1. Introduction

The use of coated microbubbles as ultrasound contrast agents has been investigated for medical applications in both imaging and therapy (Unger et al. Reference Unger, Porter, Culp, Labell, Matsunaga and Zutshi2004). Clinically available contrast agents contain microbubbles with a size distribution typically ranging from ![]() $1$ to

$1$ to ![]() $10\,\mathrm {\mu }{\rm m}$ in diameter (Frinking et al. Reference Frinking, Segers, Luan and Tranquart2020). Because of the size-dependent resonance frequency of microbubbles, only a fraction of the polydisperse size distribution will display resonance behaviour, i.e. strong ultrasound scattering (Versluis et al. Reference Versluis, Stride, Lajoinie, Dollet and Segers2020). It has been shown experimentally that the scattering of microbubble contrast agents can be greatly increased through the use of monodisperse microbubble suspensions (Streeter et al. Reference Streeter, Gessner, Miles and Dayton2010; Segers et al. Reference Segers, Kruizinga, Kok, Lajoinie, De Jong and Versluis2018b; Helbert et al. Reference Helbert, Gaud, Segers, Botteron, Frinking and Jeannot2020; Stride et al. Reference Stride, Segers, Lajoinie, Cherkaoui, Bettinger, Versluis and Borden2020).

$10\,\mathrm {\mu }{\rm m}$ in diameter (Frinking et al. Reference Frinking, Segers, Luan and Tranquart2020). Because of the size-dependent resonance frequency of microbubbles, only a fraction of the polydisperse size distribution will display resonance behaviour, i.e. strong ultrasound scattering (Versluis et al. Reference Versluis, Stride, Lajoinie, Dollet and Segers2020). It has been shown experimentally that the scattering of microbubble contrast agents can be greatly increased through the use of monodisperse microbubble suspensions (Streeter et al. Reference Streeter, Gessner, Miles and Dayton2010; Segers et al. Reference Segers, Kruizinga, Kok, Lajoinie, De Jong and Versluis2018b; Helbert et al. Reference Helbert, Gaud, Segers, Botteron, Frinking and Jeannot2020; Stride et al. Reference Stride, Segers, Lajoinie, Cherkaoui, Bettinger, Versluis and Borden2020).

Monodisperse contrast agents can be produced directly in microfluidic devices, e.g. by cross-flow, co-flow and flow focusing (Rodríguez-Rodríguez et al. Reference Rodríguez-Rodríguez, Sevilla, Martínez-Bazán and Gordillo2015). Flow-focusing chips are particularly promising for large-scale production as they allow for production rates exceeding 1 million bubbles per second (Segers et al. Reference Segers, De Rond, de Jong, Borden and Versluis2016; van Elburg et al. Reference van Elburg, Collado-Lara, Bruggert, Segers, Versluis and Lajoinie2021). Three different operating regimes of flow-focusing devices have been reported in the literature (Sullivan & Stone Reference Sullivan and Stone2008). (i) Lowest production rates are obtained in the squeezing regime, as bubbles fully block the outlet channel or orifice before they pinch off. This regime has the advantage of generally allowing high monodispersity and relatively large gas to liquid flow-rate ratios, thus creating little waste of the potentially expensive liquid phase. A disadvantage is that the microfluidic chips require a flow-focusing geometry smaller than the desired bubble size, thus being prone to clogging with dust particles when aiming to create micrometre-sized bubbles. Corresponding flow-focusing devices often have very shallow channels, creating two-dimensional (2-D) ‘pancake-like’ bubbles and typical production rates up to a few hundred bubbles per second (Garstecki et al. Reference Garstecki, Gitlin, DiLuzio, Whitesides, Kumacheva and Stone2004). (ii) The dripping regime is widely used for producing bubbles. In this regime, a gas jet is formed but its tip retracts from the outlet channel after the pinch-off of each bubble. (iii) Highest production rates are obtained in the jetting regime, where the gas jet usually stretches into the outlet channel and bubbles pinch off from its non-retracting tip. In the device used in the present work, bubbles can be produced in the dripping regime (however, only for a relatively small parameter range) and the jetting regime (with a relatively short jet). The transition is relatively smooth, with the gas jet extending further and further into the channel. Typical production rates are of the order of ![]() $10^5$ bubbles per second in the dripping regime and up to the order of

$10^5$ bubbles per second in the dripping regime and up to the order of ![]() $10^6$ bubbles per second in the jetting regime. The transition from the dripping to the jetting regime is typically initiated when both the gas pressure and the liquid flow rate are increased.

$10^6$ bubbles per second in the jetting regime. The transition from the dripping to the jetting regime is typically initiated when both the gas pressure and the liquid flow rate are increased.

Efforts to optimize these operation regimes together with chip manufacturing gave rise to various geometries for flow-focusing devices. The first proof of concept was achieved by Gañán-Calvo & Gordillo (Reference Gañán-Calvo and Gordillo2001) with a perfectly axisymmetric system consisting of an orifice through which liquid was focused. Experiments on the same set-up but within a larger parameter space were later published with a new theory by Gañán-Calvo (Reference Gañán-Calvo2004). To circumvent the difficulty of fabricating a perfectly axisymmetric geometry, Gordillo et al. (Reference Gordillo, Cheng, Gañán-Calvo, Marquez and Weitz2004) worked on a 2-D geometry, where liquid and gas were injected into a chamber and focused through an orifice to control pinch-off. Garstecki, Stone & Whitesides (Reference Garstecki, Stone and Whitesides2005) made the choice of using an even smaller channel height, leading to the production of 2-D bubbles in the squeezing regime. A new geometry with a long flow-focusing channel instead of an orifice was introduced by Castro-Hernández et al. (Reference Castro-Hernández, van Hoeve, Lohse and Gordillo2011). The channel geometry and wetting conditions of the materials used (hydrophobic polydimethylsiloxane (PDMS) bonded to a more hydrophilic glass slide), resulted in a gas thread that remained attached to the channel wall while extending far into the channel. Bubbles then pinch off from its tip. Inspired by these results obtained in the jetting regime, Segers et al. (Reference Segers, Gaud, Versluis and Frinking2018a) fabricated chips to produce phospholipid-coated contrast agents. There, the channels are etched in glass and shorter than the ones employed by Castro-Hernández et al. (Reference Castro-Hernández, van Hoeve, Lohse and Gordillo2011) to minimize the pressure drop over the device, allowing its operation with lower vapour pressure gasses (e.g. perfluorobutane). As a result of the revised geometry, the gas jet is shorter and remains centred in the channel instead of adhering to the channel wall. Other channel geometries have been employed, for example, by Hettiarachchi et al. (Reference Hettiarachchi, Talu, Longo, Dayton and Lee2007), with an immediately diverging outlet channel, by Evangelio, Campo-Cortes & Gordillo (Reference Evangelio, Campo-Cortes and Gordillo2015) where gas and liquid are focused into a capillary in an entirely axisymmetric set-up and by Zhang, Li & Thoroddsen (Reference Zhang, Li and Thoroddsen2014) who use a system combining flow focusing and co-flow with a thin capillary reaching into a converging–diverging nozzle.

The various studies on flow-focusing devices with different device geometries, bubble sizes and production rates have also led to a variety of theoretical descriptions primarily intended to predict the bubble size, although most of them also predict the production rate. The more detailed features of these models are discussed in § 2. The bubble diameter is commonly described by the relation

where ![]() $Q_g$ and

$Q_g$ and ![]() $Q_l$ are the gas and liquid flow rates respectively,

$Q_l$ are the gas and liquid flow rates respectively, ![]() $L$ is a reference length, usually the width of the orifice or flow-focusing channel, and

$L$ is a reference length, usually the width of the orifice or flow-focusing channel, and ![]() $a$ and

$a$ and ![]() $b$ are constants defined in the different models. These constants vary between flow-focusing geometries and may thereby capture the effects of liquid and gas viscosities, channel wettability, aspect ratio and so on. Furthermore, most studies exploit the relation between the gas volume flow rate and the bubble size

$b$ are constants defined in the different models. These constants vary between flow-focusing geometries and may thereby capture the effects of liquid and gas viscosities, channel wettability, aspect ratio and so on. Furthermore, most studies exploit the relation between the gas volume flow rate and the bubble size

to express the production rate as a function of bubble size or vice versa. From (1.1) and (1.2) it is apparent that the main parameters that define bubble size and production rate are the liquid and gas flow rate. In most models, the value of the exponent ![]() $a$ is the main result, while

$a$ is the main result, while ![]() $b$ is a fitting parameter obtained empirically. The length scale

$b$ is a fitting parameter obtained empirically. The length scale ![]() $L$ is the expected scaling factor. With the exclusion of some exceptions, most models do not consider any other parameters or fluid properties (e.g. liquid and gas density and viscosity, or interfacial tension between the two). Two exceptions are the models by Castro-Hernández et al. (Reference Castro-Hernández, van Hoeve, Lohse and Gordillo2011) which predict a small effect (power

