1. Introduction

A protective and functional surface coating can be created by lubricating a textured surface with an appropriate liquid. The drag-reducing properties of these liquid-infused surfaces (LISs) have been explored recently both numerically (Fu et al. Reference Fu, Arenas, Leonardi and Hultmark2017; Cartagena et al. Reference Cartagena, Arenas, Bernardini and Leonardi2018; Arenas et al. Reference Arenas, García, Fu, Orlandi, Hultmark and Leonardi2019) and experimentally (Van Buren & Smits Reference Van Buren and Smits2017; Fu et al. Reference Fu, Chen, Arnold and Hultmark2019). The LISs can also prevent fouling (Epstein et al. Reference Epstein, Wong, Belisle, Boggs and Aizenberg2012), corrosion (Wang, Lu & Zhang Reference Wang, Lu and Zhang2015) and ice formation (Kim et al. Reference Kim, Wong, Alvarenga, Kreder, Adorno-Martinez and Aizenberg2012).

The drag-reducing capabilities of LISs for liquid flows is often compared to those of superhydrophobic surfaces (SHSs), where air is used as the infused medium. The low viscosity of air is beneficial for drag reduction, but the use of SHSs in turbulent applications is restricted by mass diffusion (Ling et al. Reference Ling, Katz, Fu and Hultmark2017) and instability of the gas pockets (Seo, García-Mayoral & Mani Reference Seo, García-Mayoral and Mani2018). For LISs, the mass diffusion is negligible if the liquids are immiscible, and LISs are not susceptible to failure due to hydrostatic pressure (Wong et al. Reference Wong, Kang, Tang, Smythe, Hatton, Grinthal and Aizenberg2011). However, also for LISs, the stability of the interface depends on the texture's geometry, the surface tension between the two liquids and the contact angle at the liquid–liquid–solid interface. In particular, these surfaces may experience shear-driven drainage of the infused liquid, but this can be mitigated, for example with chemical patterning (Wexler, Jacobi & Stone Reference Wexler, Jacobi and Stone2015; Fu et al. Reference Fu, Chen, Arnold and Hultmark2019).

In this paper, we show that capillary motion of the liquid–liquid interface may drastically lower the drag-reducing performance of LISs. In the present study, the surface texture is fixed to longitudinal (streamwise-aligned) grooves. We use direct numerical simulations of a LIS in a liquid turbulent channel flow for frictional Reynolds numbers around ![]() ${Re}_\tau \approx 180$. The employed volume-of-fluid (VOF) framework allows for large interface deformations (low surface tension) and moving contact lines. When the liquid–liquid surface tension is small and/or grooves are wide, we find travelling-wave perturbations on the interface with amplitudes larger than the viscous sublayer of the turbulent flow (

${Re}_\tau \approx 180$. The employed volume-of-fluid (VOF) framework allows for large interface deformations (low surface tension) and moving contact lines. When the liquid–liquid surface tension is small and/or grooves are wide, we find travelling-wave perturbations on the interface with amplitudes larger than the viscous sublayer of the turbulent flow (![]() $a^+\approx 5\text {--}8$). These capillary waves induce a roughness effect and increase friction drag.

$a^+\approx 5\text {--}8$). These capillary waves induce a roughness effect and increase friction drag.

The detrimental capillary waves develop for viscosity and density ratios of one, which excludes interface instability mechanisms driven by density and viscosity stratification (Boomkamp & Miesen Reference Boomkamp and Miesen1996). Instead, we find that the linear instability can be described by the theory developed by Miles (Reference Miles1957) in the context of two-dimensional gravity waves. This inviscid instability is due to an energy transfer from the external flow to the waves that makes them grow in time at an exponential rate. The energy transfer can occur if (i) there is a negative curvature of the mean velocity profile where it equals the phase speed of a wave, i.e. at the critical layer, and (ii) the critical layer is not too far away from the surface, so that velocity fluctuations due to the wave (dispersive stresses) are non-zero.

The existence of energy transfer is not sufficient for failure of LISs, however. The interface fluctuations also need to grow sufficiently fast to reach large amplitudes that induce roughness effects. Figure 1(a), which summarises our main contribution, shows three domains, namely rough, smooth and transitional (grey), in a plane spanned by a groove width (![]() $w^+$) and a Weber number (

$w^+$) and a Weber number (![]() ${We}^+$), both normalised with the viscous length scale. This design map is obtained from the critical-layer theory and provides a means to design LISs that can be predicted to achieve a balance between performance (large

${We}^+$), both normalised with the viscous length scale. This design map is obtained from the critical-layer theory and provides a means to design LISs that can be predicted to achieve a balance between performance (large ![]() $w^+$) and stability (smooth domain).

$w^+$) and stability (smooth domain).

Figure 1. (![]() $a$) Design map for LIS, spanned by

$a$) Design map for LIS, spanned by ![]() ${We}^+$ and

${We}^+$ and ![]() $w^+$. Smooth and rough regions are separated using (3.12), (3.14) and (3.15). Values from simulations with

$w^+$. Smooth and rough regions are separated using (3.12), (3.14) and (3.15). Values from simulations with ![]() $w^{+0}=18$ are included, with symbols referring to

$w^{+0}=18$ are included, with symbols referring to ![]() $\mu _i/\mu _\infty = 1$ (

$\mu _i/\mu _\infty = 1$ (![]() ${\bigcirc}$),

${\bigcirc}$), ![]() $\mu _i/\mu _\infty = 0.5$ (

$\mu _i/\mu _\infty = 0.5$ (![]() $\square$) and

$\square$) and ![]() $\mu _i/\mu _\infty = 2$ (

$\mu _i/\mu _\infty = 2$ (![]() $\lozenge$) and colours to

$\lozenge$) and colours to ![]() ${We} = 50$ (green),

${We} = 50$ (green), ![]() ${We} = 100$ (blue),

${We} = 100$ (blue), ![]() ${We} = 150$ (red),

${We} = 150$ (red), ![]() ${We} = 200$ (yellow) and

${We} = 200$ (yellow) and ![]() ${We} = 400$ (turquoise). Also shown are values with wider grooves,

${We} = 400$ (turquoise). Also shown are values with wider grooves, ![]() $w^{+0} = 36$, with

$w^{+0} = 36$, with ![]() ${We} = 25$ (purple circle),

${We} = 25$ (purple circle), ![]() ${We} = 50$ (green circle) and

${We} = 50$ (green circle) and ![]() ${We} = 100$ (blue circle). The asymptotic relations (3.16) and (3.17) are shown with dashed line and dashed-dotted line, respectively. Sketches of (

${We} = 100$ (blue circle). The asymptotic relations (3.16) and (3.17) are shown with dashed line and dashed-dotted line, respectively. Sketches of (![]() $b$) the channel configuration and (

$b$) the channel configuration and (![]() $c$) a wave on a groove. The infused liquid is shown in green and the solids in grey.

$c$) a wave on a groove. The infused liquid is shown in green and the solids in grey.

