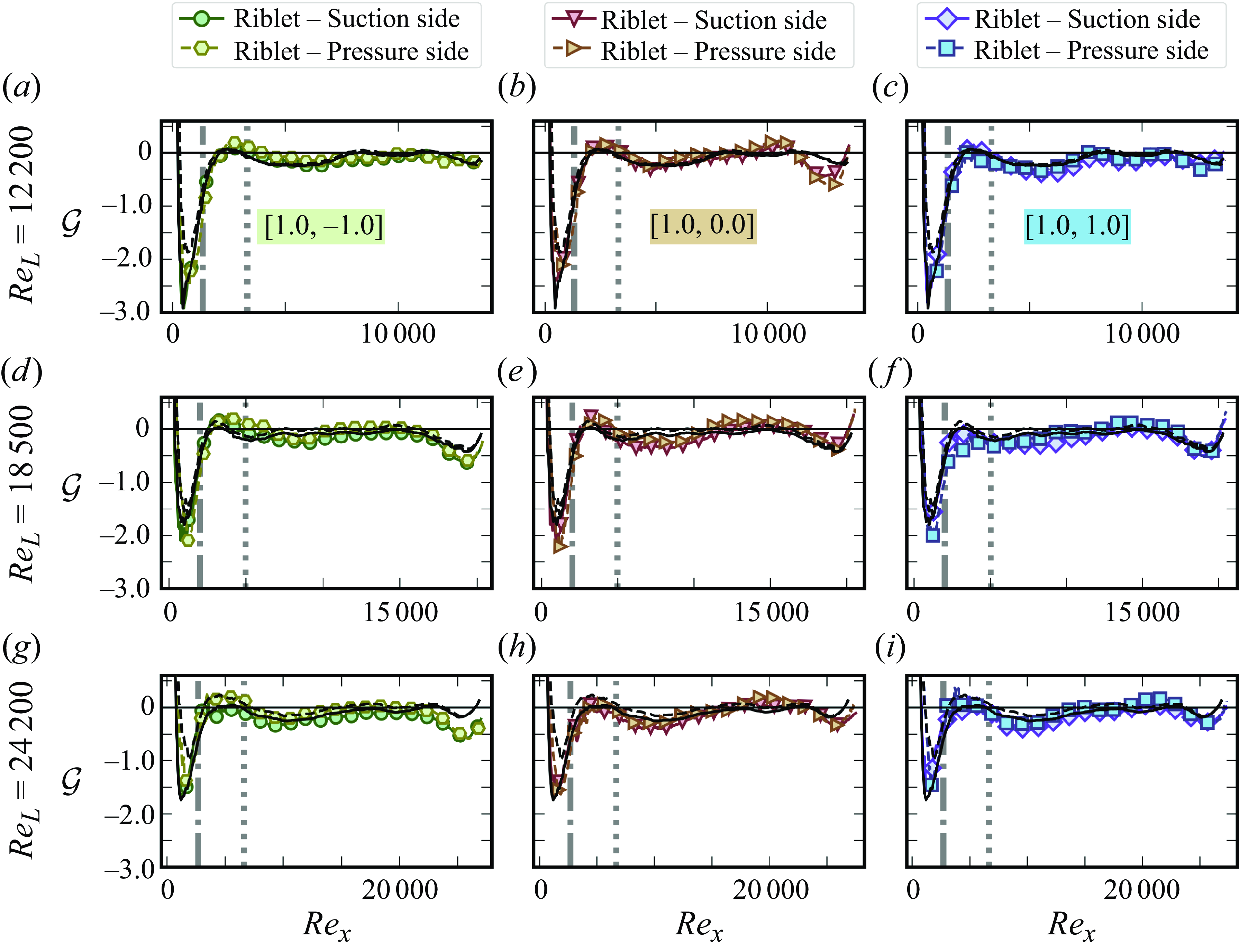

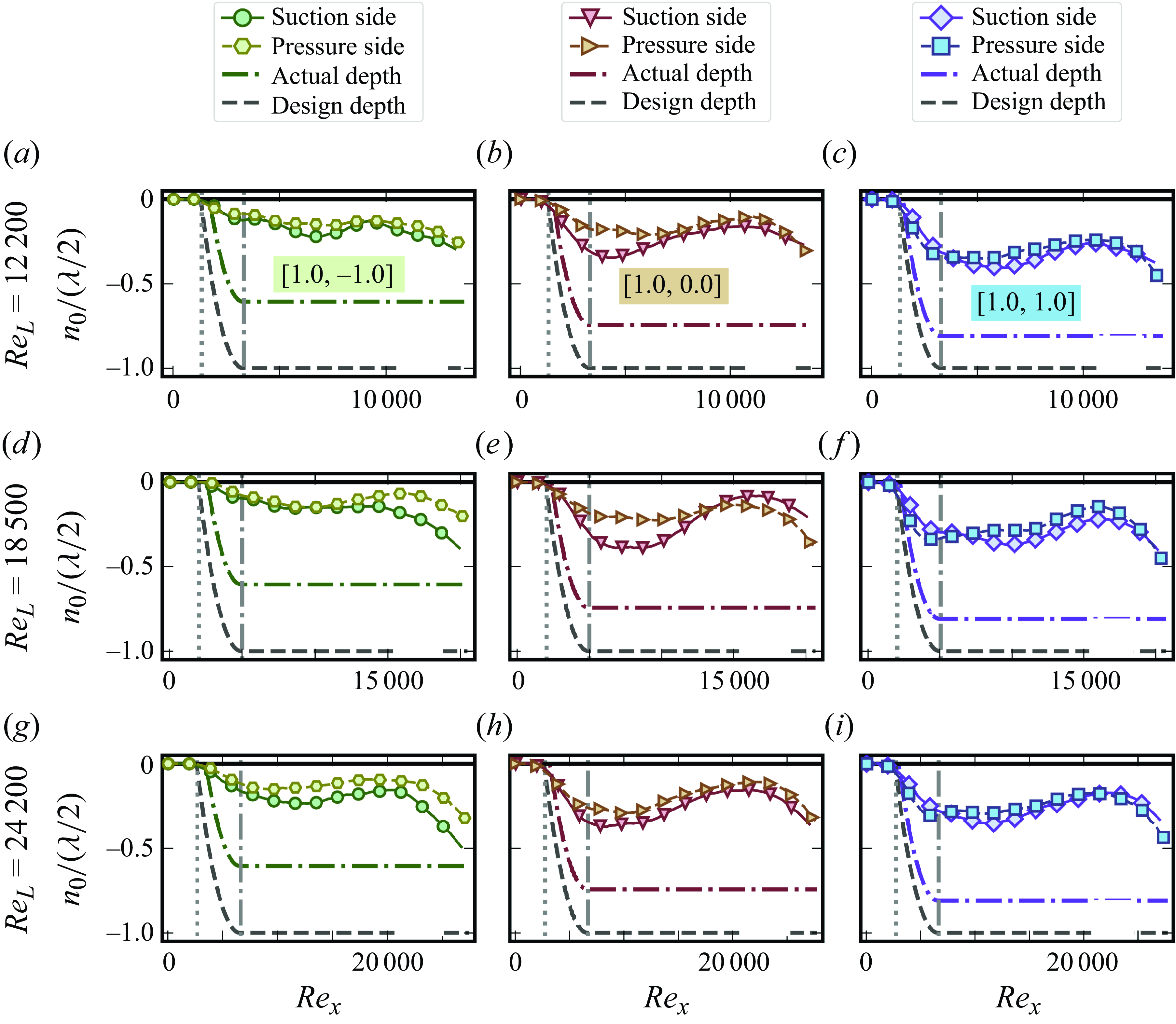

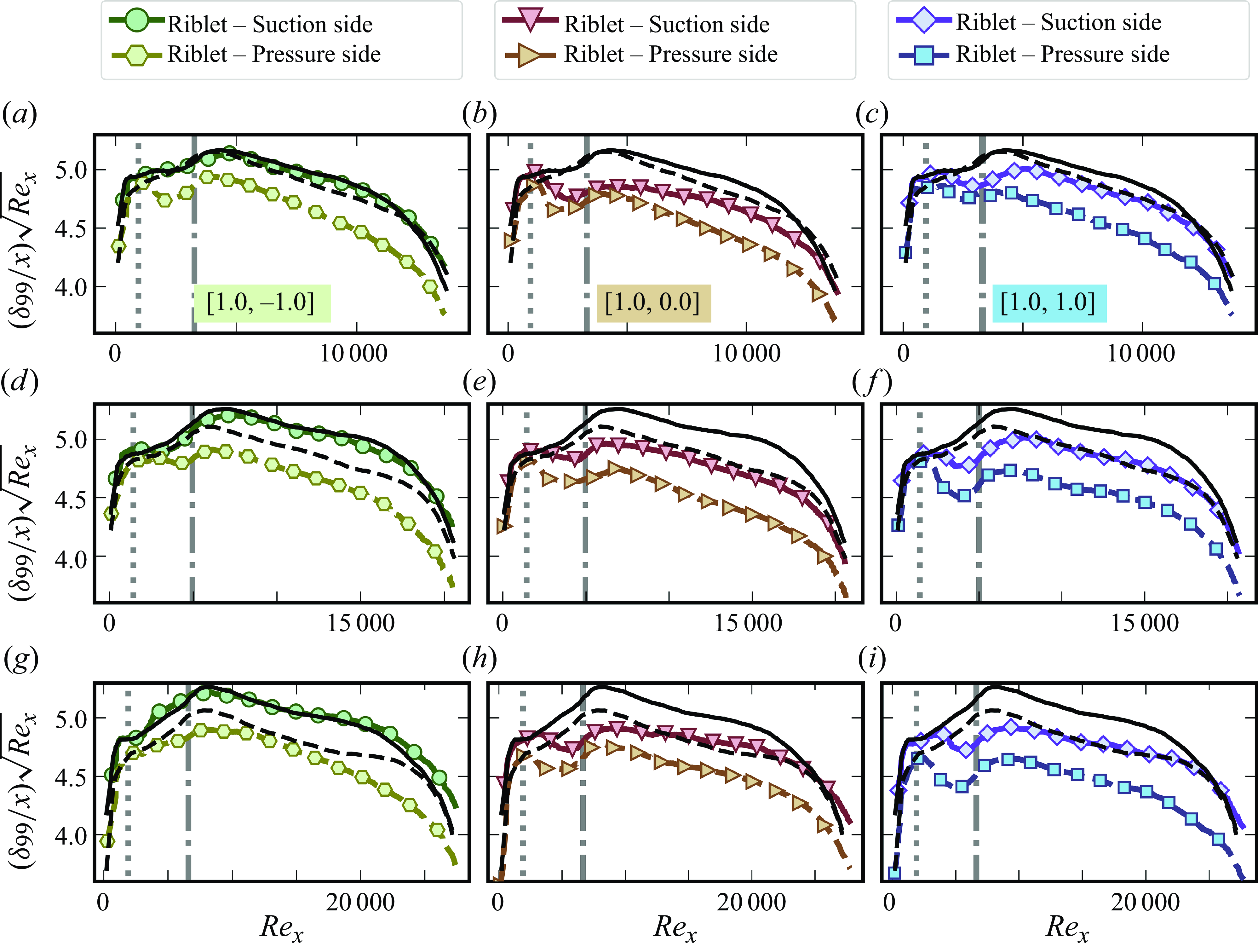

Figure 2. Distribution of

![]() $\lambda ^{+}$

and

$\lambda ^{+}$

and

![]() $A^{+}$

for all the riblet samples with

$A^{+}$

for all the riblet samples with

![]() ${\mathcal {R}} = 1.0$

on the suction and pressure side for

${\mathcal {R}} = 1.0$

on the suction and pressure side for

![]() $\textit{Re}_{L} = 18\,500$

, calculated using the spanwise-averaged shear stress measured (presented in § 3.3). Each column corresponds to specific samples. Locations of

$\textit{Re}_{L} = 18\,500$

, calculated using the spanwise-averaged shear stress measured (presented in § 3.3). Each column corresponds to specific samples. Locations of

![]() $x_{ LET}$

and

$x_{ LET}$

and

![]() $x_{Flat}$

are marked by grey dotted and dash-dotted vertical lines.

$x_{Flat}$

are marked by grey dotted and dash-dotted vertical lines.

