No CrossRef data available.

Article contents

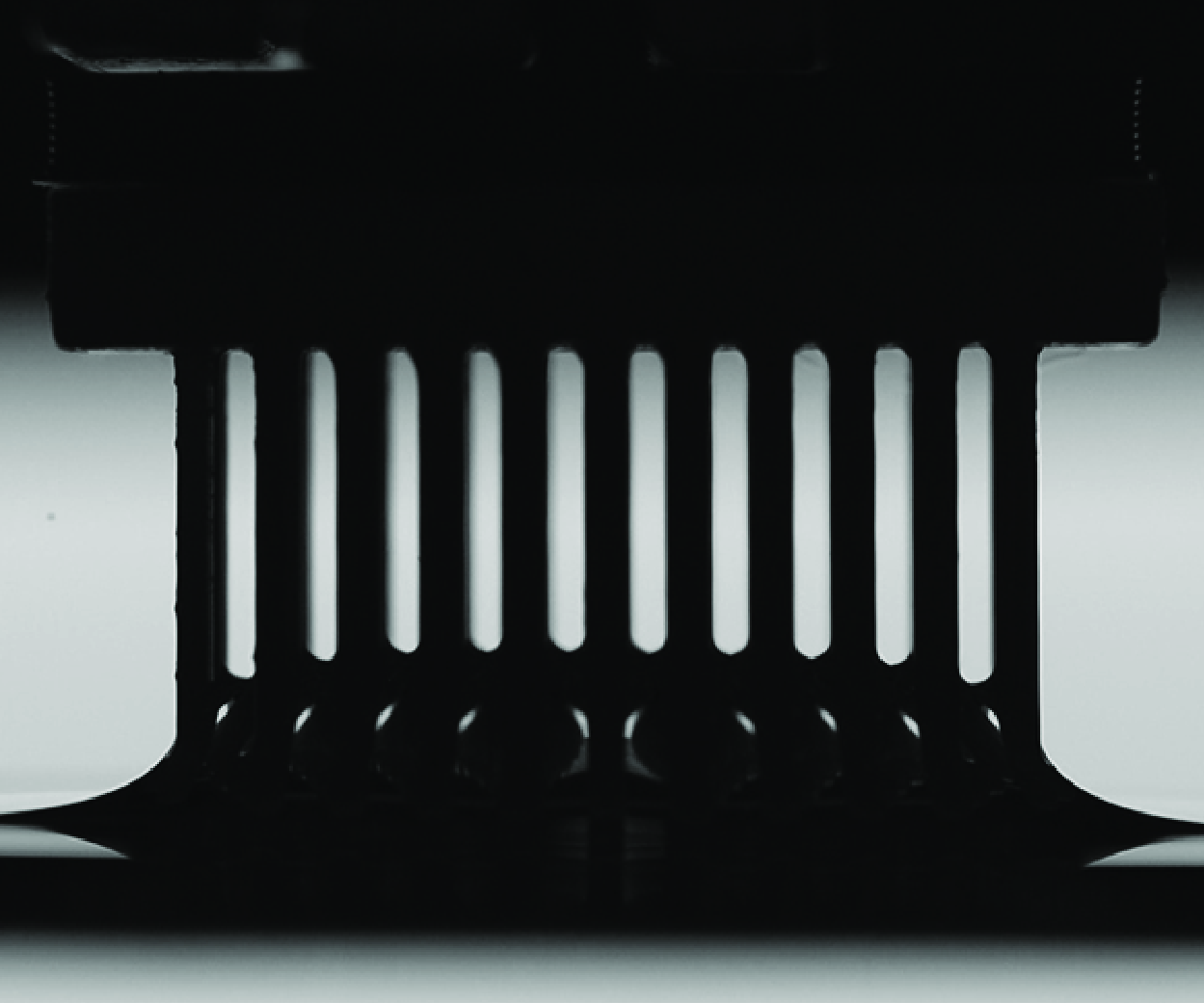

Optimal rigid brush for fluid capture

Published online by Cambridge University Press: 07 July 2025

Abstract

Assemblies of slender structures forming brushes are common in daily life from sweepers to pastry brushes and paintbrushes. These types of porous objects can easily trap liquid in their interstices when removed from a liquid bath. This property is exploited to transport liquids in many applications, ranging from painting, dip-coating and brush-coating to the capture of nectar by bees, bats and honeyeaters. Rationalising the viscous entrainment flow beyond simple scaling laws is complex due to the multiscale structure and the multidirectional flow. Here, we provide an analytical model, together with precision experiments with ideal rigid brushes, to fully characterise the flow through this anisotropic porous medium as it is withdrawn from a liquid bath. We show that the amount of liquid entrained by a brush varies non-monotonically during the withdrawal at low speed, is highly sensitive to the different parameters at play and is very well described by the model without any fitting parameter. Finally, an optimal brush geometry maximising the amount of liquid captured at a given retraction speed is derived from the model and experimentally validated. These optimal designs open routes towards efficient liquid-manipulating devices.

JFM classification

Information

- Type

- JFM Papers

- Information

- Copyright

- © The Author(s), 2025. Published by Cambridge University Press