1. Introduction

This work concerns stratification in drying films, examining how a mixture of differently sized particles arranges itself upon drying. It is seen experimentally that smaller particles typically preferentially accumulate at the top surface, but it is not fully understood why (Routh Reference Routh2013). Understanding this could have applications across a wide range of industries, from the surface of catalyst pellets, to coating surfaces with biocides (Mardones et al. Reference Mardones, Legnoverde, Monzón, Bellotti and Basaldella2019). It may have significance in the development of cheaper and more sustainable materials, as the drying process can be engineered such that expensive components are only located where they are required.

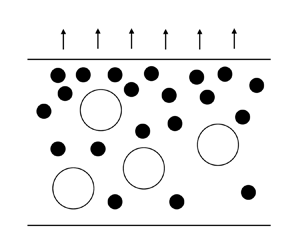

As solvent evaporates from a film, the top surface, initially at height H, descends at velocity ![]() $\dot{E}$. The situation and coordinate system used are depicted in figure 1, where z is the spatial coordinate,

$\dot{E}$. The situation and coordinate system used are depicted in figure 1, where z is the spatial coordinate, ![]() $\xi $ is the transformed spatial coordinate (see § 3.2) and t is time. Particles which are unable to diffuse away from the top are collected by the top surface. Whether or not the particles can diffuse sufficiently quickly away from the surface is characterised by the Péclet number,

$\xi $ is the transformed spatial coordinate (see § 3.2) and t is time. Particles which are unable to diffuse away from the top are collected by the top surface. Whether or not the particles can diffuse sufficiently quickly away from the surface is characterised by the Péclet number, ![]() $Pe = 6{\rm \pi}\eta R\dot{E}H/kT$, where R is the particle radius,

$Pe = 6{\rm \pi}\eta R\dot{E}H/kT$, where R is the particle radius, ![]() $\eta $ is the solvent viscosity, k is the Boltzmann constant and T is the temperature (Routh & Zimmerman Reference Routh and Zimmerman2004). Hence it is expected that drying dispersions with different size particles will lead to different particle arrangements in the dried film. On the basis of diffusional arguments alone, it would be expected that larger particles stratify to the top surface.

$\eta $ is the solvent viscosity, k is the Boltzmann constant and T is the temperature (Routh & Zimmerman Reference Routh and Zimmerman2004). Hence it is expected that drying dispersions with different size particles will lead to different particle arrangements in the dried film. On the basis of diffusional arguments alone, it would be expected that larger particles stratify to the top surface.

Figure 1. Schematic of the drying of a film containing two types of particles.

In light of experimental observations of small particles at the top surface, it is thought that a simple diffusional model may not suffice. The terminology small-on-top stratification is used in this work to describe a layer, including just a thin layer, of small particles at the top surface, and likewise for large-on-top stratification. This work derives a fluid mechanics model for both the simple diffusion case, and the case that adds a type of diffusiophoresis: an excluded volume effect. The aim is to use the numerical results to determine whether diffusiophoresis could explain these experimental observations. It will be shown that diffusiophoresis may result in small-on-top stratification, including a thin layer of small particles at the top surface.

A literature review is carried out in § 1.1 to explain the context of the work and the existing hypotheses. In § 2, the relevant theory is derived, then in § 3, the solution methodology is explained. The results of the simulations are presented and discussed in § 4. Asymptotic solutions are outlined in § 5, before drawing conclusions in § 6.

1.1. Literature review

Different approaches have been taken in the literature to model the drying of particulate films and attempt to explain the particle arrangements seen experimentally. Key works which have used thermodynamic models include (i) Routh & Zimmerman (Reference Routh and Zimmerman2004), who derived equations for the drying of a film containing just one species of particles and solved them numerically; and (ii) Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b), who extended Routh & Zimmerman's work to a film containing particles of two different sizes.

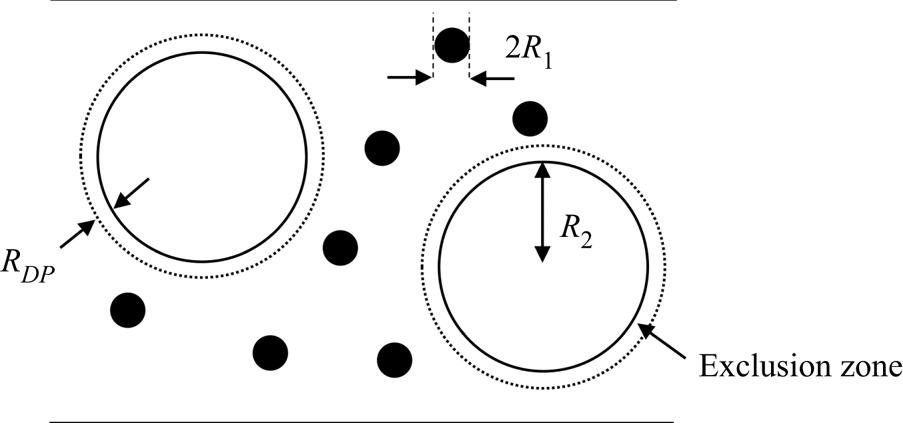

In the expression for the solute chemical potential, ![]() ${\mu _i}$, Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b) included only an entropic contribution,

${\mu _i}$, Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b) included only an entropic contribution, ![]() ${\mu _i} = \mu _i^0 + kT\ln {\phi _i}$, where

${\mu _i} = \mu _i^0 + kT\ln {\phi _i}$, where ![]() $\mu _i^0$ is the reference chemical potential and

$\mu _i^0$ is the reference chemical potential and ![]() ${\phi _i}$ is the solute volume fraction. Zhou, Jiang & Doi (Reference Zhou, Jiang and Doi2017) took a similar approach to Trueman et al., but also included a binary interaction term in the chemical potential. This cross-interaction term in the chemical potential accounts for enthalpic effects, i.e. inter-particle interactions. Zhou et al. (Reference Zhou, Jiang and Doi2017) include these up to the order

${\phi _i}$ is the solute volume fraction. Zhou, Jiang & Doi (Reference Zhou, Jiang and Doi2017) took a similar approach to Trueman et al., but also included a binary interaction term in the chemical potential. This cross-interaction term in the chemical potential accounts for enthalpic effects, i.e. inter-particle interactions. Zhou et al. (Reference Zhou, Jiang and Doi2017) include these up to the order

\begin{equation}{\mu _i} = \mu _i^0 + kT\left[ {\ln {\phi_i} + \mathop \sum \limits_j \frac{{{{({R_i} + {R_j})}^3}}}{{R_j^3}}{\phi_j}} \right].\end{equation}

\begin{equation}{\mu _i} = \mu _i^0 + kT\left[ {\ln {\phi_i} + \mathop \sum \limits_j \frac{{{{({R_i} + {R_j})}^3}}}{{R_j^3}}{\phi_j}} \right].\end{equation}

This can predict that the small particles end up on top of the larger particles. However, it does not explain why some images suggest that only a thin layer at the top is made up of small particles (Trueman et al. Reference Trueman, Lago Domingues, Emmett, Murray, Keddie and Routh2012a). A further shortcoming is that the form of the interaction terms used by Zhou et al. does not account for the change in interactions as the film approaches close packing, i.e. as the solution becomes more concentrated. Zhou et al. consider this to be acceptable, arguing that most of the stratification is formed before the film approaches close packing. Following the approach of Russel, Saville & Schowalter (Reference Russel, Saville and Schowalter1989) and Routh & Zimmerman (Reference Routh and Zimmerman2004), Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b) form particle chemical potential expressions that are valid even in non-dilute systems by using an expression for the solvent chemical potential that diverges at close packing. Having an accurate expression for the solvent chemical potential allows the chemical potentials of the two particles, ![]() ${\mu _1}$ and

${\mu _1}$ and ![]() ${\mu _2}$, to be related through the Gibbs–Duhem equation. Therefore, only

${\mu _2}$, to be related through the Gibbs–Duhem equation. Therefore, only ![]() ${\mu _1}$ or

${\mu _1}$ or ![]() ${\mu _2}$ needs to be specified to fully describe the system. In this work we choose to specify

${\mu _2}$ needs to be specified to fully describe the system. In this work we choose to specify ![]() $\boldsymbol{\nabla }{\mu _1}/\boldsymbol{\nabla }{\mu _2}$. The approach of Russel et al. will be adopted in this present work, so that the model can be run to close to the end of drying.

$\boldsymbol{\nabla }{\mu _1}/\boldsymbol{\nabla }{\mu _2}$. The approach of Russel et al. will be adopted in this present work, so that the model can be run to close to the end of drying.

An alternative to the thermodynamic approach described above is using molecular dynamics. Simulations of this type include diffusiophoresis because they simulate every particle, and do not allow the particles to overlap. In this way, excluded volume, including the small particles being excluded from around the large ones, is part of these models. These simulations can be divided into two types, implicit solvent models, where only the non-solvent particles are directly simulated, and explicit solvent models, where the solvent particles are included. This allows the hydrodynamic interactions to be simulated, resulting in greater accuracy, but at significant computational expense. This present work models volume fraction evolution, rather than every colloidal particle. In doing so, diffusiophoresis is modelled at a coarser level than, for example, molecular dynamics, at which level implicit/explicit solvent methods become important. This is intended to allow different insights to be obtained with the benefit of analytic expressions and without the computational expense.

Considering implicit solvent models, Fortini et al. (Reference Fortini, Martín-Fabiani, De La Haye, Dugas, Lansalot, D'Agosto, Bourgeat-Lami, Keddie and Sear2016) used Langevin dynamics with a short-range repulsive interaction. This method predicts layers of small particles on top, but not a single layer of small particles. Fortini et al. argue that this stratification is due to the gradient in osmotic pressure. Similar results were obtained by the Langevin dynamics simulations of Howard, Nikoubashman & Panagiotopoulos (Reference Howard, Nikoubashman and Panagiotopoulos2017a). Note that they obtain film profiles with a thin layer of large particles at the very top surface, which is present in their equilibrium film profiles before commencing drying. They argue that this is due to volume exclusion of the large particles at the interface. This is a well-known entropic effect near a boundary, as, for example, shown by Roth & Dietrich (Reference Roth and Dietrich2000) in comparing Rosenfeld density functional calculations with simulations. Directly beneath is a stratified layer of small particles, which grows over time. In addition to the Langevin dynamics simulations, Howard et al. outline, and subsequently simulate (Howard, Nikoubashman & Panagiotopoulos Reference Howard, Nikoubashman and Panagiotopoulos2017b), a model based on density functional theory. This can be thought of as an extension to the approach of Zhou et al. (Reference Zhou, Jiang and Doi2017), using a high-accuracy equation of state to calculate the chemical potentials. This would be valid for concentrated solutions.

Tang, Grest & Cheng (Reference Tang, Grest and Cheng2018) carried out molecular dynamics simulations that model the solvent explicitly, obtaining a modified threshold for the occurrence of small-on-top stratification. Statt, Howard & Panagiotopoulos (Reference Statt, Howard and Panagiotopoulos2018) argue that hydrodynamic interactions which are modelled in an explicit solvent model are important for reliably predicting stratification: small-on-top stratification is predicted using the implicit solvent method, but not with the explicit solvent one. In contrast, Tang, Grest & Cheng (Reference Tang, Grest and Cheng2019) also compare implicit and explicit solvent models, although with limitations on the film thicknesses that can be assessed with the computationally expensive explicit solvent models. For the systems they studied, the implicit solvent model was found to be sufficient, as both the implicit and explicit solvent models predicted small-on-top stratification.

Adequate modelling of the solvent is important for assessing the effect of diffusiophoresis. A recent hypothesis for explaining the accumulation of small particles at the top surface concerns a type of diffusiophoresis. Diffusiophoresis is the migration of particles along a concentration gradient of a different solute species, which could be either ionic or non-ionic (Anderson & Prieve Reference Anderson and Prieve1984). Whilst diffusiophoresis can be used as a general term, covering different mechanisms which result in such particle migration, including electrophoresis and chemiphoresis, the hypothesis in this work concerns a specific non-ionic type of diffusiophoresis. Other phoretic terms could be easily added to the model in this work if desired: this model requires an expression for the total flux, so other flux contributions can be added.