$L$ is the expected scaling factor. With the exclusion of some exceptions, most models do not consider any other parameters or fluid properties (e.g. liquid and gas density and viscosity, or interfacial tension between the two). Two exceptions are the models by Castro-Hernández et al. (Reference Castro-Hernández, van Hoeve, Lohse and Gordillo2011) which predict a small effect (power ![]() $1/12$) of both gas and liquid viscosity, and by Evangelio et al. (Reference Evangelio, Campo-Cortes and Gordillo2015) who derive different semi-empirical relations depending on the range of liquid viscosities. Experimentally, studies using different liquid viscosities (Gañán-Calvo Reference Gañán-Calvo2004) and surfactants (Garstecki et al. Reference Garstecki, Gitlin, DiLuzio, Whitesides, Kumacheva and Stone2004; Hettiarachchi et al. Reference Hettiarachchi, Talu, Longo, Dayton and Lee2007) have been reported. Numerical studies are mainly available for the squeezing regime (mostly Taylor bubbles, i.e. bullet-shaped bubbles filling almost the entire channel cross-section) and besides liquid viscosity (Jia & Zhang Reference Jia and Zhang2020; Chekifi, Boukraa & Aissani Reference Chekifi, Boukraa and Aissani2021) and surface tension (Chekifi et al. Reference Chekifi, Boukraa and Aissani2021), they focus on the role and optimization of the channel geometry (Dietrich et al. Reference Dietrich, Poncin, Midoux and Li2008; Wang et al. Reference Wang, Ding, Fan, Wang, Chen and Wang2022).

$1/12$) of both gas and liquid viscosity, and by Evangelio et al. (Reference Evangelio, Campo-Cortes and Gordillo2015) who derive different semi-empirical relations depending on the range of liquid viscosities. Experimentally, studies using different liquid viscosities (Gañán-Calvo Reference Gañán-Calvo2004) and surfactants (Garstecki et al. Reference Garstecki, Gitlin, DiLuzio, Whitesides, Kumacheva and Stone2004; Hettiarachchi et al. Reference Hettiarachchi, Talu, Longo, Dayton and Lee2007) have been reported. Numerical studies are mainly available for the squeezing regime (mostly Taylor bubbles, i.e. bullet-shaped bubbles filling almost the entire channel cross-section) and besides liquid viscosity (Jia & Zhang Reference Jia and Zhang2020; Chekifi, Boukraa & Aissani Reference Chekifi, Boukraa and Aissani2021) and surface tension (Chekifi et al. Reference Chekifi, Boukraa and Aissani2021), they focus on the role and optimization of the channel geometry (Dietrich et al. Reference Dietrich, Poncin, Midoux and Li2008; Wang et al. Reference Wang, Ding, Fan, Wang, Chen and Wang2022).

In the present paper, we aim at quantifying the effect of, on the one hand, gas and liquid properties and, on the other hand, channel geometry on bubble size and production rate in a flow-focusing device. The paper is organized as follows. We first discuss in detail most existing models (§ 2) before presenting our experimental set-up (§ 3) and experimental results obtained with two different channel geometries, different gases, glycerol–water mixtures and a variety of surfactants, including phospholipids (§ 4). The results are supported by numerical simulations of the flow, which allow us to individually tune relevant parameters such as gas density and gas viscosity to understand their roles (§ 5). We then review the theoretical models in the light of our experimental and numerical findings (§ 5.4).

2. Theoretical background

This section reviews existing theoretical models predicting the bubble size and production rate in different flow-focusing configurations. The models including their predictive equations are summarized in table 1. This table gathers the general considerations and assumptions of each model and puts a specific emphasis on the role of parameters other than liquid and gas flow rate. This includes the rationale for explicitly or implicitly neglecting certain parameters. Table 1 further includes the type of regime used (squeezing, dripping, jetting), as introduced at the beginning of § 1.

Table 1 Publications discussing power laws in chronological order. Parameters used: ![]() $d_b$ bubble diameter,

$d_b$ bubble diameter, ![]() $D$ orifice or channel diameter,

$D$ orifice or channel diameter, ![]() $d_g$ diameter of the gas thread,

$d_g$ diameter of the gas thread, ![]() $w$ channel width for a rectangular channel,

$w$ channel width for a rectangular channel, ![]() $h$ channel height for a rectangular channel,

$h$ channel height for a rectangular channel, ![]() $l$ channel length,

$l$ channel length, ![]() $U$ average liquid velocity,

$U$ average liquid velocity, ![]() $Q_g$ gas flow rate,

$Q_g$ gas flow rate, ![]() $Q_l$ liquid flow rate,

$Q_l$ liquid flow rate, ![]() $f_b$ production rate of bubbles,

$f_b$ production rate of bubbles, ![]() $\mu _l$ liquid viscosity,

$\mu _l$ liquid viscosity, ![]() $\mu _g$ gas viscosity,

$\mu _g$ gas viscosity, ![]() $\sigma$ surface tension,

$\sigma$ surface tension, ![]() ${We}_l$ liquid Weber number,

${We}_l$ liquid Weber number, ![]() ${Re}_l$ liquid Reynolds number. For the parameters, ✔ signifies that the parameter is taken into account, (✔) that it is taken into account but cancels out naturally and ✘ that the parameter is neglected.

${Re}_l$ liquid Reynolds number. For the parameters, ✔ signifies that the parameter is taken into account, (✔) that it is taken into account but cancels out naturally and ✘ that the parameter is neglected.

Despite their various origins, these models share some general features. (i) A common key question is the definition of the pressure drop at the position of bubble pinch-off. (ii) All these models assume a constant gas flow rate, an assumption which is experimentally challenged for pressure-controlled systems, where gas velocity and flow rate vary periodically at the inlet (Cleve et al. Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021). The gas volume flow rate also varies along the channel axis: as bubbles flow downstream through the flow-focusing region, they experience a pressure drop of up to several bars (Cleve et al. Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021).

The first theory on the bubble size in flow focusing was published by Gañán-Calvo & Gordillo (Reference Gañán-Calvo and Gordillo2001) for flow focusing through an orifice, meaning through a small and short opening behind which the device geometry abruptly widens again; see also schematics in table 1. The authors had considered an absolute instability analysis of the gas jet for the dripping regime, obtaining heuristically the parameters ![]() $b=1$ and

$b=1$ and ![]() $a=0.370\pm 0.005$.

$a=0.370\pm 0.005$.

Gañán-Calvo (Reference Gañán-Calvo2004) later published a revised model for the same geometry. Their widely cited scaling law is based on dimensional analysis of a simplified Navier–Stokes equation assuming large liquid Reynolds numbers ![]() ${Re}_l$, which indicates the dominance of inertial effects and justifies neglecting viscous terms. Consequently, the author only compares the components of the material derivative of the velocity with the pressure gradient

${Re}_l$, which indicates the dominance of inertial effects and justifies neglecting viscous terms. Consequently, the author only compares the components of the material derivative of the velocity with the pressure gradient

The author further argues that bubble growth is made possible by a radial pressure gradient: the pressure in the forming bubble is the same as that in the gas supply line (and jet) while the pressure in the liquid close to the orifice is lower due to energy conversion from pressure to kinetic energy. Liquid density was considered constant and left out, gas inertia (and with it the gas properties in general) was neglected owing to the low gas Reynolds numbers. The power law is then derived from (2.1) with an analysis of the order of magnitude of the three terms (unsteady term, inertial term and pressure gradient). The resulting constants for (1.1) are ![]() $a=0.4$ and heuristically obtained

$a=0.4$ and heuristically obtained ![]() $b=1.1$. No relation for the production rate is derived. It is interesting to note that the experimental parameter range investigated in this paper includes different liquid viscosities and densities, as well as different surface tensions, all collapsing on the same power law curve.

$b=1.1$. No relation for the production rate is derived. It is interesting to note that the experimental parameter range investigated in this paper includes different liquid viscosities and densities, as well as different surface tensions, all collapsing on the same power law curve.