2. Numerical methods and configuration

We consider a fully developed turbulent open channel flow. The flow domain, shown schematically in figure 1(b), has the size ![]() $(L_x, L_y, L_z) = (6.4h, h + k, 3.2h)$, where

$(L_x, L_y, L_z) = (6.4h, h + k, 3.2h)$, where ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ correspond to the streamwise, wall-normal and spanwise directions, respectively, and

$z$ correspond to the streamwise, wall-normal and spanwise directions, respectively, and ![]() $h$ is the half-channel height. At the top boundary we impose a free-slip (symmetry) boundary condition (BC). Periodic boundary conditions are imposed in the streamwise and spanwise directions. The streamwise-aligned grooves at the bottom wall have a height

$h$ is the half-channel height. At the top boundary we impose a free-slip (symmetry) boundary condition (BC). Periodic boundary conditions are imposed in the streamwise and spanwise directions. The streamwise-aligned grooves at the bottom wall have a height ![]() $k$, a width

$k$, a width ![]() $w$ and square cross-section,

$w$ and square cross-section, ![]() $k = w$. The fluid–solid ratio is set to

$k = w$. The fluid–solid ratio is set to ![]() $0.5$. The infused and external fluids have the same density

$0.5$. The infused and external fluids have the same density ![]() $\rho _i=\rho _\infty =\rho$, but different viscosities (

$\rho _i=\rho _\infty =\rho$, but different viscosities (![]() $\mu _i$ and

$\mu _i$ and ![]() $\mu _\infty$). We have used grooves of width

$\mu _\infty$). We have used grooves of width ![]() $w^{+0} = 18$. Throughout this paper,

$w^{+0} = 18$. Throughout this paper, ![]() $+0$ refers to normalisation using the friction velocity of a regular smooth wall (nominal wall units). A single superscript

$+0$ refers to normalisation using the friction velocity of a regular smooth wall (nominal wall units). A single superscript ![]() $+$ refers to normalisation using the friction velocity of each individual case. The corresponding viscous length scale is

$+$ refers to normalisation using the friction velocity of each individual case. The corresponding viscous length scale is ![]() $\delta _\nu = \mu _\infty /(\rho u_\tau )$, where

$\delta _\nu = \mu _\infty /(\rho u_\tau )$, where ![]() $u_\tau$ is the friction velocity.

$u_\tau$ is the friction velocity.

We impose a constant mass flow rate through a uniform pressure gradient over ![]() $0 < y < h$, where

$0 < y < h$, where ![]() $y = 0$ corresponds to the crest of the texture so that

$y = 0$ corresponds to the crest of the texture so that ![]() ${Re}_b = \rho h U_b/\mu _\infty =2820$, giving

${Re}_b = \rho h U_b/\mu _\infty =2820$, giving ![]() ${Re}_\tau =\rho h u_\tau /\mu _\infty \approx 180$ (with the pressure gradient implemented as a volume force). Here,

${Re}_\tau =\rho h u_\tau /\mu _\infty \approx 180$ (with the pressure gradient implemented as a volume force). Here, ![]() ${Re}_b$ and

${Re}_b$ and ![]() ${Re}_\tau$ are Reynolds numbers based on bulk velocity

${Re}_\tau$ are Reynolds numbers based on bulk velocity ![]() $U_b$ and friction velocity

$U_b$ and friction velocity ![]() $u_\tau$, respectively.

$u_\tau$, respectively.

Our simulations allow for a moving liquid–liquid–solid contact line with a dynamic contact angle different from the static value, which is ![]() $\theta = 45^{\circ }$ with respect to the infused liquid. Our method also allows for interface deformation, which is typically quantified by the Weber number, defined as

$\theta = 45^{\circ }$ with respect to the infused liquid. Our method also allows for interface deformation, which is typically quantified by the Weber number, defined as ![]() ${We} = \rho U_{b}^2 h/\gamma$, where

${We} = \rho U_{b}^2 h/\gamma$, where ![]() $\gamma$ is the surface tension. We have simulated LISs for

$\gamma$ is the surface tension. We have simulated LISs for ![]() ${We} = 100$,

${We} = 100$, ![]() $150$ and

$150$ and ![]() $200$ and viscosity ratios

$200$ and viscosity ratios ![]() $\mu _i/\mu _\infty = 0.5$,

$\mu _i/\mu _\infty = 0.5$, ![]() $1$ and

$1$ and ![]() $2$. The Weber number in wall units is

$2$. The Weber number in wall units is ![]() ${We}^+ = \rho u_\tau ^2\delta _\nu /\gamma = \mu _\infty u_\tau /\gamma$. It can be noted that the Weber number based on the friction velocity and the width of the grooves is

${We}^+ = \rho u_\tau ^2\delta _\nu /\gamma = \mu _\infty u_\tau /\gamma$. It can be noted that the Weber number based on the friction velocity and the width of the grooves is ![]() ${We}^+ w^+$.

${We}^+ w^+$.

The numerical configuration described above corresponds to an infused liquid consisting of some alkane (with dynamic viscosities similar to that of water (Van Buren & Smits Reference Van Buren and Smits2017)), a water channel with ![]() $h = 0.5\ \textrm {cm}$ and

$h = 0.5\ \textrm {cm}$ and ![]() $U_{b} = 1\ \textrm {m}\ \textrm {s}^{-1}$. This results in

$U_{b} = 1\ \textrm {m}\ \textrm {s}^{-1}$. This results in ![]() ${Re}_b= 5000$, which is close to the value in our simulations. A typical surface tension

${Re}_b= 5000$, which is close to the value in our simulations. A typical surface tension ![]() $\gamma = 50$ mN m

$\gamma = 50$ mN m![]() $^{-1}$ then results in

$^{-1}$ then results in ![]() ${We} = 100$.

${We} = 100$.

The code used for the simulations is based on the PArallel, Robust, Interface Simulator (PARIS), which employs a VOF method for the multiphase description (Aniszewski et al. Reference Aniszewski2021; Arrufat et al. Reference Arrufat, Crialesi-Esposito, Fuster, Ling, Malan, Pal, Scardovelli, Tryggvason and Zaleski2021). The cited papers also include additional test cases and validations. Height functions are used for curvature calculation for the surface tension. The interface is advected in the manner suggested by Weymouth & Yue (Reference Weymouth and Yue2010) at each substep. This advection scheme conserves the volume of both liquids to a high accuracy. At solid surfaces, a contact angle is imposed by using the height functions and a dynamic contact angle model for VOF based on hydrodynamic theory (Legendre & Maglio Reference Legendre and Maglio2015). Details are given in § S1 of the supplementary material, available at https://doi.org/10.1017/jfm.2021.241. Finally, the grid size is ![]() $(N_x, N_y, N_z) = (256, 640, 1024)$, with constant grid spacing in each direction. The flow was converged after

$(N_x, N_y, N_z) = (256, 640, 1024)$, with constant grid spacing in each direction. The flow was converged after ![]() $600 h/U_b$, and statistics were collected over a time of

$600 h/U_b$, and statistics were collected over a time of ![]() $500 h/U_b$.