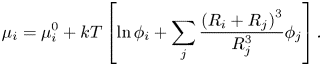

The non-ionic type of diffusiophoresis considered is an excluded volume effect, relevant in a mixture of small (component one) and large particles (component two). The small particles are excluded from a layer of solvent of thickness ![]() ${R_{DP}}$ around each of the large particles. For the case of hard spheres,

${R_{DP}}$ around each of the large particles. For the case of hard spheres, ![]() ${R_{DP}}$ is expected to equal the radius of a small particle,

${R_{DP}}$ is expected to equal the radius of a small particle, ![]() ${R_1}$. However, this work will explore what happens as

${R_1}$. However, this work will explore what happens as ![]() ${R_{DP}}$ varies, which may correspond to, for example, non-spherical particles. The situation is depicted in figure 2. The radius of each large particle is

${R_{DP}}$ varies, which may correspond to, for example, non-spherical particles. The situation is depicted in figure 2. The radius of each large particle is ![]() ${R_2}$. Note that there will also be excluded volume effects between particles of the same type but, by definition, these are not diffusiophoresis, and are excluded in the present study.

${R_2}$. Note that there will also be excluded volume effects between particles of the same type but, by definition, these are not diffusiophoresis, and are excluded in the present study.

Figure 2. Schematic of the exclusion zones around the larger particles, which give rise to diffusiophoresis.

Sear & Warren (Reference Sear and Warren2017) outline a simple model for this type of diffusiophoresis in a drying film. It is an idealised model, assuming that particles do not interact and that the particle size ratio is infinite. Diffusion of the larger particles is ignored, on the assumption that it is small compared with the diffusiophoretic flux. Diffusion of the smaller particles is included, by finding the concentration gradient of an ideal gas diffusing between two impenetrable walls, and then calculating the diffusiophoretic flux due to this concentration gradient.

Whilst Sear & Warren (Reference Sear and Warren2017) obtain elegant approximate analytical solutions, which are useful for gaining understanding, their model's applicability is limited to dilute solutions and very large size ratios. To aid insight into less idealised situations, particularly where the particle size ratio is not infinite, diffusion of both particles should be included. This allows identification of criteria for when diffusiophoresis is important. To allow the entire drying process to be modelled, not just the early stages, the model could be adapted to be valid up to close packing, again using the approach of Russel et al. (Reference Russel, Saville and Schowalter1989).

Diffusiophoresis with different relative strengths of diffusion of the large and small particles was modelled by Ault et al. (Reference Ault, Warren, Shin and Stone2017). The geometry that they chose, particle injection into or withdrawal from a semi-infinite or finite domain, is simpler than the drying geometry and has static boundaries. They formed advection–diffusion equations which are valid for dilute solutions. For the case where the diffusivity of the larger particles is neglected, Ault et al. obtain an analytical solution using the method of characteristics. This is compared with the numerical results which include diffusion of the larger particles. They found that ignoring diffusion of the larger particles accurately predicted the trajectories of the particle fronts, but not the particle concentrations around the fronts. Diffusiophoresis has also been modelled and imaged in a dead-end channel geometry (Shin et al. Reference Shin, Um, Sabass, Ault, Rahimi, Warren and Stone2016). This present work will seek to establish the relative importance of diffusion and diffusiophoresis in the geometry of a drying film.

Experimentally, it is difficult to determine whether the top layer is a monolayer of small particles, or thicker. It requires the ability to take measurements throughout the film depth, not just at the top surface. Small-angle X-ray scattering (SAXS) measurements have shown enrichment of small particles in the top several hundred layers of particles (Liu et al. Reference Liu, Carr, Yager, Routh and Bhatia2019). Existing works which include diffusiophoresis (Fortini et al. Reference Fortini, Martín-Fabiani, De La Haye, Dugas, Lansalot, D'Agosto, Bourgeat-Lami, Keddie and Sear2016; Howard et al. Reference Howard, Nikoubashman and Panagiotopoulos2017a,Reference Howard, Nikoubashman and Panagiotopoulosb) predict a growing layer of small particles at the top surface, in agreement with this. Experimental observation of a monolayer of small particles would support a different mechanism, such as interfacial effects. Atmuri, Bhatia & Routh (Reference Atmuri, Bhatia and Routh2012) added a surface interaction term to the model of Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b) to demonstrate this theoretically.

The review article by Schulz & Keddie (Reference Schulz and Keddie2018) compared predicted stratification regimes based on the interaction potential model of Zhou et al. (Reference Zhou, Jiang and Doi2017), and the diffusiophoresis models of Sear & Warren (Reference Sear and Warren2017) and Sear (Reference Sear2018), with experiments from the literature. Sear's model considers a jammed layer of small particles at the top surface, with diffusiophoretic drift of the large particles occurring just beneath it. This produces a simple criterion for small-on-top stratification: the speed of the jammed layer must be smaller than that of diffusiophoresis. Good agreement was found between experimental data for drying dilute dispersions and Zhou et al.'s predictions, but less so for concentrated ones. This suggests that a model which is valid for more concentrated solutions but allows input of Zhou et al.'s chemical potential expressions, could improve the agreement. Such a model is developed in this present work. Noting that there was a lack of experimental data in the range required to test the predicted stratification regimes of Sear & Warren and Sear, Schulz et al. (Reference Schulz, Smith, Sear, Brinkhuis and Keddie2020) subsequently carried out experiments with films containing colloid and polymer. The data obtained agree qualitatively with the predictions of Sear & Warren and Sear, but not with the exact position of the transition to small-on-top stratification.

It is clear from this survey that several hypotheses could explain the small-on-top observations, although existing simulations seem to predict a thicker final layer than is sometimes seen experimentally (Atmuri et al. Reference Atmuri, Bhatia and Routh2012). Whilst diffusiophoresis has been suggested as an explanation, it has not been directly modelled in a drying film. This work seeks to address this, adopting a fluid mechanics partial differential equation (PDE) model, since its simple formulation allows insight to be gained.

2. Derivation

2.1. Diffusion

To make explicit how the theory outlined here compares with previous work, whilst (2.7) in § 2.2 was also used by Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b), (2.12)–(2.14) correct the hydrodynamics implementation. These equations are given here in their most general forms. Also, (2.8)–(2.11) add clarification regarding diffusion reference frames. Equations (2.18)–(2.23) are reproduced from the work of Trueman et al., but they are subsequently substituted into the general conservation equation derived in § 2.2. §§ 2.3, 3.1 and 3.2 follow the same approach as Trueman et al., although again following through with the general equations.

2.1.1. Explanation of hydrodynamics correction

Using the thermodynamic approach in this present work, it is found that the extension from the one-component case of Routh & Zimmerman (Reference Routh and Zimmerman2004) to the two-component case is non-trivial. The Stokes–Einstein diffusion coefficient, ![]() ${D_{SE}}$, was originally derived for a single particle in infinite solvent, so it needs to be determined how to use

${D_{SE}}$, was originally derived for a single particle in infinite solvent, so it needs to be determined how to use ![]() ${D_{SE}}$ in a system that is no longer infinitely dilute. According to Batchelor (Reference Batchelor1976),

${D_{SE}}$ in a system that is no longer infinitely dilute. According to Batchelor (Reference Batchelor1976), ![]() ${D_{SE}}$ applies to a force-free solvent. Hence instead of deriving that the diffusive flux of particles in a one-component film,

${D_{SE}}$ applies to a force-free solvent. Hence instead of deriving that the diffusive flux of particles in a one-component film, ![]() ${\boldsymbol{j}_1}$, is

${\boldsymbol{j}_1}$, is

where ![]() $- \boldsymbol{\nabla }{\mu _1}$ is the force acting on component one due to its chemical potential,

$- \boldsymbol{\nabla }{\mu _1}$ is the force acting on component one due to its chemical potential, ![]() ${\mu _1}$, Batchelor derives

${\mu _1}$, Batchelor derives

where ![]() ${\phi _1}$ is the volume fraction of component one. The factor of

${\phi _1}$ is the volume fraction of component one. The factor of ![]() $1/(1 - {\phi _1})\; $ results from a force correction. This force correction could be expressed as

$1/(1 - {\phi _1})\; $ results from a force correction. This force correction could be expressed as

where ![]() $(4/3){\rm \pi} R_1^3$ is the volume of a particle of component one,

$(4/3){\rm \pi} R_1^3$ is the volume of a particle of component one, ![]() ${\nu _s}$ is the volume of a particle of the solvent and

${\nu _s}$ is the volume of a particle of the solvent and ![]() ${\mu _s}$ is the chemical potential of the solvent. The subscript

${\mu _s}$ is the chemical potential of the solvent. The subscript ![]() $eff$ denotes the effective driving force for diffusion. Since the ratio of particle volumes is a constant, (2.3) could be equivalently written as

$eff$ denotes the effective driving force for diffusion. Since the ratio of particle volumes is a constant, (2.3) could be equivalently written as

This correction appears in the equations of Routh & Zimmerman (Reference Routh and Zimmerman2004). Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b) incorrectly extended this by writing

where ![]() ${\phi _2}$ is the volume fraction of component two, and

${\phi _2}$ is the volume fraction of component two, and ![]() ${\mu _2}$ is its chemical potential. Whilst this appears to be a logical extension of (2.4), (2.3) is still correct for a film with any number of components, following the reasoning of Batchelor (Reference Batchelor1976). Equation (2.3) should therefore be used to replace the erroneous (2.5) in the work of Trueman et al.

${\mu _2}$ is its chemical potential. Whilst this appears to be a logical extension of (2.4), (2.3) is still correct for a film with any number of components, following the reasoning of Batchelor (Reference Batchelor1976). Equation (2.3) should therefore be used to replace the erroneous (2.5) in the work of Trueman et al.

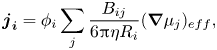

In a multicomponent solution, (2.3) is used to form an expression for ![]() ${\boldsymbol{j}_{\boldsymbol{i}}}$ by summing over the contributions from all components in the mixture

${\boldsymbol{j}_{\boldsymbol{i}}}$ by summing over the contributions from all components in the mixture

\begin{equation}{\boldsymbol{j}_{\boldsymbol{i}}} = {\phi _i}\mathop \sum \limits_j \frac{{{B_{ij}}}}{{6{\rm \pi}\eta {R_i}}}{(\boldsymbol{\nabla }{\mu _j})_{eff}},\end{equation}

\begin{equation}{\boldsymbol{j}_{\boldsymbol{i}}} = {\phi _i}\mathop \sum \limits_j \frac{{{B_{ij}}}}{{6{\rm \pi}\eta {R_i}}}{(\boldsymbol{\nabla }{\mu _j})_{eff}},\end{equation}

where ![]() ${B_{ij}}$ is the bulk mobility coefficient, which is generally a function of all

${B_{ij}}$ is the bulk mobility coefficient, which is generally a function of all ![]() ${\phi _j}$ and ratios of

${\phi _j}$ and ratios of ![]() ${R_j}$. Substituting in expressions for

${R_j}$. Substituting in expressions for ![]() ${B_{ij}}$ allows an equation of the form of (2.12) to be derived (Batchelor Reference Batchelor1983).

${B_{ij}}$ allows an equation of the form of (2.12) to be derived (Batchelor Reference Batchelor1983).

This present work will use the methodology of Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b), but with the corrected (2.12). The numerical results of Trueman et al. solved diffusion fluxes of the same leading order in ![]() $P{e_1}$ and

$P{e_1}$ and ![]() $P{e_2}$ as the equations in this present work, and so the results in § 4.1 are expected to show the same qualitative behaviour.

$P{e_2}$ as the equations in this present work, and so the results in § 4.1 are expected to show the same qualitative behaviour.

2.2. Governing equations

The conservation equation for one type of particles can be written as

where ![]() ${\boldsymbol{N}_1}$ is the total flux of particles of component one. Following the approach of Cussler (Reference Cussler2009), the total flux can be arbitrarily split up into a convective and diffusive flux

${\boldsymbol{N}_1}$ is the total flux of particles of component one. Following the approach of Cussler (Reference Cussler2009), the total flux can be arbitrarily split up into a convective and diffusive flux

where the volume average velocity of type one particles is ![]() ${\boldsymbol{U}_1}$, and their diffusive flux

${\boldsymbol{U}_1}$, and their diffusive flux ![]() $\boldsymbol{j}_1^{\boldsymbol{a}}$ relative to the reference velocity

$\boldsymbol{j}_1^{\boldsymbol{a}}$ relative to the reference velocity ![]() ${\boldsymbol{U}^{\boldsymbol{a}}}$ is

${\boldsymbol{U}^{\boldsymbol{a}}}$ is

The chemical potential of component i in the two-component film is denoted by ![]() ${\mu _i}$, and the diffusion coefficient of particles of type one in particles of type i, using a reference velocity

${\mu _i}$, and the diffusion coefficient of particles of type one in particles of type i, using a reference velocity ![]() ${\boldsymbol{U}^{\boldsymbol{a}}}$, is denoted by

${\boldsymbol{U}^{\boldsymbol{a}}}$, is denoted by ![]() $D_{1i}^a$. It is convenient to choose the volume average velocity

$D_{1i}^a$. It is convenient to choose the volume average velocity ![]() ${\boldsymbol{U}^{\boldsymbol{v}}}$as

${\boldsymbol{U}^{\boldsymbol{v}}}$as ![]() ${\boldsymbol{U}^{\boldsymbol{a}}}$, since

${\boldsymbol{U}^{\boldsymbol{a}}}$, since ![]() ${\boldsymbol{U}^{\boldsymbol{v}}} = 0$ in a static film. Hence (2.7) becomes

${\boldsymbol{U}^{\boldsymbol{v}}} = 0$ in a static film. Hence (2.7) becomes

and diffusion coefficients using a volume-fixed reference frame are required.