Rodríguez-Rodríguez et al. (Reference Rodríguez-Rodríguez, Sevilla, Martínez-Bazán and Gordillo2015) have reviewed the power laws for flow focusing in a larger context of bubble pinch-off and have derived equations based on the Rayleigh–Plesset equation, an approach originally conducted by Oguz & Prosperetti (Reference Oguz and Prosperetti1993) for pinch-off in a quiescent or co-flowing liquid. Different to the hydrostatic case, the pressure gradient is induced through fluid motion and can be estimated from the momentum equation ![]() $\rho _l\,\mathrm {D}\boldsymbol {v}_l/\mathrm {D}t = - \boldsymbol {\nabla } p$. Liquid density naturally cancels out in the final result. Similarly to the study of Gañán-Calvo (Reference Gañán-Calvo2004), the liquid viscosity term of the Rayleigh–Plesset equation is neglected. Gas properties are neglected as well and the authors state that gas pressure gradients are considered negligible for the derivation as they only play a role in the short moment of bubble pinch-off. However, whether the moment of pinch-off itself is negligible in the process remains open for debate. As for surface tension, even though it appears in the initial discussion, it is neglected in the final model. The solution leads to the same exponent

$\rho _l\,\mathrm {D}\boldsymbol {v}_l/\mathrm {D}t = - \boldsymbol {\nabla } p$. Liquid density naturally cancels out in the final result. Similarly to the study of Gañán-Calvo (Reference Gañán-Calvo2004), the liquid viscosity term of the Rayleigh–Plesset equation is neglected. Gas properties are neglected as well and the authors state that gas pressure gradients are considered negligible for the derivation as they only play a role in the short moment of bubble pinch-off. However, whether the moment of pinch-off itself is negligible in the process remains open for debate. As for surface tension, even though it appears in the initial discussion, it is neglected in the final model. The solution leads to the same exponent ![]() $a=0.4$ as found by Gañán-Calvo (Reference Gañán-Calvo2004) and to an expression for the production rate

$a=0.4$ as found by Gañán-Calvo (Reference Gañán-Calvo2004) and to an expression for the production rate

\begin{equation} f_b = \frac{6 Q_g}{{\rm \pi} d_b^3} \propto \frac{U}{D} \left(\frac{Q_g}{Q_l}\right)^{-({1}/{5})}, \end{equation}

\begin{equation} f_b = \frac{6 Q_g}{{\rm \pi} d_b^3} \propto \frac{U}{D} \left(\frac{Q_g}{Q_l}\right)^{-({1}/{5})}, \end{equation}

where ![]() $U$ is the flow velocity and

$U$ is the flow velocity and ![]() $D$ the orifice diameter.

$D$ the orifice diameter.

A similar geometric configuration, albeit with a cylindrical channel rather than a circular orifice, has later been studied by Evangelio et al. (Reference Evangelio, Campo-Cortes and Gordillo2015). The authors derive a semi-empirical model, where the definition of the pressure gradient at the position of bubble pinch-off is the most critical ingredient, except for very large bubbles where, according to the authors, the pinch-off is triggered by the global pressure loss and not the local pressure gradient. These pressures are numerically simulated in a duct without bubbles and resulting conclusions are applied in the theoretical model (i.e. flat velocity profile at the duct entrance for the inertial case and parabolic profile and corresponding pressure gradient in the viscous case). An intermediate step leads to an expression for the jet diameter, assuming that the gas velocity in the gas thread equals the liquid velocity in the centre of the channel, and for the position until which the gas thread is stable. Based on the same reasoning as Rodríguez-Rodríguez et al. (Reference Rodríguez-Rodríguez, Sevilla, Martínez-Bazán and Gordillo2015), Evangelio et al. (Reference Evangelio, Campo-Cortes and Gordillo2015) then use the Rayleigh–Plesset equation, which is a common model for the radial bubble dynamics, where they retain either the inertial or the viscous part. This simplification, in conjunction with a relevant length scale per flow regime considered, leads to different expressions for the bubble size and production rate, see table 1. Consequently, the model by Evangelio et al. (Reference Evangelio, Campo-Cortes and Gordillo2015) contains several semi-heuristic parameters and either liquid inertia or viscosity is neglected. The surface tension (of the initial gas thread) is indirectly taken into account in the different expressions for the local pressure gradient. Gas properties are not discussed. Furthermore, the effects of confinement in the microchannel are not taken into account to describe the radial bubble dynamics. It is interesting to note that, unlike most other experimental studies, both liquid and gas are pressure controlled. For the latter, a very long supply tube is used, which is supposed to result in a constant gas flow rate. A drawback of such long supply channels is a longer response time when changing flow parameters, in particular when decreasing the gas driving pressure to decrease the gas flow rate (van Elburg et al. Reference van Elburg, Collado-Lara, Bruggert, Segers, Versluis and Lajoinie2021).

Bubble production in a planar device was studied by Garstecki et al. (Reference Garstecki, Gitlin, DiLuzio, Whitesides, Kumacheva and Stone2004). In their configuration, the bubble diameter is larger than the orifice width (squeezing regime). The bubbles are also larger than the channel height so that the bubbles can be considered as disk like or two-dimensional. The theoretical expression derived for this two-dimensional squeezing case is based on the assumption that the pressure loss is governed by Poiseuille flow ![]() $\delta p \sim \mu l /h^4$ and on the empirical observation that the time to pinch-off is inversely proportional to the liquid flow rate. In the final expression reported in table 1, the channel geometry has been left out as being constant, but the whole expression could be written as

$\delta p \sim \mu l /h^4$ and on the empirical observation that the time to pinch-off is inversely proportional to the liquid flow rate. In the final expression reported in table 1, the channel geometry has been left out as being constant, but the whole expression could be written as ![]() $d_b \propto ({\rm d} p/{{\rm d}\kern0.06em x} /(Q_l h^4))^{(1/3)}$ when assuming the pressure gradient to be homogeneous along the axial direction.

$d_b \propto ({\rm d} p/{{\rm d}\kern0.06em x} /(Q_l h^4))^{(1/3)}$ when assuming the pressure gradient to be homogeneous along the axial direction.

Another type of planar device has been studied by Castro-Hernández et al. (Reference Castro-Hernández, van Hoeve, Lohse and Gordillo2011). In their configuration the flow-focusing channel is rectangular, very long with respect to the channel width (![]() $l\sim 30w$) and considerably larger than the bubbles being produced. The stable gas thread remains attached to the upper PDMS wall. The model assumes the pressure gradient in the axial direction to be equal in the gas thread (with a constant gas flow rate) and the surrounding liquid. In the liquid, the pressure gradient is expected to decrease along the flow direction due to the development of the velocity profile from uniform at the entrance of the channel to parabolic downstream. Consequently, to match the pressure gradient in the liquid, the pressure gradient in the gas also decreases in the axial direction. This decrease is achieved by an increasing gas thread diameter

$l\sim 30w$) and considerably larger than the bubbles being produced. The stable gas thread remains attached to the upper PDMS wall. The model assumes the pressure gradient in the axial direction to be equal in the gas thread (with a constant gas flow rate) and the surrounding liquid. In the liquid, the pressure gradient is expected to decrease along the flow direction due to the development of the velocity profile from uniform at the entrance of the channel to parabolic downstream. Consequently, to match the pressure gradient in the liquid, the pressure gradient in the gas also decreases in the axial direction. This decrease is achieved by an increasing gas thread diameter ![]() $d_g$ which, according to the authors, triggers the bubble pinch-off. The assumptions of high Weber numbers and of constant gas flow rate allow the use of a relation between production rate, flow velocity and gas thread diameter,

$d_g$ which, according to the authors, triggers the bubble pinch-off. The assumptions of high Weber numbers and of constant gas flow rate allow the use of a relation between production rate, flow velocity and gas thread diameter, ![]() $f_b\propto U /d_g$, known from bubble pinch-off in a co-flow (Gordillo, Sevilla & Martínez-Bazán Reference Gordillo, Sevilla and Martínez-Bazán2007). Finally, exploiting (1.2), the resulting expression features a power law exponent

$f_b\propto U /d_g$, known from bubble pinch-off in a co-flow (Gordillo, Sevilla & Martínez-Bazán Reference Gordillo, Sevilla and Martínez-Bazán2007). Finally, exploiting (1.2), the resulting expression features a power law exponent ![]() $a=5/12$ and prefactor

$a=5/12$ and prefactor ![]() $b = 2.75 (\mu _g/\mu _l)^{(1/12)}$ that accounts for the gas and liquid viscosities, where

$b = 2.75 (\mu _g/\mu _l)^{(1/12)}$ that accounts for the gas and liquid viscosities, where ![]() $2.75$ is found empirically. The model disregards the fact that the gas ligament is attached to the wall and is thus embedded inside the liquid boundary layer, which leads to an overestimation of the liquid flow rate in particular for very thin gas threads.

$2.75$ is found empirically. The model disregards the fact that the gas ligament is attached to the wall and is thus embedded inside the liquid boundary layer, which leads to an overestimation of the liquid flow rate in particular for very thin gas threads.

While all these models assume the bubble production to be driven entirely by the pressure gradient, it is important to keep in mind that co-flow, or in other words, viscous entrainment, might play a role as well. For example, Quintero, Evangelio & Gordillo (Reference Quintero, Evangelio and Gordillo2018) summarize that (i) if the pressure gradient is dominant (also with respect to surface tension)

\begin{equation} f_b \sim \sqrt{\frac{|\boldsymbol{\nabla} p|}{\rho d_b}} \quad \text{and} \quad d_b \sim \left( \frac{Q_g}{\sqrt{|\boldsymbol{\nabla} p|/\rho}} \right)^{2/5}, \end{equation}

\begin{equation} f_b \sim \sqrt{\frac{|\boldsymbol{\nabla} p|}{\rho d_b}} \quad \text{and} \quad d_b \sim \left( \frac{Q_g}{\sqrt{|\boldsymbol{\nabla} p|/\rho}} \right)^{2/5}, \end{equation}while (ii) for co-flow, where the effect of the pressure gradient is negligible,

\begin{equation} f_b \sim \frac{U}{d_g} \quad \text{and} \quad d_b \sim \left( \frac{Q_g d_g}{U} \right)^{1/3}. \end{equation}

\begin{equation} f_b \sim \frac{U}{d_g} \quad \text{and} \quad d_b \sim \left( \frac{Q_g d_g}{U} \right)^{1/3}. \end{equation}In many real cases this also implies that much more complexity can be added in the presence of both effects.

