No CrossRef data available.

Article contents

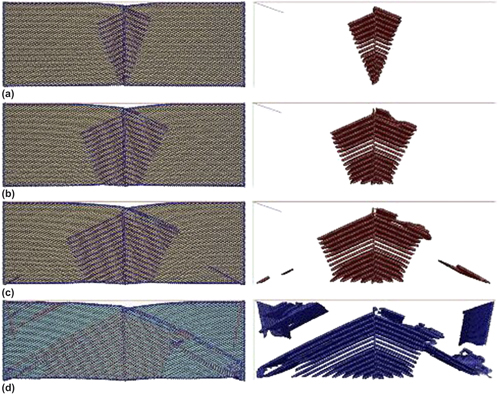

Atomistic simulation of the strain-hardening behavior of bicrystal Cu nanowires

Published online by Cambridge University Press: 16 December 2013

Abstract

To determine whether plastic-hardening behavior occurs in metal nanowires, an atomistic simulation was performed to investigate the tension process in a bicrystal Cu nanowire. The results indicate that bicrystal Cu nanowires exhibit strain-hardening behavior, unlike their single-crystal counterparts. The strain-hardening behavior is related to the orientation of two crystal grains, and the number of atoms determines whether strain-hardening behavior occurs in the asymmetrically tilted bicrystal Cu nanowires. Strain hardening occurs in almost bicrystal Cu nanowires with different orientation angles. The initial yield stress is determined by the grain whose orientation angle is closer to 45° among the two crystal grains, resulting in a high value of the tilting tendency factor, and thus making it easier to generate slip.

Information

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2013