For a volume-fixed reference frame,

so expressions for ![]() $D_{11}^v$ and

$D_{11}^v$ and ![]() $D_{12}^v$ are required. It is desired to relate these to the Stokes–Einstein diffusion coefficient of component one,

$D_{12}^v$ are required. It is desired to relate these to the Stokes–Einstein diffusion coefficient of component one, ![]() ${D_{SE,1}} = kT/6{\rm \pi}\eta {R_1}$.

${D_{SE,1}} = kT/6{\rm \pi}\eta {R_1}$.

Hydrodynamic effects are taken into account via ![]() ${K_{11}}({\phi _1},{\phi _2})$ and

${K_{11}}({\phi _1},{\phi _2})$ and ![]() ${K_{12}}({\phi _1},{\phi _2})$, which are referred to as sedimentation coefficients by analogy with sedimentation (Batchelor Reference Batchelor1976). It is expected that these will be functions of

${K_{12}}({\phi _1},{\phi _2})$, which are referred to as sedimentation coefficients by analogy with sedimentation (Batchelor Reference Batchelor1976). It is expected that these will be functions of ![]() ${R_1}$ and

${R_1}$ and ![]() ${R_2}$ as well as

${R_2}$ as well as ![]() ${\phi _1}$ and

${\phi _1}$ and ![]() ${\phi _2}$. This gives

${\phi _2}$. This gives

Defining the sedimentation coefficients such that ![]() ${U_1}$ is a velocity relative to the volume average velocity, and so can be used in (2.10) and (2.11), the conservation equation for component one becomes

${U_1}$ is a velocity relative to the volume average velocity, and so can be used in (2.10) and (2.11), the conservation equation for component one becomes

Hence, ![]() $D_{11}^v$ and

$D_{11}^v$ and ![]() $D_{12}^v$ can be found in relation to

$D_{12}^v$ can be found in relation to ![]() ${D_{SE,1}}$ by comparison with the sedimentation coefficients. Note that, in this work, the diffusive fluxes are written in terms of chemical potential gradients, as opposed to concentration gradients. This is why we divide

${D_{SE,1}}$ by comparison with the sedimentation coefficients. Note that, in this work, the diffusive fluxes are written in terms of chemical potential gradients, as opposed to concentration gradients. This is why we divide ![]() ${D_{SE,1}}$ by

${D_{SE,1}}$ by ![]() $kT$ in the flux expressions, (2.12) and (2.13), and why a factor of

$kT$ in the flux expressions, (2.12) and (2.13), and why a factor of ![]() ${\phi _1}$ appears in front of the

${\phi _1}$ appears in front of the ![]() $\boldsymbol{\nabla }{\mu _1}$ term in (2.13), and likewise for the

$\boldsymbol{\nabla }{\mu _1}$ term in (2.13), and likewise for the ![]() ${\phi _2}$ term in front of the

${\phi _2}$ term in front of the ![]() $\boldsymbol{\nabla }{\mu _2}$.

$\boldsymbol{\nabla }{\mu _2}$.

Expressions for ![]() ${K_{11}}({\phi _1},{\phi _2})$ and

${K_{11}}({\phi _1},{\phi _2})$ and ![]() ${K_{12}}({\phi _1},{\phi _2})$ for rigid spheres with zero interaction potential in dilute solution can be found in Batchelor's work (Reference Batchelor1983). However, it is desired to use generalised forms of these expressions to run the model up to close packing. A factor of

${K_{12}}({\phi _1},{\phi _2})$ for rigid spheres with zero interaction potential in dilute solution can be found in Batchelor's work (Reference Batchelor1983). However, it is desired to use generalised forms of these expressions to run the model up to close packing. A factor of ![]() ${\phi _1}$ is included in front of the

${\phi _1}$ is included in front of the ![]() $\boldsymbol{\nabla }{\mu _2}$ term in (2.13) in order to match the leading-order coefficients in

$\boldsymbol{\nabla }{\mu _2}$ term in (2.13) in order to match the leading-order coefficients in ![]() $({\phi _1},{\phi _2})$ for dilute solution. Batchelor's (Reference Batchelor1983) dilute expressions will need to be adapted such that the sedimentation coefficients fall to zero as the mixture approaches close packing, due to hydrodynamic hindrance (Russel et al. Reference Russel, Saville and Schowalter1989). Steric effects could be incorporated into the chemical potential terms if desired.

$({\phi _1},{\phi _2})$ for dilute solution. Batchelor's (Reference Batchelor1983) dilute expressions will need to be adapted such that the sedimentation coefficients fall to zero as the mixture approaches close packing, due to hydrodynamic hindrance (Russel et al. Reference Russel, Saville and Schowalter1989). Steric effects could be incorporated into the chemical potential terms if desired.

We consider the case of one-dimensional drying with the top surface decreasing normally to the substrate. By scaling with ![]() $\hat{z} = z/H$ and

$\hat{z} = z/H$ and ![]() $\hat{t} = t\dot{E}/H$, (2.13), in one dimension, becomes

$\hat{t} = t\dot{E}/H$, (2.13), in one dimension, becomes

2.2.1. Evaporation rate

For the purpose of (2.14), ![]() $\dot{E}$ needs only to be a constant, characteristic evaporation velocity used for non-dimensionalising. When evaporation at the top surface is included in the boundary condition (§ 3.2), it is assumed that the evaporation rate is approximately constant. Evaporation is driven by the thermodynamic driving force between the vapour pressure of the solvent at the top of the film and the vapour pressure of the gas above the film. The vapour pressure of the gas above the film is affected by the time scale for diffusion from the layer of saturated vapour directly above the film to the bulk gas. This time scale is orders of magnitude smaller than the evaporation time (Popòv Reference Popòv2005), leading to a quasi-static problem (Routh Reference Routh2013).

$\dot{E}$ needs only to be a constant, characteristic evaporation velocity used for non-dimensionalising. When evaporation at the top surface is included in the boundary condition (§ 3.2), it is assumed that the evaporation rate is approximately constant. Evaporation is driven by the thermodynamic driving force between the vapour pressure of the solvent at the top of the film and the vapour pressure of the gas above the film. The vapour pressure of the gas above the film is affected by the time scale for diffusion from the layer of saturated vapour directly above the film to the bulk gas. This time scale is orders of magnitude smaller than the evaporation time (Popòv Reference Popòv2005), leading to a quasi-static problem (Routh Reference Routh2013).

Routh & Russel (Reference Routh and Russel1998) derived an expression for ![]() $\dot{E}$,

$\dot{E}$,

where ![]() ${k_m}$ is the gas-side mass transfer coefficient,

${k_m}$ is the gas-side mass transfer coefficient, ![]() ${p_{vap}}$ is the vapour pressure of the solvent at the top of the film and

${p_{vap}}$ is the vapour pressure of the solvent at the top of the film and ![]() $p_{vap}^\infty $ is the vapour pressure of the bulk gas.

$p_{vap}^\infty $ is the vapour pressure of the bulk gas.

The chemical potential of the solvent is related to the osmotic pressure, ![]() $\varPi $, as

$\varPi $, as

where ![]() $\mu _s^0$ is the solvent reference potential and

$\mu _s^0$ is the solvent reference potential and ![]() $Z({\phi _1},{\phi _2})$ is the compressibility, which accounts for the non-ideality of the osmotic pressure at high volume fractions. Relating the chemical potential to the solvent pressure through

$Z({\phi _1},{\phi _2})$ is the compressibility, which accounts for the non-ideality of the osmotic pressure at high volume fractions. Relating the chemical potential to the solvent pressure through ![]() ${\mu _s} - \mu _s^0 = kT\ln ({p_{vap}}/p_{vap}^0)$, where

${\mu _s} - \mu _s^0 = kT\ln ({p_{vap}}/p_{vap}^0)$, where ![]() $p_{vap}^0$ is the solvent reference vapour pressure, and extending the approach of Routh & Russel (Reference Routh and Russel1998) to a two-component mixture, (2.16) is substituted into (2.15), giving

$p_{vap}^0$ is the solvent reference vapour pressure, and extending the approach of Routh & Russel (Reference Routh and Russel1998) to a two-component mixture, (2.16) is substituted into (2.15), giving

Since ![]() ${\nu _s} \ll (4/3){\rm \pi} R_1^3$, and

${\nu _s} \ll (4/3){\rm \pi} R_1^3$, and ![]() ${\nu _\textrm{s}} \ll (4/3){\rm \pi} R_2^3$, as long the film has not yet reached close packing, we obtain

${\nu _\textrm{s}} \ll (4/3){\rm \pi} R_2^3$, as long the film has not yet reached close packing, we obtain ![]() $\dot{E}\sim {k_m}{\nu _s}(p_{vap}^0 - p_{vap}^\infty )/kT$, which is independent of film composition. In other words, the driving force is dominated by the humidity of the gas. In this one-dimensional drying model, a large surface area of film is assumed, so geometric edge effects are not applicable (Routh Reference Routh2013). When the film is close packed,

$\dot{E}\sim {k_m}{\nu _s}(p_{vap}^0 - p_{vap}^\infty )/kT$, which is independent of film composition. In other words, the driving force is dominated by the humidity of the gas. In this one-dimensional drying model, a large surface area of film is assumed, so geometric edge effects are not applicable (Routh Reference Routh2013). When the film is close packed, ![]() $Z({\phi _1},{\phi _2})$ diverges.

$Z({\phi _1},{\phi _2})$ diverges.

This work models drying up until the film is close packed throughout. There are stages of drying beyond this (deformation and aging) that lead to film formation (Sonzogni et al. Reference Sonzogni, Passeggi, Wedepohl, Calderón, Gugliotta, Gonzalez and Minari2018), but it is the first part of drying, where the particles can move throughout the film, that affects their arrangement in the dried film. If the particles are colloids, as they would be in many common examples of films (Routh Reference Routh2013), then they are assumed to be colloidally stable. However, the model would also be valid for particles smaller than the colloidal range until the composition at which they precipitate.

2.3. Derivation of the spatial derivative of the chemical potential

The chemical potential of component one can be written as a function of ![]() ${\phi _1}$ and

${\phi _1}$ and ![]() ${\phi _2}$, such that

${\phi _2}$, such that ![]() $\partial {\mu _1}/\partial \hat{z} = f({\phi _1}(\hat{z}),{\phi _2}(\hat{z}))$, and likewise for the chemical potential of component two,

$\partial {\mu _1}/\partial \hat{z} = f({\phi _1}(\hat{z}),{\phi _2}(\hat{z}))$, and likewise for the chemical potential of component two, ![]() ${\mu _2}$. These expressions could be directly inputted into (2.14). However, it is difficult to find expressions for the chemical potential of the solutes that are valid as the solution approaches close packing. One means of resolving this is to relate

${\mu _2}$. These expressions could be directly inputted into (2.14). However, it is difficult to find expressions for the chemical potential of the solutes that are valid as the solution approaches close packing. One means of resolving this is to relate ![]() ${\mu _1}$ and

${\mu _1}$ and ![]() ${\mu _2}$ to the chemical potential of the solvent,

${\mu _2}$ to the chemical potential of the solvent, ![]() ${\mu _s}$, for which an expression that diverges at close packing can be found.

${\mu _s}$, for which an expression that diverges at close packing can be found.