2.3. Experimental procedure

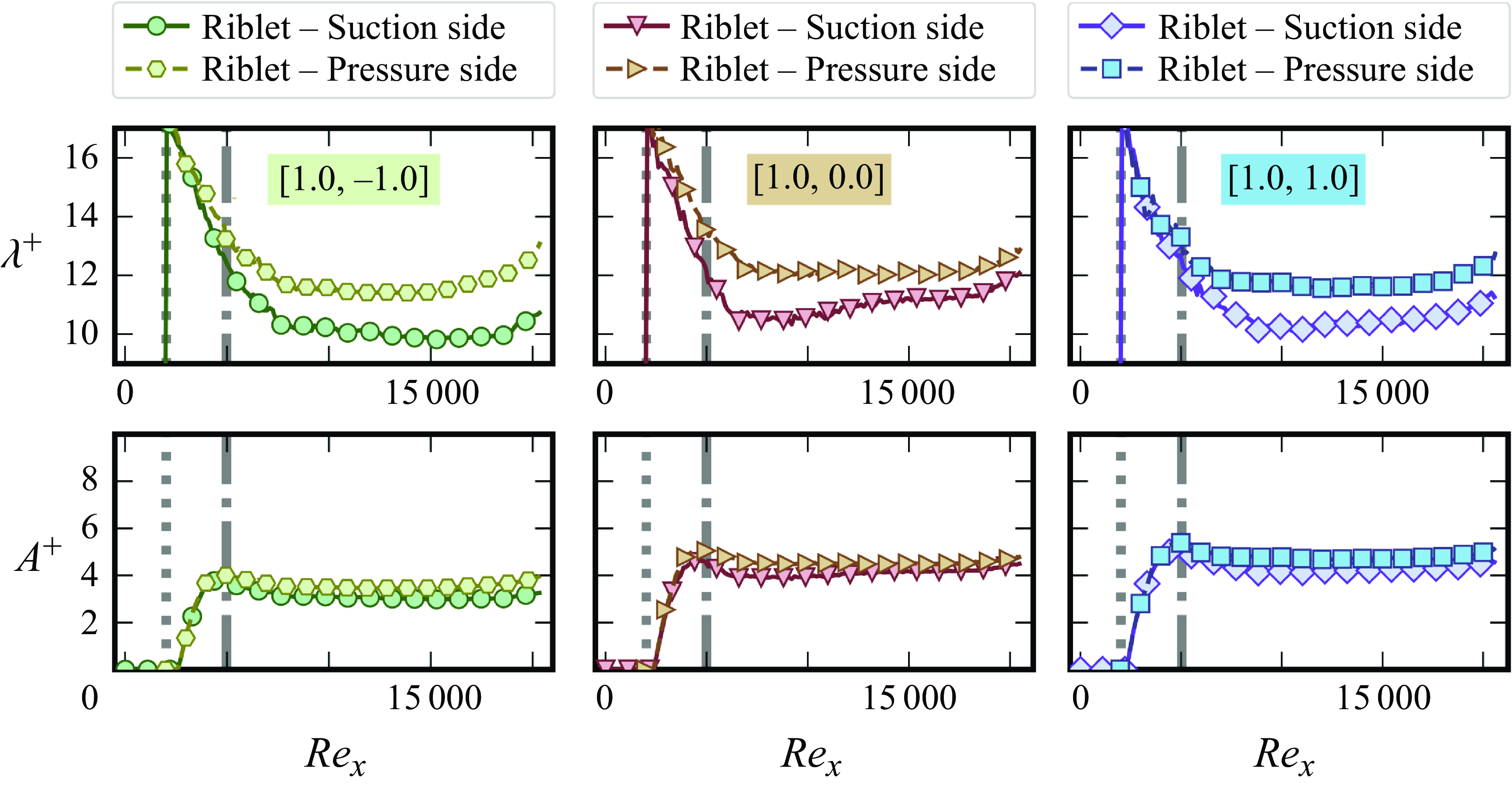

Experiments are performed following the procedure described previously (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023; Fu et al. Reference Fu and Raayai-Ardakani2023). In summary, the samples described in § 2.2 are attached to a dynamometer consisting of linear variable differential transformers (to measure the total drag force) and suspended in a water tunnel (cross-sectional area of

![]() $20 \times 20 \ \textrm { cm}$

and

$20 \times 20 \ \textrm { cm}$

and

![]() $2 \ \textrm { m}$

in length; see figure 3). The samples are positioned at around

$2 \ \textrm { m}$

in length; see figure 3). The samples are positioned at around

![]() $75 \ \textrm { cm}$

from the tunnel entrance and close to the middle of the cross-section to reduce the effects of the tunnel walls on the measurements. The experiments are performed at three free-stream velocities less than

$75 \ \textrm { cm}$

from the tunnel entrance and close to the middle of the cross-section to reduce the effects of the tunnel walls on the measurements. The experiments are performed at three free-stream velocities less than

![]() $0.25 \ \textrm {m s}^{-1}$

(

$0.25 \ \textrm {m s}^{-1}$

(

![]() $0.122$

,

$0.122$

,

![]() $0.185$

and

$0.185$

and

![]() $0.242 \ \textrm { m s}^{-1}$

) corresponding to global Reynolds numbers,

$0.242 \ \textrm { m s}^{-1}$

) corresponding to global Reynolds numbers,

![]() $\textit{Re}_{L} = \rho U_{\infty }L/\mu$

, of 12,200, 18,500 and 24,200 (turbulence intensity of the free stream is less than or about

$\textit{Re}_{L} = \rho U_{\infty }L/\mu$

, of 12,200, 18,500 and 24,200 (turbulence intensity of the free stream is less than or about

![]() $1\, \%$

).

$1\, \%$

).

The velocity field all around the sample is captured using a double-pulsed planar (two-dimensional, two-component, 2D-2C) PIV and double-illumination, consecutive-overlapping procedure (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023; Fu et al. Reference Fu and Raayai-Ardakani2023). The set-up is comprised of a double-pulsed Nd:YAG laser operated at

![]() $15 \ \textrm { Hz}$

repetition rate and the nominal output energies of

$15 \ \textrm { Hz}$

repetition rate and the nominal output energies of

![]() $10 \ \textrm { mJ}$

or

$10 \ \textrm { mJ}$

or

![]() $20 \ \textrm { mJ}$

per pulse for different free-stream velocities. The high-speed camera is set to a resolution of 720

$20 \ \textrm { mJ}$

per pulse for different free-stream velocities. The high-speed camera is set to a resolution of 720

![]() $\times$

1920 pixels and the timing between the two consecutive pulses is adjusted to

$\times$

1920 pixels and the timing between the two consecutive pulses is adjusted to

![]() $\delta t =1000$

$\delta t =1000$

![]() $\unicode {x03BC}$

s for free-stream velocities of 0.122 m s

$\unicode {x03BC}$

s for free-stream velocities of 0.122 m s

![]() $^{-1}$

and 0.185 m s–1, and

$^{-1}$

and 0.185 m s–1, and

![]() $\delta t =$

900

$\delta t =$

900

![]() $\unicode {x03BC}$

s for 0.242 m s–1 to allow for the slowest particles to have visible movement and the fastest particles to not move beyond half of the PIV analysis window (set at 32 pixels).