$500 h/U_b$.

3. Results

3.1. Dependence of drag on Weber number

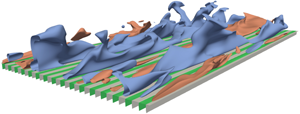

Figure 2(a) shows an instantaneous snapshot of the liquid–liquid interface, viewed from the top, for ![]() ${We} = 100$ and

${We} = 100$ and ![]() $\mu _i = \mu _\infty$. There are oscillations on the interface, due to the finite surface tension, but they remain small. The deformation of the interface increases with

$\mu _i = \mu _\infty$. There are oscillations on the interface, due to the finite surface tension, but they remain small. The deformation of the interface increases with ![]() ${We}$, however. For

${We}$, however. For ![]() ${We} = 200$, significantly larger waves develop on the interface, as shown in figure 2(b).

${We} = 200$, significantly larger waves develop on the interface, as shown in figure 2(b).

Figure 2. Top view of interfaces (green) and surface (grey) at one instant for ![]() $\mu _i/\mu _\infty = 1$ and (

$\mu _i/\mu _\infty = 1$ and (![]() $a$)

$a$) ![]() ${We} = 100$ and (

${We} = 100$ and (![]() $b$)

$b$) ![]() ${We} = 200$. The flow is from left to right. The complete domain is shown.

${We} = 200$. The flow is from left to right. The complete domain is shown.

The consequences of the waves on the overlying flow can be quantified by the drag reduction

\begin{equation} {DR} = \frac{c_f^0 - c_f}{c_f^0}, \end{equation}

\begin{equation} {DR} = \frac{c_f^0 - c_f}{c_f^0}, \end{equation}

where ![]() $c_f = 2\tau _w/(\rho U_b^2)$ is the friction coefficient and

$c_f = 2\tau _w/(\rho U_b^2)$ is the friction coefficient and ![]() $\tau _w$ is the total stress at the crest plane of the surface (computed from the pressure gradient). Here,

$\tau _w$ is the total stress at the crest plane of the surface (computed from the pressure gradient). Here, ![]() $c_f^0$ is the coefficient of a regular smooth wall at

$c_f^0$ is the coefficient of a regular smooth wall at ![]() $y=0$. For

$y=0$. For ![]() ${We}=100$ and

${We}=100$ and ![]() ${We}=200$, we obtained

${We}=200$, we obtained ![]() ${DR}=0.09$ and

${DR}=0.09$ and ![]() ${DR}=-0.04$, respectively. In other words, the capillary waves observed at

${DR}=-0.04$, respectively. In other words, the capillary waves observed at ![]() ${We} = 200$ increase frictional drag compared to a smooth and homogeneous surface and have therefore induced failure of the LIS.

${We} = 200$ increase frictional drag compared to a smooth and homogeneous surface and have therefore induced failure of the LIS.

Figure 3(a) shows ![]() ${DR}$ for

${DR}$ for ![]() ${We}=\{100,150,200\}$ and viscosity ratios

${We}=\{100,150,200\}$ and viscosity ratios ![]() $\mu _i/\mu _\infty = \{0.5,1, 2\}$ as a function of the apparent slip length,

$\mu _i/\mu _\infty = \{0.5,1, 2\}$ as a function of the apparent slip length, ![]() $b^{+0}$. The slip length

$b^{+0}$. The slip length ![]() $b$ is the distance at which the mean velocity would be zero if linearly extrapolated at the crests of the surface. It is largely unaffected by changes in

$b$ is the distance at which the mean velocity would be zero if linearly extrapolated at the crests of the surface. It is largely unaffected by changes in ![]() ${We}$, but it increases with decreasing viscosity ratio. In fact, the slip lengths extracted from our numerical simulations with

${We}$, but it increases with decreasing viscosity ratio. In fact, the slip lengths extracted from our numerical simulations with ![]() $w^+ \approx 18$ are well approximated by the slip lengths obtained by solving the Stokes equations for a periodic array of grooves exposed to unit shear (Schönecker, Baier & Hardt Reference Schönecker, Baier and Hardt2014) (black line in figure 3b). A similar agreement was observed for smaller grooves (

$w^+ \approx 18$ are well approximated by the slip lengths obtained by solving the Stokes equations for a periodic array of grooves exposed to unit shear (Schönecker, Baier & Hardt Reference Schönecker, Baier and Hardt2014) (black line in figure 3b). A similar agreement was observed for smaller grooves (![]() $w^+ \approx 9$) in turbulent flows by Fu et al. (Reference Fu, Arenas, Leonardi and Hultmark2017) and Arenas et al. (Reference Arenas, García, Fu, Orlandi, Hultmark and Leonardi2019).

$w^+ \approx 9$) in turbulent flows by Fu et al. (Reference Fu, Arenas, Leonardi and Hultmark2017) and Arenas et al. (Reference Arenas, García, Fu, Orlandi, Hultmark and Leonardi2019).

Figure 3. Drag reduction as a function of (![]() $a$) the slip length and (

$a$) the slip length and (![]() $b$) the slip length normalised by the pitch as a function of viscosity ratio. Symbols and colours are the same as in figure 1(a). In panel (

$b$) the slip length normalised by the pitch as a function of viscosity ratio. Symbols and colours are the same as in figure 1(a). In panel (![]() $b$), the points for different

$b$), the points for different ![]() ${We}$ are almost on top of each other. Analytical relations are shown by black solid lines: (

${We}$ are almost on top of each other. Analytical relations are shown by black solid lines: (![]() $a$) Rastegari & Akhavan (Reference Rastegari and Akhavan2015) and (

$a$) Rastegari & Akhavan (Reference Rastegari and Akhavan2015) and (![]() $b$) Schönecker et al. (Reference Schönecker, Baier and Hardt2014).

$b$) Schönecker et al. (Reference Schönecker, Baier and Hardt2014).