For a system which contains ![]() ${n_1} = {\phi _1}/(4/3){\rm \pi} R_1^3$ particles of component one,

${n_1} = {\phi _1}/(4/3){\rm \pi} R_1^3$ particles of component one, ![]() ${n_2} = {\phi _2}/(4/3){\rm \pi} R_2^3$ particles of component two and

${n_2} = {\phi _2}/(4/3){\rm \pi} R_2^3$ particles of component two and ![]() ${n_s} = (1 - {\phi _1} - {\phi _2})/{\nu _s}$ particles of solvent per unit volume, conservation of volume can be expressed as

${n_s} = (1 - {\phi _1} - {\phi _2})/{\nu _s}$ particles of solvent per unit volume, conservation of volume can be expressed as

The Gibbs–Duhem equation relates the chemical potentials in the system at constant temperature and pressure as

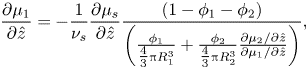

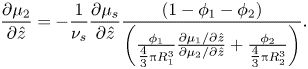

The Gibbs–Duhem equation (2.19), in one dimension, can be rearranged, giving

\begin{equation}\frac{{\partial {\mu _1}}}{{\partial \hat{z}}} ={-} \frac{1}{{{\nu _s}}}\frac{{\partial {\mu _s}}}{{\partial \hat{z}}}\frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {\frac{{{\phi_1}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_1^3}} + \frac{{{\phi_2}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_2^3}}\frac{{\partial {\mu_2}/\partial \hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}},\end{equation}

\begin{equation}\frac{{\partial {\mu _1}}}{{\partial \hat{z}}} ={-} \frac{1}{{{\nu _s}}}\frac{{\partial {\mu _s}}}{{\partial \hat{z}}}\frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {\frac{{{\phi_1}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_1^3}} + \frac{{{\phi_2}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_2^3}}\frac{{\partial {\mu_2}/\partial \hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}},\end{equation}and

\begin{equation}\frac{{\partial {\mu _2}}}{{\partial \hat{z}}} ={-} \frac{1}{{{\nu _s}}}\frac{{\partial {\mu _s}}}{{\partial \hat{z}}}\frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {\frac{{{\phi_1}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_1^3}}\frac{{\partial {\mu_1}/\partial \hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + \frac{{{\phi_2}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_2^3}}} \right)}}.\end{equation}

\begin{equation}\frac{{\partial {\mu _2}}}{{\partial \hat{z}}} ={-} \frac{1}{{{\nu _s}}}\frac{{\partial {\mu _s}}}{{\partial \hat{z}}}\frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {\frac{{{\phi_1}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_1^3}}\frac{{\partial {\mu_1}/\partial \hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + \frac{{{\phi_2}}}{{{\textstyle{4 \over 3}}{\rm \pi} R_2^3}}} \right)}}.\end{equation}

Using the spatial derivative of (2.16), plus the relationship ![]() ${R_1}/{R_2} = P{e_1}/P{e_2}$, (2.20) and (2.21) become

${R_1}/{R_2} = P{e_1}/P{e_2}$, (2.20) and (2.21) become

\begin{equation}\frac{{\partial {\mu _1}}}{{\partial \hat{z}}} = \frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {{\phi_1} + {{\left( {\frac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}\frac{{\partial {\mu_2}/\partial \hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}}\frac{\partial }{{\partial \hat{z}}}\left[ {\left( {{\phi_1} + {{\left( {\frac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}} \right)kTZ({\phi_1},{\phi_2})} \right],\end{equation}

\begin{equation}\frac{{\partial {\mu _1}}}{{\partial \hat{z}}} = \frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {{\phi_1} + {{\left( {\frac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}\frac{{\partial {\mu_2}/\partial \hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}}\frac{\partial }{{\partial \hat{z}}}\left[ {\left( {{\phi_1} + {{\left( {\frac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}} \right)kTZ({\phi_1},{\phi_2})} \right],\end{equation}and

\begin{equation}\frac{{\partial {\mu _2}}}{{\partial \hat{z}}} = \frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {{{\left( {\frac{{P{e_2}}}{{P{e_1}}}} \right)}^3}{\phi_1}\frac{{\partial {\mu_1}/\partial \hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + {\phi_2}} \right)}}\frac{\partial }{{\partial \hat{z}}}\left[ {\left( {{{\left( {\frac{{P{e_2}}}{{P{e_1}}}} \right)}^3}{\phi_1} + {\phi_2}} \right)kTZ({\phi_1},{\phi_2})} \right].\end{equation}

\begin{equation}\frac{{\partial {\mu _2}}}{{\partial \hat{z}}} = \frac{{(1 - {\phi _1} - {\phi _2})}}{{\left( {{{\left( {\frac{{P{e_2}}}{{P{e_1}}}} \right)}^3}{\phi_1}\frac{{\partial {\mu_1}/\partial \hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + {\phi_2}} \right)}}\frac{\partial }{{\partial \hat{z}}}\left[ {\left( {{{\left( {\frac{{P{e_2}}}{{P{e_1}}}} \right)}^3}{\phi_1} + {\phi_2}} \right)kTZ({\phi_1},{\phi_2})} \right].\end{equation}

The purpose of rewriting the chemical potential gradients as in (2.22) and (2.23) is to obtain the advantages, discussed below, of expressing them as functions of ![]() $\partial {\mu _s}/\partial \hat{z}$ and

$\partial {\mu _s}/\partial \hat{z}$ and ![]() $(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. The chosen model formulation intends for the effects of concentrated solution to be addressed via the divergence in solvent chemical potential,

$(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. The chosen model formulation intends for the effects of concentrated solution to be addressed via the divergence in solvent chemical potential, ![]() ${\mu _s}$, and the particle interactions to be input via

${\mu _s}$, and the particle interactions to be input via ![]() $(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. Hence, this extends approaches that are valid only for more dilute solution, for example, Zhou et al. (Reference Zhou, Jiang and Doi2017). Since the ratio of the chemical potential gradients is determined physically by the inter-particle interactions, the chemistry of the types of particles that are used to form the film, such as their surface charge, will be relevant (Atmuri et al. Reference Atmuri, Bhatia and Routh2012).

$(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. Hence, this extends approaches that are valid only for more dilute solution, for example, Zhou et al. (Reference Zhou, Jiang and Doi2017). Since the ratio of the chemical potential gradients is determined physically by the inter-particle interactions, the chemistry of the types of particles that are used to form the film, such as their surface charge, will be relevant (Atmuri et al. Reference Atmuri, Bhatia and Routh2012).

Note that the Gibbs–Duhem equation (2.19) relates ![]() ${\mu _1}$,

${\mu _1}$, ![]() ${\mu _2}$ and

${\mu _2}$ and ![]() ${\mu _s}$. Equation (2.16) gives an expression for

${\mu _s}$. Equation (2.16) gives an expression for ![]() ${\mu _s}$ which diverges at close packing. Hence, only one of

${\mu _s}$ which diverges at close packing. Hence, only one of ![]() ${\mu _1}$ and

${\mu _1}$ and ![]() ${\mu _2}$, or a relationship between them, can also be specified. Since (2.20) and (2.21) give

${\mu _2}$, or a relationship between them, can also be specified. Since (2.20) and (2.21) give ![]() $\partial {\mu _1}/\partial \hat{z}$ and

$\partial {\mu _1}/\partial \hat{z}$ and ![]() $\partial {\mu _2}/\partial \hat{z}$ only as implicit functions to be inserted into the conservation equation, different rearrangements of the Gibbs–Duhem equation could have been chosen instead. The particular rearrangements in (2.20) and (2.21) were chosen since their right-hand sides depend on

$\partial {\mu _2}/\partial \hat{z}$ only as implicit functions to be inserted into the conservation equation, different rearrangements of the Gibbs–Duhem equation could have been chosen instead. The particular rearrangements in (2.20) and (2.21) were chosen since their right-hand sides depend on ![]() $\partial {\mu _s}/\partial \hat{z}$ and the ratio

$\partial {\mu _s}/\partial \hat{z}$ and the ratio ![]() $(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. The solvent chemical potential is measurable up to close packing, where it diverges. This means that

$(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. The solvent chemical potential is measurable up to close packing, where it diverges. This means that ![]() $\partial {\mu _1}/\partial \hat{z}$ and

$\partial {\mu _1}/\partial \hat{z}$ and ![]() $\partial {\mu _2}/\partial \hat{z}$ also diverge at close packing, in an unknown fashion. An expression chosen for the ratio

$\partial {\mu _2}/\partial \hat{z}$ also diverge at close packing, in an unknown fashion. An expression chosen for the ratio ![]() $(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$ is more likely to be valid approaching close packing than expressions that could be put forward for each particle separately. Equations (2.20) and (2.21) are also of the same form as each other, as desired.

$(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$ is more likely to be valid approaching close packing than expressions that could be put forward for each particle separately. Equations (2.20) and (2.21) are also of the same form as each other, as desired.

Equation (2.16) for the osmotic pressure is used to generate an expression for ![]() ${\mu _s}$ only, rather than being used as an equation of state to also generate the other chemical potentials. The thermodynamic consistency of this approach with respect to the Maxwell relations is further explained in § S6 of the supplementary material (SI) available at https://doi.org/10.1017/jfm.2021.800.

${\mu _s}$ only, rather than being used as an equation of state to also generate the other chemical potentials. The thermodynamic consistency of this approach with respect to the Maxwell relations is further explained in § S6 of the supplementary material (SI) available at https://doi.org/10.1017/jfm.2021.800.

In summary, a thermodynamically consistent approach is achieved by satisfying the Gibbs–Duhem equation. In choosing to specify ![]() $Z({\phi _1},{\phi _2})$, as a proxy for

$Z({\phi _1},{\phi _2})$, as a proxy for ![]() $\partial {\mu _s}/\partial \hat{z}$, and

$\partial {\mu _s}/\partial \hat{z}$, and ![]() $(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$, the system chemical potentials are fully specified. As formulated, the right-hand sides of (2.22) and (2.23) require input of an expression for

$(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$, the system chemical potentials are fully specified. As formulated, the right-hand sides of (2.22) and (2.23) require input of an expression for ![]() $(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. Although the chemical potential expressions given in (2.22) and (2.23) appear complicated, they are merely (2.16) combined with rearrangements of the Gibbs–Duhem equation, in the same way as Russel et al. (Reference Russel, Saville and Schowalter1989) and Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b).

$(\partial {\mu _1}/\partial \hat{z})/(\partial {\mu _2}/\partial \hat{z})$. Although the chemical potential expressions given in (2.22) and (2.23) appear complicated, they are merely (2.16) combined with rearrangements of the Gibbs–Duhem equation, in the same way as Russel et al. (Reference Russel, Saville and Schowalter1989) and Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b).

2.4. Diffusiophoresis

The governing conservation equation (2.7) requires an expression for the total flux. In this section, the aim is to investigate the effect of diffusiophoresis. The total flux is written as the sum of two terms, one described as the diffusion term, and the other described as the diffusiophoresis term.

The deviation of osmotic pressure from ideality, and hence ![]() $Z({\phi _1},{\phi _2})$ from unity, accounts for the total excluded volume (Russel et al. Reference Russel, Saville and Schowalter1989). However, this model uses the same form of

$Z({\phi _1},{\phi _2})$ from unity, accounts for the total excluded volume (Russel et al. Reference Russel, Saville and Schowalter1989). However, this model uses the same form of ![]() $Z({\phi _1},{\phi _2})$ for the diffusion term, for both the flux of component one and two. In not differentiating between the expressions used for the two fluxes, this form of equation will not give rise to diffusiophoresis. It will give a diffusional model in the sense of the fluxes of both particle types remaining inversely proportional to their particle radius. The flux contribution that is due to diffusiophoresis can be found from first principles for a dilute solution, and written as a separate term. The language of this paper refers to this as the diffusiophoresis term.

$Z({\phi _1},{\phi _2})$ for the diffusion term, for both the flux of component one and two. In not differentiating between the expressions used for the two fluxes, this form of equation will not give rise to diffusiophoresis. It will give a diffusional model in the sense of the fluxes of both particle types remaining inversely proportional to their particle radius. The flux contribution that is due to diffusiophoresis can be found from first principles for a dilute solution, and written as a separate term. The language of this paper refers to this as the diffusiophoresis term.

Excluded volume effects are more general than diffusiophoresis resulting from excluded volume, since the latter specifically refers to one component moving in response to the concentration gradient of another, whereas in general a component can have volume excluded by both itself and other components. An alternative approach could write the total flux as one term, with a form of ![]() $Z({\phi _1},{\phi _2})$ from an equation of state that would include the diffusiophoretic flux. However, the approach taken here allows the effect of diffusiophoresis to be identified separately.

$Z({\phi _1},{\phi _2})$ from an equation of state that would include the diffusiophoretic flux. However, the approach taken here allows the effect of diffusiophoresis to be identified separately.

