Published online by Cambridge University Press: 26 February 2019

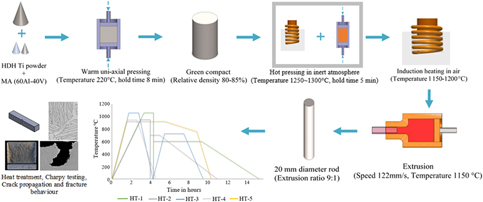

In this study, a rapid powder consolidation method combining powder compact hot pressing and extrusion was utilized to consolidate relatively cheap, high impurity blended powder mixture Ti–6Al–4V alloy. The purpose of this work was to investigate whether a suitable microstructure deriving from a particular heat treatment balance out or compensate for the presence of high interstitial impurity contents. From mechanical property data attained, it was clear that annealing in high α–β region gave a much better combination of mechanical properties: impact toughness (14 J), yield strength (878 MPa), ultimate tensile strength (1092 MPa), and ductility/plastic strain (6.2%) compared to as-extruded material despite the presence of 0.44 wt% oxygen. Therefore, it can be concluded that optimization of microstructures provides improvement to the fracture related properties and Ti–6Al–4V produced in this way is suitable for less demanding applications. For further enhancement in properties, utilization of low oxygen starting powders is vital.