When the interface is perfectly flat (![]() ${We}=0$), the drag reduction can be related to slip length as

${We}=0$), the drag reduction can be related to slip length as

where ![]() $U_b^{+0}$ is the bulk velocity in nominal wall units. This relation – shown in figure 3(a) (black line) – can be obtained by neglecting changes in the Reynolds shear stress above a smooth wall (Rastegari & Akhavan Reference Rastegari and Akhavan2015). We observe from figure 3(a) that, for

$U_b^{+0}$ is the bulk velocity in nominal wall units. This relation – shown in figure 3(a) (black line) – can be obtained by neglecting changes in the Reynolds shear stress above a smooth wall (Rastegari & Akhavan Reference Rastegari and Akhavan2015). We observe from figure 3(a) that, for ![]() ${We} = 100$ (blue) and

${We} = 100$ (blue) and ![]() ${We} = 150$ (red), there is a drag reduction (

${We} = 150$ (red), there is a drag reduction (![]() ${DR}>0$) for all three viscosity ratios. Moreover, the deviations from (3.2) are small, confirming that the drag reduction mechanism is indeed slippage. These small deviations are due to change of Reynolds shear stress. In contrast, the deviations from (3.2) are significant for

${DR}>0$) for all three viscosity ratios. Moreover, the deviations from (3.2) are small, confirming that the drag reduction mechanism is indeed slippage. These small deviations are due to change of Reynolds shear stress. In contrast, the deviations from (3.2) are significant for ![]() ${We} = 200$ (yellow), where we observe a drag increase (

${We} = 200$ (yellow), where we observe a drag increase (![]() ${DR} < 0$) for

${DR} < 0$) for ![]() $\mu _i/\mu _\infty = 1$ and

$\mu _i/\mu _\infty = 1$ and ![]() $2$ and a

$2$ and a ![]() ${DR}$ close to zero for

${DR}$ close to zero for ![]() $\mu _i/\mu _\infty = 0.5$. The corresponding mean velocity and velocity fluctuations reflect the increase in drag, and these are described in § S2 of the supplementary material.

$\mu _i/\mu _\infty = 0.5$. The corresponding mean velocity and velocity fluctuations reflect the increase in drag, and these are described in § S2 of the supplementary material.

The waves formed on the interface at ![]() ${We} = 200$ are sufficiently large to cause roughness effects. Interface height profiles at different times are shown in figure 4(b), together with amplitudes of a wave in its initial stage (figure 4c, yellow). The wave amplitude is defined as the height of the local maximum of the wave. Wave amplitudes of

${We} = 200$ are sufficiently large to cause roughness effects. Interface height profiles at different times are shown in figure 4(b), together with amplitudes of a wave in its initial stage (figure 4c, yellow). The wave amplitude is defined as the height of the local maximum of the wave. Wave amplitudes of ![]() $a^+ > 5$ are observed and these extend outside the viscous sublayer, indicating that the surface is transitionally rough. The amplitude grows initially at an exponential rate, before it levels off. In contrast, interface fluctuations for

$a^+ > 5$ are observed and these extend outside the viscous sublayer, indicating that the surface is transitionally rough. The amplitude grows initially at an exponential rate, before it levels off. In contrast, interface fluctuations for ![]() ${We}=100$ have small amplitudes (

${We}=100$ have small amplitudes (![]() $a^+<1$) (figure 4a) and show a significantly smaller growth rate (figure 4c, blue). The exponential growth rate (figure 4c, dashed) is an indication of a linear instability. In the next section, we provide evidence of a critical-layer instability (Miles Reference Miles1957), where energy is transferred to the wave perturbation from the turbulent flow.

$a^+<1$) (figure 4a) and show a significantly smaller growth rate (figure 4c, blue). The exponential growth rate (figure 4c, dashed) is an indication of a linear instability. In the next section, we provide evidence of a critical-layer instability (Miles Reference Miles1957), where energy is transferred to the wave perturbation from the turbulent flow.

Figure 4. Instantaneous interface heights in the centreline of a groove for ![]() $\mu _i/\mu _\infty = 1$: (

$\mu _i/\mu _\infty = 1$: (![]() $a$)

$a$) ![]() ${We} = 100$ for

${We} = 100$ for ![]() $3 \le x \le 6$ and (

$3 \le x \le 6$ and (![]() $b$)

$b$) ![]() ${We} = 200$ for

${We} = 200$ for ![]() $1 \le x \le 4$. The five profiles are separated by

$1 \le x \le 4$. The five profiles are separated by ![]() $\Delta t = 0.2 h/U_b$. Note the difference in vertical scale. In (

$\Delta t = 0.2 h/U_b$. Note the difference in vertical scale. In (![]() $c$), the wave amplitude developing at

$c$), the wave amplitude developing at ![]() $x/h = 4.5$ in (

$x/h = 4.5$ in (![]() $a$) and at

$a$) and at ![]() $x/h = 3.5$ in (

$x/h = 3.5$ in (![]() $b$) are shown. The phase speeds in (

$b$) are shown. The phase speeds in (![]() $a$,

$a$,![]() $b$) can be estimated as

$b$) can be estimated as ![]() $c^+ \approx 14$ and

$c^+ \approx 14$ and ![]() $c^+ \approx 10$, respectively.

$c^+ \approx 10$, respectively.

3.2. Conditions for phase speed and growth rate of capillary waves

We assume a small perturbation on the liquid–liquid interface of the form

where ![]() $z = 0$ is located in the centre of the groove. As illustrated in figure 1(c),

$z = 0$ is located in the centre of the groove. As illustrated in figure 1(c), ![]() $\eta$ is the height of the interface,

$\eta$ is the height of the interface, ![]() $A$ is the initial wave amplitude,

$A$ is the initial wave amplitude, ![]() $c$ is a complex wave speed and

$c$ is a complex wave speed and ![]() $t$ is time. Moreover,

$t$ is time. Moreover, ![]() $k_x = 2{\rm \pi} /\lambda _x$ and

$k_x = 2{\rm \pi} /\lambda _x$ and ![]() $k_z = 2{\rm \pi} /\lambda _z$ are streamwise and spanwise wavenumbers, respectively. The spanwise wavelength can have a maximum value of

$k_z = 2{\rm \pi} /\lambda _z$ are streamwise and spanwise wavenumbers, respectively. The spanwise wavelength can have a maximum value of ![]() $\lambda _z = 2w$, due to the finite width of the grooves. This value can be seen to dominate in the snapshots of figure 2, as most waves only have one crest or one trough in the spanwise direction. We also observe from figure 2 that streamwise wavelengths are generally similar to, or larger than,

$\lambda _z = 2w$, due to the finite width of the grooves. This value can be seen to dominate in the snapshots of figure 2, as most waves only have one crest or one trough in the spanwise direction. We also observe from figure 2 that streamwise wavelengths are generally similar to, or larger than, ![]() $\lambda _z$. This three-dimensionality implies that both spanwise and streamwise curvatures contribute to the capillary pressure of a wave,

$\lambda _z$. This three-dimensionality implies that both spanwise and streamwise curvatures contribute to the capillary pressure of a wave,

Here, ![]() $k = \sqrt {k_x^2 + k_z^2}$ and

$k = \sqrt {k_x^2 + k_z^2}$ and ![]() $p_0^+$ (

$p_0^+$ (![]() $p_0^-$) is the pressure above (below) the interface.

$p_0^-$) is the pressure above (below) the interface.