With this approach, a model including diffusiophoresis is constructed, assuming ![]() ${R_2} \gg {R_1}$. The particles of type one are modelled using an extension of the Asakura–Oosawa model to concentrated solution. Under the Asakura–Oosawa model, the type one particles are assumed to be excluded from a layer of solvent of thickness

${R_2} \gg {R_1}$. The particles of type one are modelled using an extension of the Asakura–Oosawa model to concentrated solution. Under the Asakura–Oosawa model, the type one particles are assumed to be excluded from a layer of solvent of thickness ![]() ${R_{DP}}$ around each particle of type two. Using this model, in a dilute solution, the drift velocity of the large particles due to diffusiophoresis,

${R_{DP}}$ around each particle of type two. Using this model, in a dilute solution, the drift velocity of the large particles due to diffusiophoresis, ![]() ${\boldsymbol{U}_{\boldsymbol{P}}}$, in a static film is given by

${\boldsymbol{U}_{\boldsymbol{P}}}$, in a static film is given by

where ![]() ${\varGamma _1}$ is the diffusiophoretic drift coefficient (Anderson & Prieve Reference Anderson and Prieve1984; Sear & Warren Reference Sear and Warren2017). Following the approach of Marbach, Yoshida & Bocquet (Reference Marbach, Yoshida and Bocquet2017), this is extended to concentrated solution via invoking the osmotic pressure (SI, § S1.2), to obtain

${\varGamma _1}$ is the diffusiophoretic drift coefficient (Anderson & Prieve Reference Anderson and Prieve1984; Sear & Warren Reference Sear and Warren2017). Following the approach of Marbach, Yoshida & Bocquet (Reference Marbach, Yoshida and Bocquet2017), this is extended to concentrated solution via invoking the osmotic pressure (SI, § S1.2), to obtain

This is taken to be the extra slip velocity, in addition to that due to diffusion, between the particles of component two and the solvent. For the case of hard spheres, which is considered here, ![]() ${R_{DP}} = {R_1}$. Since

${R_{DP}} = {R_1}$. Since ![]() ${\boldsymbol{U}_{\boldsymbol{P}}}$ gives the relative diffusiophoretic velocity between type two particles and the solvent, this needs to be converted to a velocity relative to the volume average velocity,

${\boldsymbol{U}_{\boldsymbol{P}}}$ gives the relative diffusiophoretic velocity between type two particles and the solvent, this needs to be converted to a velocity relative to the volume average velocity, ![]() ${\boldsymbol{U}^{\boldsymbol{v}}}$. Note that the result in (2.24) is the correct diffusiophoretic drift velocity for dilute solution, expected to agree with explicit solvent models. This contrasts with the result of implicit solvent methods which neglect the solvent dynamics, and consequently may overpredict the diffusiophoretic velocity (Sear & Warren Reference Sear and Warren2017).

${\boldsymbol{U}^{\boldsymbol{v}}}$. Note that the result in (2.24) is the correct diffusiophoretic drift velocity for dilute solution, expected to agree with explicit solvent models. This contrasts with the result of implicit solvent methods which neglect the solvent dynamics, and consequently may overpredict the diffusiophoretic velocity (Sear & Warren Reference Sear and Warren2017).

The velocity of each type of particle i is split up into a component due to diffusion (denoted by the superscript ![]() $D$), which has been found in § 2.2, and a component due to diffusiophoresis (denoted by the superscript

$D$), which has been found in § 2.2, and a component due to diffusiophoresis (denoted by the superscript ![]() $P$)

$P$)

The local average velocities of the type one, type two and solvent particles are denoted by ![]() ${\boldsymbol{U}_1}$,

${\boldsymbol{U}_1}$, ![]() ${\boldsymbol{U}_2}$ and

${\boldsymbol{U}_2}$ and ![]() ${\boldsymbol{U}_{\boldsymbol{s}}}$, respectively.

${\boldsymbol{U}_{\boldsymbol{s}}}$, respectively.

It is necessary to obtain relationships between ![]() $\boldsymbol{U}_1^{\boldsymbol{P}}$,

$\boldsymbol{U}_1^{\boldsymbol{P}}$, ![]() $\boldsymbol{U}_2^{\boldsymbol{P}}$ and

$\boldsymbol{U}_2^{\boldsymbol{P}}$ and ![]() $\boldsymbol{U}_{\boldsymbol{s}}^{\boldsymbol{P}}$. First, note that for a static film,

$\boldsymbol{U}_{\boldsymbol{s}}^{\boldsymbol{P}}$. First, note that for a static film, ![]() ${\boldsymbol{U}^{\boldsymbol{v}}} = 0$, so

${\boldsymbol{U}^{\boldsymbol{v}}} = 0$, so

The components of the velocities due to diffusion already obey

Hence, subtracting equation (2.28) from (2.27), provides

The velocity of component two and the velocity of the solvent are related by

Under the assumptions of this model, diffusiophoresis does not affect the velocity of component one relative to the solvent,

This is the case in an idealised model and is therefore used as a starting point for a non-ideal model, with finite size ratios. Although deviation from this will be expected when the particle size ratio is finite (Howard & Nikoubashman Reference Howard and Nikoubashman2020), it would not be expected to be large. Solving (2.29)–(2.31) simultaneously, and including sedimentation coefficients, ![]() ${K_{P1}}({\phi _1},{\phi _2})$ and

${K_{P1}}({\phi _1},{\phi _2})$ and ![]() ${K_{P2}}({\phi _1},{\phi _2})$, obtains

${K_{P2}}({\phi _1},{\phi _2})$, obtains

and

To satisfy continuity, it is required that ![]() ${K_{P2}}({\phi _1},{\phi _2}) = {K_{P1}}({\phi _1},{\phi _2}) = {K_P}({\phi _1},{\phi _2})$. Note that this is not a general result; it is just a result of how this model chooses to write the total flux as two separate terms. Addressing the more general question of whether

${K_{P2}}({\phi _1},{\phi _2}) = {K_{P1}}({\phi _1},{\phi _2}) = {K_P}({\phi _1},{\phi _2})$. Note that this is not a general result; it is just a result of how this model chooses to write the total flux as two separate terms. Addressing the more general question of whether ![]() ${K_{12}}({\phi _1},{\phi _2}) = {K_{21}}({\phi _1},{\phi _2})$, these are not equal, as can be seen from analytical expressions for dilute solution (Batchelor Reference Batchelor1983). However, equating these expressions would be a reasonable approximation for generating example solutions.

${K_{12}}({\phi _1},{\phi _2}) = {K_{21}}({\phi _1},{\phi _2})$, these are not equal, as can be seen from analytical expressions for dilute solution (Batchelor Reference Batchelor1983). However, equating these expressions would be a reasonable approximation for generating example solutions. ![]() ${K_{ij}}({\phi _1},{\phi _2})$ and

${K_{ij}}({\phi _1},{\phi _2})$ and ![]() ${K_P}({\phi _1},{\phi _2})$ are both denoted with ‘

${K_P}({\phi _1},{\phi _2})$ are both denoted with ‘![]() $K$’ since they are both sedimentation coefficients, i.e. they represent the same physical phenomenon of hydrodynamic hindrance. The different subscripts identify the terms for which these are the coefficients.

$K$’ since they are both sedimentation coefficients, i.e. they represent the same physical phenomenon of hydrodynamic hindrance. The different subscripts identify the terms for which these are the coefficients.

Equation (2.32) can be interpreted as showing that component one and the solvent move backwards compared with the diffusiophoretic motion of component two, in order to conserve volume. Using (2.12), which gives ![]() $\boldsymbol{U}_1^{\boldsymbol{D}}$, and the analogous expression for

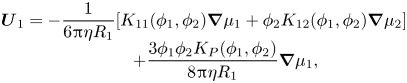

$\boldsymbol{U}_1^{\boldsymbol{D}}$, and the analogous expression for ![]() $\boldsymbol{U}_2^{\boldsymbol{D}}$, the complete expressions for the component velocities including both diffusion and diffusiophoresis are

$\boldsymbol{U}_2^{\boldsymbol{D}}$, the complete expressions for the component velocities including both diffusion and diffusiophoresis are

\begin{equation}\begin{array}{c} {\boldsymbol{U}_1} ={-} \dfrac{1}{{6{\rm \pi}\eta {R_1}}}[{K_{11}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _1} + {\phi _2}{K_{12}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _2}]\\ \qquad\ \, + \dfrac{{3{\phi _1}{\phi _2}{K_P}({\phi _1},{\phi _2})}}{{8{\rm \pi}\eta {R_1}}}\boldsymbol{\nabla }{\mu _1}, \end{array}\end{equation}

\begin{equation}\begin{array}{c} {\boldsymbol{U}_1} ={-} \dfrac{1}{{6{\rm \pi}\eta {R_1}}}[{K_{11}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _1} + {\phi _2}{K_{12}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _2}]\\ \qquad\ \, + \dfrac{{3{\phi _1}{\phi _2}{K_P}({\phi _1},{\phi _2})}}{{8{\rm \pi}\eta {R_1}}}\boldsymbol{\nabla }{\mu _1}, \end{array}\end{equation}and

\begin{equation}\begin{array}{c} {\boldsymbol{U}_2}={-} \dfrac{1}{{6{\rm \pi}\eta {R_2}}}[{K_{22}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _2} + {\phi _1}{K_{21}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _1}]\\ \qquad\ \, - \dfrac{{3{\phi _1}(1 - {\phi _2}){K_P}({\phi _1},{\phi _2})}}{{8{\rm \pi}\eta {R_1}}}\boldsymbol{\nabla }{\mu _1}. \end{array}\end{equation}

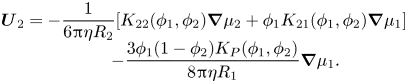

\begin{equation}\begin{array}{c} {\boldsymbol{U}_2}={-} \dfrac{1}{{6{\rm \pi}\eta {R_2}}}[{K_{22}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _2} + {\phi _1}{K_{21}}({\phi _1},{\phi _2})\boldsymbol{\nabla }{\mu _1}]\\ \qquad\ \, - \dfrac{{3{\phi _1}(1 - {\phi _2}){K_P}({\phi _1},{\phi _2})}}{{8{\rm \pi}\eta {R_1}}}\boldsymbol{\nabla }{\mu _1}. \end{array}\end{equation}Including diffusiophoresis, the conservation equation for particles of type one is now

\begin{equation}\begin{array}{c} \dfrac{{\partial {\phi _1}}}{{\partial t}} = \boldsymbol{\nabla }\boldsymbol{\cdot }\left[ {\left[ {\dfrac{{{\phi_1}}}{{6{\rm \pi}\eta {R_1}}}{K_{11}}({\phi_1},{\phi_2}) - \dfrac{{3{{({\phi_1})}^2}{\phi_2}{K_P}({\phi_1},{\phi_2})}}{{8{\rm \pi}\eta {R_1}}}} \right]} \right.\boldsymbol{\nabla }{\mu _1}\\ \qquad\ \ \left. { + \dfrac{{{\phi_1}}}{{6{\rm \pi}\eta {R_1}}}{\phi_2}{K_{12}}({\phi_1},{\phi_2})\boldsymbol{\nabla }{\mu_2}} \right], \end{array}\end{equation}

\begin{equation}\begin{array}{c} \dfrac{{\partial {\phi _1}}}{{\partial t}} = \boldsymbol{\nabla }\boldsymbol{\cdot }\left[ {\left[ {\dfrac{{{\phi_1}}}{{6{\rm \pi}\eta {R_1}}}{K_{11}}({\phi_1},{\phi_2}) - \dfrac{{3{{({\phi_1})}^2}{\phi_2}{K_P}({\phi_1},{\phi_2})}}{{8{\rm \pi}\eta {R_1}}}} \right]} \right.\boldsymbol{\nabla }{\mu _1}\\ \qquad\ \ \left. { + \dfrac{{{\phi_1}}}{{6{\rm \pi}\eta {R_1}}}{\phi_2}{K_{12}}({\phi_1},{\phi_2})\boldsymbol{\nabla }{\mu_2}} \right], \end{array}\end{equation}and that for particles of type two becomes

\begin{equation}\begin{array}{c} \dfrac{{\partial {\phi _2}}}{{\partial t}} = \boldsymbol{\nabla }\boldsymbol{\cdot }\left[ {\left[ {\dfrac{{{\phi_2}}}{{6{\rm \pi}\eta {R_2}}}{\phi_1}{K_{21}}({\phi_1},{\phi_2}) + \dfrac{{3{\phi_1}{\phi_2}(1 - {\phi_2}){K_P}({\phi_1},{\phi_2})}}{{8{\rm \pi}\eta {R_1}}}} \right]\boldsymbol{\nabla }{\mu_1}} \right.\\ \qquad\ \ \left. { + \dfrac{{{\phi_2}}}{{6{\rm \pi}\eta {R_2}}}{K_{22}}({\phi_1},{\phi_2})\boldsymbol{\nabla }{\mu_2}} \right]. \end{array}\end{equation}

\begin{equation}\begin{array}{c} \dfrac{{\partial {\phi _2}}}{{\partial t}} = \boldsymbol{\nabla }\boldsymbol{\cdot }\left[ {\left[ {\dfrac{{{\phi_2}}}{{6{\rm \pi}\eta {R_2}}}{\phi_1}{K_{21}}({\phi_1},{\phi_2}) + \dfrac{{3{\phi_1}{\phi_2}(1 - {\phi_2}){K_P}({\phi_1},{\phi_2})}}{{8{\rm \pi}\eta {R_1}}}} \right]\boldsymbol{\nabla }{\mu_1}} \right.\\ \qquad\ \ \left. { + \dfrac{{{\phi_2}}}{{6{\rm \pi}\eta {R_2}}}{K_{22}}({\phi_1},{\phi_2})\boldsymbol{\nabla }{\mu_2}} \right]. \end{array}\end{equation}