Given the high level of complexity of the full problem, these models are bound to use simplifying assumptions that are more or less specific to a given geometry. Each of the studies presents models that agree well with the respective experimental measurements they aim to describe. Furthermore, and despite significant difference in the underlying physical principles that they are based upon, these models propose comparable power laws with an exponent near ![]() $0.4$. Given limited experimental accuracy and operating range of the microfluidic chips, which typically do not exceed one order of magnitude, the subtle differences in power laws are insufficient to discriminate correct from potentially inaccurate conceptual approaches. This would require finer theoretical descriptions going beyond scaling law consideration and which account for the specific properties of the fluids used. Specifically, recent work (Cleve et al. Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021) suggests that neglecting liquid viscosity and assuming a constant gas flow rate may not always be justified. Likewise, it was suggested that gas inertia has a role to play albeit during a short but meaningful fraction of the bubble formation process, i.e. close to the moment of pinch-off (Gordillo et al. Reference Gordillo, Sevilla, Rodríguez-Rodríguez and Martínez-Bazán2005; Dollet et al. Reference Dollet, Van Hoeve, Raven, Marmottant and Versluis2008), so that changes of the bubble size of approximately 10 % due to different gas densities between air and helium bubbles have been reported (Gordillo et al. Reference Gordillo, Sevilla and Martínez-Bazán2007). Once again, hindered by the complexity of the full problem, it is doubtful that a general analytical model with all experimentally relevant parameters can be conceived. Nevertheless, a broader experimental investigation of the parameter space may yet allow to narrow the relevant physical considerations without oversimplifying the problem.

$0.4$. Given limited experimental accuracy and operating range of the microfluidic chips, which typically do not exceed one order of magnitude, the subtle differences in power laws are insufficient to discriminate correct from potentially inaccurate conceptual approaches. This would require finer theoretical descriptions going beyond scaling law consideration and which account for the specific properties of the fluids used. Specifically, recent work (Cleve et al. Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021) suggests that neglecting liquid viscosity and assuming a constant gas flow rate may not always be justified. Likewise, it was suggested that gas inertia has a role to play albeit during a short but meaningful fraction of the bubble formation process, i.e. close to the moment of pinch-off (Gordillo et al. Reference Gordillo, Sevilla, Rodríguez-Rodríguez and Martínez-Bazán2005; Dollet et al. Reference Dollet, Van Hoeve, Raven, Marmottant and Versluis2008), so that changes of the bubble size of approximately 10 % due to different gas densities between air and helium bubbles have been reported (Gordillo et al. Reference Gordillo, Sevilla and Martínez-Bazán2007). Once again, hindered by the complexity of the full problem, it is doubtful that a general analytical model with all experimentally relevant parameters can be conceived. Nevertheless, a broader experimental investigation of the parameter space may yet allow to narrow the relevant physical considerations without oversimplifying the problem.

3. Materials and methods

3.1. Experimental set-up

Experiments were conducted in flow-focusing devices, which were fabricated from two isotropically etched glass wafers, aligned and bonded together. The flow-focusing channel has a length ![]() $l$ and its cross-section has a width

$l$ and its cross-section has a width ![]() $w$ and a height

$w$ and a height ![]() $h$ with rounded corners (radius of curvature

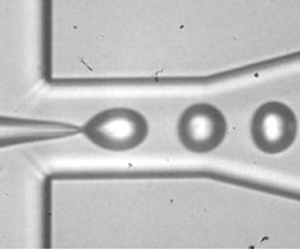

$h$ with rounded corners (radius of curvature ![]() $h/2$), see Cleve et al. (Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021) and Segers et al. (Reference Segers, Gaud, Versluis and Frinking2018a) for more detail. Two different channel sizes were used, as shown in figure 1(a,b). The geometry and channel cross-section are depicted in figure 1(c).

$h/2$), see Cleve et al. (Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021) and Segers et al. (Reference Segers, Gaud, Versluis and Frinking2018a) for more detail. Two different channel sizes were used, as shown in figure 1(a,b). The geometry and channel cross-section are depicted in figure 1(c).

Figure 1. (a) Snapshot of the short channel during bubble production with 42 % glycerol and 2 % Tween 80 in water and N![]() $_2$ as the gas phase. (b) Snapshot of the long channel with DSPC/DPPE-PEG500 in saline and N

$_2$ as the gas phase. (b) Snapshot of the long channel with DSPC/DPPE-PEG500 in saline and N![]() $_2$ as the gas phase. (Saline is an isotonic solution of 0.9 % w/v NaCl in water, used for injection in the human body.) (c) Geometry of the flow-focusing channels with

$_2$ as the gas phase. (Saline is an isotonic solution of 0.9 % w/v NaCl in water, used for injection in the human body.) (c) Geometry of the flow-focusing channels with ![]() $w$ channel width,

$w$ channel width, ![]() $h$ channel height,

$h$ channel height, ![]() $S$ section area and

$S$ section area and ![]() $l$ channel length. Furthermore, the bubble diameter

$l$ channel length. Furthermore, the bubble diameter ![]() $d_b$ is indicated. (d) Schematic of the experimental set-up.

$d_b$ is indicated. (d) Schematic of the experimental set-up.

The chips were integrated in a stand-alone monodisperse bubble production system, as introduced by van Elburg et al. (Reference van Elburg, Collado-Lara, Bruggert, Segers, Versluis and Lajoinie2021). A schematic is presented in figure 1(d). The liquid was flow rate controlled (EL-FLOW series, Bronkhorst, NL) and the gas was pressure controlled (EL-PRESS series, Bronkhorst, NL). For the experiments reported here, the liquid flow rate ranged between 50 and ![]() $250\,\mathrm {\mu }$l min

$250\,\mathrm {\mu }$l min![]() $^{-1}$ and the gas pressure ranged between 1 and 3 bar overpressure. For the specific case of high liquid viscosity experiments, the gas pressure was increased up to 8 bar. The temperature of the whole production system could be increased up to

$^{-1}$ and the gas pressure ranged between 1 and 3 bar overpressure. For the specific case of high liquid viscosity experiments, the gas pressure was increased up to 8 bar. The temperature of the whole production system could be increased up to ![]() $60\,^{\circ }{\rm C}$ to minimize the on-chip coalescence of phospholipid-coated bubbles (Segers et al. Reference Segers, Lassus, Bussat, Gaud and Frinking2019). In order to measure the production rate, the device is equipped with a low power (5 mW) laser module and a fast photodiode (FDS100, Thorlabs, Si detector, 350–1100 nm, 14 ns rise time and 13 mm

$60\,^{\circ }{\rm C}$ to minimize the on-chip coalescence of phospholipid-coated bubbles (Segers et al. Reference Segers, Lassus, Bussat, Gaud and Frinking2019). In order to measure the production rate, the device is equipped with a low power (5 mW) laser module and a fast photodiode (FDS100, Thorlabs, Si detector, 350–1100 nm, 14 ns rise time and 13 mm![]() $^2$ aperture), see van Elburg et al. (Reference van Elburg, Collado-Lara, Bruggert, Segers, Versluis and Lajoinie2021) for more details. Snapshots were recorded at 15 fps with a CCD camera (Lumenera LM165M,

$^2$ aperture), see van Elburg et al. (Reference van Elburg, Collado-Lara, Bruggert, Segers, Versluis and Lajoinie2021) for more details. Snapshots were recorded at 15 fps with a CCD camera (Lumenera LM165M, ![]() $1280\times 1024$ pixels with a pixel size of

$1280\times 1024$ pixels with a pixel size of ![]() $6.45\,\mathrm {\mu }{\rm m}$ and equipped with a

$6.45\,\mathrm {\mu }{\rm m}$ and equipped with a ![]() $15\times$ objective resulting in an image resolution of

$15\times$ objective resulting in an image resolution of ![]() $0.44\,\mathrm {\mu }$m pixel

$0.44\,\mathrm {\mu }$m pixel![]() $^{-1}$) illuminated using a LED flash light emitting a 100 ns light pulse for each frame.

$^{-1}$) illuminated using a LED flash light emitting a 100 ns light pulse for each frame.