Next, we consider a wall-normal velocity disturbance ![]() $v(x,y,z,t)$ on the turbulent mean flow

$v(x,y,z,t)$ on the turbulent mean flow ![]() $U(y)$ with the same waveform as

$U(y)$ with the same waveform as ![]() $\eta$. If we neglect viscous and nonlinear effects, the amplitude

$\eta$. If we neglect viscous and nonlinear effects, the amplitude ![]() $\hat v(y)$ is governed by the Rayleigh equation (§ S3 A of the supplementary material)

$\hat v(y)$ is governed by the Rayleigh equation (§ S3 A of the supplementary material)

where ![]() $^\prime$ denotes a derivative with respect to

$^\prime$ denotes a derivative with respect to ![]() $y$. The velocity perturbation must vanish at infinity and satisfy the kinematic condition at the interface,

$y$. The velocity perturbation must vanish at infinity and satisfy the kinematic condition at the interface, ![]() $v/(U-c) = \textrm {i}k_x\eta$. The equation for the pressure amplitude,

$v/(U-c) = \textrm {i}k_x\eta$. The equation for the pressure amplitude, ![]() $\hat {p}(y)$, corresponding to (3.5) is

$\hat {p}(y)$, corresponding to (3.5) is

Our aim is to find an approximate solution to (3.4)–(3.6) in order to determine the phase speed ![]() $\mathrm {Re}(c)$ (real part) and growth rate

$\mathrm {Re}(c)$ (real part) and growth rate ![]() $\mathrm {Im}(k_xc)$ (imaginary part) of the interface perturbation (3.3).

$\mathrm {Im}(k_xc)$ (imaginary part) of the interface perturbation (3.3).

Miles (Reference Miles1957) formulated a similar set of equations for describing wind-induced water waves, where gravity – instead of capillarity – balances fluid pressure. He suggested the following approximate solution for ![]() $v$:

$v$:

This expression, which satisfies the boundary conditions at ![]() $y\rightarrow \infty$, implies that

$y\rightarrow \infty$, implies that ![]() $1/k$ is the relevant length scale over which

$1/k$ is the relevant length scale over which ![]() $v$ decreases. The assumption of exponential decay can also be used in the grooves:

$v$ decreases. The assumption of exponential decay can also be used in the grooves:

Here, we have assumed that the grooves are sufficiently deep such that the velocity perturbation is nearly zero at the bottom of the groove. With a depth ![]() $w$,

$w$, ![]() $kw > k_zw \ge (2{\rm \pi} /(2w)) w = {\rm \pi}$, and, since

$kw > k_zw \ge (2{\rm \pi} /(2w)) w = {\rm \pi}$, and, since ![]() $\textrm {e}^{-{\rm \pi} } \ll 1$, the assumption is valid for our configuration. We have also neglected

$\textrm {e}^{-{\rm \pi} } \ll 1$, the assumption is valid for our configuration. We have also neglected ![]() $U$ and its derivative inside the groove. Inserting (3.8) into (3.6) results in the following expression for the pressure immediately below the interface (

$U$ and its derivative inside the groove. Inserting (3.8) into (3.6) results in the following expression for the pressure immediately below the interface (![]() $y\rightarrow 0^-$):

$y\rightarrow 0^-$):

Similarly, by inserting (3.7) into (3.6) the pressure just above the interface is

where ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$ are real constants and

$\beta$ are real constants and ![]() $U_1$ is an arbitrary reference velocity. It is shown in § S3 C of the supplementary material that the parameter

$U_1$ is an arbitrary reference velocity. It is shown in § S3 C of the supplementary material that the parameter ![]() $\alpha$ can be decomposed into two parts,

$\alpha$ can be decomposed into two parts, ![]() $\alpha = \alpha _1 + \alpha _2$, where

$\alpha = \alpha _1 + \alpha _2$, where ![]() $\alpha _1$ corresponds to (3.9) and

$\alpha _1$ corresponds to (3.9) and ![]() $\alpha _2$ incorporates the remaining contributions from the slip velocity and the shear. Using this decomposition and inserting (3.9) and (3.10) into (3.4), we obtain (see § S3 D of the supplementary material)

$\alpha _2$ incorporates the remaining contributions from the slip velocity and the shear. Using this decomposition and inserting (3.9) and (3.10) into (3.4), we obtain (see § S3 D of the supplementary material)

Here ![]() $c_w = \sqrt {\gamma k^3/(2\rho k_x^2)}$ is the free phase speed, i.e. the speed of a capillary wave without forcing from the overlying flow.

$c_w = \sqrt {\gamma k^3/(2\rho k_x^2)}$ is the free phase speed, i.e. the speed of a capillary wave without forcing from the overlying flow.

The free phase speed is shown in figure 5(a) (in nominal wall units) as a function of ![]() $\lambda _x/w$ for

$\lambda _x/w$ for ![]() ${We}=\{100,150,200\}$. We note that two-dimensional capillary waves (

${We}=\{100,150,200\}$. We note that two-dimensional capillary waves (![]() $k_z = 0$) have a phase speed that monotonically decreases with

$k_z = 0$) have a phase speed that monotonically decreases with ![]() $\lambda _x$. However, for LISs, there is a minimum phase speed due to the finite spanwise wavelength. This minimum is approximately (for the analytical expression, see § S3 D of the supplementary material)

$\lambda _x$. However, for LISs, there is a minimum phase speed due to the finite spanwise wavelength. This minimum is approximately (for the analytical expression, see § S3 D of the supplementary material)

For ![]() ${We} = 200$ (and

${We} = 200$ (and ![]() $\mu _i/\mu _\infty = 1$),

$\mu _i/\mu _\infty = 1$), ![]() $c_{w, min}^+ = 7.0$, which is slightly lower than the phase speed of the wave shown in figure 4(b). One may use

$c_{w, min}^+ = 7.0$, which is slightly lower than the phase speed of the wave shown in figure 4(b). One may use ![]() $c^+_{w,min}$ as a lower bound of the actual phase speed of capillary waves on LISs.

$c^+_{w,min}$ as a lower bound of the actual phase speed of capillary waves on LISs.

Figure 5. (![]() $a$) The free phase speed

$a$) The free phase speed ![]() $c^{+0}_w$ for

$c^{+0}_w$ for ![]() ${We} = \{100, 150, 200\}$ when

${We} = \{100, 150, 200\}$ when ![]() $k_z = {\rm \pi}/w$ (i.e.

$k_z = {\rm \pi}/w$ (i.e. ![]() $\lambda _z/w = 2$). For

$\lambda _z/w = 2$). For ![]() ${We} = 200$, the phase speed of a two-dimensional wave (

${We} = 200$, the phase speed of a two-dimensional wave (![]() $k_z = 0$) is also shown. (

$k_z = 0$) is also shown. (![]() $b$) The growth rate coefficient

$b$) The growth rate coefficient ![]() $\beta$ versus

$\beta$ versus ![]() $ky_c$, showing a fast decrease in

$ky_c$, showing a fast decrease in ![]() $\beta$ for

$\beta$ for ![]() $ky_c \gtrsim 1$.

$ky_c \gtrsim 1$.