$\unicode {x03BC}$

s for 0.242 m s–1 to allow for the slowest particles to have visible movement and the fastest particles to not move beyond half of the PIV analysis window (set at 32 pixels).

To get simultaneous access to both sides of a non-transparent sample and avoid any assumptions regarding the symmetry of the flow around the foils, we use a double-illumination strategy (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023; Fu et al. Reference Fu and Raayai-Ardakani2023). This optical set-up is comprised of a half-wave plate and a polarising beam splitter to divide the incoming laser into two almost equal beams. These beams are then guided toward either side of the sample through additional mirrors where two combinations of light-sheet optics, involving two spherical lenses and one cylindrical lens, are positioned on opposite sides of the water tunnel to create light sheets with thicknesses of about

![]() $ 1 \ \textrm { mm}$

.

$ 1 \ \textrm { mm}$

.

Figure 3. Schematic of the experimental set-up, showing front and side views of the water tunnel, the installed sample and the PIV set-up.

To have access to the velocity field in both the BL and the far field, we use a consecutive-overlapping imaging procedure (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023; Fu et al. Reference Fu and Raayai-Ardakani2023). We attach the camera to a CNC rail and traverse the entire area of interest of the flow with about

![]() $40\, \%\!-\!45\,\%$

overlap between the fields of views. To have access to the velocity profiles in the BL, we use a magnification of 1 px

$40\, \%\!-\!45\,\%$

overlap between the fields of views. To have access to the velocity profiles in the BL, we use a magnification of 1 px

![]() $\equiv$

15–16

$\equiv$

15–16

![]() $\unicode {x03BC}\textrm {m}$

that limits the total field of view of the camera at a time and the consecutive-overlapping imaging allows us to overcome this limitation and capture a larger area of interest. Here we use a one-dimensional sweep in the streamwise direction, with 36 overlapping steps to capture a span of about 180

$\unicode {x03BC}\textrm {m}$

that limits the total field of view of the camera at a time and the consecutive-overlapping imaging allows us to overcome this limitation and capture a larger area of interest. Here we use a one-dimensional sweep in the streamwise direction, with 36 overlapping steps to capture a span of about 180

![]() $\textrm {mm}$

in the streamwise direction and about 25 mm in the normal direction. On either side, the BL thickness does not go beyond 3 mm.

$\textrm {mm}$

in the streamwise direction and about 25 mm in the normal direction. On either side, the BL thickness does not go beyond 3 mm.

At each step, 50 image pairs are captured. Fu & Raayai-Ardakani (Reference Fu and Raayai-Ardakani2023) have previously shown that 50 image pairs are enough for the measurements to reach convergence in a similar range of Reynolds number as that used here. The images (and subsequently the analysed velocity fields) are then stitched together based on the global locations of the camera as controlled with the CNC rail. The PIV images at each step of imaging are analysed using an in-house Python script utilising the open-source software OpenPIV (Liberzon et al. Reference Liberzon2020) (with

![]() $32 \times 32$

windows and a search area of

$32 \times 32$

windows and a search area of

![]() $64 \times 64$

with

$64 \times 64$

with

![]() $85\, \%$

overlap) to find the velocity in the

$85\, \%$

overlap) to find the velocity in the

![]() $x$

and

$x$

and

![]() $y$

directions (

$y$

directions (

![]() $u$

and

$u$

and

![]() $v$

, respectively) with an additional correction loop for the velocities close to the wall region (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023) to avoid bias errors due to the large shear rates close to the walls (Kähler, Scharnowski & Cierpka Reference Kähler, Scharnowski and Cierpka2012).

$v$

, respectively) with an additional correction loop for the velocities close to the wall region (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023) to avoid bias errors due to the large shear rates close to the walls (Kähler, Scharnowski & Cierpka Reference Kähler, Scharnowski and Cierpka2012).

2.4. Data analysis

2.4.1. Angle of attack

While each sample is positioned as close to parallel to the streamwise direction as possible, there is always the potential for a slight non-zero angle of attack,

![]() $\alpha$

, not visible to the naked eye in the set-up and the final angle of attack of the sample with respect to the free-stream velocity is not known a priori. This

$\alpha$

, not visible to the naked eye in the set-up and the final angle of attack of the sample with respect to the free-stream velocity is not known a priori. This

![]() $\alpha$

results in an asymmetry in the flow and subsequently differences between the local responses of the front (

$\alpha$

results in an asymmetry in the flow and subsequently differences between the local responses of the front (

![]() $y\gt 0$

) and back (

$y\gt 0$

) and back (

![]() $y\lt 0$

) sides of the samples. To find this angle of attack more accurately for each of the experiments, we use the velocity field upstream of the leading edge and a potential model of flow past an elliptical leading edge (previously described by Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023) and fit the velocity measurements to the potential model to find the

$y\lt 0$

) sides of the samples. To find this angle of attack more accurately for each of the experiments, we use the velocity field upstream of the leading edge and a potential model of flow past an elliptical leading edge (previously described by Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023) and fit the velocity measurements to the potential model to find the

![]() $\alpha$

between the sample and the free-stream velocity, as listed in the last column of table 1. Since the experiments with each sample were performed in one session (only changing the velocity), the values of the

$\alpha$

between the sample and the free-stream velocity, as listed in the last column of table 1. Since the experiments with each sample were performed in one session (only changing the velocity), the values of the

![]() $\alpha$

are a mean of fits at 30 locations within

$\alpha$

are a mean of fits at 30 locations within

![]() $x/L\lt -0.14$

of the leading edge and for all the threeruns (different

$x/L\lt -0.14$

of the leading edge and for all the threeruns (different

![]() $\textit{Re}_L$

) of each sample for a total of 90 values. Owing to the angle of attack, and with the geometric configuration of the experimental set-up, the front/back sides of the samples coincide with the suction/pressure sides of the foils, respectively.