The bubble volume was extracted from the images by volume integration assuming axisymmetry. From the volume the equivalent diameter of a spherical bubble was calculated. Bubbles positioned between 15 and ![]() $30\,\mathrm {\mu }{\rm m}$ into the flow-focusing channel were evaluated, as this avoids increased motion blur due to very high velocities close to the inlet. Note that the final mean bubble diameter of lipid-coated bubbles is typically two to three times smaller once the bubbles have stabilized though diffusive dissolution, which mechanically compresses the initially loosely pact lipid shell (Segers et al. Reference Segers, Lohse, Versluis and Frinking2017). The bubbles produced in this study thus had relevant sizes for medical applications.

$30\,\mathrm {\mu }{\rm m}$ into the flow-focusing channel were evaluated, as this avoids increased motion blur due to very high velocities close to the inlet. Note that the final mean bubble diameter of lipid-coated bubbles is typically two to three times smaller once the bubbles have stabilized though diffusive dissolution, which mechanically compresses the initially loosely pact lipid shell (Segers et al. Reference Segers, Lohse, Versluis and Frinking2017). The bubbles produced in this study thus had relevant sizes for medical applications.

3.2. Experimental procedure

Bubble production using 10 different surfactant mixtures (phospholipid mixed with PEGylated phospholipid DSPC/DPPE-PEG5000, 9/1 molar ratio; DOPC/DPPE-PEG5000, 9/1; DMPC/DPPE-PEG5000, 9/1; pure DPPE-PEG5000; PEG40s; Tween 80; Tween 20; Sodium dodecyl sulphate; Zonyl FSO; Pluronic F68) and one without any surfactant were compared to investigate the effect of interfacial tension. Either Tween 80 or DSPC:DPPE-PEG5000, both showing a very similar effect on bubble production, were used by default when varying gas or liquid properties. Further experiments were conducted with glycerol concentrations of up to 50 % in water and with the surfactant Tween 80 to study bubble production under increased liquid viscosity. The gas used by default was N![]() $_2$, however, measurements with three other gases (CO

$_2$, however, measurements with three other gases (CO![]() $_2$, SF

$_2$, SF![]() $_6$ and C

$_6$ and C![]() $_4$F

$_4$F![]() $_{10}$) were also conducted to quantify the role of the gas properties on bubble production. Note, however, that the change of either surfactant, glycerol concentration or gas can simultaneously modify several physical fluid parameters. For instance, the addition of glycerol not only increases the liquid viscosity but also decreases the interfacial tension and increases the liquid density (Takamura, Fischer & Morrow Reference Takamura, Fischer and Morrow2012). Likewise, the addition of most surfactants can also increase liquid viscosity. Changing the gas leads to different gas densities, gas viscosities and interfacial tensions. Unless otherwise specified, all experiments with phospholipids were conducted at

$_{10}$) were also conducted to quantify the role of the gas properties on bubble production. Note, however, that the change of either surfactant, glycerol concentration or gas can simultaneously modify several physical fluid parameters. For instance, the addition of glycerol not only increases the liquid viscosity but also decreases the interfacial tension and increases the liquid density (Takamura, Fischer & Morrow Reference Takamura, Fischer and Morrow2012). Likewise, the addition of most surfactants can also increase liquid viscosity. Changing the gas leads to different gas densities, gas viscosities and interfacial tensions. Unless otherwise specified, all experiments with phospholipids were conducted at ![]() $60\,^{\circ }{\rm C}$ and all experiments without surfactants and with other types of surfactants at

$60\,^{\circ }{\rm C}$ and all experiments without surfactants and with other types of surfactants at ![]() $40\,^{\circ }{\rm C}$.

$40\,^{\circ }{\rm C}$.

For one measurement series (i.e. one specific combination of liquid, gas and temperature), we explored the full range of gas pressures and liquid flow rates for which stable bubble production with ![]() $d_b< h$ in the jetting regime was possible. This operating regime was limited for low liquid flow rates by the possibility to stably create bubbles in the jetting regime itself, i.e. the regime where the gas jet remains inside the flow-focusing channel (and does not retract from the channel periodically such as in the dripping regime). Note, however, that the limiting conditions highly depended on the stability of the system, which could easily be affected by, e.g. dust particles. The minimum gas pressure required depends on the liquid flow rate but also on the liquid and gas properties, as it has to overcome the pressure drop inside the flow-focusing channel. For too low pressures, the gas flow would stop, and no bubbles would be produced. For high liquid flow rates, experiments were limited mostly by increased motion blur in the images. This also means that for some measurement points we can only present results for the production rate; production rate detection with the laser-photodiode system was reliable at any flow velocity. During the experiments the production rate was constantly monitored by which its stability was assured during each experiment consisting of a series of 90 images.

$d_b< h$ in the jetting regime was possible. This operating regime was limited for low liquid flow rates by the possibility to stably create bubbles in the jetting regime itself, i.e. the regime where the gas jet remains inside the flow-focusing channel (and does not retract from the channel periodically such as in the dripping regime). Note, however, that the limiting conditions highly depended on the stability of the system, which could easily be affected by, e.g. dust particles. The minimum gas pressure required depends on the liquid flow rate but also on the liquid and gas properties, as it has to overcome the pressure drop inside the flow-focusing channel. For too low pressures, the gas flow would stop, and no bubbles would be produced. For high liquid flow rates, experiments were limited mostly by increased motion blur in the images. This also means that for some measurement points we can only present results for the production rate; production rate detection with the laser-photodiode system was reliable at any flow velocity. During the experiments the production rate was constantly monitored by which its stability was assured during each experiment consisting of a series of 90 images.

3.3. High-speed recording experiments

To enable a detailed discussion on bubble formation, we also recorded high-speed movies for a few experimental settings. The employed high-speed imaging set-up is described in detail in Cleve et al. (Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021). This set-up does, however, not allow temperature regulation and real-time monitoring of the production rate. In short, the liquid was driven by a syringe pump (Harvard PhD) and the gas flow was pressure controlled (IMI Norgren). Imaging was achieved with an ultra-high-speed camera (Shimadzu HPV-X2) operated at a frame rate of 10 million frames per second with a resolution of ![]() $400\times 250\,{\rm pixels}^{2}$ (imaging resolution

$400\times 250\,{\rm pixels}^{2}$ (imaging resolution ![]() $0.25\,\mathrm {\mu }$m pixel

$0.25\,\mathrm {\mu }$m pixel![]() $^{-1}$). The total image magnification was

$^{-1}$). The total image magnification was ![]() $120\times$. Light was supplied by a Xenon strobe light (Vision Light Tech).

$120\times$. Light was supplied by a Xenon strobe light (Vision Light Tech).

3.4. Numerical method

To support the experimental observations, we also conducted a series of numerical simulations. The numerical model used is explained in more detail in Cleve et al. (Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021). In short, both the liquid and gas dynamics were modelled using the incompressible Navier–Stokes equation using sharp-interface arbitrary Lagrangian–Eulerian finite element scheme. The simulated domain is ‘two-dimensional’ assuming radial symmetry of the flow-focusing channel. This model was validated in terms of the bubble shape dynamics (formation and pinch-off), production rate, velocity of the bubbles and average and oscillatory velocity of the surrounding liquid (Cleve et al. Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021). Note that, owing to the restriction of the axisymmetric geometry, the simulation cannot perfectly reproduce the non-axisymmetric experimental channel (see figure 1c), thereby displaying quantitative differences when compared with experimental results over a large parameter range. In the present study, this numerical model is used to qualitatively describe the influence of individually varied physical fluid properties on bubble production. To that end, all numerical results are discussed with respect to the reference case ![]() $Q_l=100\,\mathrm {\mu }$l min

$Q_l=100\,\mathrm {\mu }$l min![]() $^{-1}$,

$^{-1}$, ![]() $p_g=0.7$ bar

$p_g=0.7$ bar ![]() $\rho _l=1000$ kg m

$\rho _l=1000$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $\rho _g=1$ kg m

$\rho _g=1$ kg m![]() $^{-3}$,

$^{-3}$, ![]() $\mu _l=1$ mPa s,

$\mu _l=1$ mPa s, ![]() $\mu _g=17.5\,\mathrm {\mu }$Pa s and

$\mu _g=17.5\,\mathrm {\mu }$Pa s and ![]() $\sigma = 72$ mN m

$\sigma = 72$ mN m![]() $^{-1}$. The numerical flow-focusing channel has a diameter of

$^{-1}$. The numerical flow-focusing channel has a diameter of ![]() $18.4\,\mathrm {\mu }{\rm m}$ and a length of

$18.4\,\mathrm {\mu }{\rm m}$ and a length of ![]() $30\,\mathrm {\mu }{\rm m}$, thus having similar dimensions as the experimental one (see short channel, figure 1c).

$30\,\mathrm {\mu }{\rm m}$, thus having similar dimensions as the experimental one (see short channel, figure 1c).