Note that the divergence of the total flux should reflect the total excluded volume, which is incorporated into ![]() $Z({\phi _1},{\phi _2})$, hence all the flux terms, including the diffusiophoresis terms, should diverge in the same form as

$Z({\phi _1},{\phi _2})$, hence all the flux terms, including the diffusiophoresis terms, should diverge in the same form as ![]() $Z({\phi _1},{\phi _2})$. Since all of the flux terms contain a factor of

$Z({\phi _1},{\phi _2})$. Since all of the flux terms contain a factor of ![]() $\boldsymbol{\nabla }{\mu _1}$ or

$\boldsymbol{\nabla }{\mu _1}$ or ![]() $\boldsymbol{\nabla }{\mu _2}$, which diverge via

$\boldsymbol{\nabla }{\mu _2}$, which diverge via ![]() $Z({\phi _1},{\phi _2})$ through the formulations for (2.22) and (2.23), (2.36) and (2.37) obtain suitable divergence at close packing.

$Z({\phi _1},{\phi _2})$ through the formulations for (2.22) and (2.23), (2.36) and (2.37) obtain suitable divergence at close packing.

3. Methodology

3.1. Scaling

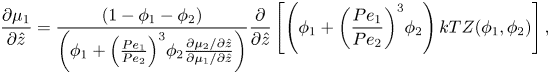

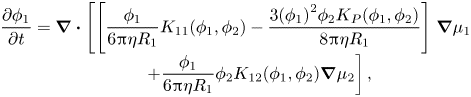

Equations (2.22) and (2.23), the spatial derivatives of the chemical potentials, are substituted into (2.36), and scaled in one dimension, to form the conservation equation for component one,

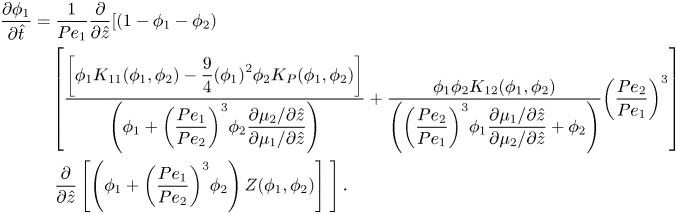

\begin{align}

\dfrac{{\partial {\phi _1}}}{{\partial \hat{t}}} & =

\dfrac{1}{{P{e_1}}}\dfrac{\partial }{{\partial

\hat{z}}}[{(1 - {\phi_1} - {\phi_2})} \notag\\ & \quad \left[

{\dfrac{{\left[ {{\phi_1}{K_{11}}({\phi_1},{\phi_2}) -

\dfrac{9}{4}{{({\phi_1})}^2}{\phi_2}{K_P}({\phi_1},{\phi_2})}

\right]}}{{\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial

\hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}} +

\dfrac{{{\phi_1}{\phi_2}{K_{12}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial

\hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + {\phi_2}}

\right)}}{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}} \right)}^3}}

\right]\notag\\ & \quad \left. {\dfrac{\partial }{{\partial

\hat{z}}}\left[ {\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}}

\right)Z({\phi_1},{\phi_2})} \right]\; } \right].

\end{align}

\begin{align}

\dfrac{{\partial {\phi _1}}}{{\partial \hat{t}}} & =

\dfrac{1}{{P{e_1}}}\dfrac{\partial }{{\partial

\hat{z}}}[{(1 - {\phi_1} - {\phi_2})} \notag\\ & \quad \left[

{\dfrac{{\left[ {{\phi_1}{K_{11}}({\phi_1},{\phi_2}) -

\dfrac{9}{4}{{({\phi_1})}^2}{\phi_2}{K_P}({\phi_1},{\phi_2})}

\right]}}{{\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial

\hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}} +

\dfrac{{{\phi_1}{\phi_2}{K_{12}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial

\hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + {\phi_2}}

\right)}}{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}} \right)}^3}}

\right]\notag\\ & \quad \left. {\dfrac{\partial }{{\partial

\hat{z}}}\left[ {\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}}

\right)Z({\phi_1},{\phi_2})} \right]\; } \right].

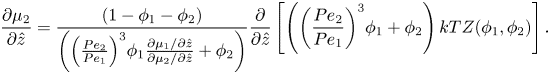

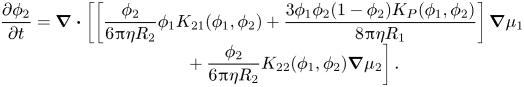

\end{align}For component two, substituting equations (2.22) and (2.23) into (2.37) and scaling gives

\begin{align}

\dfrac{{\partial {\phi _2}}}{{\partial \hat{t}}} & =

\dfrac{1}{{P{e_2}}}\dfrac{\partial }{{\partial

\hat{z}}}\left[\vphantom{\left(\dfrac{{P{e_2}}}{{P{e_1}}}\right)}{(1 - {\phi_1} - {\phi_2})} \right.\notag\\ & \quad \left. \left[

{{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}} \right)}^3}\left[

{\dfrac{{{\phi_1}{\phi_2}{K_{21}}({\phi_1},{\phi_2}) +

\dfrac{9}{4}\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right){\phi_1}{\phi_2}(1 -

{\phi_2}){K_P}({\phi_1},{\phi_2})}}{{\left( {{\phi_1} +

{{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial

\hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}}}

\right]\right.\right. \notag\\ &\quad + \left.\left.

\dfrac{{{\phi_2}{K_{22}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial

\hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + {\phi_2}}

\right)}} \right]\right. \notag\\ & \quad \left. {\; \dfrac{\partial

}{{\partial \hat{z}}}\left[ {\left( {{{\left(

{\dfrac{{P{e_2}}}{{P{e_1}}}} \right)}^3}{\phi_1} +

{\phi_2}} \right)Z({\phi_1},{\phi_2})} \right]} \right].

\end{align}

\begin{align}

\dfrac{{\partial {\phi _2}}}{{\partial \hat{t}}} & =

\dfrac{1}{{P{e_2}}}\dfrac{\partial }{{\partial

\hat{z}}}\left[\vphantom{\left(\dfrac{{P{e_2}}}{{P{e_1}}}\right)}{(1 - {\phi_1} - {\phi_2})} \right.\notag\\ & \quad \left. \left[

{{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}} \right)}^3}\left[

{\dfrac{{{\phi_1}{\phi_2}{K_{21}}({\phi_1},{\phi_2}) +

\dfrac{9}{4}\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right){\phi_1}{\phi_2}(1 -

{\phi_2}){K_P}({\phi_1},{\phi_2})}}{{\left( {{\phi_1} +

{{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial

\hat{z}}}{{\partial {\mu_1}/\partial \hat{z}}}} \right)}}}

\right]\right.\right. \notag\\ &\quad + \left.\left.

\dfrac{{{\phi_2}{K_{22}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial

\hat{z}}}{{\partial {\mu_2}/\partial \hat{z}}} + {\phi_2}}

\right)}} \right]\right. \notag\\ & \quad \left. {\; \dfrac{\partial

}{{\partial \hat{z}}}\left[ {\left( {{{\left(

{\dfrac{{P{e_2}}}{{P{e_1}}}} \right)}^3}{\phi_1} +

{\phi_2}} \right)Z({\phi_1},{\phi_2})} \right]} \right].

\end{align}

A key observation is that the only dimensionless groups appearing in (3.1) and (3.2) are ![]() $P{e_1}$ and

$P{e_1}$ and ![]() $P{e_2}$ i.e. no further dimensionless groups appear due to diffusiophoresis, as would be expected from dimensional analysis.

$P{e_2}$ i.e. no further dimensionless groups appear due to diffusiophoresis, as would be expected from dimensional analysis.

3.2. Coordinate transform

In order to create a static top boundary, the conservation equations are transformed using ![]() $\xi = \hat{z}/(1 - \hat{t})$ and

$\xi = \hat{z}/(1 - \hat{t})$ and ![]() $\tau = \hat{t}$. This results in

$\tau = \hat{t}$. This results in

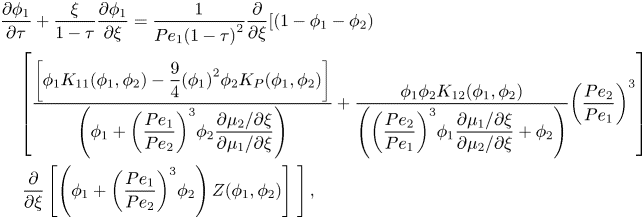

\begin{align}

& \dfrac{{\partial {\phi _1}}}{{\partial \tau }} +

\dfrac{\xi }{{1 - \tau }}\dfrac{{\partial {\phi

_1}}}{{\partial \xi }} = \dfrac{1}{{P{e_1}{{(1 - \tau

)}^2}}}\dfrac{\partial }{{\partial \xi }}[{(1 - {\phi_1} -

{\phi_2})} \notag\\ & \quad \left[ {\dfrac{{\left[

{{\phi_1}{K_{11}}({\phi_1},{\phi_2}) -

\dfrac{9}{4}{{({\phi_1})}^2}{\phi_2}{K_P}({\phi_1},{\phi_2})}

\right]}}{{\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial \xi

}}{{\partial {\mu_1}/\partial \xi }}} \right)}} +

\dfrac{{{\phi_1}{\phi_2}{K_{12}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial \xi

}}{{\partial {\mu_2}/\partial \xi }} + {\phi_2}}

\right)}}{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}} \right)}^3}}

\right]\notag\\ & \quad \left. {\dfrac{\partial }{{\partial \xi

}}\left[ {\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}}

\right)Z({\phi_1},{\phi_2})} \right]\; } \right],

\end{align}

\begin{align}

& \dfrac{{\partial {\phi _1}}}{{\partial \tau }} +

\dfrac{\xi }{{1 - \tau }}\dfrac{{\partial {\phi

_1}}}{{\partial \xi }} = \dfrac{1}{{P{e_1}{{(1 - \tau

)}^2}}}\dfrac{\partial }{{\partial \xi }}[{(1 - {\phi_1} -

{\phi_2})} \notag\\ & \quad \left[ {\dfrac{{\left[

{{\phi_1}{K_{11}}({\phi_1},{\phi_2}) -

\dfrac{9}{4}{{({\phi_1})}^2}{\phi_2}{K_P}({\phi_1},{\phi_2})}

\right]}}{{\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial \xi

}}{{\partial {\mu_1}/\partial \xi }}} \right)}} +

\dfrac{{{\phi_1}{\phi_2}{K_{12}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial \xi

}}{{\partial {\mu_2}/\partial \xi }} + {\phi_2}}

\right)}}{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}} \right)}^3}}

\right]\notag\\ & \quad \left. {\dfrac{\partial }{{\partial \xi

}}\left[ {\left( {{\phi_1} + {{\left(

{\dfrac{{P{e_1}}}{{P{e_2}}}} \right)}^3}{\phi_2}}

\right)Z({\phi_1},{\phi_2})} \right]\; } \right],

\end{align}and

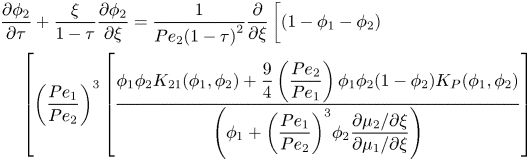

\begin{align}&

\dfrac{{\partial {\phi _2}}}{{\partial \tau }} + \dfrac{\xi

}{{1 - \tau }}\dfrac{{\partial {\phi _2}}}{{\partial \xi }}

= \dfrac{1}{{P{e_2}{{(1 - \tau )}^2}}}\dfrac{\partial

}{{\partial \xi }}\left[\vphantom{\left(\dfrac{{P{e_2}}}{{P{e_1}}}\right)}{(1 - {\phi_1} -{\phi_2})} \right. \notag\\ &\quad\left.