$\textit{Re}_L$

) of each sample for a total of 90 values. Owing to the angle of attack, and with the geometric configuration of the experimental set-up, the front/back sides of the samples coincide with the suction/pressure sides of the foils, respectively.

2.4.2. Shear stress distribution

To calculate the local shear stress distribution, we employ the PIV data to find the velocity profiles at each

![]() $x$

location and calculate the local velocity gradient normal to the wall as a function of the local Reynolds number,

$x$

location and calculate the local velocity gradient normal to the wall as a function of the local Reynolds number,

![]() $\textit{Re}_x = \rho U(x) x/\mu$

, where

$\textit{Re}_x = \rho U(x) x/\mu$

, where

![]() $U(x)$

is the velocity at the edge of the BL. Numerical simulations of a BL over riblet surfaces (Choi et al. Reference Choi, Moin and Kim1993; Goldstein et al. Reference Goldstein, Handler and Sirovich1995; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2020) have previously shown that in the presence of the riblets, the velocity profiles are dependent on all three dimensions,

$U(x)$

is the velocity at the edge of the BL. Numerical simulations of a BL over riblet surfaces (Choi et al. Reference Choi, Moin and Kim1993; Goldstein et al. Reference Goldstein, Handler and Sirovich1995; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2020) have previously shown that in the presence of the riblets, the velocity profiles are dependent on all three dimensions,

![]() $\mathbf{u}(x,y,z)$

, and dependent on the spanwise direction,

$\mathbf{u}(x,y,z)$

, and dependent on the spanwise direction,

![]() $z$

, in a periodic manner. This is directly a result of the shape of the riblet surface and the no-slip wall. However, the previous numerical and experimental observations (Djenidi et al. Reference Djenidi, Liandrat, Anselmet and Fulachier1989, Reference Djenidi, Anselmet, Liandrat and Fulachier1994; Choi et al. Reference Choi, Moin and Kim1993; Djenidi & Antonia Reference Djenidi and Antonia1996; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019, Reference Raayai-Ardakani and McKinley2020) all show that the spatial variations in the velocity profiles are dominant inside the riblet unit element. While moving outside the grooves, all velocity profiles at a given

$z$

, in a periodic manner. This is directly a result of the shape of the riblet surface and the no-slip wall. However, the previous numerical and experimental observations (Djenidi et al. Reference Djenidi, Liandrat, Anselmet and Fulachier1989, Reference Djenidi, Anselmet, Liandrat and Fulachier1994; Choi et al. Reference Choi, Moin and Kim1993; Djenidi & Antonia Reference Djenidi and Antonia1996; Raayai-Ardakani & McKinley Reference Raayai-Ardakani and McKinley2017, Reference Raayai-Ardakani and McKinley2019, Reference Raayai-Ardakani and McKinley2020) all show that the spatial variations in the velocity profiles are dominant inside the riblet unit element. While moving outside the grooves, all velocity profiles at a given

![]() $x$

location collapse onto each other with no spanwise dependence visible.

$x$

location collapse onto each other with no spanwise dependence visible.

In planar PIV the flow measurements performed in the thin plane of the light sheet are an average of the velocity field within this light sheet. Thus, in our current experiments, we set the thickness of the light sheet to about 1 mm to match the spacing of one riblet unit and ensure the depth of field of the camera is also around 1 mm to capture a spanwise-averaged velocity measurement. Writing the velocity profile as

![]() $\mathbf{u}(x,y,z)$

, the measured velocity profile is then

$\mathbf{u}(x,y,z)$

, the measured velocity profile is then

![]() $\langle \mathbf{u} \rangle (x,y)$

, where

$\langle \mathbf{u} \rangle (x,y)$

, where

![]() $\langle \cdots \rangle (x,y)$

denotes the spanwise-averaging operation. Owing to the opaqueness of the samples, only the velocity distribution outside of the grooves (

$\langle \cdots \rangle (x,y)$

denotes the spanwise-averaging operation. Owing to the opaqueness of the samples, only the velocity distribution outside of the grooves (

![]() $n\gt 0$

) is visible to the camera, and the rest of the profiles have their respective no-slip wall hidden inside the grooves, below the level accessible to imaging. Thus, the origin of the average velocity

$n\gt 0$

) is visible to the camera, and the rest of the profiles have their respective no-slip wall hidden inside the grooves, below the level accessible to imaging. Thus, the origin of the average velocity

![]() $\langle \mathbf{u} \rangle$

is located below the peak of the riblets (

$\langle \mathbf{u} \rangle$

is located below the peak of the riblets (

![]() $n\lt 0$

). We use this origin as a representative average origin of the velocity within one texture unit and denote it as the ‘effective origin’ of the riblets,

$n\lt 0$

). We use this origin as a representative average origin of the velocity within one texture unit and denote it as the ‘effective origin’ of the riblets,

![]() $n_0$

.

$n_0$

.

