Published online by Cambridge University Press: 14 November 2016

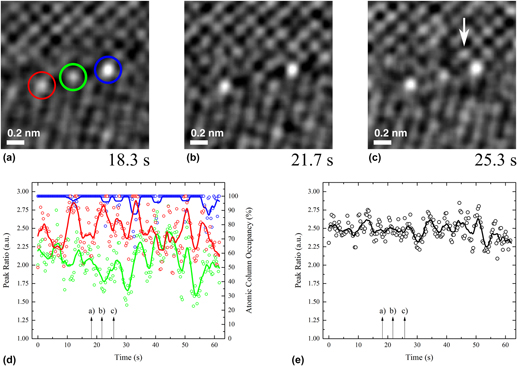

Besides the high spatial resolution achieved in aberration-corrected scanning transmission microscopy, beam-induced dynamic effects have to be considered for quantitative chemical characterization on the level of single atomic columns. The present study investigates the influence of imaging conditions in an aberration-corrected scanning transmission electron microscope on the beam-induced atomic migration at a complex Ag-segregated, nanofaceted Cu grain boundary. Three distinct imaging conditions including static single image and serial image acquisition have been utilized. Chemical information on the Ag column occupation of single atomic columns at the grain boundary was extracted by the evolution of peak intensity ratios and compared to idealized scanning transmission electron microscopy image simulations. The atomic column occupation is underestimated when using conventional single frame acquisition due to an averaging of Ag atomic migration events during acquisition. Possible migration paths for the beam-induced atomic motion at a complex Cu grain boundary are presented.

Contributing Editor: Rafal E. Dunin-Borkowski