We now turn our attention to the imaginary part of (3.11) to approximate the growth rate of the instability. As shown by Miles (Reference Miles1957) – and repeated in § S3 E of the supplementary material – one may integrate the Rayleigh equation and evaluate the pressure equation (3.6) at the interface to find

where the subscript ![]() $c$ denotes values at the position of the critical layer

$c$ denotes values at the position of the critical layer ![]() $y_c$. In order for an infinitesimal wave to have a positive growth rate, i.e.

$y_c$. In order for an infinitesimal wave to have a positive growth rate, i.e. ![]() $\beta > 0$, a first requirement is that

$\beta > 0$, a first requirement is that ![]() $U''_c<0$, i.e. negative curvature at the critical layer. This is satisfied if the critical layer is outside of the viscous sublayer.

$U''_c<0$, i.e. negative curvature at the critical layer. This is satisfied if the critical layer is outside of the viscous sublayer.

A second requirement for ![]() $\beta >0$ is that

$\beta >0$ is that ![]() $v_c$ in (3.13) is non-zero at the critical layer. The approximate solution of

$v_c$ in (3.13) is non-zero at the critical layer. The approximate solution of ![]() $v$ in (3.7) implies, however, that

$v$ in (3.7) implies, however, that ![]() $v$ is zero at the critical layer. As shown in § 3 E of the supplementary material, one may transform the condition for positive growth rate to an integral form to estimate

$v$ is zero at the critical layer. As shown in § 3 E of the supplementary material, one may transform the condition for positive growth rate to an integral form to estimate ![]() $v$ in the vicinity of the critical layer. By further assuming a logarithmic mean velocity profile and setting the reference velocity to

$v$ in the vicinity of the critical layer. By further assuming a logarithmic mean velocity profile and setting the reference velocity to ![]() $U_1=u_\tau /\kappa$ (where

$U_1=u_\tau /\kappa$ (where ![]() $\kappa$ is the von Kármán constant), one may evaluate the expression for

$\kappa$ is the von Kármán constant), one may evaluate the expression for ![]() $\beta$ (as a function of

$\beta$ (as a function of ![]() $ky_c$), and obtain what is shown in figure 5(b).

$ky_c$), and obtain what is shown in figure 5(b).

We observe from figure 5(b) that, when ![]() $ky_c > 3/2$, then

$ky_c > 3/2$, then ![]() $\beta < 0.02$, which results in very slow-growing waves, whereas when

$\beta < 0.02$, which results in very slow-growing waves, whereas when ![]() $ky_c < 1/2$, we have

$ky_c < 1/2$, we have ![]() $\beta >0.8$, resulting in a factor 40 or more faster growth. The grey region in figure 5(b) marks the range

$\beta >0.8$, resulting in a factor 40 or more faster growth. The grey region in figure 5(b) marks the range ![]() $1/2 < ky_c < 3/2$ where there is a transition from low to high growth rates. Now, since

$1/2 < ky_c < 3/2$ where there is a transition from low to high growth rates. Now, since ![]() $k>k_z$ and the upper limit of

$k>k_z$ and the upper limit of ![]() $\lambda _z$ is

$\lambda _z$ is ![]() $2w$, we may formulate bounds for the position of the critical layer. When

$2w$, we may formulate bounds for the position of the critical layer. When

the growth rate can be expected to be significant, in contrast to when

for which the growth is negligible.

Equations (3.12), (3.14) and (3.15) provide relationships between ![]() ${We}^+$,

${We}^+$, ![]() $w^+$ and

$w^+$ and ![]() $c_{w,min}^+$,

$c_{w,min}^+$, ![]() $y_{c,max}^+$ that can be confirmed by our simulations. Equation (3.12) states that a large

$y_{c,max}^+$ that can be confirmed by our simulations. Equation (3.12) states that a large ![]() ${We}^+$ and/or

${We}^+$ and/or ![]() $w^+$ give a small phase speed. This is observed qualitatively by following the travelling waves on the interface in figure 4(a,b). More quantitatively, the space–time correlations of the interface height for

$w^+$ give a small phase speed. This is observed qualitatively by following the travelling waves on the interface in figure 4(a,b). More quantitatively, the space–time correlations of the interface height for ![]() ${We} = 100$ and

${We} = 100$ and ![]() ${We} = 200$ give

${We} = 200$ give ![]() $c^+ = 15.1$ and

$c^+ = 15.1$ and ![]() $c^+ = 10.5$, respectively (see figure S8 of the supplementary material).

$c^+ = 10.5$, respectively (see figure S8 of the supplementary material).

Compared to ![]() ${We}=100$, the lower phase speed for

${We}=100$, the lower phase speed for ![]() ${We} = 200$ results in a lower position of the critical layer. When the height of the critical layer approaches the interface and satisfies (3.14), the growth rate coefficient

${We} = 200$ results in a lower position of the critical layer. When the height of the critical layer approaches the interface and satisfies (3.14), the growth rate coefficient ![]() $\beta$ of the waves (3.13) is large. This is confirmed by our simulations, where we observe in figure 4(c) that both the growth rate and interface amplitudes are larger for

$\beta$ of the waves (3.13) is large. This is confirmed by our simulations, where we observe in figure 4(c) that both the growth rate and interface amplitudes are larger for ![]() ${We}=200$ compared to

${We}=200$ compared to ![]() ${We}=100$.

${We}=100$.

We use an inviscid model here to get a tractable analytical solution, and to illustrate the important physics involved. It has been shown that the effect of introducing viscosity on capillary waves with relevant wavenumbers would be a slight damping (Jeng et al. Reference Jeng, Esibov, Crow and Steyerl1998). However, it is possible that viscosity influences the velocity induced by the waves deep inside the grooves to a higher extent.

3.3. Implications for the design of LISs

The conditions (3.12), (3.14) and (3.15) can be used as design criteria for LISs. One may expect a high-performing LIS by choosing a groove width and a surface tension of the infused liquid such that – for relevant friction Reynolds numbers – the design falls within the smooth region of figure 1(a). This region is defined by ![]() $({We}^+,w^+)$, where

$({We}^+,w^+)$, where ![]() $y^+_c\geq 1.5 w^+/{\rm \pi}$, and thus from (3.15) very small growth rates of capillary waves are predicted. Conversely, the rough region in figure 1(a) shows

$y^+_c\geq 1.5 w^+/{\rm \pi}$, and thus from (3.15) very small growth rates of capillary waves are predicted. Conversely, the rough region in figure 1(a) shows ![]() $({We}^+,w^+)$, where

$({We}^+,w^+)$, where ![]() $y^+_c\leq 0.5 w^+/{\rm \pi}$, and therefore waves will amplify rapidly. Here, we may expect either a very low-performing LIS or even a drag-increasing LIS due to roughness effects. In between the smooth and rough domains, we show in figure 1(a) a transitional region (grey), which corresponds to