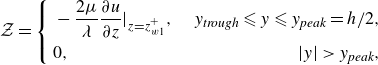

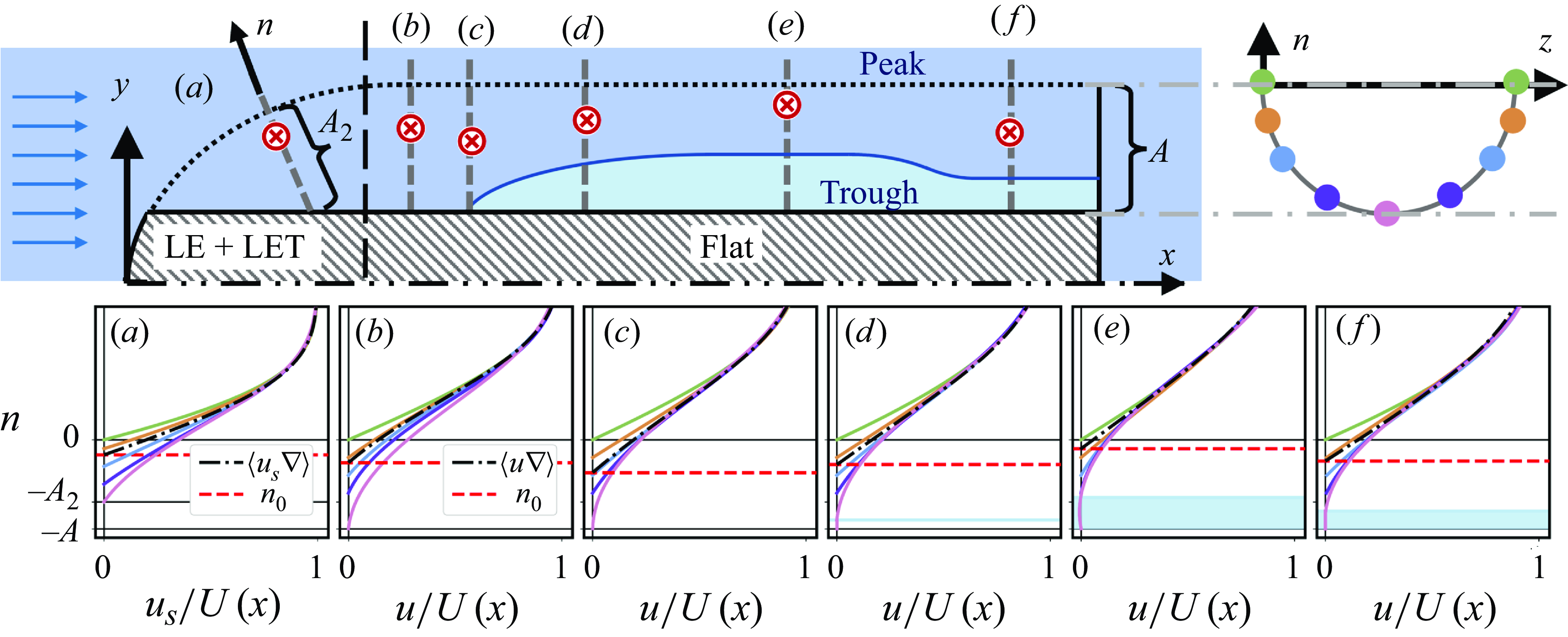

From the PIV data, we calculate the spanwise-averaged velocity gradient and subsequently the local spanwise-averaged shear stress,

![]() $\langle \tau \rangle = \mu \partial \langle u_{s} \rangle /\partial n$

. Instead of depending on only a few measurement points close to the wall, we use as many of the measured velocity points as possible and characterise the velocity profiles in a mathematical format and fit the profiles to an appropriate functional form. Here, we employ an updated form of the Falkner–Skan (FS) (Falkner & Skan Reference Falkneb and Skan1931) family of BLs in a localised manner to capture the behaviour of the tangential velocity, denoted by

$\langle \tau \rangle = \mu \partial \langle u_{s} \rangle /\partial n$

. Instead of depending on only a few measurement points close to the wall, we use as many of the measured velocity points as possible and characterise the velocity profiles in a mathematical format and fit the profiles to an appropriate functional form. Here, we employ an updated form of the Falkner–Skan (FS) (Falkner & Skan Reference Falkneb and Skan1931) family of BLs in a localised manner to capture the behaviour of the tangential velocity, denoted by

![]() $\langle u_{s} \rangle = \langle u \rangle \cos \theta + \langle v \rangle \sin \theta$

(where

$\langle u_{s} \rangle = \langle u \rangle \cos \theta + \langle v \rangle \sin \theta$

(where

![]() $\theta$

is the local angle between

$\theta$

is the local angle between

![]() $\hat {s}$

and

$\hat {s}$

and

![]() $x$

directions). In this updated formulation, we define

$x$

directions). In this updated formulation, we define

![]() $\langle u_{s} \rangle$

as a function of the local Reynolds number,

$\langle u_{s} \rangle$

as a function of the local Reynolds number,

![]() $\textit{Re}_{x} = {\rho x U(x)}/{\mu }$

,

$\textit{Re}_{x} = {\rho x U(x)}/{\mu }$

,

![]() $n$

,

$n$

,

![]() $m$

, and the effective origin

$m$

, and the effective origin

![]() $n_0$

, in the form of

$n_0$

, in the form of

![]() $\langle u_{s} \rangle = \mathcal{H}(\textit{Re}_{x},n;m,n_{0})$

, where the averaged velocity profile is a function of an updated similarity variable

$\langle u_{s} \rangle = \mathcal{H}(\textit{Re}_{x},n;m,n_{0})$

, where the averaged velocity profile is a function of an updated similarity variable

![]() $\eta ^*$

, of the form

$\eta ^*$

, of the form

![]() ${\langle u_{s}\rangle }/{U} = \mathcal{F}^{\prime}(\eta ^{*})$

with

${\langle u_{s}\rangle }/{U} = \mathcal{F}^{\prime}(\eta ^{*})$

with

![]() $\eta ^{*}$

defined as

$\eta ^{*}$

defined as

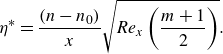

\begin{align} \eta ^{*} = \dfrac {(n-n_{0})}{x} \sqrt {\textit{Re}_x\left (\dfrac {m+1}{2}\right )}. \end{align}

\begin{align} \eta ^{*} = \dfrac {(n-n_{0})}{x} \sqrt {\textit{Re}_x\left (\dfrac {m+1}{2}\right )}. \end{align}

Now, with this formulation, and the experimental data for

![]() $\langle u_{s} \rangle$

, the local normal direction,

$\langle u_{s} \rangle$

, the local normal direction,

![]() $n$

, and

$n$

, and

![]() $\textit{Re}_x$

, we locally fit the data to the FS solutions to the BL equations and find the best values of

$\textit{Re}_x$

, we locally fit the data to the FS solutions to the BL equations and find the best values of

![]() $m$

and

$m$

and

![]() $n_0$

that capture the profiles at every location. A few examples of the fitted velocities along the suction side of the [1.0, 0.0] sample operated at

$n_0$

that capture the profiles at every location. A few examples of the fitted velocities along the suction side of the [1.0, 0.0] sample operated at

![]() $\textit{Re}_{L} = 18\,500$

are shown in figure SI.2(a) of the supplementary material. In the curved leading edge area (LE and LET),

$\textit{Re}_{L} = 18\,500$

are shown in figure SI.2(a) of the supplementary material. In the curved leading edge area (LE and LET),

![]() $n \nparallel y$

, and for simplicity, instead of

$n \nparallel y$

, and for simplicity, instead of

![]() $s$

we use

$s$

we use

![]() $x$

and

$x$

and

![]() $\textit{Re}_x$

to characterise the streamwise velocity profiles (with every

$\textit{Re}_x$

to characterise the streamwise velocity profiles (with every

![]() $x$

having a unique mapping to

$x$

having a unique mapping to

![]() $s$

and vice versa, we let the marginal effect of the difference between the magnitude of