\left[ {{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}\left[

{\dfrac{{{\phi_1}{\phi_2}{K_{21}}({\phi_1},{\phi_2}) +

\dfrac{9}{4}\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right){\phi_1}{\phi_2}(1 -

{\phi_2}){K_P}({\phi_1},{\phi_2})}}{{\left( {{\phi_1} +

{{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial \xi

}}{{\partial {\mu_1}/\partial \xi }}} \right)}}} \right]\right.\right. \notag\\ &\quad + \left. \left.

\dfrac{{{\phi_2}{K_{22}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial \xi

}}{{\partial {\mu_2}/\partial \xi }} + {\phi_2}} \right)}}

\right]\right. \notag\\ & \quad \left. {\; \dfrac{\partial }{{\partial

\xi }}\left[ {\left( {{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1} + {\phi_2}}

\right)Z({\phi_1},{\phi_2})} \right]} \right].

\end{align}

\begin{align}&

\dfrac{{\partial {\phi _2}}}{{\partial \tau }} + \dfrac{\xi

}{{1 - \tau }}\dfrac{{\partial {\phi _2}}}{{\partial \xi }}

= \dfrac{1}{{P{e_2}{{(1 - \tau )}^2}}}\dfrac{\partial

}{{\partial \xi }}\left[\vphantom{\left(\dfrac{{P{e_2}}}{{P{e_1}}}\right)}{(1 - {\phi_1} -{\phi_2})} \right. \notag\\ &\quad\left.

\left[ {{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}\left[

{\dfrac{{{\phi_1}{\phi_2}{K_{21}}({\phi_1},{\phi_2}) +

\dfrac{9}{4}\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right){\phi_1}{\phi_2}(1 -

{\phi_2}){K_P}({\phi_1},{\phi_2})}}{{\left( {{\phi_1} +

{{\left( {\dfrac{{P{e_1}}}{{P{e_2}}}}

\right)}^3}{\phi_2}\dfrac{{\partial {\mu_2}/\partial \xi

}}{{\partial {\mu_1}/\partial \xi }}} \right)}}} \right]\right.\right. \notag\\ &\quad + \left. \left.

\dfrac{{{\phi_2}{K_{22}}({\phi_1},{\phi_2})}}{{\left(

{{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1}\dfrac{{\partial {\mu_1}/\partial \xi

}}{{\partial {\mu_2}/\partial \xi }} + {\phi_2}} \right)}}

\right]\right. \notag\\ & \quad \left. {\; \dfrac{\partial }{{\partial

\xi }}\left[ {\left( {{{\left( {\dfrac{{P{e_2}}}{{P{e_1}}}}

\right)}^3}{\phi_1} + {\phi_2}}

\right)Z({\phi_1},{\phi_2})} \right]} \right].

\end{align}This is the coordinate transform that is classically used in solving problems with this geometry, as in Routh & Zimmerman (Reference Routh and Zimmerman2004), Trueman et al. (Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b) and Howard et al. (Reference Howard, Nikoubashman and Panagiotopoulos2017b). The boundary conditions are no flux of particles at both the top and bottom boundaries (see Section S1.1 of the SI). For the top boundary condition, the evaporation rate is assumed to be constant, as explained in § 2.2.

Setting ![]() ${K_P}({\phi _1},{\phi _2}) = 0$ in (3.3)–(3.4) gives a system of PDEs to describe a diffusion-only model that neglects diffusiophoresis. This can be compared with the diffusion–diffusiophoresis model, with non-zero

${K_P}({\phi _1},{\phi _2}) = 0$ in (3.3)–(3.4) gives a system of PDEs to describe a diffusion-only model that neglects diffusiophoresis. This can be compared with the diffusion–diffusiophoresis model, with non-zero ![]() ${K_P}({\phi _1},{\phi _2})$, to observe the effect of diffusiophoresis. Discussion regarding satisfying the Onsager reciprocal relations with each model is provided in the SI, § S3.3.

${K_P}({\phi _1},{\phi _2})$, to observe the effect of diffusiophoresis. Discussion regarding satisfying the Onsager reciprocal relations with each model is provided in the SI, § S3.3.

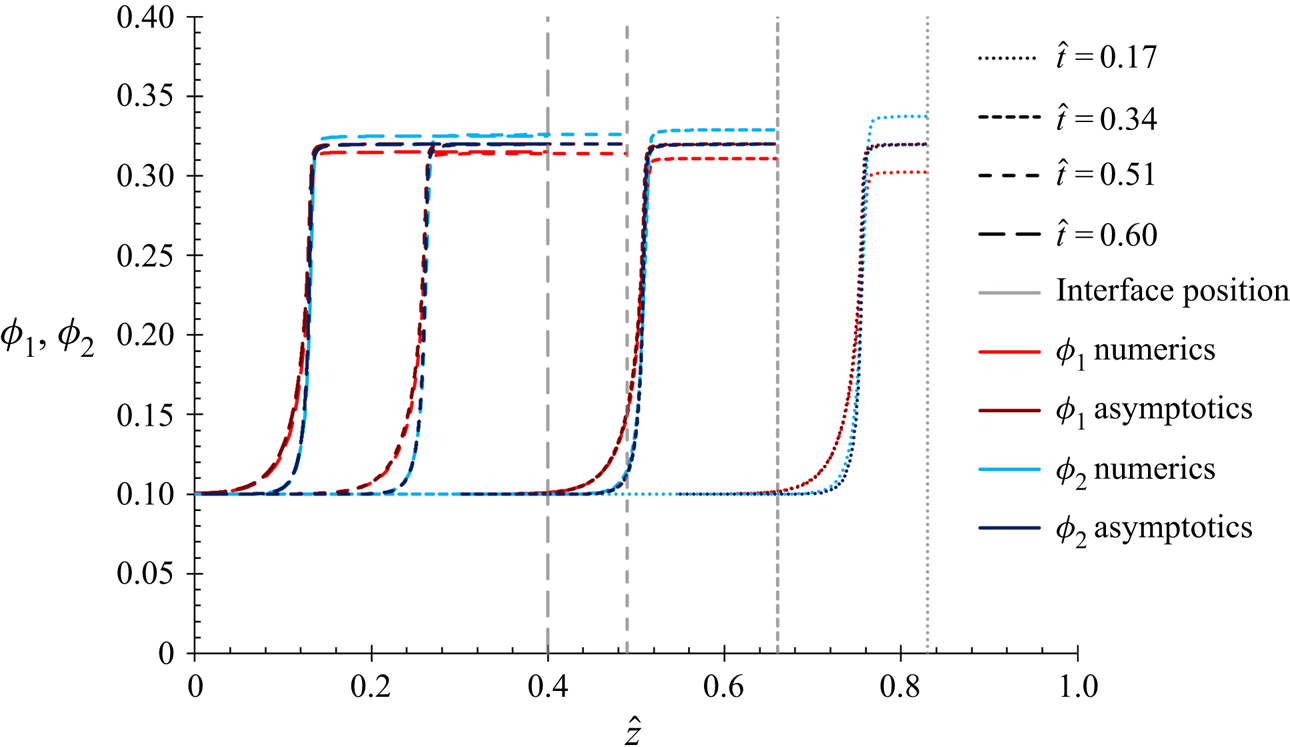

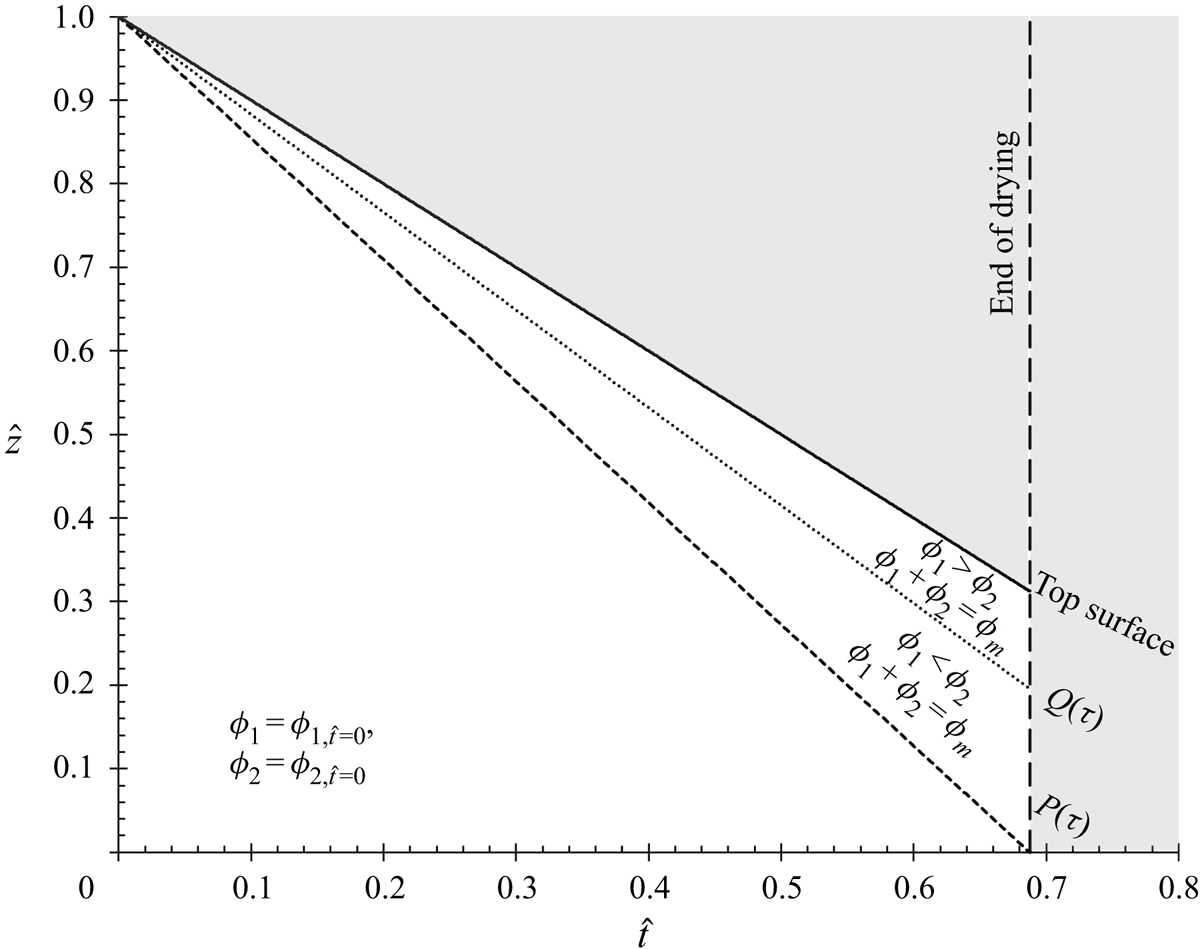

3.3. Numerical method

The system of (3.3)–(3.4) can be solved if ![]() ${\phi _{1,t = 0}}$,

${\phi _{1,t = 0}}$, ![]() ${\phi _{2,t = 0}}$,

${\phi _{2,t = 0}}$, ![]() $P{e_1}$,

$P{e_1}$, ![]() $P{e_2}$ and the maximum volume fraction,

$P{e_2}$ and the maximum volume fraction, ![]() ${\phi _m}$, which could be a function of

${\phi _m}$, which could be a function of ![]() ${\phi _1}$ and

${\phi _1}$ and ![]() $\; {\phi _2}$, are specified. Appropriate forms of

$\; {\phi _2}$, are specified. Appropriate forms of ![]() $K({\phi _1},{\phi _2})$ and

$K({\phi _1},{\phi _2})$ and ![]() $Z({\phi _1},{\phi _2})$ can be taken from the literature. Also needing to be specified is the ratio of the chemical potential gradients, as explained in § 2.3.

$Z({\phi _1},{\phi _2})$ can be taken from the literature. Also needing to be specified is the ratio of the chemical potential gradients, as explained in § 2.3.