$y^+_c\leq 0.5 w^+/{\rm \pi}$, and therefore waves will amplify rapidly. Here, we may expect either a very low-performing LIS or even a drag-increasing LIS due to roughness effects. In between the smooth and rough domains, we show in figure 1(a) a transitional region (grey), which corresponds to ![]() $0.5w^+/{\rm \pi} \leq y^+_c\leq 1.5w^+/{\rm \pi}$. Here, we cannot predict if the resulting waves induce roughness effects using our analytical approach. It should be mentioned that the boundaries of the transitional region in figure 1(a) are determined in three steps: (i) given

$0.5w^+/{\rm \pi} \leq y^+_c\leq 1.5w^+/{\rm \pi}$. Here, we cannot predict if the resulting waves induce roughness effects using our analytical approach. It should be mentioned that the boundaries of the transitional region in figure 1(a) are determined in three steps: (i) given ![]() $w^+$, determine

$w^+$, determine ![]() $y^+_c$ from (3.14) (lower boundary) or (3.15) (upper boundary); (ii) given

$y^+_c$ from (3.14) (lower boundary) or (3.15) (upper boundary); (ii) given ![]() $y^+_c$, determine

$y^+_c$, determine ![]() $c^+$ (phase speed) from

$c^+$ (phase speed) from ![]() $U^+(y^+_c)=c^+$, where

$U^+(y^+_c)=c^+$, where ![]() $U^+(y)$ is a turbulent mean profile of a smooth wall; and finally (iii) given

$U^+(y)$ is a turbulent mean profile of a smooth wall; and finally (iii) given ![]() $c^+$, assume

$c^+$, assume ![]() $c^+\approx c^{+0}_{w,min}$ and determine

$c^+\approx c^{+0}_{w,min}$ and determine ![]() ${We}^+$ from (3.12) (or the exact coefficient of (3.12) given in the supplementary material).

${We}^+$ from (3.12) (or the exact coefficient of (3.12) given in the supplementary material).

Figure 1(a) also shows scaling laws between smooth and rough regions. For small ![]() $w^+$ (and thus

$w^+$ (and thus ![]() $y_c^+$), we may assume that the critical-layer velocity is

$y_c^+$), we may assume that the critical-layer velocity is ![]() $U_c^+ \approx y_c^+$. This is acceptable right above the viscous sublayer where the mean flow has some curvature. Then (3.12) gives that the height of the lowest critical layer is

$U_c^+ \approx y_c^+$. This is acceptable right above the viscous sublayer where the mean flow has some curvature. Then (3.12) gives that the height of the lowest critical layer is ![]() $y_c^+ \approx \sqrt {{\rm \pi} /({We}^+w^+)}$. By assuming that

$y_c^+ \approx \sqrt {{\rm \pi} /({We}^+w^+)}$. By assuming that ![]() $y_c^+\sim w^+/{\rm \pi}$, we obtain

$y_c^+\sim w^+/{\rm \pi}$, we obtain

which is shown with the dashed line in figure 1(a). It is observed that this asymptotic relation represents a reasonable scaling law for ![]() $w^+\lesssim 20$.

$w^+\lesssim 20$.

For larger ![]() $w^+$, away from the viscous sublayer, we assume

$w^+$, away from the viscous sublayer, we assume ![]() $U^+ = (1/\kappa)\log (y^+) + B$, where

$U^+ = (1/\kappa)\log (y^+) + B$, where ![]() $B$ is a constant. This gives a nonlinear relation

$B$ is a constant. This gives a nonlinear relation

This curve is shown in figure 1(a) with a dashed-dotted line, and provides a scaling of the neutral curve for ![]() $w^+\gtrsim 30$.

$w^+\gtrsim 30$.

The scaling laws illustrate that, when ![]() $w^+$ increases, there needs to be rapid decrease of

$w^+$ increases, there needs to be rapid decrease of ![]() ${We}^+$ to remain in the smooth region. For example, for

${We}^+$ to remain in the smooth region. For example, for ![]() $w^+\approx 70$, we need

$w^+\approx 70$, we need ![]() ${We}^+ \approx 3\times 10^{-4}$, which corresponds to

${We}^+ \approx 3\times 10^{-4}$, which corresponds to ![]() ${We} \approx 10$. This is relevant for drag reduction, since the width of the grooves should be maximised for a given surface tension to optimise

${We} \approx 10$. This is relevant for drag reduction, since the width of the grooves should be maximised for a given surface tension to optimise ![]() ${DR}$ (see figure 3), but without entering the rough zone in figure 1(a). Note that, for a fixed geometry, increasing the flow speed, and thereby

${DR}$ (see figure 3), but without entering the rough zone in figure 1(a). Note that, for a fixed geometry, increasing the flow speed, and thereby ![]() $u_\tau$, increases both

$u_\tau$, increases both ![]() ${We}^+$ and

${We}^+$ and ![]() $w^+$, so that the design needs to be made for the largest flow speed to which the surface is exposed.

$w^+$, so that the design needs to be made for the largest flow speed to which the surface is exposed.

Finally, in figure 1(a), the values of our numerical simulations are shown with symbols. These also include more extreme Weber numbers, ![]() ${We} = 50$ and

${We} = 50$ and ![]() ${We} = 400$ (using

${We} = 400$ (using ![]() $\mu _i/\mu _\infty = 1$), which resulted in a drag reduction of

$\mu _i/\mu _\infty = 1$), which resulted in a drag reduction of ![]() $9.3\,\%$ and

$9.3\,\%$ and ![]() $-15\,\%$, respectively, confirming the trend of the other simulations. In addition to the simulations at

$-15\,\%$, respectively, confirming the trend of the other simulations. In addition to the simulations at ![]() $w^{+0}=18$, we also show points (circles) for larger grooves of width

$w^{+0}=18$, we also show points (circles) for larger grooves of width ![]() $w^{+0} = 36$ (also using

$w^{+0} = 36$ (also using ![]() $\mu _i/\mu _\infty = 1$). For these grooves, there was a drag reduction by

$\mu _i/\mu _\infty = 1$). For these grooves, there was a drag reduction by ![]() $18\,\%$ for

$18\,\%$ for ![]() ${We} = 25$ (purple circle) and

${We} = 25$ (purple circle) and ![]() $17\,\%$ for

$17\,\%$ for ![]() ${We} = 50$ (green circle), whereas for

${We} = 50$ (green circle), whereas for ![]() ${We} = 100$ (blue circle), the drag reduction was lowered to

${We} = 100$ (blue circle), the drag reduction was lowered to ![]() $2\,\%$ and we observed large waves. This implies that the growth rate rapidly increases between the last two cases as they fall in the transitional zone in figure 1(a).

$2\,\%$ and we observed large waves. This implies that the growth rate rapidly increases between the last two cases as they fall in the transitional zone in figure 1(a).