$s$

and vice versa, we let the marginal effect of the difference between the magnitude of

![]() $s$

and

$s$

and

![]() $x$

be captured in the

$x$

be captured in the

![]() $m$

parameter). The first reliable fit is around

$m$

parameter). The first reliable fit is around

![]() $x=1 \ \textrm { mm}$

where

$x=1 \ \textrm { mm}$

where

![]() $s/x \approx 1.27$

and by the end of the LET

$s/x \approx 1.27$

and by the end of the LET

![]() $s/x \approx 1 .015$

. In the Flat region, the streamwise and normal direction align with

$s/x \approx 1 .015$

. In the Flat region, the streamwise and normal direction align with

![]() $x$

and

$x$

and

![]() $y$

coordinates (

$y$

coordinates (

![]() $\langle u_{s} \rangle = \langle u \rangle )$

.

$\langle u_{s} \rangle = \langle u \rangle )$

.

Note that due to the finite thickness of the sample, the BL edge velocity,

![]() $U(x) \geqslant U_{\infty }$

, and, thus, local

$U(x) \geqslant U_{\infty }$

, and, thus, local

![]() $\textit{Re}_x$

values are larger than Reynolds numbers calculated using

$\textit{Re}_x$

values are larger than Reynolds numbers calculated using

![]() $\rho U_{\infty }L/\mu$

and, thus,

$\rho U_{\infty }L/\mu$

and, thus,

![]() $\textit{Re}_{x=L}\gt \textit{Re}_{L}$

. Here, we do not find one single

$\textit{Re}_{x=L}\gt \textit{Re}_{L}$

. Here, we do not find one single

![]() $m$

for the entire flow, but use this family of FS solutions and the parameter

$m$

for the entire flow, but use this family of FS solutions and the parameter

![]() $m$

as mathematical tools to characterise the local behaviour of the flow field, especially including terms that cannot be captured directly with the planar PIV measurements (discussed further in the upcoming § 3.4).

$m$

as mathematical tools to characterise the local behaviour of the flow field, especially including terms that cannot be captured directly with the planar PIV measurements (discussed further in the upcoming § 3.4).

Knowing the mathematical form of the FS solutions as well as the distribution of the

![]() $m$

and

$m$

and

![]() $n_0$

from the available data, the local spanwise-averaged shear stress distribution along each side of the plate at

$n_0$

from the available data, the local spanwise-averaged shear stress distribution along each side of the plate at

![]() $n=0$

is found as

$n=0$

is found as

\begin{align} \langle \tau _{n=0} \rangle (x) = \mu \left . \dfrac {\partial \langle u_{s} \rangle }{\partial n} \right \vert _{n=0} = \left . \left (\frac {m+1}{2}\right )^{0.5}\frac {\rho U(x)^{2}}{\sqrt {\textit{Re}_x}}\mathcal{F}^{{\prime}{\prime}}\right \vert _{\eta ^{*}=\eta ^{*}_0} ,\end{align}

\begin{align} \langle \tau _{n=0} \rangle (x) = \mu \left . \dfrac {\partial \langle u_{s} \rangle }{\partial n} \right \vert _{n=0} = \left . \left (\frac {m+1}{2}\right )^{0.5}\frac {\rho U(x)^{2}}{\sqrt {\textit{Re}_x}}\mathcal{F}^{{\prime}{\prime}}\right \vert _{\eta ^{*}=\eta ^{*}_0} ,\end{align}

and the spanwise-averaged skin-friction coefficient is determined by

![]() $\langle C_f \rangle (x) = \langle \tau _{n=0} \rangle (x)/{({1}/{2})\rho U(x)^{2}}$

. Since we only have access to the velocity distribution outside the grooves, as written in (2.3), we use the gradient of

$\langle C_f \rangle (x) = \langle \tau _{n=0} \rangle (x)/{({1}/{2})\rho U(x)^{2}}$

. Since we only have access to the velocity distribution outside the grooves, as written in (2.3), we use the gradient of

![]() $\langle u_{s} \rangle$

profiles on the

$\langle u_{s} \rangle$

profiles on the

![]() $n=0$

plane to find

$n=0$

plane to find

![]() $\langle \tau _{n=0} \rangle$

distribution at every location. We show that by using a simple control volume analysis inside the grooves (as discussed in § SI.2 of the supplementary material) the gradient of

$\langle \tau _{n=0} \rangle$

distribution at every location. We show that by using a simple control volume analysis inside the grooves (as discussed in § SI.2 of the supplementary material) the gradient of

![]() $\langle u_{s} \rangle$

profiles on the

$\langle u_{s} \rangle$

profiles on the

![]() $n=0$

is able to capture the essence of the velocity gradient distribution at the riblet wall while also capturing the effect of the excess wetted surface area of the riblets compared with the smooth reference. We also provide further analysis in § SI.2 ofthe supplementary material on the upper and lower bounds of the difference between

$n=0$

is able to capture the essence of the velocity gradient distribution at the riblet wall while also capturing the effect of the excess wetted surface area of the riblets compared with the smooth reference. We also provide further analysis in § SI.2 ofthe supplementary material on the upper and lower bounds of the difference between

![]() $\langle \tau _{{ w}} \rangle$

(which is the spanwise-averaged shear stress on the riblet wall) and

$\langle \tau _{{ w}} \rangle$

(which is the spanwise-averaged shear stress on the riblet wall) and

![]() $\langle \tau _{n=0} \rangle$

measured on the

$\langle \tau _{n=0} \rangle$

measured on the

![]() $n=0$

plane based on the available PIV measurements. Note, at each local Reynolds number, the direct effect of

$n=0$

plane based on the available PIV measurements. Note, at each local Reynolds number, the direct effect of

![]() $n_0$

on the magnitude of the

$n_0$

on the magnitude of the

![]() $\langle \tau _{n=0} \rangle$

, as written in (2.3), is mainly hidden in the value of the

$\langle \tau _{n=0} \rangle$

, as written in (2.3), is mainly hidden in the value of the

![]() $\eta ^{*}_0$

at the peak of the grooves. We use the

$\eta ^{*}_0$

at the peak of the grooves. We use the

![]() $\langle \tau _{n=0} \rangle$

of the riblets and the

$\langle \tau _{n=0} \rangle$

of the riblets and the

![]() $\tau _{_{0}}$

of the smooth reference (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023) as local measures for comparing the frictional (shear) response of the surfaces.