The compressibility is taken to be ![]() $Z({\phi _1},{\phi _2}) = {\phi _m}{({\phi _m} - {\phi _1} - {\phi _2})^{ - 1}}$ (Trueman et al. Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b). The canonical concentrated extension of the dilute form of

$Z({\phi _1},{\phi _2}) = {\phi _m}{({\phi _m} - {\phi _1} - {\phi _2})^{ - 1}}$ (Trueman et al. Reference Trueman, Lago Domingues, Emmett, Murray and Routh2012b). The canonical concentrated extension of the dilute form of ![]() $K(\phi )$ for the one-component case,

$K(\phi )$ for the one-component case, ![]() $1 - 6.55\phi $, is

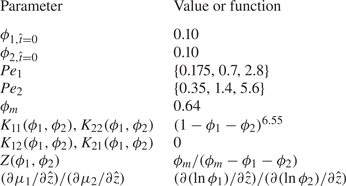

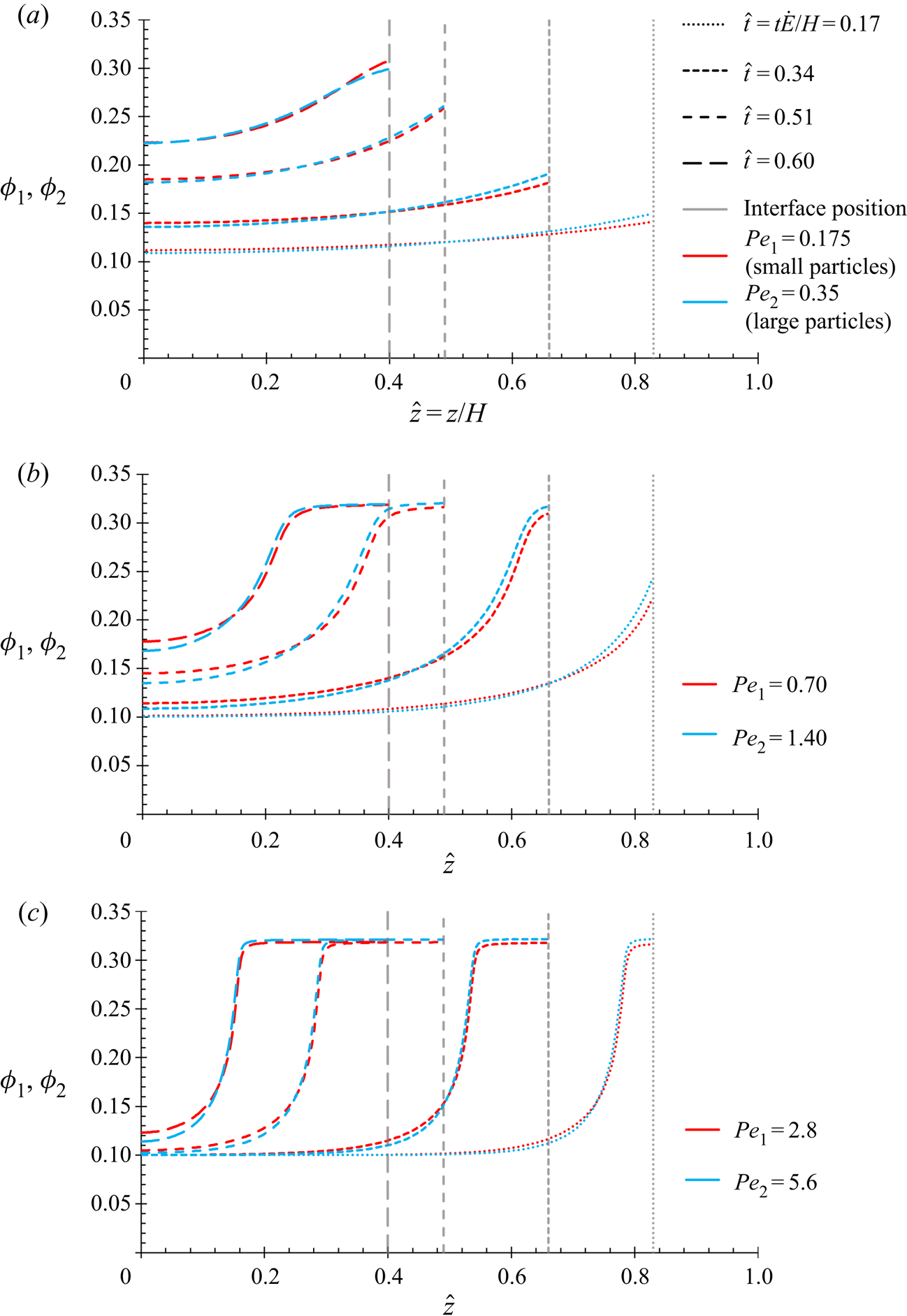

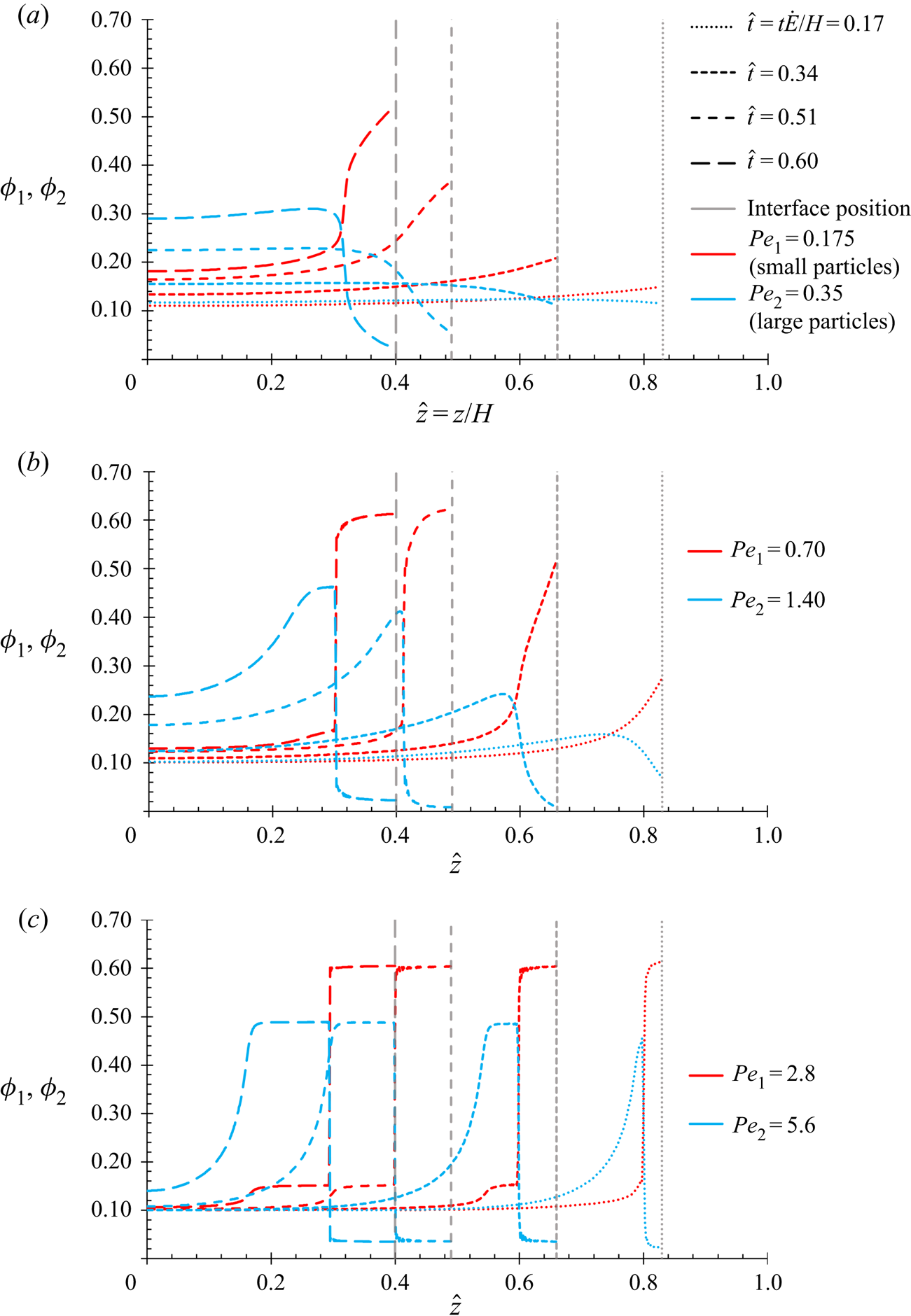

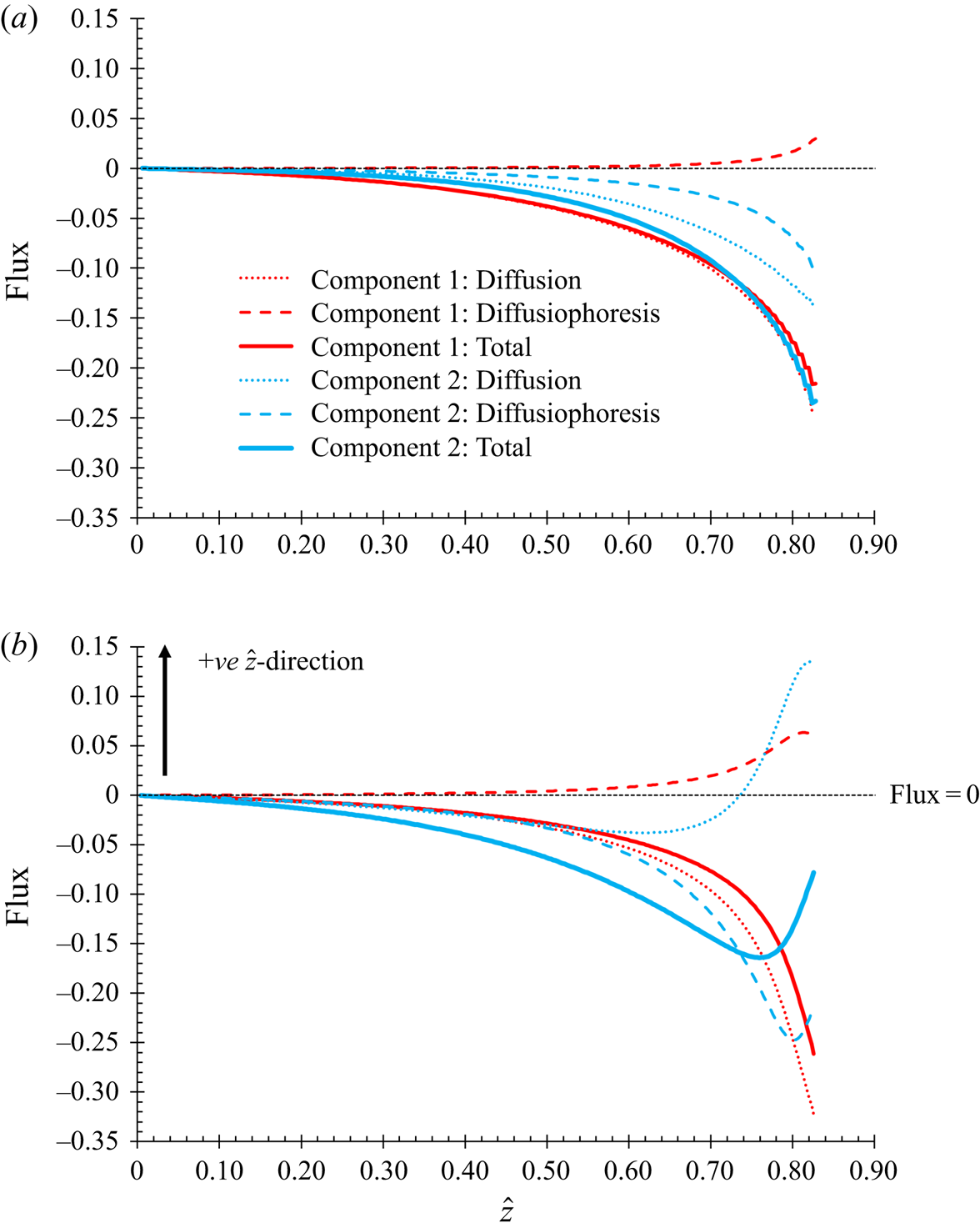

$1 - 6.55\phi $, is ![]() ${(1 - \phi )^{6.55}}$ (Russel et al. Reference Russel, Saville and Schowalter1989). For the two-component case, this is extended to