Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Ye, Xiaoxin

Tse, Zion T.H.

Tang, Guoyi

and

Song, Guolin

2014.

RETRACTED: Effect of electroplastic rolling on deformability, mechanical property and microstructure evolution of Ti–6Al–4V alloy strip.

Materials Characterization,

Vol. 98,

Issue. ,

p.

147.

Xin, Ying

Jiang, Wei Hui

Feng, Guo

Liu, Jian Min

Zhang, Quan

Wu, Qian

and

Miao, Li Feng

2015.

Low Temperature Synthesis of Yttrium-Stabilized Zirconia (YSZ) Fibers by Non-Hydrolytic Sol-Gel Method.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

101.

Jiang, Shi Feng

Li, Zhen Qiu

Chen, Hong Nan

and

Wang, Er Qiang

2015.

Cs-P Oxide Catalysts for Aldol Condensation to Produce Methyl Acrylate.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

51.

Ni, Hao Yin

and

Chen, Cai Xia

2015.

Computational Results Show Gas Phase Reactions Have Great Impact on the Deposition Rate of Silicon in Siemens CVD Reactors.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

39.

Ye, Xiaoxin

Tang, Guoyi

and

Song, Guolin

2015.

RETRACTED: The effect of electropulsing induced gradient topographic oxide coating of Ti–Al–V alloy strips on the fibroblast adhesion and growth.

Surface and Coatings Technology,

Vol. 261,

Issue. ,

p.

213.

Ye, Xiaoxin

Tse, Zion T.H.

Tang, Guoyi

Geng, Yubo

and

Song, Guolin

2015.

RETRACTED: Influence of electropulsing globularization on the microstructure and mechanical properties of Ti–6Al–4V alloy strip with lamellar microstructure.

Materials Science and Engineering: A,

Vol. 622,

Issue. ,

p.

1.

Ye, Xiaoxin

Tse, Zion T.H.

Tang, Guoyi

Li, Xiaohui

and

Song, Guolin

2015.

RETRACTED: Effect of electropulsing treatment on microstructure and mechanical properties of cold-rolled pure titanium strips.

Journal of Materials Processing Technology,

Vol. 222,

Issue. ,

p.

27.

Ye, Xiaoxin

Tse, Zion T.H.

and

Tang, Guoyi

2015.

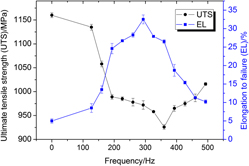

Mechanical properties and tensile fracture of Ti–Al–V alloy strip under electropulsing-induced phase change.

Journal of Materials Research,

Vol. 30,

Issue. 2,

p.

206.

Gui, Fang

Zhou, Shi Yun

Yan, Wan Jun

Zhang, Chun Hong

and

Chen, Shao Bo

2015.

First-Principles Study of Electronic Structure and Optical Properties of V-Doped CrSi<sub>2</sub>.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

125.

Ye, Xiaoxin

Tse, Zion T.H.

Tang, Guoyi

and

Song, Guolin

2015.

RETRACTED: Mechanical properties and phase transition of biomedical titanium alloy strips with initial quasi-single phase state under high-energy electropulses.

Journal of the Mechanical Behavior of Biomedical Materials,

Vol. 42,

Issue. ,

p.

100.

Shi, Wei Mei

Ding, Ye Chun

and

Wu, Long Huo

2015.

The Adsorption Properties of Ciprofloxacin by KMnO<sub>4 </sub>Modified <i>Durio zibethinus </i>Murr Shells.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

111.

Liu, Qi Song

Xu, Bo

He, Jin Long

Sun, Ru

and

Chang, Hong Gang

2015.

Optimal Conditions for Bio-Oxidation of Biodesulfurization in Natural Gas Sweetening Process Using <i>Thiobacillus</i>.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

57.

Ye, Xiaoxin

Wang, Lingsheng

Tse, Zion T.H.

Tang, Guoyi

and

Song, Guolin

2015.

RETRACTED: Effects of high-energy electro-pulsing treatment on microstructure, mechanical properties and corrosion behavior of Ti–6Al–4V alloy.

Materials Science and Engineering: C,

Vol. 49,

Issue. ,

p.

851.

Zhou, Tong Qing

Chen, Ting

Jiang, Wei Hui

Liu, Jian Min

Zhang, Xiao Jun

and

Miao, Li Feng

2015.

Preparation of α-Al<sub>2</sub>O<sub>3</sub> Powders via Non-Hydrolytic Sol-Gel Method.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

3.

Ye, Xiaoxin

Liu, Tao

Ye, Yongda

Wang, Haibo

Tang, Guoyi

and

Song, Guolin

2015.

RETRACTED: Enhanced grain refinement and microhardness of Ti–Al–V alloy by electropulsing ultrasonic shock.

Journal of Alloys and Compounds,

Vol. 621,

Issue. ,

p.

66.

Ye, Xiaoxin

Tse, Zion T. H.

Tang, Guoyi

and

Song, Guolin

2015.

Retracted: Effect of High‐Energy Electropulsing on the Phase Transition and Mechanical Properties of Two‐Phase Titanium Alloy Strips.

Advanced Engineering Materials,

Vol. 17,

Issue. 7,

p.

995.

Gao, Xiao Ju

Yan, Dong Ming

Cao, Jian Wu

Zhang, Cong

Mu, Xiao Ming

Zhou, Ya Wei

Wang, Meng

Qu, Fa Zeng

Li, Guo Bin

Wang, Guo Jiang

and

Zhang, Da Jiang

2015.

The Study on the Property and the Microstructure of Pressureless Sintered h-BN Ceramics.

Advanced Materials Research,

Vol. 1104,

Issue. ,

p.

9.

Kuang, Jie

Low, Thaddeus Song En

Niezgoda, Stephen R.

Li, Xiaohui

Geng, Yubo

Luo, Alan A.

and

Tang, Guoyi

2016.

Abnormal texture development in magnesium alloy Mg–3Al–1Zn during large strain electroplastic rolling: Effect of pulsed electric current.

International Journal of Plasticity,

Vol. 87,

Issue. ,

p.

86.

Zhang, Bing

Wang, Haibo

Zhang, Shuo

Song, Guolin

Kure-Chu, Song-Zhu

Wang, Xinglong

Kuang, Jie

and

Tang, Guoyi

2016.

Effect of electropulsing-ultrasonic surface treatment on the surface properties and the corrosion behavior of 45 steel.

Journal of Materials Research,

Vol. 31,

Issue. 14,

p.

2114.

Ye, Yongda

Kuang, Jie

Kure-Chu, Song-Zhu

Song, Guolin

Sun, Zhiyan

and

Tang, Guoyi

2016.

Improvement of microstructure and surface behaviors of welded S50C steel components under electropulsing assisted ultrasonic surface modification.

Journal of Materials Research,

Vol. 31,

Issue. 14,

p.

2125.