$\tau _{_{0}}$

of the smooth reference (Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023) as local measures for comparing the frictional (shear) response of the surfaces.

2.4.3. Pressure and pressure gradient distribution

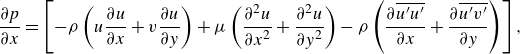

We use the PIV data to find the pressure gradient and pressure distribution by using the Reynolds-averaged Navier--Stokes (RANS) equations inthe

![]() $x$

and

$x$

and

![]() $y$

direction and lineintegration of the gradient terms in those directions (Liu & Katz Reference Liu and Katz2006; Charonko et al. Reference Charonko, King, Smith and Vlachos2010; de Kat & Ganapathisubramani Reference de Kat and Ganapathisubramani2013; van Oudheusden Reference van Oudheusden2013; Liu, Moreto & Siddle-Mitchell Reference Liu, Moreto and Siddle-Mitchell2016; Liu & Moreto Reference Liu and Moreto2020; Nie et al. Reference Nie, Whitehead, Richards, Smith and Pan2022; Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023; Suchandra & Raayai-Ardakani Reference Suchandra and Raayai-Ardakani2024):

$y$

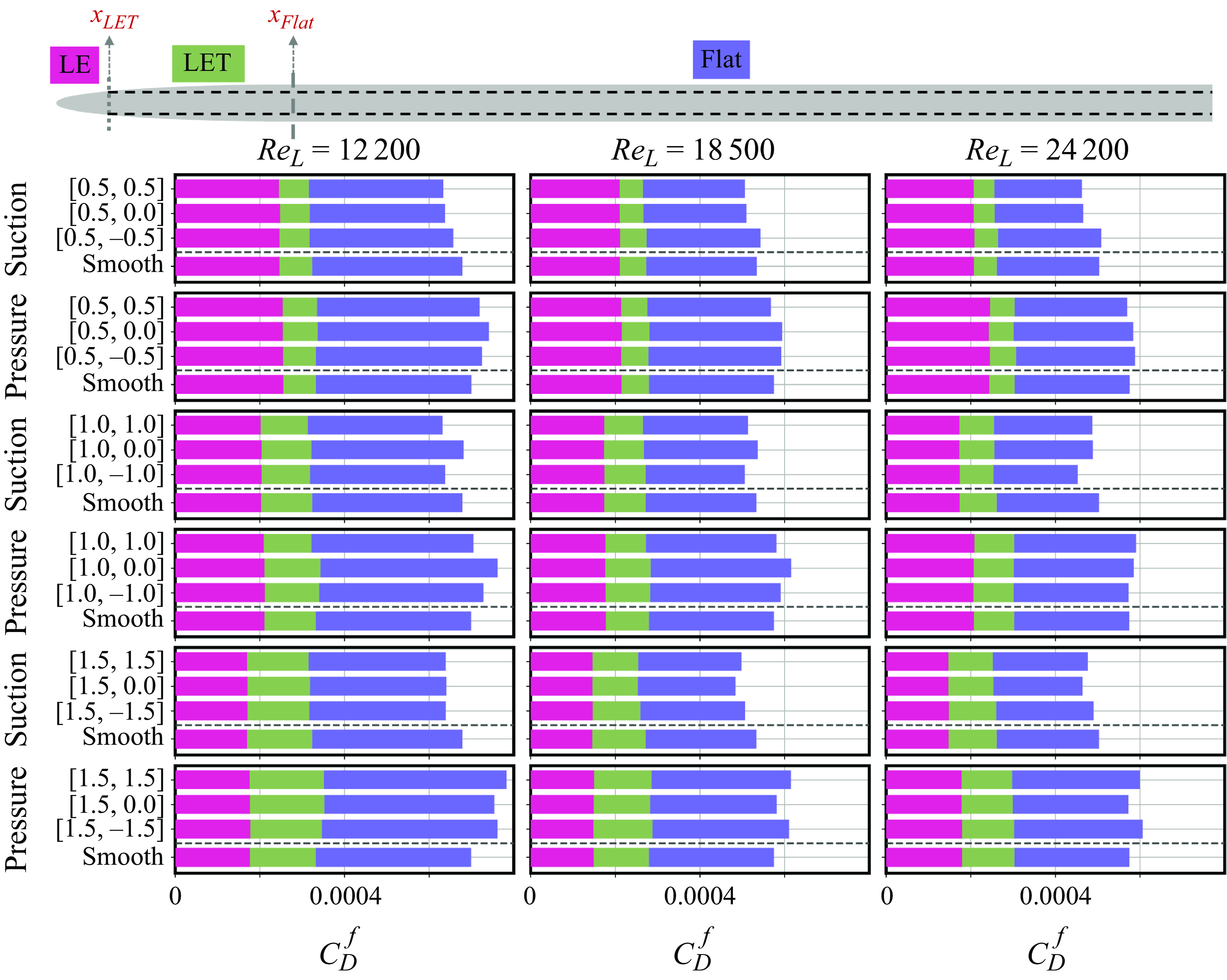

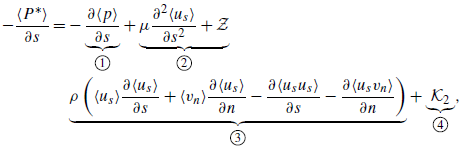

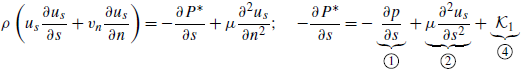

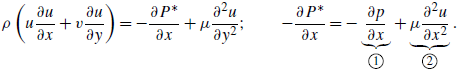

direction and lineintegration of the gradient terms in those directions (Liu & Katz Reference Liu and Katz2006; Charonko et al. Reference Charonko, King, Smith and Vlachos2010; de Kat & Ganapathisubramani Reference de Kat and Ganapathisubramani2013; van Oudheusden Reference van Oudheusden2013; Liu, Moreto & Siddle-Mitchell Reference Liu, Moreto and Siddle-Mitchell2016; Liu & Moreto Reference Liu and Moreto2020; Nie et al. Reference Nie, Whitehead, Richards, Smith and Pan2022; Fu & Raayai-Ardakani Reference Fu and Raayai-Ardakani2023; Suchandra & Raayai-Ardakani Reference Suchandra and Raayai-Ardakani2024):