4. Experimental results

4.1. Channel geometry

Figure 2 shows the experimental results for the two channel geometries conducted both with water with the DSPC/DPPE-PEG5000 mixture and N![]() $_2$. For both chips, the production rate depends strongly on the liquid flow rate, see figure 2(a). For a given liquid flow rate, several experiments with varying gas pressure were conducted, but all resulting production rates collapse on a single curve. Consequently, as long as the gas pressure was large enough to allow stable bubble production (typically of the order of 1 bar, but depending on the liquid flow rate and the liquid and gas properties), no significant influence of the gas pressure or gas flow rate was observed. For the same liquid flow rate, the production rate in the short channel is twice as high as in the long channel. This difference can partly, but not fully, be explained by the smaller channel sections of the short channel and correspondingly higher liquid flow velocities.

$_2$. For both chips, the production rate depends strongly on the liquid flow rate, see figure 2(a). For a given liquid flow rate, several experiments with varying gas pressure were conducted, but all resulting production rates collapse on a single curve. Consequently, as long as the gas pressure was large enough to allow stable bubble production (typically of the order of 1 bar, but depending on the liquid flow rate and the liquid and gas properties), no significant influence of the gas pressure or gas flow rate was observed. For the same liquid flow rate, the production rate in the short channel is twice as high as in the long channel. This difference can partly, but not fully, be explained by the smaller channel sections of the short channel and correspondingly higher liquid flow velocities.

Figure 2. Experimental results for the two different channel sizes. All experiments are conducted with water containing the DSPC/DPPE-PEG5000 mixture and N![]() $_2$ gas. Production rate and bubble size are shown as functions of the liquid flow rate in (a,b), respectively. Panel (c) shows the bubble size as a function of the gas to liquid flow rate ratio. The fitted power law features an exponent

$_2$ gas. Production rate and bubble size are shown as functions of the liquid flow rate in (a,b), respectively. Panel (c) shows the bubble size as a function of the gas to liquid flow rate ratio. The fitted power law features an exponent ![]() $a=0.38$ for both channels. The grey square corresponds to a numerical simulation (

$a=0.38$ for both channels. The grey square corresponds to a numerical simulation (![]() $\sigma =45$ mN m

$\sigma =45$ mN m![]() $^{-1}$ and otherwise the reference conditions given in § 3.4) and shows a good agreement.

$^{-1}$ and otherwise the reference conditions given in § 3.4) and shows a good agreement.

As opposed to the production rate, the bubble size for a given liquid flow rate does not collapse on a single curve, i.e. it depends on the gas pressure, see figure 2(b). Note that with increasing flow rate smaller bubbles can be produced; the black line in figure 2(b) indicates this trend, it corresponds to the minimum bubble size as a function of the liquid flow rate and decreases linearly in the studied parameter range. Maximum bubble sizes were limited by the maximum set gas driving pressure and only bubbles smaller than the channel width were considered. In figure 2(c), the bubble size is furthermore plotted as a function of the gas to liquid flow-rate ratio ![]() $Q_g/Q_l$. Following the general form used in the literature, a scaling law of the form

$Q_g/Q_l$. Following the general form used in the literature, a scaling law of the form

is fitted to the experimental results. For both geometries a factor ![]() $a\approx 0.38$ and

$a\approx 0.38$ and ![]() $b \approx 0.45\pm 0.05$ is found. For the normalization, the channel width

$b \approx 0.45\pm 0.05$ is found. For the normalization, the channel width ![]() $w$ yielded the best agreement for

$w$ yielded the best agreement for ![]() $b$ between the short and the long channel. However, other options such as the hydraulic diameter

$b$ between the short and the long channel. However, other options such as the hydraulic diameter ![]() $d_{hyd} = 4 * S / P$ with

$d_{hyd} = 4 * S / P$ with ![]() $P={\rm \pi} *h + 2*(w-h)$ or an average diameter

$P={\rm \pi} *h + 2*(w-h)$ or an average diameter ![]() $d_{av} = (w+h)/2$ are still of the same order of magnitude and lie within approximately 10 % of each other.

$d_{av} = (w+h)/2$ are still of the same order of magnitude and lie within approximately 10 % of each other.

4.2. Temperature

Experiments with Tween 80 in water and N![]() $_2$ in the short channel were conducted for temperatures ranging from

$_2$ in the short channel were conducted for temperatures ranging from ![]() $40\,^{\circ }$C to

$40\,^{\circ }$C to ![]() $60\,^{\circ }$C. Even though most physical parameters vary slightly with temperature (see table 2), its effect on the bubble size or production rate was found to be small enough to be neglected in the following (see figure 3). Within the temperature range tested and with increasing temperature, the liquid viscosity decreases by approximately 25 %, the liquid density decreases by less than 1 % (based on Takamura et al. Reference Takamura, Fischer and Morrow2012), the gas density decreases by 7 % and the gas viscosity increases by approximately 5 % (Lemmon et al. Reference Lemmon, Bell, Huber and McLinden2022). Surface tension of pure water would decrease by approximately 5 %.

$60\,^{\circ }$C. Even though most physical parameters vary slightly with temperature (see table 2), its effect on the bubble size or production rate was found to be small enough to be neglected in the following (see figure 3). Within the temperature range tested and with increasing temperature, the liquid viscosity decreases by approximately 25 %, the liquid density decreases by less than 1 % (based on Takamura et al. Reference Takamura, Fischer and Morrow2012), the gas density decreases by 7 % and the gas viscosity increases by approximately 5 % (Lemmon et al. Reference Lemmon, Bell, Huber and McLinden2022). Surface tension of pure water would decrease by approximately 5 %.

Figure 3. Experimental results in the short channel operated with water, Tween 80 and N![]() $_2$ at different temperatures. Production rate and bubble size are shown as functions of the liquid flow rate in (a,b), respectively. (c) Bubble size as a function of the gas to liquid flow rate ratio.

$_2$ at different temperatures. Production rate and bubble size are shown as functions of the liquid flow rate in (a,b), respectively. (c) Bubble size as a function of the gas to liquid flow rate ratio.

Table 2. Effect of temperature on gas and liquid properties. All values are obtained from Lemmon et al. (Reference Lemmon, Bell, Huber and McLinden2022).

4.3. Gas composition

Changing the gas composition modifies primarily the gas density, but also the gas viscosity and surface tension. Surface tension has been shown to be affected by the presence of fluorocarbon gases (Krafft, Fainerman & Miller Reference Krafft, Fainerman and Miller2015). We have conducted a pendant-drop experiment and can confirm that using perfluorobutane (C![]() $_4$F

$_4$F![]() $_{10}$) instead of air decreases the surface tension of pure water by approximately 2 % and water with the DSPC/DPPEPEG5000 mixture by approximately 8 %.

$_{10}$) instead of air decreases the surface tension of pure water by approximately 2 % and water with the DSPC/DPPEPEG5000 mixture by approximately 8 %.

The effect of changing the gas composition on bubble size and production rate is shown in figure 4. Gas properties are summarized in table 3. For the same liquid flow rate, smaller bubbles (approximately 30 %, figure 4b) and considerably larger production rates (approximately 60 %, figure 4a) are measured for C![]() $_4$F

$_4$F![]() $_{10}$ as compared with N

$_{10}$ as compared with N![]() $_2$. The combined effect (on bubble size and production rate) leads to a decrease in the prefactor of the power law (figure 4c). The same trend is observed for the short chip (see figure S1 in the supplementary material available at https://doi.org/10.1017/jfm.2023.704). It must be noted that a lower gas driving pressure was generally necessary for the higher gas densities. It is also noted that the minimum driving pressure required to start the production of bubbles typically decreased with increasing gas density (and gas viscosity). A possible explanation is that the higher density gases together with the extremely high gas velocities in the jet neck, see more details in § 5.3.1, provide a larger ‘inertial push’ capable of stabilizing the gas thread. Finally, it should be mentioned that the typical flow-rate ratio for bubble production decreases with increasing liquid flow rate, which can partly explain the convex shape for C

$_2$. The combined effect (on bubble size and production rate) leads to a decrease in the prefactor of the power law (figure 4c). The same trend is observed for the short chip (see figure S1 in the supplementary material available at https://doi.org/10.1017/jfm.2023.704). It must be noted that a lower gas driving pressure was generally necessary for the higher gas densities. It is also noted that the minimum driving pressure required to start the production of bubbles typically decreased with increasing gas density (and gas viscosity). A possible explanation is that the higher density gases together with the extremely high gas velocities in the jet neck, see more details in § 5.3.1, provide a larger ‘inertial push’ capable of stabilizing the gas thread. Finally, it should be mentioned that the typical flow-rate ratio for bubble production decreases with increasing liquid flow rate, which can partly explain the convex shape for C![]() $_4$F

$_4$F![]() $_{10}$ in figure 4(a) due to the conservation of volume (1.2). This observation will be discussed in more detail in § 5.4 and figure 15.

$_{10}$ in figure 4(a) due to the conservation of volume (1.2). This observation will be discussed in more detail in § 5.4 and figure 15.