3.4. Contact line depinning

The capillary waves modify the contact angle between the interface and the wall, and may potentially result in a depinning of the interface from the corners of the ridges. According to Gibbs’ criterion, which is a purely geometrical criterion, the interface remains pinned if ![]() $\theta < \phi < 90^{\circ } + \theta$, where

$\theta < \phi < 90^{\circ } + \theta$, where ![]() $\phi$ is the angle the interface makes to the inner wall of the groove. The lower limit is the limit for when the contact line moves into the groove, while the upper is the limit for when it moves on top of the ridge (Gibbs Reference Gibbs1906). This is illustrated in figure 6(a). In contrast to the cases

$\phi$ is the angle the interface makes to the inner wall of the groove. The lower limit is the limit for when the contact line moves into the groove, while the upper is the limit for when it moves on top of the ridge (Gibbs Reference Gibbs1906). This is illustrated in figure 6(a). In contrast to the cases ![]() ${We} = 100$ or

${We} = 100$ or ![]() $150$ (figure 2), we observed that for

$150$ (figure 2), we observed that for ![]() ${We} = 200$ the interface depinned occasionally due to the waves on the interface.

${We} = 200$ the interface depinned occasionally due to the waves on the interface.

Figure 6. (![]() $a$) If

$a$) If ![]() $\theta < \phi < \theta + 90^{\circ }$, the contact line remains pinned according to Gibbs’ criterion (grey area). This is illustrated for

$\theta < \phi < \theta + 90^{\circ }$, the contact line remains pinned according to Gibbs’ criterion (grey area). This is illustrated for ![]() $\theta = 45^{\circ }$. If

$\theta = 45^{\circ }$. If ![]() $\phi$ is outside this range, the contact line depins, and moves in the direction indicated by the arrows. (

$\phi$ is outside this range, the contact line depins, and moves in the direction indicated by the arrows. (![]() $b$) The p.d.f. of

$b$) The p.d.f. of ![]() $\phi$ from simulations for the pinned cases with

$\phi$ from simulations for the pinned cases with ![]() $w^{+0} = 18$,

$w^{+0} = 18$, ![]() $\theta = 45^{\circ }$,

$\theta = 45^{\circ }$, ![]() $\mu _i/\mu _\infty = 0.5$ (dashed line),

$\mu _i/\mu _\infty = 0.5$ (dashed line), ![]() $\mu _i/\mu _\infty = 1$ (solid line) and

$\mu _i/\mu _\infty = 1$ (solid line) and ![]() $\mu _i/\mu _\infty = 2$ (dashed-dotted line) and the Weber numbers

$\mu _i/\mu _\infty = 2$ (dashed-dotted line) and the Weber numbers ![]() ${We} = 100$ (blue) and

${We} = 100$ (blue) and ![]() ${We} = 150$ (red). The boundaries of the interval corresponding to a probability of 95 % for the widest p.d.f. are also shown (dotted line).

${We} = 150$ (red). The boundaries of the interval corresponding to a probability of 95 % for the widest p.d.f. are also shown (dotted line).

The measured probability density functions (p.d.f.s) of ![]() $\phi$ for

$\phi$ for ![]() ${We} = 100$ and

${We} = 100$ and ![]() $150$ with

$150$ with ![]() $\theta = 45^{\circ }$ are plotted in figure 6(b) for all three viscosity ratios. Since the contact line was observed to remain pinned for these parameters, the p.d.f.s are independent of

$\theta = 45^{\circ }$ are plotted in figure 6(b) for all three viscosity ratios. Since the contact line was observed to remain pinned for these parameters, the p.d.f.s are independent of ![]() $\theta$ and can be used to predict limits for the contact angle. It can be noted that the p.d.f.s for all parameters shown are centred around

$\theta$ and can be used to predict limits for the contact angle. It can be noted that the p.d.f.s for all parameters shown are centred around ![]() $\phi = 90^{\circ }$ and that

$\phi = 90^{\circ }$ and that ![]() $\phi$ is unlikely to reach below

$\phi$ is unlikely to reach below ![]() $70^{\circ }$ or above

$70^{\circ }$ or above ![]() $110^{\circ }$. The interval between these values corresponds to a probability of more than 95 % for the widest p.d.f. The standard deviation of

$110^{\circ }$. The interval between these values corresponds to a probability of more than 95 % for the widest p.d.f. The standard deviation of ![]() $\phi$ decreases with

$\phi$ decreases with ![]() $\mu _i/\mu _\infty$ and increases with

$\mu _i/\mu _\infty$ and increases with ![]() ${We}$, as is indicated by the width of the p.d.f. This is to be expected, since the dissipation rate increases with the viscosity and the restoring force of surface tension becomes weaker with increasing

${We}$, as is indicated by the width of the p.d.f. This is to be expected, since the dissipation rate increases with the viscosity and the restoring force of surface tension becomes weaker with increasing ![]() ${We}$.

${We}$.

A restoring force for the contact line also comes from mass conservation. If the contact line occasionally does depin into the groove on one position, it will be raised elsewhere. Based on this observation and the statistics in figure 6(b), depinning is not the main failure mode of LISs for the geometry chosen in this study. Depinning is, however, expected to be important for a LIS with grooves of finite length.

4. Conclusions

We have explored the behaviour of LISs in a turbulent channel flow with square longitudinal grooves for ![]() ${Re}_\tau \approx 180$. By allowing the interface and the contact line to move, we could investigate the unconstrained motion of the interface. For a fixed groove width, we found a rapid increase in drag of LISs above a certain Weber number due to the appearance of large capillary waves. The generation mechanism of these waves was elucidated using the theory developed by Miles (Reference Miles1957). The limit for when these waves act as roughness is set by the width of the grooves

${Re}_\tau \approx 180$. By allowing the interface and the contact line to move, we could investigate the unconstrained motion of the interface. For a fixed groove width, we found a rapid increase in drag of LISs above a certain Weber number due to the appearance of large capillary waves. The generation mechanism of these waves was elucidated using the theory developed by Miles (Reference Miles1957). The limit for when these waves act as roughness is set by the width of the grooves ![]() $w^+$ and the Weber number

$w^+$ and the Weber number ![]() ${We}^+$, as illustrated in figure 1(a). It should also be noted that these non-dimensional parameters depend on the flow speed. Using an analytical analysis, we have provided scaling laws and design criteria for robust drag-reducing LISs. Specifically, the relations show how to achieve a balance between large groove widths (enhancing drag reduction) and high surface tension of the infused liquid (enhancing stability) for different flow speeds.

${We}^+$, as illustrated in figure 1(a). It should also be noted that these non-dimensional parameters depend on the flow speed. Using an analytical analysis, we have provided scaling laws and design criteria for robust drag-reducing LISs. Specifically, the relations show how to achieve a balance between large groove widths (enhancing drag reduction) and high surface tension of the infused liquid (enhancing stability) for different flow speeds.

Supplementary material

Supplementary material is available at https://doi.org/10.1017/jfm.2021.241.

Acknowledgements

Simulations were performed on resources provided by the Swedish National Infrastructure of Computing (SNIC).

Funding

This work was supported by SSF, the Swedish Foundation for Strategic Research (Future Leaders grant FFL15:0001).

Declaration of interests

The authors report no conflict of interest.