Figure 4. Experimental results for four different gases. All experiments are conducted with the long channel and with the same liquid, water with the DSPC/DPPE-PEG5000 mixture. The production rate and bubble size as functions of the liquid flow rate are shown in (a,b), respectively. Panel (c) shows the bubble size with respect to the flow-rate ratio, including a fit with a power law. The exponent of the power law is ![]() $a=0.38\pm 0.1$ for all cases, the pre-factors are

$a=0.38\pm 0.1$ for all cases, the pre-factors are ![]() $b=0.53$ for N

$b=0.53$ for N![]() $_2$,

$_2$, ![]() $0.5$ for CO

$0.5$ for CO![]() $_2$,

$_2$, ![]() $0.48$ for SF

$0.48$ for SF![]() $_4$ and

$_4$ and ![]() $0.46$ for C

$0.46$ for C![]() $_4$F

$_4$F![]() $_{10}$. While driving pressures associated with the experimental points for N

$_{10}$. While driving pressures associated with the experimental points for N![]() $_2$ range between 2.75 and 3.75 bar, those for C

$_2$ range between 2.75 and 3.75 bar, those for C![]() $_4$F

$_4$F![]() $_{10}$ range between 1.75 and 2.75 bar.

$_{10}$ range between 1.75 and 2.75 bar.

Table 3. Different gases used and their physical properties. All values are obtained from Lemmon et al. (Reference Lemmon, Bell, Huber and McLinden2022) for ![]() $60\,^{\circ }$C and 1 bar. As will be discussed later, certain gases can further affect the surface tension between the gas and a given liquid.

$60\,^{\circ }$C and 1 bar. As will be discussed later, certain gases can further affect the surface tension between the gas and a given liquid.

4.4. Liquid: water–glycerol solutions

The viscosity of the continuous phase can be increased by adding glycerol, with a marginal increase in liquid density and decrease in surface tension, see also table 4. For example, a solution composed of water and 40 % glycerol is over three times more viscous than water, the density is increased by 10 % and surface tension decreased by 4 % (Takamura et al. Reference Takamura, Fischer and Morrow2012). Experiments have been conducted in both the short channel and the long channel, see figure 5. Interestingly, in the short channel, the production rate as a function of the liquid flow rate is not affected by the change in viscosity, as can be seen in the collapse of all data points in figure 5(a); the applied gas pressure has a minor influence. However, lower liquid flow rates are necessary to produce similar sized bubbles at higher viscosities, see figure 5(b). Together, these lead to a significant increase of the prefactor in the power law with an increase in liquid viscosity, see figure 5(c). For the long channel, despite difficulties to keep bubble production stable for high glycerol concentrations (the points are more scattered), one can observe that the production rate as a function of the liquid flow rate clearly increases with increasing liquid viscosity, see figure 5(d). As for the short channel, lower liquid flow rates are necessary to produce similar sized bubbles at higher viscosities, see figure 5(e). Different from the short channel, the prefactor of the power law for the long channel remains rather constant, see figure 5( f). In summary, an increase in liquid viscosity only significantly affects the size of the bubbles formed in the short channel and the production rate in the long channel.

Table 4. Physical properties of water–glycerol solutions used in the present study. Liquid viscosity is calculated based on Cheng (Reference Cheng2008), density and surface tension values are extrapolated from Takamura et al. (Reference Takamura, Fischer and Morrow2012). The values printed in grey are not used for figures 5 and 6.

Figure 5. Experimental results for different glycerol concentrations, with N![]() $_2$ and Tween80 in the short channel at

$_2$ and Tween80 in the short channel at ![]() $40\,^{\circ }$C (a–c) and long channel at

$40\,^{\circ }$C (a–c) and long channel at ![]() $60\,^{\circ }$C (d–f). The viscosity is shown in colour code, the values are also summarized in table 4. Theproduction rates are shown in (a,d), and the bubble sizes with respect to the liquid flow rate in (b,e). Panels (c, f) show the bubble size with respect to the flow-rate ratio including a fit with a power law.

$60\,^{\circ }$C (d–f). The viscosity is shown in colour code, the values are also summarized in table 4. Theproduction rates are shown in (a,d), and the bubble sizes with respect to the liquid flow rate in (b,e). Panels (c, f) show the bubble size with respect to the flow-rate ratio including a fit with a power law.

Figure 6. Gas pressure vs liquid flow rate corresponding to the data in figure 5. (a,b) Correspond to the short channel at ![]() $40\,^{\circ }$C, (c,d) to the long channel at

$40\,^{\circ }$C, (c,d) to the long channel at ![]() $60\,^{\circ }$C. Panels (a,c) show the set experimental pressure, while in (b,d) the pressure is normalized by the liquid viscosity.

$60\,^{\circ }$C. Panels (a,c) show the set experimental pressure, while in (b,d) the pressure is normalized by the liquid viscosity.

As expected, operating the chips with higher liquid viscosity requires a higher gas pressure for the same liquid flow rate, see figures 6(a) and 6(c). The pressure drop across the nozzle can be written as the contribution of 2 terms: the viscous (linear) pressure drop in the bubble production channel, that scales with ![]() $\Delta p \propto \mu _l (Q_g+Q_l)$, and the geometric (entry) pressure drop, that scales with

$\Delta p \propto \mu _l (Q_g+Q_l)$, and the geometric (entry) pressure drop, that scales with ![]() ${\rm \Delta} p \propto \rho Q_l^2$ (see Cleve et al. (Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021) for more details). Thus, the linear pressure drop dominates for high viscosities. The cross-over between a dominant viscous pressure drop and a dominant geometric pressure drop can clearly be seen in figure 6(b), where the solid black lines depict the minimum pressures required to produce stable bubbles. No such transition is visible for the long channel, where the pressure drop is always dominated by viscous effects, figure 6(d).

${\rm \Delta} p \propto \rho Q_l^2$ (see Cleve et al. (Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021) for more details). Thus, the linear pressure drop dominates for high viscosities. The cross-over between a dominant viscous pressure drop and a dominant geometric pressure drop can clearly be seen in figure 6(b), where the solid black lines depict the minimum pressures required to produce stable bubbles. No such transition is visible for the long channel, where the pressure drop is always dominated by viscous effects, figure 6(d).

4.5. Surfactants

The influence of the type of surfactant (see figure 7) is generally weaker than that of different gas and/or different glycerol concentrations. For the finer effect, the surfactants can be categorized in three groups (see summary in table 5). (i) When using mixtures of DSPC/DPPE-PEG5000, DOPC/DPPE-PEG5000, DMPC/DPPE-PEG5000 or Tween 80, (figure 7a–f) which all have a large molecular weight, no significant difference is observed with respect to pure water for the short channel. For the long channel, a slight shift of the bubble size is visible. (ii) For solutions with the low molecular weight surfactants DPPE-PEG5000, PEG40s and Zonyl FSO, (figure 7g–l) we observe a ![]() $\sim$20 % increase in bubble production rate. For the DPPE-PEG5000 and PEG40s solutions this also results in a slight decrease in bubble size. For the long channel, this shift is less pronounced. (iii) In the presence of Tween 20, SDS and Pluronic F68 (figure 7m–r) we observe a range of production rates for a given liquid flow rate instead of one single value. Furthermore, in this group, the bubble sizes (figure 7n,q) are strongly shifted with respect to the case of pure water. The division into three groups is an aid for reading the figure and displays similar general features. A very strict separation is, however, not possible. In particular, the different behaviour in two channels alone already highlights the complexity of the entire process.

$\sim$20 % increase in bubble production rate. For the DPPE-PEG5000 and PEG40s solutions this also results in a slight decrease in bubble size. For the long channel, this shift is less pronounced. (iii) In the presence of Tween 20, SDS and Pluronic F68 (figure 7m–r) we observe a range of production rates for a given liquid flow rate instead of one single value. Furthermore, in this group, the bubble sizes (figure 7n,q) are strongly shifted with respect to the case of pure water. The division into three groups is an aid for reading the figure and displays similar general features. A very strict separation is, however, not possible. In particular, the different behaviour in two channels alone already highlights the complexity of the entire process.

Figure 7. Experimental results for bubble production with different surfactant solutions in the short (a–c) and the long channel (d–f). All experiments have been conducted with N![]() $_2$ and either at

$_2$ and either at ![]() $60\,^{\circ }$C for phospholipids or

$60\,^{\circ }$C for phospholipids or ![]() $40\,^{\circ }$C for other surfactants. The surfactants presented in these panels are discussed as group (i) in the main text. Pure water is used as a reference.

$40\,^{\circ }$C for other surfactants. The surfactants presented in these panels are discussed as group (i) in the main text. Pure water is used as a reference.

Figure 7 The surfactants presented in these panels are discussed as group (ii) in the main text. Pure water is used as a reference.

Figure 7 The surfactants presented in these panels are discussed as group (iii) in the main text. Pure water is used as a reference.

Table 5. List of surfactants, their concentrations used in the experiments presented in figures 7 and 8 and surface tensions at room temperature obtained via a pendant-drop method.

![]() $^{\ast }$no visible difference for 10 and 20 mg ml

$^{\ast }$no visible difference for 10 and 20 mg ml![]() $^{-1}$, no visible difference for water instead of saline

$^{-1}$, no visible difference for water instead of saline

![]() $^{\ast \ast }$no visible difference for 0.5 % to 5 %

$^{\ast \ast }$no visible difference for 0.5 % to 5 %

The main purpose of surfactants is to increase the lifetime of a bubble by reducing the interfacial tension between the gas and the liquid phases in order to stabilize the bubble against dissolution. Surfactants are also necessary to stabilize bubbles during their formation, i.e. without surfactants all bubbles would coalesce in the microfluidic chip. We have measured the surface tension with a pendant-drop experiment at room temperature a few seconds after the creation of the pendant drop. These measurements were performed for water and for the non-phospholipid surfactants and these agree with values found in the literature (Basu Ray et al. Reference Basu Ray, Chakraborty, Ghosh and Moulik2007; Bąk & Podgórska Reference Bk and Podgórska2016). In general, one can further expect that the surface tension is up to a few Nm m![]() $^{-1}$ lower due to the increased temperature in the flow-focusing experiments with respect to the pendant-drop experiment (Phongikaroon et al. Reference Phongikaroon, Hoffmaster, Judd, Smith and Handler2005). We furthermore measured the surface tension of our DSPC/DPPE-PEG5000 solution at room temperature and a few seconds after drop formation and obtained approximately 53 mN m

$^{-1}$ lower due to the increased temperature in the flow-focusing experiments with respect to the pendant-drop experiment (Phongikaroon et al. Reference Phongikaroon, Hoffmaster, Judd, Smith and Handler2005). We furthermore measured the surface tension of our DSPC/DPPE-PEG5000 solution at room temperature and a few seconds after drop formation and obtained approximately 53 mN m![]() $^{-1}$. The temperature dependence of phospholipid solution on temperature is much higher (tens of mN m

$^{-1}$. The temperature dependence of phospholipid solution on temperature is much higher (tens of mN m![]() $^{-1}$) (Lee, Kim & Needham Reference Lee, Kim and Needham2001). On the other hand, it takes of the order of a minute to reach the final value. All in all, the value of 53 mN m

$^{-1}$) (Lee, Kim & Needham Reference Lee, Kim and Needham2001). On the other hand, it takes of the order of a minute to reach the final value. All in all, the value of 53 mN m![]() $^{-1}$ should be taken with extreme care. During the very short time of bubble creation the surfactants are still mainly dissolved in the bulk and have little surface active effects. (Some surfactants are certainly already present on the gas cusp, but the gas–liquid interface is considerably increasing during bubble pinch-off, which makes it likely that the surfactants are far from tightly packed during bubble pinch-off.) Bubble production frequencies are plotted as a function of the steady-state surface tension for a fixed liquid flow rate

$^{-1}$ should be taken with extreme care. During the very short time of bubble creation the surfactants are still mainly dissolved in the bulk and have little surface active effects. (Some surfactants are certainly already present on the gas cusp, but the gas–liquid interface is considerably increasing during bubble pinch-off, which makes it likely that the surfactants are far from tightly packed during bubble pinch-off.) Bubble production frequencies are plotted as a function of the steady-state surface tension for a fixed liquid flow rate ![]() $Q_l = 100\,\mathrm {\mu }$l min

$Q_l = 100\,\mathrm {\mu }$l min![]() $^{-1}$, see figure 8. It is interesting to note that, in general, the production rate decreases with increasing surface tension. As the values for DSPC follow the general trend, we have included it in the representation. Yet, we should once more recall the above discussed limits and uncertainties involved in obtaining this value.

$^{-1}$, see figure 8. It is interesting to note that, in general, the production rate decreases with increasing surface tension. As the values for DSPC follow the general trend, we have included it in the representation. Yet, we should once more recall the above discussed limits and uncertainties involved in obtaining this value.

Figure 8. Range of bubble production rates (represented by the vertical lines) found for ![]() $Q_l=100\,\mathrm {\mu }$l min

$Q_l=100\,\mathrm {\mu }$l min![]() $^{-1}$ in figure 7(a,g,m) as a function of the surface tension of the liquid and air interface, measured at room temperature in a pendant-drop experiment. The limits of these values due to different temperatures and time scales are discussed in the main text. The simulated data (see also figure 10b) will be discussed in § 5.3.

$^{-1}$ in figure 7(a,g,m) as a function of the surface tension of the liquid and air interface, measured at room temperature in a pendant-drop experiment. The limits of these values due to different temperatures and time scales are discussed in the main text. The simulated data (see also figure 10b) will be discussed in § 5.3.

5. Discussion

5.1. Preliminary consideration

Before discussing in detail the influence of the different parameters on the bubble production, we first need to include short considerations on the power law and expression for the production rate. Solving (1.1) and (1.2) for the production rate, one obtains

If the ![]() $a= 1/3$, then the influence of the gas flow rate on the production rate cancels out and

$a= 1/3$, then the influence of the gas flow rate on the production rate cancels out and ![]() $f_b\sim Q_l$.

$f_b\sim Q_l$.

For the experimentally obtained power law exponent, one should bear in mind that, first, the flow-rate ratio only varies by one order of magnitude within the stable operating range of the chip and, second, we deduce the gas flow rate from the bubble size and production rate. Furthermore, practical limitations (e.g. resolution, motion blur, uncertainties in the driving condition, etc.) do not allow for making a statistically relevant distinction between a ![]() $1/3$ or

$1/3$ or ![]() $2/5$ power law. However, let us consider the case of

$2/5$ power law. However, let us consider the case of ![]() $a\approx 0.38$ as was found in figure 2(c). On the one hand, this implies a weak dependence on the gas flow rate (

$a\approx 0.38$ as was found in figure 2(c). On the one hand, this implies a weak dependence on the gas flow rate (![]() $\,f_b \sim Q_g^{-0.14}$). On the other hand, the expected dependence on the liquid flow rate is a power function leading to a slightly convex curve (

$\,f_b \sim Q_g^{-0.14}$). On the other hand, the expected dependence on the liquid flow rate is a power function leading to a slightly convex curve (![]() $\,f_b\sim Q_l^{1.14}$). While obviously these models are simplified, they can partly explain that (i) the production rate as a function of the liquid flow rate is close linear or slightly convex, and that (ii) the dependence on the gas flow rate seems to be mostly negligible.

$\,f_b\sim Q_l^{1.14}$). While obviously these models are simplified, they can partly explain that (i) the production rate as a function of the liquid flow rate is close linear or slightly convex, and that (ii) the dependence on the gas flow rate seems to be mostly negligible.

5.2. Pressure drop due to channel geometry

As discussed in the introduction, the pressure gradient has been identified as an important ingredient for bubble pinch-off in many previous papers. Castro-Hernández et al. (Reference Castro-Hernández, van Hoeve, Lohse and Gordillo2011) base their model on the comparison between the viscous pressure loss in the gas and liquid. Rodríguez-Rodríguez et al. (Reference Rodríguez-Rodríguez, Sevilla, Martínez-Bazán and Gordillo2015) discuss the significance of the changing sign in pressure between bubble growth and detachment, Evangelio et al. (Reference Evangelio, Campo-Cortes and Gordillo2015) try to find an optimal description of the pressure gradient for each of their considered cases. From our previous paper (Cleve et al. Reference Cleve, Diddens, Segers, Lajoinie and Versluis2021), we know that the pressure variation in the inlet region scales as ![]() ${\rm \Delta} p \sim \rho _l Q_l^2 / S^2$, with

${\rm \Delta} p \sim \rho _l Q_l^2 / S^2$, with ![]() $S$ being the cross-sectional surface area, and the viscous pressure loss along the channel as

$S$ being the cross-sectional surface area, and the viscous pressure loss along the channel as ![]() ${\rm d} p/{{\rm d}\kern0.06em x} \sim \mu _l Q_l/S^2$ (see also more detailed explanation in the supplementary material). By plotting the bubble size and production rate as a function of

${\rm d} p/{{\rm d}\kern0.06em x} \sim \mu _l Q_l/S^2$ (see also more detailed explanation in the supplementary material). By plotting the bubble size and production rate as a function of ![]() $Q_l/S^2$ (instead the previously used

$Q_l/S^2$ (instead the previously used ![]() $Q_l$), we can obtain a perfect match between the data for the short and long channel from figure 2, see figure S3 in the supplementary material. This correction factor of

$Q_l$), we can obtain a perfect match between the data for the short and long channel from figure 2, see figure S3 in the supplementary material. This correction factor of ![]() $1/S^2$ thus points towards a dominance of the viscous pressure loss. However, having only data for two different channels does not allow for a decisive conclusion.

$1/S^2$ thus points towards a dominance of the viscous pressure loss. However, having only data for two different channels does not allow for a decisive conclusion.

5.3. Liquid and gas properties